Exploring Thermite's Potential in Aerospace Engineering

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite in Aerospace: Background and Objectives

Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, has been a subject of interest in aerospace engineering for decades. Its high energy density and ability to generate intense heat have made it a promising candidate for various applications in the aerospace industry. The evolution of thermite technology can be traced back to its discovery in 1893 by German chemist Hans Goldschmidt. Initially used in welding and incendiary devices, thermite's potential in aerospace applications began to emerge in the mid-20th century.

The aerospace industry's interest in thermite stems from its unique properties, including its ability to produce high temperatures rapidly, its stability under normal conditions, and its potential for generating thrust. These characteristics have led researchers to explore thermite's use in areas such as propulsion systems, welding and repair of aerospace structures, and even as a potential heat source for space-based power generation.

As the aerospace sector continues to push the boundaries of technology, the objectives for thermite research have become increasingly focused. One primary goal is to develop more efficient and controllable thermite reactions for use in micro-propulsion systems for small satellites and spacecraft. Another objective is to enhance the precision and reliability of thermite-based welding techniques for in-space manufacturing and repair operations.

The exploration of thermite's potential in aerospace engineering also aims to address several key challenges. These include improving the ignition control and reaction rate of thermite mixtures, enhancing the safety of handling and storage, and developing methods to harness the intense heat generated by thermite reactions more effectively. Researchers are also investigating ways to tailor thermite compositions to meet specific aerospace requirements, such as producing minimal debris in space environments.

Recent advancements in nanotechnology have opened new avenues for thermite research in aerospace applications. Nano-sized thermite particles, known as metastable intermolecular composites (MICs), have shown promise in enhancing reaction rates and energy release. This has led to renewed interest in thermite as a potential component in advanced propulsion systems and energetic materials for aerospace use.

As we look towards the future of aerospace engineering, the continued exploration of thermite's potential could lead to breakthrough technologies in space propulsion, in-orbit manufacturing, and energy generation for long-duration space missions. The ongoing research aims to unlock new capabilities that could significantly impact the design and operation of future spacecraft and satellites, potentially revolutionizing our approach to space exploration and utilization.

The aerospace industry's interest in thermite stems from its unique properties, including its ability to produce high temperatures rapidly, its stability under normal conditions, and its potential for generating thrust. These characteristics have led researchers to explore thermite's use in areas such as propulsion systems, welding and repair of aerospace structures, and even as a potential heat source for space-based power generation.

As the aerospace sector continues to push the boundaries of technology, the objectives for thermite research have become increasingly focused. One primary goal is to develop more efficient and controllable thermite reactions for use in micro-propulsion systems for small satellites and spacecraft. Another objective is to enhance the precision and reliability of thermite-based welding techniques for in-space manufacturing and repair operations.

The exploration of thermite's potential in aerospace engineering also aims to address several key challenges. These include improving the ignition control and reaction rate of thermite mixtures, enhancing the safety of handling and storage, and developing methods to harness the intense heat generated by thermite reactions more effectively. Researchers are also investigating ways to tailor thermite compositions to meet specific aerospace requirements, such as producing minimal debris in space environments.

Recent advancements in nanotechnology have opened new avenues for thermite research in aerospace applications. Nano-sized thermite particles, known as metastable intermolecular composites (MICs), have shown promise in enhancing reaction rates and energy release. This has led to renewed interest in thermite as a potential component in advanced propulsion systems and energetic materials for aerospace use.

As we look towards the future of aerospace engineering, the continued exploration of thermite's potential could lead to breakthrough technologies in space propulsion, in-orbit manufacturing, and energy generation for long-duration space missions. The ongoing research aims to unlock new capabilities that could significantly impact the design and operation of future spacecraft and satellites, potentially revolutionizing our approach to space exploration and utilization.

Market Analysis for Aerospace Thermite Applications

The aerospace industry has shown a growing interest in thermite applications, driven by the material's unique properties and potential to enhance various aerospace systems. Market analysis reveals a significant demand for thermite-based solutions in aerospace engineering, with a projected market size expected to reach several billion dollars by 2030. This growth is primarily fueled by the increasing need for lightweight, high-performance materials in aircraft and spacecraft manufacturing.

