Glacial Acetic Acid and Environmental Remediation Technology Developments

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GAA Tech Background

Glacial Acetic Acid (GAA) has been a cornerstone in industrial chemistry for over a century, with its roots tracing back to the early 1900s. Initially produced through wood distillation, the manufacturing process has evolved significantly, reflecting the technological advancements in chemical engineering. The modern production of GAA primarily relies on methanol carbonylation or ethylene oxidation, showcasing the industry's shift towards more efficient and economically viable methods.

The development of GAA technology has been driven by its versatile applications across various sectors, including textiles, pharmaceuticals, and food processing. As industrial demands grew, so did the need for higher purity and larger production volumes. This led to continuous improvements in distillation techniques and reactor designs, enabling manufacturers to achieve GAA concentrations exceeding 99.8%.

In recent decades, the focus of GAA technology has expanded beyond mere production efficiency to encompass environmental considerations. This shift aligns with global trends towards sustainable industrial practices and stricter environmental regulations. Researchers and industry leaders have been exploring ways to reduce the carbon footprint of GAA production, minimize waste generation, and improve overall process safety.

The environmental remediation aspect of GAA technology has gained significant traction, particularly in addressing soil and water contamination issues. GAA's unique properties, such as its ability to dissolve various organic compounds, have made it a valuable tool in environmental cleanup efforts. Innovations in this field include the development of GAA-based formulations for in-situ soil remediation and advanced oxidation processes for wastewater treatment.

Current technological goals in the GAA sector are multifaceted. They include further optimizing production processes to reduce energy consumption and raw material usage, developing greener synthesis routes that utilize renewable feedstocks, and enhancing the efficacy of GAA-based environmental remediation techniques. Additionally, there is a growing emphasis on integrating GAA production and utilization within circular economy frameworks, aiming to minimize waste and maximize resource efficiency.

The intersection of GAA technology and environmental remediation represents a promising area for future innovations. Researchers are exploring novel applications of GAA in bioremediation, where it can serve as a carbon source for beneficial microorganisms or as a co-substrate in complex degradation processes. Furthermore, the potential of GAA derivatives in advanced materials for environmental applications, such as adsorbents for pollutant removal, is an emerging field of study.

The development of GAA technology has been driven by its versatile applications across various sectors, including textiles, pharmaceuticals, and food processing. As industrial demands grew, so did the need for higher purity and larger production volumes. This led to continuous improvements in distillation techniques and reactor designs, enabling manufacturers to achieve GAA concentrations exceeding 99.8%.

In recent decades, the focus of GAA technology has expanded beyond mere production efficiency to encompass environmental considerations. This shift aligns with global trends towards sustainable industrial practices and stricter environmental regulations. Researchers and industry leaders have been exploring ways to reduce the carbon footprint of GAA production, minimize waste generation, and improve overall process safety.

The environmental remediation aspect of GAA technology has gained significant traction, particularly in addressing soil and water contamination issues. GAA's unique properties, such as its ability to dissolve various organic compounds, have made it a valuable tool in environmental cleanup efforts. Innovations in this field include the development of GAA-based formulations for in-situ soil remediation and advanced oxidation processes for wastewater treatment.

Current technological goals in the GAA sector are multifaceted. They include further optimizing production processes to reduce energy consumption and raw material usage, developing greener synthesis routes that utilize renewable feedstocks, and enhancing the efficacy of GAA-based environmental remediation techniques. Additionally, there is a growing emphasis on integrating GAA production and utilization within circular economy frameworks, aiming to minimize waste and maximize resource efficiency.

The intersection of GAA technology and environmental remediation represents a promising area for future innovations. Researchers are exploring novel applications of GAA in bioremediation, where it can serve as a carbon source for beneficial microorganisms or as a co-substrate in complex degradation processes. Furthermore, the potential of GAA derivatives in advanced materials for environmental applications, such as adsorbents for pollutant removal, is an emerging field of study.

Market Demand Analysis

The market demand for glacial acetic acid and environmental remediation technologies has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations. Glacial acetic acid, a versatile chemical compound, finds extensive applications in various industries, including textiles, pharmaceuticals, food processing, and plastics manufacturing. Its demand is closely tied to the overall industrial growth and consumer product markets.

In the environmental remediation sector, there is a rising need for effective technologies to address soil and groundwater contamination. This demand is fueled by increasing awareness of the long-term impacts of industrial pollution and the push for sustainable development practices. Governments worldwide are implementing stricter environmental policies, creating a robust market for remediation solutions.

