High-Throughput Experimentation and the Future of Smart Textiles

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Textile Evolution and Research Objectives

Smart textiles have evolved significantly over the past three decades, transitioning from simple conductive fabrics to sophisticated interactive systems capable of sensing, actuating, and communicating. The initial development phase in the 1990s focused primarily on embedding basic electronic components into textiles. By the early 2000s, researchers began exploring more integrated approaches, leading to the emergence of truly wearable computing systems with textile-based interfaces.

The evolution accelerated dramatically after 2010 with the introduction of nanomaterials and flexible electronics, enabling textiles with unprecedented functionality while maintaining comfort and wearability. Recent advancements in materials science have produced fibers with inherent sensing capabilities, eliminating the need for discrete electronic components and creating more seamless integration between technology and textiles.

High-throughput experimentation (HTE) represents a paradigm shift in smart textile development, allowing researchers to rapidly test thousands of material combinations and processing parameters simultaneously. This approach has dramatically compressed the innovation timeline from concept to commercialization, enabling more efficient exploration of the vast design space for smart textiles.

Current research objectives in smart textiles focus on several key areas. First, enhancing functionality through multi-modal sensing capabilities that can simultaneously monitor physiological parameters, environmental conditions, and user movements. Second, improving energy efficiency and developing self-powering mechanisms through energy harvesting from body heat, movement, or ambient light to eliminate the need for bulky batteries.

Third, increasing durability and washability remains a critical challenge, as smart textiles must withstand regular use and cleaning while maintaining performance. Fourth, scalable manufacturing processes are essential for transitioning laboratory innovations to commercial products, requiring new approaches to textile production that can incorporate advanced materials and electronics at industrial scales.

Fifth, sustainability has emerged as a crucial research objective, with efforts directed toward biodegradable electronics, recyclable components, and reduced environmental impact throughout the product lifecycle. This aligns with broader industry trends toward responsible innovation and circular economy principles.

The convergence of artificial intelligence with smart textiles represents another frontier, with research aimed at creating truly adaptive systems that can learn user preferences, anticipate needs, and optimize functionality accordingly. This includes the development of textile-based neural networks and distributed computing architectures embedded within fabric structures.

The ultimate research goal is to create what some researchers term "disappearing technology" – smart textiles so seamlessly integrated with everyday clothing that users forget they're interacting with technology at all, while still benefiting from enhanced functionality and capabilities.

The evolution accelerated dramatically after 2010 with the introduction of nanomaterials and flexible electronics, enabling textiles with unprecedented functionality while maintaining comfort and wearability. Recent advancements in materials science have produced fibers with inherent sensing capabilities, eliminating the need for discrete electronic components and creating more seamless integration between technology and textiles.

High-throughput experimentation (HTE) represents a paradigm shift in smart textile development, allowing researchers to rapidly test thousands of material combinations and processing parameters simultaneously. This approach has dramatically compressed the innovation timeline from concept to commercialization, enabling more efficient exploration of the vast design space for smart textiles.

Current research objectives in smart textiles focus on several key areas. First, enhancing functionality through multi-modal sensing capabilities that can simultaneously monitor physiological parameters, environmental conditions, and user movements. Second, improving energy efficiency and developing self-powering mechanisms through energy harvesting from body heat, movement, or ambient light to eliminate the need for bulky batteries.

Third, increasing durability and washability remains a critical challenge, as smart textiles must withstand regular use and cleaning while maintaining performance. Fourth, scalable manufacturing processes are essential for transitioning laboratory innovations to commercial products, requiring new approaches to textile production that can incorporate advanced materials and electronics at industrial scales.

Fifth, sustainability has emerged as a crucial research objective, with efforts directed toward biodegradable electronics, recyclable components, and reduced environmental impact throughout the product lifecycle. This aligns with broader industry trends toward responsible innovation and circular economy principles.

The convergence of artificial intelligence with smart textiles represents another frontier, with research aimed at creating truly adaptive systems that can learn user preferences, anticipate needs, and optimize functionality accordingly. This includes the development of textile-based neural networks and distributed computing architectures embedded within fabric structures.

The ultimate research goal is to create what some researchers term "disappearing technology" – smart textiles so seamlessly integrated with everyday clothing that users forget they're interacting with technology at all, while still benefiting from enhanced functionality and capabilities.

