High-Throughput Experimentation in Ceramic Surface Fabrication

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Surface HTE Background and Objectives

High-throughput experimentation (HTE) represents a paradigm shift in materials science research, enabling rapid synthesis and characterization of multiple samples simultaneously. In the context of ceramic surface fabrication, this approach has evolved from traditional trial-and-error methods to systematic exploration of vast compositional and processing parameter spaces. The historical trajectory began in the pharmaceutical industry during the 1990s, with materials science adoption following in the early 2000s. For ceramic surfaces specifically, HTE methodologies have gained significant traction over the past decade as computational capabilities and automation technologies have matured.

The fundamental objective of implementing HTE in ceramic surface fabrication is to accelerate innovation cycles while reducing resource expenditure. Traditional ceramic development processes typically require months or years of iterative experimentation, whereas HTE approaches can potentially compress this timeline to weeks or days. This acceleration is particularly crucial for addressing emerging market demands for specialized ceramic surfaces with tailored properties such as enhanced durability, thermal resistance, biocompatibility, or aesthetic qualities.

Current technological objectives focus on establishing robust methodologies for parallel synthesis, high-speed characterization, and data-driven analysis of ceramic surface compositions and structures. This includes developing automated deposition systems capable of creating compositional gradients or discrete libraries of ceramic formulations, coupled with rapid characterization techniques that can evaluate multiple performance metrics simultaneously. The integration of machine learning algorithms represents a critical objective to extract meaningful patterns from the extensive datasets generated through HTE campaigns.

Beyond technical goals, the implementation of HTE in ceramic surface fabrication aims to democratize advanced materials development, enabling smaller enterprises to compete with larger corporations by reducing capital investment requirements for innovation. Additionally, environmental sustainability objectives are increasingly prominent, with HTE offering pathways to minimize material waste and energy consumption during the research and development phase.

The convergence of computational materials science, robotics, and data analytics has created unprecedented opportunities for ceramic surface innovation through HTE. As we examine the current landscape, the primary goal remains establishing standardized protocols and platforms that can reliably translate laboratory-scale HTE discoveries into industrially viable manufacturing processes, thereby bridging the persistent gap between academic research and commercial implementation in the ceramic industry.

The fundamental objective of implementing HTE in ceramic surface fabrication is to accelerate innovation cycles while reducing resource expenditure. Traditional ceramic development processes typically require months or years of iterative experimentation, whereas HTE approaches can potentially compress this timeline to weeks or days. This acceleration is particularly crucial for addressing emerging market demands for specialized ceramic surfaces with tailored properties such as enhanced durability, thermal resistance, biocompatibility, or aesthetic qualities.

Current technological objectives focus on establishing robust methodologies for parallel synthesis, high-speed characterization, and data-driven analysis of ceramic surface compositions and structures. This includes developing automated deposition systems capable of creating compositional gradients or discrete libraries of ceramic formulations, coupled with rapid characterization techniques that can evaluate multiple performance metrics simultaneously. The integration of machine learning algorithms represents a critical objective to extract meaningful patterns from the extensive datasets generated through HTE campaigns.

Beyond technical goals, the implementation of HTE in ceramic surface fabrication aims to democratize advanced materials development, enabling smaller enterprises to compete with larger corporations by reducing capital investment requirements for innovation. Additionally, environmental sustainability objectives are increasingly prominent, with HTE offering pathways to minimize material waste and energy consumption during the research and development phase.

The convergence of computational materials science, robotics, and data analytics has created unprecedented opportunities for ceramic surface innovation through HTE. As we examine the current landscape, the primary goal remains establishing standardized protocols and platforms that can reliably translate laboratory-scale HTE discoveries into industrially viable manufacturing processes, thereby bridging the persistent gap between academic research and commercial implementation in the ceramic industry.

Market Analysis for Advanced Ceramic Surfaces

The global market for advanced ceramic surfaces is experiencing robust growth, driven by increasing demand across multiple industries including electronics, automotive, healthcare, and construction. Currently valued at approximately 9.2 billion USD, this market is projected to reach 14.7 billion USD by 2028, representing a compound annual growth rate (CAGR) of 6.8%. This growth trajectory is particularly pronounced in regions with strong manufacturing bases such as East Asia, North America, and Western Europe.

