Future Trends in Thermite‑Based Technologies

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Tech Evolution

Thermite technology has undergone significant evolution since its inception in the late 19th century. Initially developed as a welding technique, thermite reactions have found diverse applications across various industries. The evolution of thermite-based technologies can be traced through several key stages, each marked by notable advancements and expanding applications.

In the early 20th century, thermite welding became widely adopted in the railway industry for joining rail tracks. This period saw the refinement of thermite mixtures and ignition techniques, leading to more reliable and efficient welding processes. The military sector also began exploring thermite for incendiary devices, recognizing its potential for high-temperature reactions.

The mid-20th century witnessed a broadening of thermite applications. Researchers developed new thermite compositions, incorporating various metal oxides and reducing agents to achieve specific properties. This era saw the emergence of thermite-based cutting tools for industrial use, as well as the application of thermite reactions in metallurgy for producing high-purity metals.

The late 20th century brought about significant advancements in thermite technology. The development of nano-scale thermite materials, often referred to as "nanothermites," marked a revolutionary step. These materials exhibited enhanced reactivity and energy release compared to traditional thermite mixtures, opening up new possibilities in propulsion systems and energetic materials.

In recent decades, the focus has shifted towards more controlled and precise thermite reactions. Researchers have explored methods to tailor the reaction kinetics and energy release of thermite systems. This has led to the development of "smart" thermite materials that can be activated under specific conditions, finding applications in areas such as self-healing materials and targeted drug delivery systems.

The current trend in thermite technology is moving towards environmentally friendly and sustainable applications. Researchers are investigating green thermite formulations that minimize harmful byproducts and exploring the use of thermite reactions in waste treatment and recycling processes. Additionally, there is growing interest in harnessing thermite reactions for energy storage and conversion, potentially contributing to renewable energy solutions.

Looking ahead, the future of thermite-based technologies appears promising. Ongoing research is focused on further miniaturization of thermite systems, exploring their potential in microelectronics and nanodevices. The integration of thermite reactions with advanced manufacturing techniques, such as 3D printing, is also an area of active investigation, potentially revolutionizing the production of complex thermite-based components.

In the early 20th century, thermite welding became widely adopted in the railway industry for joining rail tracks. This period saw the refinement of thermite mixtures and ignition techniques, leading to more reliable and efficient welding processes. The military sector also began exploring thermite for incendiary devices, recognizing its potential for high-temperature reactions.

The mid-20th century witnessed a broadening of thermite applications. Researchers developed new thermite compositions, incorporating various metal oxides and reducing agents to achieve specific properties. This era saw the emergence of thermite-based cutting tools for industrial use, as well as the application of thermite reactions in metallurgy for producing high-purity metals.

The late 20th century brought about significant advancements in thermite technology. The development of nano-scale thermite materials, often referred to as "nanothermites," marked a revolutionary step. These materials exhibited enhanced reactivity and energy release compared to traditional thermite mixtures, opening up new possibilities in propulsion systems and energetic materials.

In recent decades, the focus has shifted towards more controlled and precise thermite reactions. Researchers have explored methods to tailor the reaction kinetics and energy release of thermite systems. This has led to the development of "smart" thermite materials that can be activated under specific conditions, finding applications in areas such as self-healing materials and targeted drug delivery systems.

The current trend in thermite technology is moving towards environmentally friendly and sustainable applications. Researchers are investigating green thermite formulations that minimize harmful byproducts and exploring the use of thermite reactions in waste treatment and recycling processes. Additionally, there is growing interest in harnessing thermite reactions for energy storage and conversion, potentially contributing to renewable energy solutions.

Looking ahead, the future of thermite-based technologies appears promising. Ongoing research is focused on further miniaturization of thermite systems, exploring their potential in microelectronics and nanodevices. The integration of thermite reactions with advanced manufacturing techniques, such as 3D printing, is also an area of active investigation, potentially revolutionizing the production of complex thermite-based components.

Market Demand Analysis

The market demand for thermite-based technologies is experiencing significant growth, driven by various factors across multiple industries. In the defense sector, there is an increasing need for advanced thermite-based incendiary devices and pyrotechnics, particularly for military applications such as breaching tools, demolition charges, and specialized ammunition. This demand is fueled by ongoing global conflicts and the modernization of armed forces worldwide.