The aerospace thermite market can be segmented into several key application areas. Propulsion systems represent a major segment, where thermite-based materials are being explored for their potential to improve rocket engine performance and efficiency. The high energy density and rapid reaction rates of thermite compositions make them attractive candidates for advanced propellant formulations.

Another promising segment is thermal protection systems for spacecraft and hypersonic vehicles. Thermite-based coatings and materials offer superior heat resistance and ablative properties, crucial for protecting aerospace structures during atmospheric re-entry or high-speed flight. This application area is expected to see substantial growth as space exploration and hypersonic technologies advance.

The market for thermite applications in aerospace welding and repair is also expanding. Thermite reactions can generate localized high temperatures, making them ideal for in-situ welding and repair of aerospace components. This capability is particularly valuable for maintenance and repair operations in remote or challenging environments, such as space stations or during long-duration missions.

Geographically, North America currently dominates the aerospace thermite market, owing to its advanced aerospace industry and significant research and development investments. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing aerospace activities in countries like China and India.

Key market drivers include the ongoing pursuit of improved fuel efficiency, reduced emissions, and enhanced performance in aerospace vehicles. Additionally, the growing focus on space exploration and commercial space activities is creating new opportunities for thermite applications in spacecraft systems and infrastructure.

However, the market faces challenges such as stringent safety regulations and the need for extensive testing and certification processes. The reactive nature of thermite materials necessitates careful handling and storage, which can impact adoption rates in certain aerospace applications.

Despite these challenges, the overall market outlook for aerospace thermite applications remains positive. Ongoing research and development efforts are expected to unlock new possibilities and overcome existing limitations, further expanding the market potential in the coming years.

The aerospace thermite market can be segmented into several key application areas. Propulsion systems represent a major segment, where thermite-based materials are being explored for their potential to improve rocket engine performance and efficiency. The high energy density and rapid reaction rates of thermite compositions make them attractive candidates for advanced propellant formulations.

Another promising segment is thermal protection systems for spacecraft and hypersonic vehicles. Thermite-based coatings and materials offer superior heat resistance and ablative properties, crucial for protecting aerospace structures during atmospheric re-entry or high-speed flight. This application area is expected to see substantial growth as space exploration and hypersonic technologies advance.

The market for thermite applications in aerospace welding and repair is also expanding. Thermite reactions can generate localized high temperatures, making them ideal for in-situ welding and repair of aerospace components. This capability is particularly valuable for maintenance and repair operations in remote or challenging environments, such as space stations or during long-duration missions.

Geographically, North America currently dominates the aerospace thermite market, owing to its advanced aerospace industry and significant research and development investments. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing aerospace activities in countries like China and India.

Key market drivers include the ongoing pursuit of improved fuel efficiency, reduced emissions, and enhanced performance in aerospace vehicles. Additionally, the growing focus on space exploration and commercial space activities is creating new opportunities for thermite applications in spacecraft systems and infrastructure.

However, the market faces challenges such as stringent safety regulations and the need for extensive testing and certification processes. The reactive nature of thermite materials necessitates careful handling and storage, which can impact adoption rates in certain aerospace applications.

Despite these challenges, the overall market outlook for aerospace thermite applications remains positive. Ongoing research and development efforts are expected to unlock new possibilities and overcome existing limitations, further expanding the market potential in the coming years.

Current Challenges in Aerospace Thermite Technology

Despite the promising potential of thermite in aerospace engineering, several significant challenges currently hinder its widespread adoption and application in the field. One of the primary obstacles is the difficulty in controlling the reaction rate and energy release of thermite mixtures. The highly exothermic nature of thermite reactions can lead to unpredictable and potentially dangerous outcomes if not properly managed, posing safety risks in aerospace applications.

Another major challenge lies in the development of suitable ignition systems for thermite-based propulsion or energy generation in aerospace environments. Traditional ignition methods may not be reliable or efficient under the extreme conditions encountered in space or high-altitude flight, necessitating the development of novel ignition technologies tailored specifically for aerospace thermite applications.