The global glacial acetic acid market is expected to experience significant growth in the coming years. Key factors contributing to this growth include the expanding textile industry, particularly in developing countries, and the increasing use of purified terephthalic acid (PTA) in the production of polyester fibers and resins. Additionally, the rising demand for vinegar in the food industry and the growing adoption of acetic acid in the production of various chemicals are driving market expansion.

Environmental remediation technologies are witnessing a surge in demand across both developed and developing nations. This growth is attributed to the legacy of industrial contamination, ongoing urbanization, and the need to reclaim brownfield sites for development. In-situ remediation techniques, which treat contaminants without removing soil or groundwater, are gaining popularity due to their cost-effectiveness and minimal site disruption.

The market for bioremediation, a subset of environmental remediation that uses microorganisms to degrade pollutants, is experiencing rapid growth. This eco-friendly approach aligns with the global shift towards sustainable practices and is increasingly preferred for its lower environmental impact compared to traditional chemical treatments.

Emerging economies, particularly in Asia-Pacific and Latin America, are expected to be significant drivers of market growth for both glacial acetic acid and environmental remediation technologies. These regions are witnessing rapid industrialization and urbanization, leading to increased demand for industrial chemicals and a parallel need for environmental cleanup solutions.

The COVID-19 pandemic has had a mixed impact on these markets. While it temporarily disrupted supply chains and industrial activities, it has also heightened awareness of environmental health issues, potentially accelerating the adoption of remediation technologies in the long term. As economies recover, the demand for both glacial acetic acid and environmental remediation solutions is anticipated to rebound strongly, driven by pent-up industrial activity and renewed focus on environmental sustainability.

In the environmental remediation sector, there is a rising need for effective technologies to address soil and groundwater contamination. This demand is fueled by increasing awareness of the long-term impacts of industrial pollution and the push for sustainable development practices. Governments worldwide are implementing stricter environmental policies, creating a robust market for remediation solutions.

The global glacial acetic acid market is expected to experience significant growth in the coming years. Key factors contributing to this growth include the expanding textile industry, particularly in developing countries, and the increasing use of purified terephthalic acid (PTA) in the production of polyester fibers and resins. Additionally, the rising demand for vinegar in the food industry and the growing adoption of acetic acid in the production of various chemicals are driving market expansion.

Environmental remediation technologies are witnessing a surge in demand across both developed and developing nations. This growth is attributed to the legacy of industrial contamination, ongoing urbanization, and the need to reclaim brownfield sites for development. In-situ remediation techniques, which treat contaminants without removing soil or groundwater, are gaining popularity due to their cost-effectiveness and minimal site disruption.

The market for bioremediation, a subset of environmental remediation that uses microorganisms to degrade pollutants, is experiencing rapid growth. This eco-friendly approach aligns with the global shift towards sustainable practices and is increasingly preferred for its lower environmental impact compared to traditional chemical treatments.

Emerging economies, particularly in Asia-Pacific and Latin America, are expected to be significant drivers of market growth for both glacial acetic acid and environmental remediation technologies. These regions are witnessing rapid industrialization and urbanization, leading to increased demand for industrial chemicals and a parallel need for environmental cleanup solutions.

The COVID-19 pandemic has had a mixed impact on these markets. While it temporarily disrupted supply chains and industrial activities, it has also heightened awareness of environmental health issues, potentially accelerating the adoption of remediation technologies in the long term. As economies recover, the demand for both glacial acetic acid and environmental remediation solutions is anticipated to rebound strongly, driven by pent-up industrial activity and renewed focus on environmental sustainability.

Current Challenges

The development of glacial acetic acid and environmental remediation technologies faces several significant challenges that hinder their widespread adoption and effectiveness. One of the primary obstacles is the high production cost of glacial acetic acid, which limits its large-scale application in environmental remediation processes. The current manufacturing methods often involve energy-intensive processes and expensive catalysts, making it economically unfeasible for many environmental applications.

Environmental concerns also pose a challenge to the production and use of glacial acetic acid. Traditional production methods can generate substantial amounts of greenhouse gases and other pollutants, contradicting the very purpose of environmental remediation. This paradox necessitates the development of greener production techniques that minimize environmental impact while maintaining efficiency.

The stability and reactivity of glacial acetic acid in various environmental conditions present another hurdle. Its high corrosivity can lead to equipment degradation and potential safety hazards during handling and application. Moreover, its volatility can result in atmospheric emissions, requiring sophisticated containment and recovery systems to prevent unintended environmental release.