The electronics sector constitutes the largest market segment, accounting for nearly 38% of the total market share. This dominance is attributed to the critical role of ceramic surfaces in semiconductor manufacturing, electronic packaging, and display technologies. The automotive industry follows as the second-largest consumer, utilizing advanced ceramic surfaces for components requiring high wear resistance, thermal stability, and reduced friction.

Healthcare applications represent the fastest-growing segment with a CAGR of 8.3%, driven by the biocompatibility of certain ceramic formulations and their increasing use in medical implants, diagnostic equipment, and antimicrobial surfaces. The COVID-19 pandemic has further accelerated demand for ceramic surfaces with antimicrobial properties in healthcare settings.

Consumer demand patterns indicate a growing preference for multifunctional ceramic surfaces that combine aesthetic appeal with technical performance characteristics such as self-cleaning properties, scratch resistance, and enhanced durability. This trend is particularly evident in high-end consumer electronics and premium automotive interiors.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, led by China, Japan, and South Korea. These countries have established robust manufacturing ecosystems for electronics and automotive components. North America and Europe collectively account for approximately 48% of the market, with significant research and development activities focused on innovative ceramic surface technologies.

The market is characterized by increasing competition between established materials science corporations and emerging specialized ceramic technology firms. Price sensitivity varies significantly by application, with high-performance electronics and medical applications demonstrating lower price elasticity compared to construction and general industrial applications.

Future market growth is expected to be driven by technological advancements in high-throughput experimentation methods that enable rapid development and customization of ceramic surfaces with tailored properties. Additionally, sustainability considerations are becoming increasingly important, with growing demand for ceramic surfaces produced through energy-efficient processes and utilizing environmentally friendly raw materials.

The electronics sector constitutes the largest market segment, accounting for nearly 38% of the total market share. This dominance is attributed to the critical role of ceramic surfaces in semiconductor manufacturing, electronic packaging, and display technologies. The automotive industry follows as the second-largest consumer, utilizing advanced ceramic surfaces for components requiring high wear resistance, thermal stability, and reduced friction.

Healthcare applications represent the fastest-growing segment with a CAGR of 8.3%, driven by the biocompatibility of certain ceramic formulations and their increasing use in medical implants, diagnostic equipment, and antimicrobial surfaces. The COVID-19 pandemic has further accelerated demand for ceramic surfaces with antimicrobial properties in healthcare settings.

Consumer demand patterns indicate a growing preference for multifunctional ceramic surfaces that combine aesthetic appeal with technical performance characteristics such as self-cleaning properties, scratch resistance, and enhanced durability. This trend is particularly evident in high-end consumer electronics and premium automotive interiors.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, led by China, Japan, and South Korea. These countries have established robust manufacturing ecosystems for electronics and automotive components. North America and Europe collectively account for approximately 48% of the market, with significant research and development activities focused on innovative ceramic surface technologies.

The market is characterized by increasing competition between established materials science corporations and emerging specialized ceramic technology firms. Price sensitivity varies significantly by application, with high-performance electronics and medical applications demonstrating lower price elasticity compared to construction and general industrial applications.

Future market growth is expected to be driven by technological advancements in high-throughput experimentation methods that enable rapid development and customization of ceramic surfaces with tailored properties. Additionally, sustainability considerations are becoming increasingly important, with growing demand for ceramic surfaces produced through energy-efficient processes and utilizing environmentally friendly raw materials.

Current HTE Challenges in Ceramic Fabrication

Despite the significant advancements in High-Throughput Experimentation (HTE) for ceramic surface fabrication, several critical challenges continue to impede its widespread implementation and effectiveness. One of the primary obstacles is the inherent complexity of ceramic materials systems, which often involve multiple components, phases, and processing parameters that interact in non-linear ways. This complexity makes it difficult to design comprehensive experimental matrices that can adequately capture all relevant variables and their interactions.

Sample preparation represents another significant bottleneck in ceramic HTE workflows. Unlike metals or polymers, ceramics typically require high-temperature processing and precise control of sintering conditions, which are difficult to parallelize while maintaining consistency across multiple samples. The miniaturization of ceramic processing techniques, essential for true high-throughput capabilities, often leads to properties that do not accurately reflect those of conventionally processed materials.