The integration of thermite-based systems into existing aerospace structures and components presents additional hurdles. Engineers must address issues related to weight, volume, and compatibility with other materials and systems, ensuring that the incorporation of thermite technology does not compromise the overall performance or safety of aerospace vehicles.

Furthermore, the long-term stability and storage of thermite mixtures in aerospace environments remain significant concerns. Exposure to extreme temperatures, radiation, and vacuum conditions in space can potentially alter the properties of thermite materials, affecting their reliability and performance over extended periods.

The precise control of thermite reaction products in aerospace applications also poses a challenge. The formation and dispersion of reaction byproducts, including molten metals and oxide particles, must be carefully managed to prevent damage to sensitive equipment or contamination of spacecraft systems.

Additionally, the development of scalable and cost-effective manufacturing processes for aerospace-grade thermite materials represents a significant hurdle. Current production methods may not be suitable for large-scale implementation in the aerospace industry, necessitating innovations in material synthesis and fabrication techniques.

Lastly, the regulatory landscape surrounding the use of thermite in aerospace applications presents a complex challenge. Stringent safety regulations and certification requirements must be navigated to gain approval for the use of thermite-based technologies in commercial and government aerospace projects, potentially slowing down the adoption and implementation of these innovative solutions.

Another major challenge lies in the development of suitable ignition systems for thermite-based propulsion or energy generation in aerospace environments. Traditional ignition methods may not be reliable or efficient under the extreme conditions encountered in space or high-altitude flight, necessitating the development of novel ignition technologies tailored specifically for aerospace thermite applications.

The integration of thermite-based systems into existing aerospace structures and components presents additional hurdles. Engineers must address issues related to weight, volume, and compatibility with other materials and systems, ensuring that the incorporation of thermite technology does not compromise the overall performance or safety of aerospace vehicles.

Furthermore, the long-term stability and storage of thermite mixtures in aerospace environments remain significant concerns. Exposure to extreme temperatures, radiation, and vacuum conditions in space can potentially alter the properties of thermite materials, affecting their reliability and performance over extended periods.

The precise control of thermite reaction products in aerospace applications also poses a challenge. The formation and dispersion of reaction byproducts, including molten metals and oxide particles, must be carefully managed to prevent damage to sensitive equipment or contamination of spacecraft systems.

Additionally, the development of scalable and cost-effective manufacturing processes for aerospace-grade thermite materials represents a significant hurdle. Current production methods may not be suitable for large-scale implementation in the aerospace industry, necessitating innovations in material synthesis and fabrication techniques.

Lastly, the regulatory landscape surrounding the use of thermite in aerospace applications presents a complex challenge. Stringent safety regulations and certification requirements must be navigated to gain approval for the use of thermite-based technologies in commercial and government aerospace projects, potentially slowing down the adoption and implementation of these innovative solutions.

Existing Thermite Solutions for Aerospace Applications

01 Thermite composition and applications

Thermite is a pyrotechnic composition of metal powder fuel and metal oxide. It's used in various applications including welding, incendiary devices, and metal purification. The reaction produces intense heat and molten metal, making it suitable for specialized industrial and military uses.- Thermite composition and ignition methods: Thermite compositions typically consist of metal oxides and aluminum powder. Various ignition methods are used, including electrical, chemical, and mechanical means. The reaction produces intense heat and molten metal, making it useful for welding, incendiary devices, and metal purification.

- Applications in oil and gas industry: Thermite reactions are utilized in the oil and gas industry for various purposes, including well perforation, cutting tubular structures, and sealing wellbores. These applications take advantage of the high-temperature reaction to create precise holes or cuts in downhole equipment.

- Thermite welding techniques: Thermite welding is used to join railway tracks, pipes, and other large metal structures. The process involves igniting a thermite mixture in a mold surrounding the joint, resulting in a strong, continuous weld. Advancements in this field focus on improving weld quality and efficiency.

- Safety and control mechanisms: Given the high-energy nature of thermite reactions, safety measures and control mechanisms are crucial. These include specialized containment vessels, remote ignition systems, and precise mixture ratios to ensure controlled reactions and prevent accidents during handling and use.