The aerospace industry represents another key market for thermite-based technologies. Space agencies and private companies are exploring the use of thermite reactions for in-space manufacturing, satellite de-orbiting, and propulsion systems. The growing number of satellite launches and space exploration missions is expected to drive demand for these innovative applications in the coming years.

In the manufacturing sector, thermite welding continues to be a crucial technique for joining large metal components, particularly in railway track construction and maintenance. As countries invest in expanding and upgrading their rail networks, the demand for thermite welding materials and equipment is projected to rise. Additionally, the automotive industry is showing interest in thermite-based technologies for lightweight material joining and advanced welding processes.

The energy sector is another area where thermite-based technologies are gaining traction. Research is underway to develop thermite-based heat storage systems for concentrated solar power plants, potentially offering more efficient and cost-effective energy storage solutions. This could lead to increased adoption of thermite technologies in renewable energy applications.

Emerging applications in the field of materials science are also contributing to market growth. Researchers are exploring the use of thermite reactions to synthesize advanced materials, including nanoparticles and composite materials with unique properties. This trend is likely to open up new market opportunities in industries such as electronics, healthcare, and advanced manufacturing.

The global market for thermite-based technologies is expected to expand at a steady pace over the next decade. While precise market size figures are challenging to determine due to the diverse applications and ongoing research, industry analysts project a compound annual growth rate in the mid to high single digits. Factors such as increasing defense budgets, space exploration initiatives, infrastructure development, and technological advancements are expected to be key drivers of this growth.

However, market growth may face challenges such as environmental concerns related to the use of certain thermite compositions and regulatory restrictions on the handling and transportation of reactive materials. Addressing these issues through the development of safer, more environmentally friendly thermite formulations could be crucial for sustained market expansion and broader adoption across industries.

The aerospace industry represents another key market for thermite-based technologies. Space agencies and private companies are exploring the use of thermite reactions for in-space manufacturing, satellite de-orbiting, and propulsion systems. The growing number of satellite launches and space exploration missions is expected to drive demand for these innovative applications in the coming years.

In the manufacturing sector, thermite welding continues to be a crucial technique for joining large metal components, particularly in railway track construction and maintenance. As countries invest in expanding and upgrading their rail networks, the demand for thermite welding materials and equipment is projected to rise. Additionally, the automotive industry is showing interest in thermite-based technologies for lightweight material joining and advanced welding processes.

The energy sector is another area where thermite-based technologies are gaining traction. Research is underway to develop thermite-based heat storage systems for concentrated solar power plants, potentially offering more efficient and cost-effective energy storage solutions. This could lead to increased adoption of thermite technologies in renewable energy applications.

Emerging applications in the field of materials science are also contributing to market growth. Researchers are exploring the use of thermite reactions to synthesize advanced materials, including nanoparticles and composite materials with unique properties. This trend is likely to open up new market opportunities in industries such as electronics, healthcare, and advanced manufacturing.

The global market for thermite-based technologies is expected to expand at a steady pace over the next decade. While precise market size figures are challenging to determine due to the diverse applications and ongoing research, industry analysts project a compound annual growth rate in the mid to high single digits. Factors such as increasing defense budgets, space exploration initiatives, infrastructure development, and technological advancements are expected to be key drivers of this growth.

However, market growth may face challenges such as environmental concerns related to the use of certain thermite compositions and regulatory restrictions on the handling and transportation of reactive materials. Addressing these issues through the development of safer, more environmentally friendly thermite formulations could be crucial for sustained market expansion and broader adoption across industries.

Current Challenges

Thermite-based technologies, while offering significant potential in various applications, face several critical challenges that hinder their widespread adoption and further development. One of the primary obstacles is the control and containment of the intense exothermic reactions characteristic of thermite mixtures. The extremely high temperatures generated during these reactions pose safety risks and make it difficult to harness the energy effectively for practical applications.

Another significant challenge lies in the precise control of reaction rates and energy release. Current thermite formulations often exhibit rapid, almost instantaneous reactions, which can be problematic in scenarios requiring sustained or controlled energy output. This limitation restricts the use of thermite-based technologies in applications that demand a more gradual or regulated energy release.

The environmental impact of thermite reactions presents an additional hurdle. The byproducts of these reactions, including metal oxides and other potentially harmful substances, raise concerns about environmental contamination and long-term ecological effects. This aspect becomes particularly critical when considering large-scale applications or frequent use of thermite-based technologies.