In the context of environmental remediation, the effectiveness of glacial acetic acid-based technologies varies significantly depending on the specific contaminants and environmental matrices involved. While it shows promise in certain applications, such as heavy metal removal from soil and wastewater treatment, its performance can be inconsistent across different pollutant types and concentrations. This variability necessitates extensive research to optimize formulations and application methods for diverse environmental scenarios.

The regulatory landscape surrounding the use of glacial acetic acid in environmental remediation is another critical challenge. Stringent environmental regulations in many countries limit the use of chemical agents in remediation processes, requiring thorough safety assessments and long-term environmental impact studies. Obtaining necessary approvals and permits for large-scale applications can be a time-consuming and costly process, deterring potential adopters of these technologies.

Furthermore, the integration of glacial acetic acid-based remediation technologies with existing environmental management systems poses technical and operational challenges. Many current remediation infrastructures are not designed to accommodate the specific requirements of acetic acid-based processes, necessitating significant modifications or the development of entirely new systems.

Lastly, there is a notable knowledge gap in understanding the long-term ecological impacts of using glacial acetic acid in environmental remediation. While short-term effectiveness may be demonstrated, the potential for unintended consequences on ecosystem balance and biodiversity over extended periods remains a concern that requires comprehensive, long-term studies.

Environmental concerns also pose a challenge to the production and use of glacial acetic acid. Traditional production methods can generate substantial amounts of greenhouse gases and other pollutants, contradicting the very purpose of environmental remediation. This paradox necessitates the development of greener production techniques that minimize environmental impact while maintaining efficiency.

The stability and reactivity of glacial acetic acid in various environmental conditions present another hurdle. Its high corrosivity can lead to equipment degradation and potential safety hazards during handling and application. Moreover, its volatility can result in atmospheric emissions, requiring sophisticated containment and recovery systems to prevent unintended environmental release.

In the context of environmental remediation, the effectiveness of glacial acetic acid-based technologies varies significantly depending on the specific contaminants and environmental matrices involved. While it shows promise in certain applications, such as heavy metal removal from soil and wastewater treatment, its performance can be inconsistent across different pollutant types and concentrations. This variability necessitates extensive research to optimize formulations and application methods for diverse environmental scenarios.

The regulatory landscape surrounding the use of glacial acetic acid in environmental remediation is another critical challenge. Stringent environmental regulations in many countries limit the use of chemical agents in remediation processes, requiring thorough safety assessments and long-term environmental impact studies. Obtaining necessary approvals and permits for large-scale applications can be a time-consuming and costly process, deterring potential adopters of these technologies.

Furthermore, the integration of glacial acetic acid-based remediation technologies with existing environmental management systems poses technical and operational challenges. Many current remediation infrastructures are not designed to accommodate the specific requirements of acetic acid-based processes, necessitating significant modifications or the development of entirely new systems.

Lastly, there is a notable knowledge gap in understanding the long-term ecological impacts of using glacial acetic acid in environmental remediation. While short-term effectiveness may be demonstrated, the potential for unintended consequences on ecosystem balance and biodiversity over extended periods remains a concern that requires comprehensive, long-term studies.

Remediation Solutions

01 Production methods of glacial acetic acid

Various methods are employed to produce glacial acetic acid, including oxidation of acetaldehyde, fermentation processes, and catalytic reactions. These methods often involve specific reaction conditions, catalysts, and purification steps to achieve high purity acetic acid.- Production methods of glacial acetic acid: Various methods are employed to produce glacial acetic acid, including oxidation of acetaldehyde, fermentation processes, and catalytic reactions. These methods often involve specific reaction conditions, catalysts, and purification steps to achieve high purity acetic acid.

- Purification and concentration techniques: Purification and concentration of acetic acid to achieve glacial grade involves distillation, crystallization, and membrane separation processes. These techniques aim to remove impurities and increase the acid concentration to near 100%.

- Applications in chemical synthesis: Glacial acetic acid serves as a crucial reagent and solvent in various chemical synthesis processes, including the production of vinyl acetate, cellulose acetate, and other organic compounds. Its high purity makes it suitable for sensitive reactions and industrial applications.

- Storage and handling equipment: Specialized equipment and materials are used for storing and handling glacial acetic acid due to its corrosive nature. This includes corrosion-resistant tanks, piping systems, and safety measures to prevent leaks and ensure proper containment.

- Environmental and safety considerations: The production and use of glacial acetic acid require strict environmental and safety protocols. This includes emission control systems, waste treatment processes, and personal protective equipment to mitigate risks associated with its corrosive and potentially harmful properties.