- Novel thermite compositions and additives: Research continues on developing new thermite compositions and additives to enhance performance, control reaction rates, and tailor properties for specific applications. This includes nano-sized particles, alternative fuel components, and catalysts to improve efficiency and versatility.

02 Thermite in downhole operations

Thermite reactions are utilized in downhole operations for oil and gas wells. This includes cutting or severing tubulars, setting plugs, and initiating other downhole tools. The high-temperature reaction of thermite provides a reliable and efficient method for these operations in challenging downhole environments.Expand Specific Solutions03 Enhanced thermite formulations

Research focuses on improving thermite formulations for specific applications. This includes adding components to control reaction rates, increase energy output, or produce specific products. Enhanced formulations may incorporate nanomaterials, binders, or additional oxidizers to tailor the thermite's properties for particular uses.Expand Specific Solutions04 Thermite in additive manufacturing

Thermite reactions are being explored in additive manufacturing processes. This novel application uses the heat generated by thermite reactions to fuse metal powders, potentially allowing for rapid, localized metal deposition or part repair. The technique could offer advantages in certain manufacturing or repair scenarios.Expand Specific Solutions05 Safety and control mechanisms for thermite reactions

Given the intense nature of thermite reactions, safety and control mechanisms are crucial. This includes methods for initiating the reaction in a controlled manner, containing the reaction products, and ensuring safe handling of thermite materials. Innovations in this area focus on improving safety in both industrial and research applications of thermite.Expand Specific Solutions

Key Players in Aerospace Thermite Research

The exploration of thermite's potential in aerospace engineering is in a nascent stage, with the market size and technological maturity still developing. Key players like Lockheed Martin Corp., The Boeing Co., and Airbus Defence & Space SAS are investing in research and development to harness thermite's unique properties for aerospace applications. Universities and research institutions, such as Nanjing University of Science & Technology and Naval Research Laboratory, are contributing to fundamental research. The industry is characterized by a mix of established aerospace giants and specialized materials companies like BiSN Oil Tools Ltd. and Solvay Specialty Polymers USA LLC. As the technology progresses, we can expect increased collaboration between academic institutions and industry leaders to overcome technical challenges and expand practical applications in aerospace engineering.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has conducted extensive research on thermite materials for aerospace applications, particularly focusing on their use in hypersonic vehicle thermal protection systems. Their approach involves developing novel thermite compositions that can absorb and dissipate heat effectively during hypersonic flight. The laboratory has also explored using thermite reactions for emergency destruction of sensitive equipment on military aircraft and spacecraft. Additionally, they have investigated thermite-based welding techniques for in-space manufacturing and repair of large structures.

Strengths: Potential for advanced thermal protection in extreme environments and secure equipment destruction. Weaknesses: Challenges in precise control of reaction rates and potential for accidental activation.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced thermite-based propulsion systems for aerospace applications. Their technology utilizes a controlled thermite reaction to generate high-temperature gases for propulsion. The system incorporates precise mixture ratios of metal fuel and metal oxide oxidizer, along with advanced ignition and combustion control mechanisms. This allows for sustained, controllable thrust suitable for various aerospace missions, including satellite maneuvering and space debris removal. The company has also explored using thermite reactions for welding and repair operations in space environments.

Strengths: High energy density, long shelf life, and ability to operate in vacuum. Weaknesses: Challenges in precise control of reaction rate and potential safety concerns during storage and handling.