Scalability remains a persistent challenge in the field. While thermite reactions are well-understood and controllable on a small scale, translating this knowledge to larger, industrial-scale applications presents significant engineering and safety challenges. The unpredictable nature of scaled-up reactions and the potential for catastrophic failures have limited the expansion of thermite technologies beyond specialized, small-scale uses.

The materials used in thermite mixtures also present challenges. Many effective thermite compositions rely on rare or expensive materials, making large-scale production economically unfeasible. Additionally, the stability and shelf life of thermite mixtures can be problematic, with some formulations degrading over time or becoming sensitive to environmental factors like humidity or temperature fluctuations.

In the realm of energy efficiency, thermite reactions, while highly energetic, often suffer from incomplete combustion or energy transfer. This inefficiency results in a significant portion of the potential energy being lost as heat or light, rather than being harnessed for useful work. Improving the energy conversion efficiency of thermite reactions remains a key challenge for researchers and engineers in the field.

Lastly, the regulatory landscape surrounding thermite-based technologies presents a complex challenge. Due to the potential dual-use nature of these materials and their associated safety risks, stringent regulations often limit research, development, and application. Navigating these regulatory hurdles while advancing the technology requires careful consideration and often slows the pace of innovation in this field.

Another significant challenge lies in the precise control of reaction rates and energy release. Current thermite formulations often exhibit rapid, almost instantaneous reactions, which can be problematic in scenarios requiring sustained or controlled energy output. This limitation restricts the use of thermite-based technologies in applications that demand a more gradual or regulated energy release.

The environmental impact of thermite reactions presents an additional hurdle. The byproducts of these reactions, including metal oxides and other potentially harmful substances, raise concerns about environmental contamination and long-term ecological effects. This aspect becomes particularly critical when considering large-scale applications or frequent use of thermite-based technologies.

Scalability remains a persistent challenge in the field. While thermite reactions are well-understood and controllable on a small scale, translating this knowledge to larger, industrial-scale applications presents significant engineering and safety challenges. The unpredictable nature of scaled-up reactions and the potential for catastrophic failures have limited the expansion of thermite technologies beyond specialized, small-scale uses.

The materials used in thermite mixtures also present challenges. Many effective thermite compositions rely on rare or expensive materials, making large-scale production economically unfeasible. Additionally, the stability and shelf life of thermite mixtures can be problematic, with some formulations degrading over time or becoming sensitive to environmental factors like humidity or temperature fluctuations.

In the realm of energy efficiency, thermite reactions, while highly energetic, often suffer from incomplete combustion or energy transfer. This inefficiency results in a significant portion of the potential energy being lost as heat or light, rather than being harnessed for useful work. Improving the energy conversion efficiency of thermite reactions remains a key challenge for researchers and engineers in the field.

Lastly, the regulatory landscape surrounding thermite-based technologies presents a complex challenge. Due to the potential dual-use nature of these materials and their associated safety risks, stringent regulations often limit research, development, and application. Navigating these regulatory hurdles while advancing the technology requires careful consideration and often slows the pace of innovation in this field.

Existing Thermite Apps

01 Thermite-based welding and joining technologies

Thermite reactions are utilized in welding and joining processes, particularly for large metal structures or components. This technology involves the exothermic reaction between metal oxides and aluminum, generating intense heat for melting and fusing metals. Applications include rail track welding, pipe joining, and structural repairs in various industries.- Thermite-based welding and joining technologies: Thermite reactions are utilized in welding and joining processes, particularly for large metal structures or components. These technologies involve the use of thermite mixtures to generate intense heat for melting and fusing metals together. The process is often applied in railway track welding, pipeline connections, and structural steel joining.

- Thermite-based incendiary devices and ammunition: Thermite compositions are employed in the development of incendiary devices and specialized ammunition. These applications leverage the high-temperature reactions of thermite to create intense heat and light, often used in military or pyrotechnic contexts. The technology includes various formulations and ignition mechanisms to achieve desired effects.

- Thermite-based metal purification and extraction: Thermite reactions are applied in metallurgical processes for metal purification and extraction. This technology utilizes the high temperatures generated by thermite reactions to reduce metal oxides and separate pure metals from ores or compounds. It is particularly useful in producing high-purity metals or alloys with specific compositions.