Data acquisition and analysis present formidable challenges as well. Ceramic surface properties often require multiple characterization techniques to fully evaluate performance, including mechanical testing, chemical resistance assessment, and microstructural analysis. These diverse measurements generate heterogeneous datasets that are difficult to integrate and analyze holistically. Furthermore, many characterization techniques for ceramics remain time-intensive and resistant to automation, creating bottlenecks that undermine the high-throughput approach.

The lack of standardized protocols specifically designed for ceramic HTE constitutes another significant hurdle. While HTE methodologies have been well-established in pharmaceutical and catalysis research, their adaptation to ceramic materials science has been piecemeal and inconsistent. This has resulted in difficulties comparing results across different research groups and translating findings from laboratory-scale HTE to industrial production.

Computational challenges further complicate ceramic HTE implementation. Current machine learning and artificial intelligence tools, while powerful, often struggle with the complex phase relationships and processing-structure-property correlations inherent to ceramic systems. The relative scarcity of comprehensive materials databases for ceramics, compared to metals or organic compounds, limits the effectiveness of data-driven approaches.

Equipment limitations also pose significant constraints. Specialized HTE equipment for ceramic processing remains expensive and often requires customization for specific applications. Many research institutions and smaller companies lack access to these sophisticated tools, creating disparities in research capabilities and slowing overall progress in the field.

Finally, bridging the gap between HTE findings and industrial implementation remains problematic. Scaling up promising formulations or processes identified through HTE to commercial production volumes often encounters unforeseen challenges, as the behavior of ceramic materials can change significantly with processing scale.

Sample preparation represents another significant bottleneck in ceramic HTE workflows. Unlike metals or polymers, ceramics typically require high-temperature processing and precise control of sintering conditions, which are difficult to parallelize while maintaining consistency across multiple samples. The miniaturization of ceramic processing techniques, essential for true high-throughput capabilities, often leads to properties that do not accurately reflect those of conventionally processed materials.

Data acquisition and analysis present formidable challenges as well. Ceramic surface properties often require multiple characterization techniques to fully evaluate performance, including mechanical testing, chemical resistance assessment, and microstructural analysis. These diverse measurements generate heterogeneous datasets that are difficult to integrate and analyze holistically. Furthermore, many characterization techniques for ceramics remain time-intensive and resistant to automation, creating bottlenecks that undermine the high-throughput approach.

The lack of standardized protocols specifically designed for ceramic HTE constitutes another significant hurdle. While HTE methodologies have been well-established in pharmaceutical and catalysis research, their adaptation to ceramic materials science has been piecemeal and inconsistent. This has resulted in difficulties comparing results across different research groups and translating findings from laboratory-scale HTE to industrial production.

Computational challenges further complicate ceramic HTE implementation. Current machine learning and artificial intelligence tools, while powerful, often struggle with the complex phase relationships and processing-structure-property correlations inherent to ceramic systems. The relative scarcity of comprehensive materials databases for ceramics, compared to metals or organic compounds, limits the effectiveness of data-driven approaches.

Equipment limitations also pose significant constraints. Specialized HTE equipment for ceramic processing remains expensive and often requires customization for specific applications. Many research institutions and smaller companies lack access to these sophisticated tools, creating disparities in research capabilities and slowing overall progress in the field.

Finally, bridging the gap between HTE findings and industrial implementation remains problematic. Scaling up promising formulations or processes identified through HTE to commercial production volumes often encounters unforeseen challenges, as the behavior of ceramic materials can change significantly with processing scale.

Current HTE Methodologies for Ceramic Surfaces

01 Automated laboratory systems for high-throughput experimentation

Automated laboratory systems are designed to increase experimental throughput by integrating robotics, liquid handling systems, and data management tools. These systems can perform multiple experiments simultaneously, reducing manual intervention and increasing efficiency. They often include features like automated sample preparation, reagent dispensing, and result analysis, enabling researchers to conduct a larger number of experiments in less time.- Automated laboratory systems for high-throughput experimentation: Automated laboratory systems can significantly increase experimental throughput by integrating robotics, liquid handling systems, and computerized control. These systems enable parallel processing of multiple samples simultaneously, reducing manual intervention and increasing efficiency. Advanced automation platforms can operate continuously, performing standardized protocols with precision and consistency across large sample sets.