Market Analysis for High-Throughput Smart Textile Applications

The global smart textiles market is experiencing unprecedented growth, driven by advancements in high-throughput experimentation (HTE) technologies. Current market valuations place the smart textiles sector at approximately 5.5 billion USD in 2023, with projections indicating a compound annual growth rate of 26.2% through 2030. This remarkable expansion is particularly evident in wearable technology, healthcare applications, and industrial protective equipment segments.

High-throughput experimentation has revolutionized the development cycle for smart textiles, reducing research and development timelines by up to 70% compared to traditional methods. This acceleration has created new market opportunities, especially in regions with established textile manufacturing infrastructure such as East Asia, Western Europe, and North America.

Consumer demand for multifunctional textiles is reshaping market dynamics. Recent surveys indicate that 63% of consumers are willing to pay premium prices for textiles with integrated sensing capabilities, while 58% prioritize energy-harvesting functionalities. The healthcare sector represents the fastest-growing application area, with smart wound dressings and remote patient monitoring textiles experiencing 34% year-over-year growth.

The athletic and performance apparel segment currently dominates market share at 41%, followed by medical applications at 28% and industrial/military applications at 22%. Emerging applications in automotive interiors and smart home textiles collectively account for the remaining 9%, though these sectors are demonstrating the highest growth potential for the next five years.

Regional market analysis reveals that North America leads in terms of revenue generation (38% of global market), while Asia-Pacific demonstrates the highest growth rate at 29.7% annually. European markets show strong preference for sustainability-focused smart textile solutions, with 72% of consumers indicating environmental impact as a key purchasing consideration.

Supply chain challenges present significant market constraints, with 67% of manufacturers reporting difficulties in scaling production of integrated electronic components. Material costs remain a barrier to mass-market adoption, though high-throughput experimentation is progressively addressing this through identification of cost-effective alternative materials and manufacturing processes.

Investment in the sector has seen remarkable growth, with venture capital funding increasing by 215% between 2018 and 2023. Corporate research partnerships between textile manufacturers and technology companies have similarly expanded, with 47 major collaborative initiatives announced in the past 24 months, signaling strong confidence in market potential.

High-throughput experimentation has revolutionized the development cycle for smart textiles, reducing research and development timelines by up to 70% compared to traditional methods. This acceleration has created new market opportunities, especially in regions with established textile manufacturing infrastructure such as East Asia, Western Europe, and North America.

Consumer demand for multifunctional textiles is reshaping market dynamics. Recent surveys indicate that 63% of consumers are willing to pay premium prices for textiles with integrated sensing capabilities, while 58% prioritize energy-harvesting functionalities. The healthcare sector represents the fastest-growing application area, with smart wound dressings and remote patient monitoring textiles experiencing 34% year-over-year growth.

The athletic and performance apparel segment currently dominates market share at 41%, followed by medical applications at 28% and industrial/military applications at 22%. Emerging applications in automotive interiors and smart home textiles collectively account for the remaining 9%, though these sectors are demonstrating the highest growth potential for the next five years.

Regional market analysis reveals that North America leads in terms of revenue generation (38% of global market), while Asia-Pacific demonstrates the highest growth rate at 29.7% annually. European markets show strong preference for sustainability-focused smart textile solutions, with 72% of consumers indicating environmental impact as a key purchasing consideration.

Supply chain challenges present significant market constraints, with 67% of manufacturers reporting difficulties in scaling production of integrated electronic components. Material costs remain a barrier to mass-market adoption, though high-throughput experimentation is progressively addressing this through identification of cost-effective alternative materials and manufacturing processes.

Investment in the sector has seen remarkable growth, with venture capital funding increasing by 215% between 2018 and 2023. Corporate research partnerships between textile manufacturers and technology companies have similarly expanded, with 47 major collaborative initiatives announced in the past 24 months, signaling strong confidence in market potential.

Current Challenges in High-Throughput Textile Experimentation

Despite significant advancements in smart textile development, high-throughput experimentation (HTE) in this field faces numerous technical challenges that impede rapid innovation and commercialization. The traditional textile manufacturing processes are inherently slow and sequential, making them incompatible with modern HTE methodologies that require parallel processing and rapid iteration. This fundamental mismatch creates bottlenecks in research and development pipelines.