- Thermite-based thermal batteries and energy storage: Thermite reactions are employed in the development of thermal batteries and energy storage systems. These technologies harness the heat generated by thermite reactions to produce electrical energy or store thermal energy for later use. Applications include emergency power sources, space exploration, and military equipment.

- Thermite-based cutting and perforation technologies: Thermite compositions are used in cutting and perforation technologies, particularly for thick metal structures or in underwater environments. These applications leverage the intense heat and focused energy of thermite reactions to create precise cuts or perforations in materials that are challenging to process using conventional methods.

02 Thermite-based incendiary devices and munitions

Thermite compositions are employed in military and defense applications for creating incendiary devices and specialized munitions. These formulations leverage the high-temperature reaction of thermite to produce intense heat and molten metal, useful for penetrating armor, destroying equipment, or creating diversionary effects in combat situations.Expand Specific Solutions03 Thermite-based metal purification and extraction

Thermite reactions are applied in metallurgical processes for metal purification and extraction. This technology utilizes the high temperatures generated by thermite reactions to reduce metal oxides and separate pure metals from ores or compounds. It is particularly useful in producing high-purity metals or alloys for specialized applications.Expand Specific Solutions04 Thermite-based thermal batteries and energy storage

Thermite compositions are used in the development of thermal batteries and energy storage systems. These technologies harness the exothermic nature of thermite reactions to generate heat and electrical energy on demand. Applications include power sources for missiles, torpedoes, and other specialized equipment requiring rapid, high-energy activation.Expand Specific Solutions05 Thermite-based material synthesis and processing

Thermite reactions are employed in advanced material synthesis and processing techniques. This technology utilizes the high temperatures and reducing environment of thermite reactions to create novel materials, nanoparticles, or modify existing materials. Applications include producing specialized ceramics, composites, and engineered materials with unique properties.Expand Specific Solutions

Key Industry Players

The thermite-based technologies market is in a growth phase, with increasing applications across various industries. The market size is expanding, driven by advancements in materials science and growing demand for high-energy reactions. Technological maturity varies, with established players like Lockheed Martin Corp. and Northrop Grumman Systems Corp. leading in defense applications. Emerging companies such as BiSN Oil Tools Ltd. and Heatgen LLC are innovating in energy and industrial sectors. Academic institutions like Purdue University and Massachusetts Institute of Technology are contributing to fundamental research, while national laboratories like Naval Research Laboratory are pushing the boundaries of thermite applications. The competitive landscape is diverse, with collaborations between industry and academia driving innovation in this field.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced thermite-based technologies for military and aerospace applications. Their approach focuses on enhancing the energy density and controllability of thermite reactions. They have engineered nano-structured thermite materials that offer improved ignition properties and faster reaction rates. Lockheed Martin's research also includes the development of thermite-based propulsion systems for small satellites and space vehicles, leveraging the high energy output of thermite reactions for efficient thrust generation in space environments.

Strengths: Extensive experience in aerospace and defense applications, access to advanced research facilities. Weaknesses: High costs associated with research and development, potential regulatory challenges in non-military applications.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory (NRL) is at the forefront of thermite-based technology research for naval applications. Their focus is on developing thermite compositions that can function effectively in underwater environments. NRL has made significant progress in creating waterproof thermite mixtures that maintain their reactivity even when submerged. They are also exploring the use of thermite reactions for underwater welding and cutting operations, which could revolutionize submarine maintenance and repair procedures. Additionally, NRL is investigating the potential of thermite-based materials for neutralizing underwater mines and other explosive ordnance.

Strengths: Specialized expertise in naval applications, government funding for long-term research. Weaknesses: Limited focus on commercial applications, potential classification restrictions on research findings.

Innovative Thermite R&D

Solid-state thermite composition based heating device

PatentWO2010117857A2

Innovation

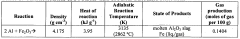

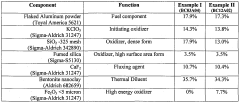

- A solid-state thermite reaction composition comprising a fuel component, primary oxidizer, initiating oxidizers, thermal diluent, and fluxing agents, integrated with a heating device featuring a reaction chamber and actuable trigger mechanism, allowing controlled thermite reactions for precise heat generation, with activation mechanisms like piezoelectric spark ignitors or exothermic couples to initiate the reaction safely.