Innovative Thermite Formulations for Aerospace Use

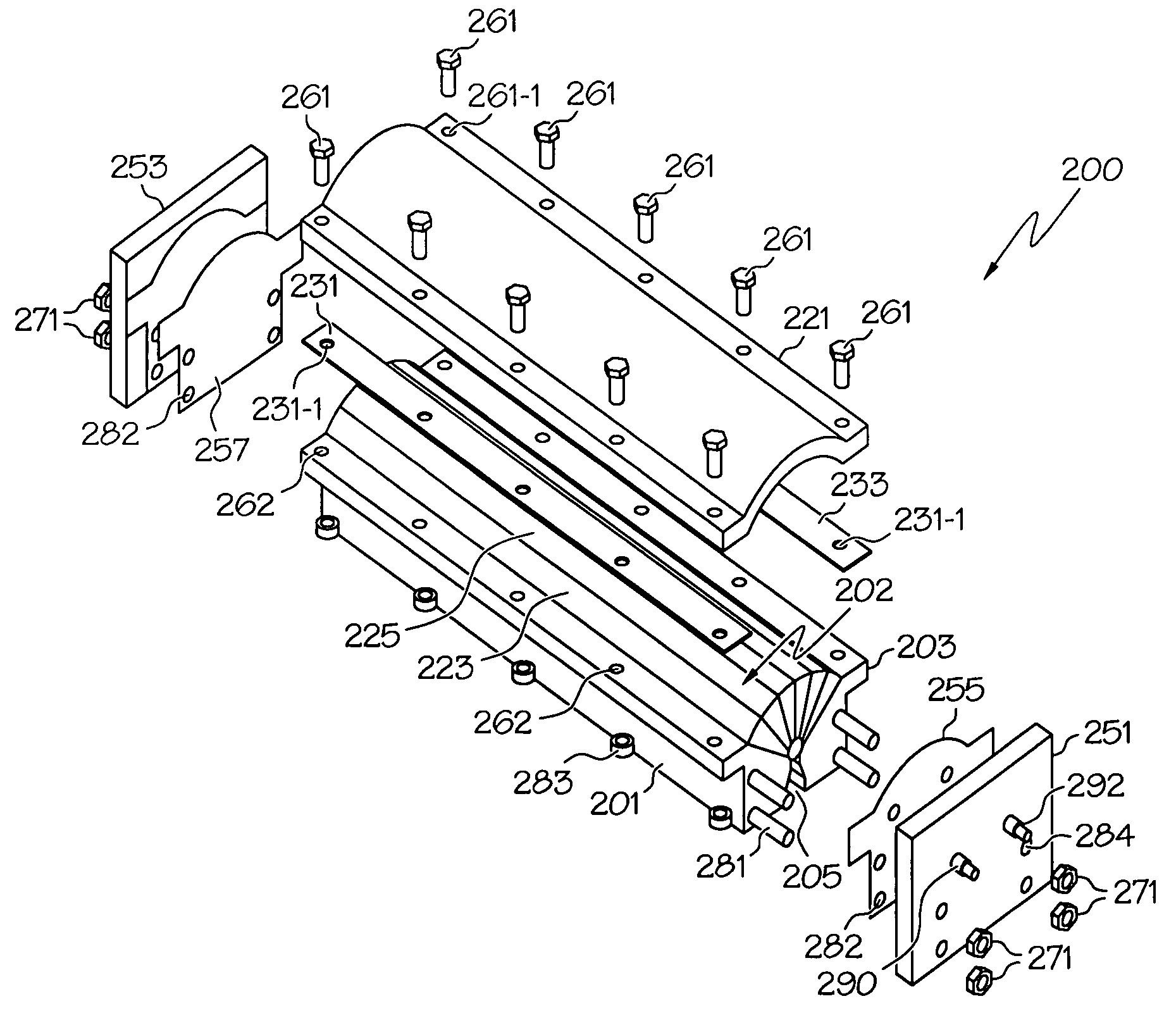

Thermite torch formulation including molybdenum trioxide

PatentInactiveUS20100089507A1

Innovation

- A thermite formulation using a magnalium alloy as the metal fuel and a combination of CuO and MoO3 as oxidizers, with a binder, optimized to provide excellent material perforation and low toxicity, where the magnalium alloy comprises about 3-35 weight percent, CuO 30-70 weight percent, MoO3 15-35 weight percent, and a small amount of binder, such as polytetrafluoroethylene.

Thermite charge

PatentActiveUS7555986B2

Innovation

- A linear or curvilinear thermite charge apparatus with a compartmentalized design and modular structure, using potassium permanganate and potassium ferrate to enhance cutting power, and oxygen augmentation to produce a sustained high-temperature jet for efficient cutting through materials like steel, concrete, and rock without explosive hazards.