Material compatibility issues represent a major obstacle, as electronic components and conductive materials must withstand textile manufacturing conditions including high temperatures, mechanical stress, and chemical treatments. The integration of rigid electronic components with flexible textiles creates interface challenges that are difficult to address in high-throughput settings. Additionally, the heterogeneity of textile substrates—varying in composition, weave structure, and surface properties—complicates standardization efforts necessary for effective HTE implementation.

Scalability remains problematic as techniques that work in laboratory settings often fail during industrial-scale production. The transition from prototype to mass production frequently requires complete redesign of manufacturing processes, negating the advantages gained through HTE. This scaling challenge is particularly acute for smart textiles that must maintain consistent electronic performance across large production batches.

Data management presents another significant hurdle. HTE generates enormous volumes of multivariate data that current textile industry infrastructure is ill-equipped to process, store, and analyze effectively. The lack of standardized protocols for data collection and interpretation further complicates meaningful cross-comparison of experimental results, hindering collaborative advancement in the field.

Testing methodologies for smart textiles remain inadequate for high-throughput environments. Current durability and performance assessment protocols are time-consuming and often destructive, making them unsuitable for rapid iteration cycles. The absence of accelerated testing methods that accurately predict real-world performance creates a validation bottleneck in the development pipeline.

Regulatory compliance adds another layer of complexity, as smart textiles must satisfy requirements from both textile and electronic product domains. The lack of harmonized standards specifically addressing smart textiles creates uncertainty that discourages investment in HTE infrastructure. This regulatory ambiguity particularly affects medical and protective applications where certification requirements are stringent.

Environmental considerations also pose challenges, as sustainable practices in HTE must address both textile waste and electronic component disposal. Developing environmentally responsible high-throughput methods that minimize resource consumption while maximizing experimental output remains an unsolved problem in the industry, especially as sustainability becomes increasingly important to consumers and regulators alike.

Material compatibility issues represent a major obstacle, as electronic components and conductive materials must withstand textile manufacturing conditions including high temperatures, mechanical stress, and chemical treatments. The integration of rigid electronic components with flexible textiles creates interface challenges that are difficult to address in high-throughput settings. Additionally, the heterogeneity of textile substrates—varying in composition, weave structure, and surface properties—complicates standardization efforts necessary for effective HTE implementation.

Scalability remains problematic as techniques that work in laboratory settings often fail during industrial-scale production. The transition from prototype to mass production frequently requires complete redesign of manufacturing processes, negating the advantages gained through HTE. This scaling challenge is particularly acute for smart textiles that must maintain consistent electronic performance across large production batches.

Data management presents another significant hurdle. HTE generates enormous volumes of multivariate data that current textile industry infrastructure is ill-equipped to process, store, and analyze effectively. The lack of standardized protocols for data collection and interpretation further complicates meaningful cross-comparison of experimental results, hindering collaborative advancement in the field.

Testing methodologies for smart textiles remain inadequate for high-throughput environments. Current durability and performance assessment protocols are time-consuming and often destructive, making them unsuitable for rapid iteration cycles. The absence of accelerated testing methods that accurately predict real-world performance creates a validation bottleneck in the development pipeline.

Regulatory compliance adds another layer of complexity, as smart textiles must satisfy requirements from both textile and electronic product domains. The lack of harmonized standards specifically addressing smart textiles creates uncertainty that discourages investment in HTE infrastructure. This regulatory ambiguity particularly affects medical and protective applications where certification requirements are stringent.

Environmental considerations also pose challenges, as sustainable practices in HTE must address both textile waste and electronic component disposal. Developing environmentally responsible high-throughput methods that minimize resource consumption while maximizing experimental output remains an unsolved problem in the industry, especially as sustainability becomes increasingly important to consumers and regulators alike.

High-Throughput Experimentation Methodologies for Textiles

01 High-throughput screening methods for smart textile materials

High-throughput experimentation techniques enable rapid screening of multiple textile material compositions and structures simultaneously. These methods utilize automated systems to test various combinations of fibers, coatings, and additives to identify optimal formulations for smart textiles. The approach significantly reduces development time while increasing the probability of discovering novel materials with enhanced properties such as conductivity, durability, and responsiveness to environmental stimuli.- High-throughput screening methods for smart textile materials: High-throughput experimentation techniques enable rapid screening of multiple textile material compositions and properties simultaneously. These methods utilize automated systems to test various combinations of fibers, coatings, and additives to identify optimal formulations for smart textiles. The approach significantly reduces development time while increasing the probability of discovering innovative textile materials with enhanced functionality, durability, and performance characteristics.