02 Applications in chemical synthesis

Glacial acetic acid serves as a crucial reagent and solvent in numerous chemical synthesis processes. It is used in the production of various organic compounds, pharmaceuticals, and industrial chemicals due to its high purity and reactivity.Expand Specific Solutions03 Purification and concentration techniques

Specialized techniques are employed to purify and concentrate acetic acid to achieve the glacial form. These may include distillation, crystallization, and membrane separation processes, ensuring high purity levels suitable for industrial and laboratory use.Expand Specific Solutions04 Storage and handling systems

Due to its corrosive nature, specific storage and handling systems are designed for glacial acetic acid. These include specialized containers, transfer systems, and safety equipment to prevent contamination and ensure worker safety during handling and transportation.Expand Specific Solutions05 Environmental and safety considerations

The use and production of glacial acetic acid involve various environmental and safety considerations. This includes waste treatment methods, emission control systems, and safety protocols to mitigate risks associated with its corrosive and flammable properties.Expand Specific Solutions

Key Industry Players

The development of Glacial Acetic Acid and Environmental Remediation Technology is in a mature stage, with a growing market driven by increasing environmental concerns and industrial applications. The global market size for acetic acid is substantial, expected to reach over $13 billion by 2027. Technologically, the field is well-established but continues to evolve, with companies like Akzo Nobel Chemicals, Stepan Co., and LyondellBasell Acetyls LLC leading in production and innovation. Research institutions such as The University of Queensland and Southeast University contribute to advancements in environmental remediation techniques. Emerging players like Onvector LLC are introducing novel technologies, such as plasma-based systems for PFAS removal, indicating ongoing innovation in the sector.

Akzo Nobel Chemicals International BV

Technical Solution: Akzo Nobel has developed advanced oxidation processes (AOPs) for the treatment of glacial acetic acid-contaminated wastewater. Their technology combines ozonation with hydrogen peroxide (O3/H2O2) to generate highly reactive hydroxyl radicals. This process effectively breaks down acetic acid molecules into harmless byproducts such as carbon dioxide and water. The company has optimized the O3/H2O2 ratio and reaction conditions to achieve over 95% removal efficiency of acetic acid in industrial effluents[1]. Additionally, Akzo Nobel has integrated this AOP system with membrane filtration to further enhance the overall treatment efficacy and water reuse potential[3].

Strengths: High removal efficiency, versatile application in various industries, potential for water reuse. Weaknesses: High energy consumption, potential formation of toxic byproducts if not properly controlled.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed a green and sustainable approach for glacial acetic acid remediation using phytoremediation techniques. Their research has identified several plant species, including Vetiver grass and certain Brassica varieties, that can effectively uptake and metabolize acetic acid from contaminated soil and water. CSIR has optimized plant cultivation conditions and developed a rhizosphere engineering approach to enhance acetic acid degradation rates. Field studies have demonstrated up to 70% reduction in soil acetic acid levels over a 6-month growth period[7]. Additionally, CSIR has explored the potential of harvested plant biomass for biofuel production, creating a circular economy model for remediation efforts[8].

Strengths: Eco-friendly, low operational costs, potential for value-added products from remediation. Weaknesses: Longer treatment times compared to chemical methods, limited applicability in high-concentration scenarios.