Nano-thermite well plug

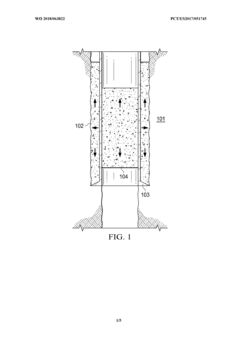

PatentWO2018063822A1

Innovation

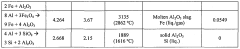

- The use of nano-thermite compositions, comprising aluminum and bismuth, which exhibit lower ignition temperatures and faster reaction rates, allowing for the formation of efficient plugs without the need for extensive rig equipment, as they can be ignited using common heaters and form seals across wellbores with smaller amounts of material.

Safety Regulations

The safety regulations surrounding thermite-based technologies are evolving rapidly to keep pace with the advancements in this field. As these technologies find new applications in various industries, regulatory bodies are focusing on developing comprehensive guidelines to ensure their safe use and handling.

One of the primary concerns addressed by current safety regulations is the storage and transportation of thermite materials. Strict protocols have been established for packaging, labeling, and shipping these highly reactive substances. These regulations often require specialized containers designed to withstand high temperatures and prevent accidental ignition during transit.

In manufacturing and industrial settings, safety regulations are increasingly emphasizing the importance of proper training for personnel handling thermite-based technologies. This includes mandatory safety courses, regular refresher training, and certification programs for operators and supervisors. Additionally, regulations are mandating the use of advanced personal protective equipment (PPE) specifically designed for high-temperature environments.

Environmental considerations are also becoming a significant aspect of safety regulations in thermite-based technologies. Regulatory bodies are implementing stricter controls on emissions and waste management, particularly in applications involving large-scale thermite reactions. This includes guidelines for proper disposal of byproducts and measures to minimize the environmental impact of thermite use.

As thermite technologies find new applications in fields such as aerospace and defense, safety regulations are being tailored to address the unique challenges in these sectors. This includes specific protocols for the use of thermite in controlled demolitions, welding operations in extreme environments, and military applications.

The advent of nanotechnology in thermite compositions has prompted regulatory bodies to develop new safety guidelines. These regulations focus on the handling and containment of nano-scale thermite particles, which can pose unique health and safety risks due to their increased reactivity and potential for aerosolization.

Looking ahead, safety regulations are likely to become more stringent and comprehensive. There is a growing emphasis on developing international standards for thermite-based technologies to ensure consistency in safety practices across different countries and industries. This global approach aims to facilitate the safe adoption and transfer of these technologies worldwide.

Future regulations may also incorporate advanced monitoring and control systems. This could include the mandatory use of real-time sensors and automated safety systems in facilities working with thermite technologies, enabling rapid response to potential hazards and improving overall safety management.

One of the primary concerns addressed by current safety regulations is the storage and transportation of thermite materials. Strict protocols have been established for packaging, labeling, and shipping these highly reactive substances. These regulations often require specialized containers designed to withstand high temperatures and prevent accidental ignition during transit.

In manufacturing and industrial settings, safety regulations are increasingly emphasizing the importance of proper training for personnel handling thermite-based technologies. This includes mandatory safety courses, regular refresher training, and certification programs for operators and supervisors. Additionally, regulations are mandating the use of advanced personal protective equipment (PPE) specifically designed for high-temperature environments.

Environmental considerations are also becoming a significant aspect of safety regulations in thermite-based technologies. Regulatory bodies are implementing stricter controls on emissions and waste management, particularly in applications involving large-scale thermite reactions. This includes guidelines for proper disposal of byproducts and measures to minimize the environmental impact of thermite use.

As thermite technologies find new applications in fields such as aerospace and defense, safety regulations are being tailored to address the unique challenges in these sectors. This includes specific protocols for the use of thermite in controlled demolitions, welding operations in extreme environments, and military applications.

The advent of nanotechnology in thermite compositions has prompted regulatory bodies to develop new safety guidelines. These regulations focus on the handling and containment of nano-scale thermite particles, which can pose unique health and safety risks due to their increased reactivity and potential for aerosolization.