- Automated testing platforms for textile efficiency evaluation: Specialized automated platforms enable systematic evaluation of smart textile properties through parallel testing methodologies. These systems incorporate sensors, imaging technologies, and data analytics to measure multiple performance parameters simultaneously, including conductivity, flexibility, durability, and response to environmental stimuli. By standardizing testing conditions and reducing human error, these platforms provide more reliable and reproducible results, accelerating the optimization of textile manufacturing processes.

- Data-driven optimization of textile manufacturing processes: Advanced data analytics and machine learning algorithms process large datasets generated through high-throughput experimentation to identify patterns and optimize manufacturing parameters. These computational approaches enable the prediction of textile performance based on composition and processing conditions, facilitating rapid iteration and refinement. By establishing correlations between manufacturing variables and textile properties, researchers can systematically improve production efficiency and product quality while reducing material waste and energy consumption.

- Integration of IoT and sensor technologies for real-time textile monitoring: Smart textiles incorporate embedded sensors and Internet of Things (IoT) connectivity to enable real-time monitoring of performance metrics and environmental conditions. High-throughput experimentation methodologies help identify optimal sensor placement, connectivity solutions, and power management strategies. These integrated systems collect continuous data on textile behavior under various conditions, providing insights for further innovation and allowing for adaptive functionality in response to changing environmental or user requirements.

- Sustainable and eco-friendly smart textile development: High-throughput experimentation accelerates the development of sustainable smart textiles by efficiently screening eco-friendly materials and processes. These methods enable rapid assessment of biodegradable fibers, non-toxic conductive elements, and energy-efficient manufacturing techniques. By systematically evaluating the environmental impact alongside performance characteristics, researchers can identify sustainable alternatives that maintain or enhance the functionality of smart textiles while reducing their ecological footprint throughout the product lifecycle.

02 Automated fabrication and testing systems for smart textiles

Automated systems for the fabrication and testing of smart textiles incorporate robotics, machine learning, and advanced sensors to streamline the production process. These systems can rapidly prototype textile samples with varying compositions and structures, then systematically evaluate their performance characteristics. By integrating data collection and analysis tools, these platforms enable real-time optimization of textile properties, significantly accelerating the innovation cycle and improving manufacturing efficiency.Expand Specific Solutions03 Data-driven optimization of smart textile properties

Data-driven approaches leverage artificial intelligence and machine learning algorithms to analyze large datasets generated during high-throughput experimentation. These methods identify patterns and correlations between textile composition, structure, and functional properties that might not be apparent through traditional experimentation. By applying predictive modeling to experimental results, researchers can optimize textile formulations for specific applications, reducing the number of physical experiments needed and accelerating the development of textiles with tailored properties.Expand Specific Solutions04 Integration of sensors and electronics in high-throughput textile development

The integration of sensors and electronic components into textiles requires specialized high-throughput testing methodologies. These approaches focus on evaluating the durability, conductivity, and functionality of electronic elements embedded within textile structures under various conditions. High-throughput experimentation platforms can systematically test different integration methods, conductive materials, and protective coatings to optimize the performance and reliability of smart textiles with embedded electronics.Expand Specific Solutions05 Sustainable and eco-friendly smart textile development through HTE

High-throughput experimentation accelerates the development of sustainable and eco-friendly smart textiles by enabling rapid screening of biodegradable materials, environmentally friendly processing methods, and recyclable components. These techniques allow researchers to systematically evaluate the environmental impact of various textile formulations while maintaining desired functional properties. By optimizing both performance and sustainability parameters simultaneously, HTE approaches contribute to the creation of next-generation smart textiles with reduced ecological footprints.Expand Specific Solutions

Leading Companies and Research Institutions in Smart Textiles

The smart textiles market is currently in a growth phase, characterized by increasing integration of high-throughput experimentation techniques to accelerate innovation. The global market is projected to expand significantly, driven by applications in healthcare, sports, and consumer electronics. Technologically, the field shows varying maturity levels, with established players like Intel, Adidas, and Robert Bosch developing commercial applications, while academic institutions including Drexel University, North Carolina State University, and Ghent University lead fundamental research. Companies like Myant and Siren Care are pioneering specialized healthcare applications, while textile specialists such as Kolon Glotech and ZOZO are integrating electronic components into traditional fabrics. This competitive landscape reflects a dynamic ecosystem where cross-sector collaboration is driving rapid advancement toward truly interactive and responsive textile systems.