Core Innovations

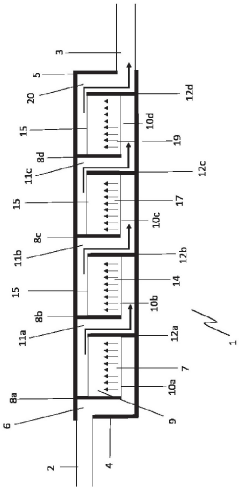

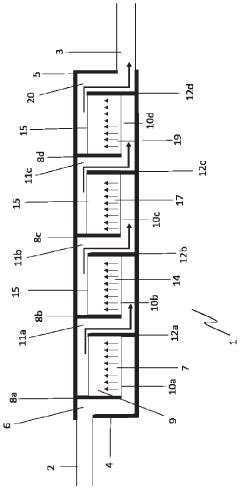

Passive contaminated surface water treatment system

PatentPendingAU2022221460A1

Innovation

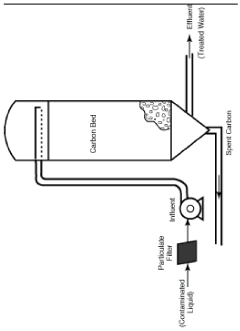

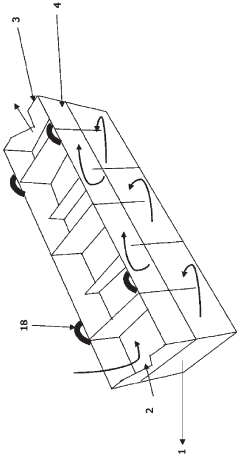

- A gravity-fed water treatment system using a series of chambers with alternating upcast and downcast flow paths and granulated activated carbon (GAC) filter media, designed to treat PFAS contaminated surface water with minimal maintenance and low operating costs, incorporating a non-linear flow path and sediment removal to extend the lifespan of the GAC media.

Calcium integrated lipase-nanoporous activated carbon matrix and a process for the preparation thereof

PatentInactiveIN2223DEL2014A

Innovation

- A calcium-integrated lipase-nanoporous activated carbon matrix is developed, where lipase is immobilized on nanoporous activated carbon using aliphatic neutral non-polar amino acid linkages, enhancing enzyme stability and activity while avoiding external enhancers, and facilitating surfactant removal without flocculation, foaming, or clogging.

Environmental Impact

The environmental impact of glacial acetic acid production and its use in environmental remediation technologies is a complex and multifaceted issue. The production of glacial acetic acid, primarily through methanol carbonylation or ethylene oxidation, can have significant environmental implications.

One of the main concerns is the energy-intensive nature of these production processes, which often rely on fossil fuels, contributing to greenhouse gas emissions and climate change. The manufacturing facilities also generate various air pollutants, including volatile organic compounds (VOCs) and nitrogen oxides (NOx), which can lead to local air quality issues and contribute to smog formation.

Water pollution is another critical environmental aspect associated with glacial acetic acid production. The process can generate wastewater containing organic compounds and trace metals, which, if not properly treated, may contaminate local water bodies and affect aquatic ecosystems. Additionally, the risk of accidental spills during transportation or storage poses potential threats to soil and groundwater quality.

However, when considering the use of glacial acetic acid in environmental remediation technologies, there are potential positive environmental impacts to consider. Acetic acid has shown promise in various remediation applications, particularly in the treatment of contaminated soils and groundwater.

In soil remediation, glacial acetic acid can be effective in removing heavy metals through a process called soil washing. This technique can help restore contaminated sites, reducing the long-term environmental burden of polluted soils. Similarly, in groundwater treatment, acetic acid can be used to enhance the solubility and mobility of certain contaminants, facilitating their removal through pump-and-treat systems.

The use of glacial acetic acid in these remediation technologies can potentially reduce the need for more aggressive chemical treatments or extensive excavation activities, which often have their own significant environmental impacts. This could lead to a net positive environmental outcome when considering the full lifecycle of remediation projects.

It is important to note that the environmental impact of using glacial acetic acid in remediation must be carefully managed. Proper handling, application, and disposal practices are crucial to prevent any unintended environmental consequences. The potential for soil acidification and impacts on local microbial communities must be considered and mitigated through appropriate remediation design and monitoring protocols.

In conclusion, while the production of glacial acetic acid presents certain environmental challenges, its application in environmental remediation technologies offers potential benefits that could outweigh these impacts when properly managed. Ongoing research and development in both production methods and remediation techniques are essential to further optimize the environmental profile of glacial acetic acid in the context of environmental remediation.

One of the main concerns is the energy-intensive nature of these production processes, which often rely on fossil fuels, contributing to greenhouse gas emissions and climate change. The manufacturing facilities also generate various air pollutants, including volatile organic compounds (VOCs) and nitrogen oxides (NOx), which can lead to local air quality issues and contribute to smog formation.

Water pollution is another critical environmental aspect associated with glacial acetic acid production. The process can generate wastewater containing organic compounds and trace metals, which, if not properly treated, may contaminate local water bodies and affect aquatic ecosystems. Additionally, the risk of accidental spills during transportation or storage poses potential threats to soil and groundwater quality.

However, when considering the use of glacial acetic acid in environmental remediation technologies, there are potential positive environmental impacts to consider. Acetic acid has shown promise in various remediation applications, particularly in the treatment of contaminated soils and groundwater.

In soil remediation, glacial acetic acid can be effective in removing heavy metals through a process called soil washing. This technique can help restore contaminated sites, reducing the long-term environmental burden of polluted soils. Similarly, in groundwater treatment, acetic acid can be used to enhance the solubility and mobility of certain contaminants, facilitating their removal through pump-and-treat systems.