Safety Regulations for Thermite in Aerospace Industry

The use of thermite in aerospace engineering presents unique safety challenges that necessitate stringent regulations. The aerospace industry has developed comprehensive safety protocols to mitigate risks associated with thermite's high reactivity and extreme heat generation.

Regulatory bodies, such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), have established specific guidelines for the handling, storage, and application of thermite in aerospace contexts. These regulations typically mandate rigorous training programs for personnel involved in thermite-related operations, ensuring they are well-versed in proper handling techniques and emergency procedures.

Storage requirements for thermite in aerospace facilities are particularly stringent. Regulations often specify the use of specialized containment units designed to withstand extreme temperatures and prevent accidental ignition. These storage areas must be equipped with advanced fire suppression systems and be located away from critical infrastructure and flammable materials.

Transportation of thermite within aerospace manufacturing and maintenance facilities is subject to strict protocols. Regulations typically require the use of specially designed transport containers that can withstand impact and prevent accidental ignition during movement. Additionally, designated routes for thermite transportation within facilities are often mandated to minimize potential risks to personnel and equipment.

Safety regulations also address the application of thermite in aerospace manufacturing processes. Detailed procedures for thermite welding and cutting operations are prescribed, including mandatory use of personal protective equipment (PPE) such as heat-resistant suits, face shields, and respiratory protection. Work areas where thermite is used must be isolated and equipped with appropriate ventilation systems to manage fumes and particulates.

Environmental considerations are increasingly prominent in thermite-related aerospace regulations. Guidelines often specify proper disposal methods for thermite residues and byproducts, emphasizing the need to prevent contamination of soil and water sources. Some regulations also mandate the use of more environmentally friendly thermite formulations when feasible.

Emergency response protocols form a critical component of thermite safety regulations in the aerospace industry. These include detailed procedures for handling thermite fires, which require specialized extinguishing agents and techniques. Facilities using thermite are typically required to have dedicated emergency response teams trained in handling thermite-related incidents.

Compliance with these safety regulations is rigorously enforced through regular inspections and audits by regulatory authorities. Non-compliance can result in severe penalties, including fines and suspension of operations. As aerospace technologies continue to evolve, these safety regulations are periodically reviewed and updated to address new challenges and incorporate emerging best practices in thermite handling and application.

Regulatory bodies, such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), have established specific guidelines for the handling, storage, and application of thermite in aerospace contexts. These regulations typically mandate rigorous training programs for personnel involved in thermite-related operations, ensuring they are well-versed in proper handling techniques and emergency procedures.

Storage requirements for thermite in aerospace facilities are particularly stringent. Regulations often specify the use of specialized containment units designed to withstand extreme temperatures and prevent accidental ignition. These storage areas must be equipped with advanced fire suppression systems and be located away from critical infrastructure and flammable materials.

Transportation of thermite within aerospace manufacturing and maintenance facilities is subject to strict protocols. Regulations typically require the use of specially designed transport containers that can withstand impact and prevent accidental ignition during movement. Additionally, designated routes for thermite transportation within facilities are often mandated to minimize potential risks to personnel and equipment.

Safety regulations also address the application of thermite in aerospace manufacturing processes. Detailed procedures for thermite welding and cutting operations are prescribed, including mandatory use of personal protective equipment (PPE) such as heat-resistant suits, face shields, and respiratory protection. Work areas where thermite is used must be isolated and equipped with appropriate ventilation systems to manage fumes and particulates.

Environmental considerations are increasingly prominent in thermite-related aerospace regulations. Guidelines often specify proper disposal methods for thermite residues and byproducts, emphasizing the need to prevent contamination of soil and water sources. Some regulations also mandate the use of more environmentally friendly thermite formulations when feasible.

Emergency response protocols form a critical component of thermite safety regulations in the aerospace industry. These include detailed procedures for handling thermite fires, which require specialized extinguishing agents and techniques. Facilities using thermite are typically required to have dedicated emergency response teams trained in handling thermite-related incidents.