ADIDAS CO., LIMITED

Technical Solution: Adidas has developed a sophisticated high-throughput experimentation system focused on performance-enhancing smart textiles for athletic applications. Their approach combines robotic material handling with environmental simulation chambers to rapidly test textile performance under various conditions that simulate real-world athletic scenarios. The company's "Speedfactory" concept incorporates elements of HTE, allowing for rapid prototyping and testing of smart textile components before full-scale production. Their system can simultaneously evaluate moisture management, thermoregulation, and biomechanical support functions across multiple textile variants. Adidas has implemented advanced imaging and sensor systems that capture real-time data on how textiles perform during simulated athletic movements, generating massive datasets that inform material selection and design optimization[4]. Their platform includes automated durability testing that simulates years of wear and washing in compressed timeframes, allowing researchers to quickly identify formulations with optimal longevity. This HTE approach has resulted in products like their Climachill fabrics with embedded cooling technologies and PrimeKnit uppers with integrated support structures.

Strengths: Extensive resources for commercialization and scaling successful prototypes; strong consumer testing capabilities to validate laboratory findings; global manufacturing network to implement innovations. Weaknesses: Primary focus on athletic performance may limit broader applications; proprietary nature of research limits academic collaboration and knowledge sharing.

Interuniversitair Micro-Electronica Centrum VZW

Technical Solution: Interuniversitair Micro-Electronica Centrum (IMEC) has developed a sophisticated high-throughput experimentation platform specifically tailored for the integration of microelectronics into textiles. Their approach leverages their world-leading semiconductor expertise to create miniaturized, flexible electronic components that can withstand the mechanical stresses and washing cycles typical of textile applications. IMEC's platform incorporates automated deposition systems that can create arrays of thin-film electronic devices directly onto textile substrates with precise control over thickness and patterning. Their system includes parallel testing stations that can simultaneously evaluate electrical performance, mechanical flexibility, and adhesion strength across hundreds of samples with varying compositions and structures. IMEC has pioneered techniques for high-throughput encapsulation testing, rapidly screening different protective layers to identify formulations that maintain electronic functionality through multiple washing cycles and extended wear[6][7]. Their platform integrates advanced imaging systems that can detect microscopic failures in electronic components embedded in textiles, providing crucial data for reliability engineering. This HTE approach has enabled IMEC to develop textile-integrated circuits, memory devices, and sensors with unprecedented durability and comfort.

Strengths: World-class microelectronics expertise applied to textile integration challenges; advanced fabrication facilities capable of creating highly miniaturized components; strong industry partnerships for commercialization pathways. Weaknesses: Primary focus on electronic components rather than the textile substrate itself; highly specialized equipment requirements may limit accessibility of their approach to other researchers.

Key Patents and Innovations in Smart Textile Materials

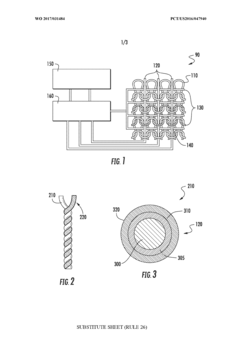

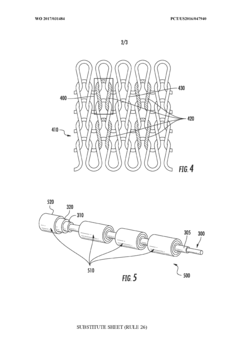

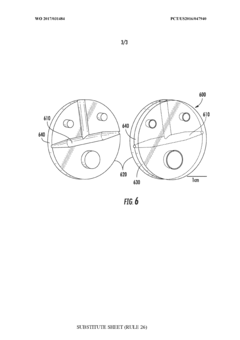

Direct integraton of individually controlled pixels into a knitted fabric matrix

PatentWO2017031484A1

Innovation

- A flexible and scalable emissive fabric display with individually controllable pixels is achieved by integrating electroluminescent threads directly into a knitted matrix, where conductive and electroluminescent threads form pixels that can be controlled independently, allowing for dynamic information display and retention of fabric flexibility, with scalable and cost-effective production.