The use of glacial acetic acid in these remediation technologies can potentially reduce the need for more aggressive chemical treatments or extensive excavation activities, which often have their own significant environmental impacts. This could lead to a net positive environmental outcome when considering the full lifecycle of remediation projects.

It is important to note that the environmental impact of using glacial acetic acid in remediation must be carefully managed. Proper handling, application, and disposal practices are crucial to prevent any unintended environmental consequences. The potential for soil acidification and impacts on local microbial communities must be considered and mitigated through appropriate remediation design and monitoring protocols.

In conclusion, while the production of glacial acetic acid presents certain environmental challenges, its application in environmental remediation technologies offers potential benefits that could outweigh these impacts when properly managed. Ongoing research and development in both production methods and remediation techniques are essential to further optimize the environmental profile of glacial acetic acid in the context of environmental remediation.

Regulatory Framework

The regulatory framework surrounding glacial acetic acid and environmental remediation technologies has evolved significantly in recent years, reflecting growing concerns about environmental protection and public health. At the international level, the United Nations Environment Programme (UNEP) has established guidelines for the safe handling and disposal of acetic acid and its derivatives, emphasizing the importance of proper waste management and pollution prevention.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use and disposal of glacial acetic acid. The Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA) provide the legal basis for controlling the production, use, and disposal of this chemical. The Occupational Safety and Health Administration (OSHA) has set strict exposure limits and safety protocols for workers handling glacial acetic acid in industrial settings.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which requires manufacturers and importers to assess and manage the risks associated with chemicals, including glacial acetic acid. This comprehensive approach ensures that potential environmental and health impacts are thoroughly evaluated before a substance can be marketed or used in remediation technologies.

In Asia, countries like China and Japan have strengthened their environmental regulations in recent years. China's Ministry of Ecology and Environment has introduced stricter controls on industrial emissions and waste disposal, directly impacting the use of acetic acid in various industries. Japan's Chemical Substances Control Law (CSCL) provides a framework for assessing and managing the risks of chemical substances, including those used in environmental remediation.

Regulatory bodies worldwide are increasingly focusing on the development and implementation of green chemistry principles. This approach encourages the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances, including alternatives to glacial acetic acid in certain applications.

The regulatory landscape also addresses the use of glacial acetic acid in environmental remediation technologies. Many countries have established specific guidelines for soil and groundwater remediation, often requiring the use of environmentally friendly and sustainable technologies. These regulations often mandate thorough site assessments, remediation action plans, and post-treatment monitoring to ensure the effectiveness and safety of the remediation process.

As environmental concerns continue to grow, it is expected that regulations will become more stringent, potentially leading to increased research and development in alternative, less hazardous substances and more efficient remediation technologies. This evolving regulatory framework will likely shape the future direction of glacial acetic acid usage and environmental remediation practices globally.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating the use and disposal of glacial acetic acid. The Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA) provide the legal basis for controlling the production, use, and disposal of this chemical. The Occupational Safety and Health Administration (OSHA) has set strict exposure limits and safety protocols for workers handling glacial acetic acid in industrial settings.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which requires manufacturers and importers to assess and manage the risks associated with chemicals, including glacial acetic acid. This comprehensive approach ensures that potential environmental and health impacts are thoroughly evaluated before a substance can be marketed or used in remediation technologies.

In Asia, countries like China and Japan have strengthened their environmental regulations in recent years. China's Ministry of Ecology and Environment has introduced stricter controls on industrial emissions and waste disposal, directly impacting the use of acetic acid in various industries. Japan's Chemical Substances Control Law (CSCL) provides a framework for assessing and managing the risks of chemical substances, including those used in environmental remediation.

Regulatory bodies worldwide are increasingly focusing on the development and implementation of green chemistry principles. This approach encourages the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances, including alternatives to glacial acetic acid in certain applications.

The regulatory landscape also addresses the use of glacial acetic acid in environmental remediation technologies. Many countries have established specific guidelines for soil and groundwater remediation, often requiring the use of environmentally friendly and sustainable technologies. These regulations often mandate thorough site assessments, remediation action plans, and post-treatment monitoring to ensure the effectiveness and safety of the remediation process.

As environmental concerns continue to grow, it is expected that regulations will become more stringent, potentially leading to increased research and development in alternative, less hazardous substances and more efficient remediation technologies. This evolving regulatory framework will likely shape the future direction of glacial acetic acid usage and environmental remediation practices globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!