Compliance with these safety regulations is rigorously enforced through regular inspections and audits by regulatory authorities. Non-compliance can result in severe penalties, including fines and suspension of operations. As aerospace technologies continue to evolve, these safety regulations are periodically reviewed and updated to address new challenges and incorporate emerging best practices in thermite handling and application.

Environmental Impact of Thermite in Aerospace Applications

The environmental impact of thermite in aerospace applications is a critical consideration as the industry explores its potential uses. Thermite reactions, known for their high-temperature exothermic nature, can have significant environmental implications when employed in aerospace engineering.

One of the primary environmental concerns associated with thermite use in aerospace is the emission of particulate matter and gases during the reaction. The combustion of thermite produces aluminum oxide particles, which can contribute to air pollution if released in large quantities. These particles may remain suspended in the atmosphere for extended periods, potentially affecting air quality and visibility in the surrounding areas.

Furthermore, the high temperatures generated by thermite reactions can lead to the formation of nitrogen oxides (NOx) when the reaction occurs in the presence of air. NOx emissions are known contributors to smog formation and can have adverse effects on human health and ecosystems. The aerospace industry must carefully consider these potential emissions and implement appropriate mitigation strategies to minimize their environmental impact.

The use of thermite in aerospace applications may also result in the release of metal oxides, depending on the specific composition of the thermite mixture. These metal oxides can potentially contaminate soil and water systems if not properly contained or disposed of. Long-term accumulation of these substances in the environment could lead to ecological imbalances and pose risks to local flora and fauna.

Another environmental consideration is the potential for thermite reactions to cause localized thermal pollution. The intense heat generated during the reaction can temporarily alter the temperature of the immediate surroundings, which may disrupt local ecosystems or affect wildlife habitats, particularly in sensitive areas where aerospace activities take place.

The production and disposal of thermite materials used in aerospace applications also warrant environmental scrutiny. The manufacturing process of thermite components may involve energy-intensive processes and the use of potentially hazardous chemicals. Proper handling, storage, and disposal protocols must be established to prevent environmental contamination and ensure worker safety throughout the lifecycle of thermite-based aerospace technologies.

However, it is important to note that the environmental impact of thermite in aerospace applications can be mitigated through careful engineering and responsible practices. The development of more efficient thermite compositions, improved containment systems, and advanced emission control technologies can significantly reduce the potential environmental footprint of thermite use in the aerospace industry.

One of the primary environmental concerns associated with thermite use in aerospace is the emission of particulate matter and gases during the reaction. The combustion of thermite produces aluminum oxide particles, which can contribute to air pollution if released in large quantities. These particles may remain suspended in the atmosphere for extended periods, potentially affecting air quality and visibility in the surrounding areas.

Furthermore, the high temperatures generated by thermite reactions can lead to the formation of nitrogen oxides (NOx) when the reaction occurs in the presence of air. NOx emissions are known contributors to smog formation and can have adverse effects on human health and ecosystems. The aerospace industry must carefully consider these potential emissions and implement appropriate mitigation strategies to minimize their environmental impact.

The use of thermite in aerospace applications may also result in the release of metal oxides, depending on the specific composition of the thermite mixture. These metal oxides can potentially contaminate soil and water systems if not properly contained or disposed of. Long-term accumulation of these substances in the environment could lead to ecological imbalances and pose risks to local flora and fauna.

Another environmental consideration is the potential for thermite reactions to cause localized thermal pollution. The intense heat generated during the reaction can temporarily alter the temperature of the immediate surroundings, which may disrupt local ecosystems or affect wildlife habitats, particularly in sensitive areas where aerospace activities take place.

The production and disposal of thermite materials used in aerospace applications also warrant environmental scrutiny. The manufacturing process of thermite components may involve energy-intensive processes and the use of potentially hazardous chemicals. Proper handling, storage, and disposal protocols must be established to prevent environmental contamination and ensure worker safety throughout the lifecycle of thermite-based aerospace technologies.

However, it is important to note that the environmental impact of thermite in aerospace applications can be mitigated through careful engineering and responsible practices. The development of more efficient thermite compositions, improved containment systems, and advanced emission control technologies can significantly reduce the potential environmental footprint of thermite use in the aerospace industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!