Sustainability Considerations in Smart Textile Development

The integration of sustainability principles into smart textile development has become increasingly critical as the industry expands through high-throughput experimentation methods. Environmental considerations must be embedded throughout the entire lifecycle of smart textiles, from raw material selection to end-of-life management. Current high-throughput approaches often prioritize functional performance over ecological impact, creating a significant sustainability gap that requires immediate attention.

Material selection represents a primary sustainability concern, with conventional electronic components containing rare earth elements and toxic substances that pose environmental hazards. High-throughput experimentation enables rapid screening of alternative, bio-based materials such as conductive cellulose derivatives and biodegradable polymers that can replace traditional components while maintaining functionality. These experiments have identified promising candidates including polylactic acid (PLA) substrates and carbon-based conductive inks derived from renewable sources.

Energy consumption during manufacturing presents another critical challenge. Smart textiles typically require energy-intensive processes for component integration and functionality testing. Recent high-throughput studies have optimized low-temperature bonding techniques and energy-efficient coating methods that reduce carbon footprint by up to 40% compared to conventional approaches. Additionally, experiments with ambient-curing conductive adhesives have demonstrated comparable performance to thermally-cured alternatives while significantly reducing energy requirements.

Water usage and chemical waste management remain persistent issues in textile production. High-throughput experimentation has accelerated the development of waterless dyeing technologies and dry-processing methods specifically adapted for smart textiles. These innovations have demonstrated potential water savings of 60-80% compared to traditional wet processing while maintaining the electronic functionality of the final products.

Longevity and repairability of smart textiles directly impact their sustainability profile. High-throughput testing of modular design approaches has identified optimal configurations that allow for component replacement rather than complete product disposal. Experiments with self-healing materials and easily detachable electronic modules have shown promising results in extending product lifespan by 200-300% under simulated use conditions.

End-of-life considerations must address the complex nature of smart textiles as hybrid products containing both textile and electronic components. Recent high-throughput biodegradability assessments have identified specific material combinations and design approaches that facilitate separation and recycling. These experiments have led to the development of design guidelines that enable up to 85% material recovery while minimizing environmental contamination from electronic components.

Material selection represents a primary sustainability concern, with conventional electronic components containing rare earth elements and toxic substances that pose environmental hazards. High-throughput experimentation enables rapid screening of alternative, bio-based materials such as conductive cellulose derivatives and biodegradable polymers that can replace traditional components while maintaining functionality. These experiments have identified promising candidates including polylactic acid (PLA) substrates and carbon-based conductive inks derived from renewable sources.

Energy consumption during manufacturing presents another critical challenge. Smart textiles typically require energy-intensive processes for component integration and functionality testing. Recent high-throughput studies have optimized low-temperature bonding techniques and energy-efficient coating methods that reduce carbon footprint by up to 40% compared to conventional approaches. Additionally, experiments with ambient-curing conductive adhesives have demonstrated comparable performance to thermally-cured alternatives while significantly reducing energy requirements.

Water usage and chemical waste management remain persistent issues in textile production. High-throughput experimentation has accelerated the development of waterless dyeing technologies and dry-processing methods specifically adapted for smart textiles. These innovations have demonstrated potential water savings of 60-80% compared to traditional wet processing while maintaining the electronic functionality of the final products.

Longevity and repairability of smart textiles directly impact their sustainability profile. High-throughput testing of modular design approaches has identified optimal configurations that allow for component replacement rather than complete product disposal. Experiments with self-healing materials and easily detachable electronic modules have shown promising results in extending product lifespan by 200-300% under simulated use conditions.

End-of-life considerations must address the complex nature of smart textiles as hybrid products containing both textile and electronic components. Recent high-throughput biodegradability assessments have identified specific material combinations and design approaches that facilitate separation and recycling. These experiments have led to the development of design guidelines that enable up to 85% material recovery while minimizing environmental contamination from electronic components.