Looking ahead, safety regulations are likely to become more stringent and comprehensive. There is a growing emphasis on developing international standards for thermite-based technologies to ensure consistency in safety practices across different countries and industries. This global approach aims to facilitate the safe adoption and transfer of these technologies worldwide.

Future regulations may also incorporate advanced monitoring and control systems. This could include the mandatory use of real-time sensors and automated safety systems in facilities working with thermite technologies, enabling rapid response to potential hazards and improving overall safety management.

Environmental Impact

The environmental impact of thermite-based technologies is a critical consideration as these technologies continue to evolve and find new applications. Thermite reactions, known for their high-temperature exothermic nature, have traditionally been associated with significant environmental concerns, particularly in terms of emissions and waste products.

One of the primary environmental challenges associated with thermite reactions is the production of metal oxide fumes and particulate matter. These emissions can contribute to air pollution and pose potential health risks to both workers and surrounding communities. As thermite technologies advance, there is a growing focus on developing cleaner burning formulations and improved containment systems to minimize these emissions.

Water contamination is another environmental concern, especially when thermite reactions are conducted near water sources or in areas with high groundwater levels. The high temperatures and reactive nature of thermite can lead to the leaching of metals and other contaminants into water systems. Future trends in thermite technologies are likely to include the development of more environmentally friendly compositions that reduce the risk of water pollution.

Soil contamination is also a significant issue, particularly in applications such as welding or demolition where thermite reactions come into direct contact with the ground. The residual heat and chemical byproducts can alter soil composition and affect local ecosystems. Emerging research is focusing on creating thermite formulations that minimize soil impact and developing remediation techniques for affected areas.

As sustainability becomes increasingly important across industries, there is a growing emphasis on the lifecycle assessment of thermite-based technologies. This includes considering the environmental impact of raw material extraction, production processes, and end-of-life disposal or recycling of thermite products. Future trends are likely to see a shift towards more sustainable sourcing of thermite components and the development of closed-loop systems that minimize waste.

Advancements in nanotechnology are opening up new possibilities for environmentally friendly thermite formulations. Nano-sized particles can potentially increase reaction efficiency, reducing the overall amount of material needed and minimizing waste. However, the environmental implications of nanoparticles themselves are still being studied, and future research will need to carefully balance the benefits and potential risks.

In conclusion, the future of thermite-based technologies will likely be shaped by a strong focus on environmental stewardship. Innovations aimed at reducing emissions, minimizing contamination, and improving overall sustainability will be crucial in ensuring the continued viability and acceptance of these technologies across various applications.

One of the primary environmental challenges associated with thermite reactions is the production of metal oxide fumes and particulate matter. These emissions can contribute to air pollution and pose potential health risks to both workers and surrounding communities. As thermite technologies advance, there is a growing focus on developing cleaner burning formulations and improved containment systems to minimize these emissions.

Water contamination is another environmental concern, especially when thermite reactions are conducted near water sources or in areas with high groundwater levels. The high temperatures and reactive nature of thermite can lead to the leaching of metals and other contaminants into water systems. Future trends in thermite technologies are likely to include the development of more environmentally friendly compositions that reduce the risk of water pollution.

Soil contamination is also a significant issue, particularly in applications such as welding or demolition where thermite reactions come into direct contact with the ground. The residual heat and chemical byproducts can alter soil composition and affect local ecosystems. Emerging research is focusing on creating thermite formulations that minimize soil impact and developing remediation techniques for affected areas.

As sustainability becomes increasingly important across industries, there is a growing emphasis on the lifecycle assessment of thermite-based technologies. This includes considering the environmental impact of raw material extraction, production processes, and end-of-life disposal or recycling of thermite products. Future trends are likely to see a shift towards more sustainable sourcing of thermite components and the development of closed-loop systems that minimize waste.

Advancements in nanotechnology are opening up new possibilities for environmentally friendly thermite formulations. Nano-sized particles can potentially increase reaction efficiency, reducing the overall amount of material needed and minimizing waste. However, the environmental implications of nanoparticles themselves are still being studied, and future research will need to carefully balance the benefits and potential risks.

In conclusion, the future of thermite-based technologies will likely be shaped by a strong focus on environmental stewardship. Innovations aimed at reducing emissions, minimizing contamination, and improving overall sustainability will be crucial in ensuring the continued viability and acceptance of these technologies across various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!