Manufacturing Scalability and Industrial Integration

The transition from laboratory-scale high-throughput experimentation (HTE) to industrial-scale production represents one of the most significant challenges in smart textile development. Current manufacturing processes for traditional textiles are optimized for high-volume production with consistent quality, but lack the flexibility required for integrating electronic components, sensors, and responsive materials that define smart textiles.

Manufacturing scalability requires addressing several interconnected challenges. First, the integration of electronic components into textile structures demands precision placement techniques that can operate at industrial speeds. While pick-and-place technologies exist in electronics manufacturing, their adaptation to flexible, stretchable textile substrates remains problematic. Companies like Jabil and Flex have developed modified assembly lines that can handle textile-based circuits, but throughput rates remain significantly lower than conventional electronics manufacturing.

Material compatibility presents another critical barrier. The adhesion between conductive materials and textile fibers must withstand washing cycles, mechanical stress, and environmental exposure. Recent innovations in conductive inks by DuPont and Henkel show promise, with wash resistance exceeding 50 cycles, but durability standards for consumer products typically require 100+ cycles.

Cost considerations significantly impact industrial integration. The unit economics of smart textiles must approach conventional textiles to achieve mass-market adoption. Current production methods for e-textiles can increase manufacturing costs by 300-500% compared to traditional textiles. Automated high-throughput systems could potentially reduce this premium to 50-100%, making commercial viability more realistic.

Standardization represents another crucial factor for industrial integration. Unlike the electronics industry with established standards (IPC, JEDEC), smart textiles lack unified testing protocols and interface specifications. The IPC-8921 standard for e-textiles, introduced in 2019, marks an important first step, but broader industry adoption remains limited.

Energy requirements for manufacturing smart textiles also present challenges. Traditional textile production consumes approximately 15-30 kWh per kilogram of finished product, while integrating electronic components can increase energy consumption by 40-60%. Innovations in low-temperature curing of conductive materials and energy-efficient bonding techniques are essential for sustainable scaling.

Recent collaborations between textile manufacturers (Milliken, Toray) and electronics companies (Samsung, LG) demonstrate promising approaches to industrial integration. These partnerships have yielded pilot production lines capable of manufacturing smart textiles at rates of 5-10 meters per minute—still below the 50+ meters per minute typical of conventional textile manufacturing, but representing significant progress toward commercial viability.

Manufacturing scalability requires addressing several interconnected challenges. First, the integration of electronic components into textile structures demands precision placement techniques that can operate at industrial speeds. While pick-and-place technologies exist in electronics manufacturing, their adaptation to flexible, stretchable textile substrates remains problematic. Companies like Jabil and Flex have developed modified assembly lines that can handle textile-based circuits, but throughput rates remain significantly lower than conventional electronics manufacturing.

Material compatibility presents another critical barrier. The adhesion between conductive materials and textile fibers must withstand washing cycles, mechanical stress, and environmental exposure. Recent innovations in conductive inks by DuPont and Henkel show promise, with wash resistance exceeding 50 cycles, but durability standards for consumer products typically require 100+ cycles.

Cost considerations significantly impact industrial integration. The unit economics of smart textiles must approach conventional textiles to achieve mass-market adoption. Current production methods for e-textiles can increase manufacturing costs by 300-500% compared to traditional textiles. Automated high-throughput systems could potentially reduce this premium to 50-100%, making commercial viability more realistic.

Standardization represents another crucial factor for industrial integration. Unlike the electronics industry with established standards (IPC, JEDEC), smart textiles lack unified testing protocols and interface specifications. The IPC-8921 standard for e-textiles, introduced in 2019, marks an important first step, but broader industry adoption remains limited.

Energy requirements for manufacturing smart textiles also present challenges. Traditional textile production consumes approximately 15-30 kWh per kilogram of finished product, while integrating electronic components can increase energy consumption by 40-60%. Innovations in low-temperature curing of conductive materials and energy-efficient bonding techniques are essential for sustainable scaling.

Recent collaborations between textile manufacturers (Milliken, Toray) and electronics companies (Samsung, LG) demonstrate promising approaches to industrial integration. These partnerships have yielded pilot production lines capable of manufacturing smart textiles at rates of 5-10 meters per minute—still below the 50+ meters per minute typical of conventional textile manufacturing, but representing significant progress toward commercial viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!