- Data processing and analysis methods for high-throughput experiments: Specialized software and algorithms are essential for processing the large volumes of data generated by high-throughput experiments. These computational methods enable rapid analysis, pattern recognition, and extraction of meaningful insights from experimental results. Advanced data processing techniques include machine learning algorithms, statistical analysis tools, and visualization methods that help researchers interpret complex datasets efficiently.

- Parallel processing architectures for increased experimental throughput: Parallel processing architectures allow multiple experiments to be conducted simultaneously rather than sequentially. These systems distribute computational and experimental workloads across multiple processing units or experimental stations, significantly reducing the time required to complete large experimental sets. Parallel architectures can be implemented in both hardware configurations and software algorithms to maximize throughput.

- Miniaturization technologies for high-throughput screening: Miniaturization technologies enable the reduction of sample volumes and experimental footprints, allowing more experiments to be conducted in the same physical space. Microfluidic devices, microwell plates, and lab-on-a-chip technologies facilitate the handling of nanoliter to microliter volumes, reducing reagent consumption while increasing experimental density. These approaches are particularly valuable in pharmaceutical screening and materials discovery applications.

- Network-based systems for collaborative high-throughput research: Networked systems enable distributed high-throughput experimentation across multiple locations or laboratories. These platforms facilitate real-time data sharing, remote monitoring of experiments, and collaborative analysis of results. Cloud-based infrastructure and standardized communication protocols allow seamless integration of experimental equipment and computational resources, enabling research teams to coordinate complex experimental workflows across geographical boundaries.

02 Parallel processing techniques for data analysis

Parallel processing techniques enable the simultaneous analysis of multiple experimental datasets, significantly increasing throughput in high-throughput experimentation. These techniques distribute computational tasks across multiple processors or computing nodes, allowing for faster data processing and analysis. By implementing parallel algorithms and distributed computing frameworks, researchers can efficiently handle the large volumes of data generated in high-throughput experiments.Expand Specific Solutions03 Microfluidic platforms for accelerated experimentation

Microfluidic platforms enable the miniaturization of experimental setups, allowing for the simultaneous execution of multiple experiments on a single chip. These platforms reduce reagent consumption, decrease experimental time, and increase throughput by facilitating parallel processing of samples. Advanced microfluidic systems incorporate features like integrated sensors, automated flow control, and multiplexed analysis capabilities to further enhance experimental efficiency.Expand Specific Solutions04 Machine learning and AI for experimental optimization

Machine learning and artificial intelligence techniques are increasingly used to optimize high-throughput experimentation workflows. These approaches can predict experimental outcomes, identify optimal experimental conditions, and suggest the most promising experiments to conduct next. By reducing the number of experiments needed to achieve desired results, AI-driven optimization significantly increases effective throughput and accelerates the discovery process.Expand Specific Solutions05 Integrated data management systems for high-throughput workflows

Integrated data management systems are essential for handling the large volumes of data generated in high-throughput experimentation. These systems provide tools for data capture, storage, analysis, and visualization, enabling researchers to efficiently process experimental results. Advanced data management platforms incorporate features like automated data validation, standardized metadata annotation, and seamless integration with laboratory instruments to streamline workflows and increase overall throughput.Expand Specific Solutions

Leading Companies in Ceramic HTE Industry

High-Throughput Experimentation (HTE) in ceramic surface fabrication is currently in a growth phase, with the market expanding due to increasing demand for advanced ceramic materials across industries. The global market is estimated to reach significant value as manufacturers seek more efficient production methods. Technologically, the field is advancing rapidly but remains in mid-maturity, with established players like Corning and SCHOTT AG leading innovation through extensive R&D investments. These companies, along with UBE Corp. and BASF, are developing automated systems for parallel testing of multiple ceramic compositions. Academic-industrial partnerships are emerging, with institutions like Fraunhofer-Gesellschaft and Northwestern Polytechnical University collaborating with companies such as 3M and Samsung Electro-Mechanics to accelerate material discovery and process optimization through AI-enhanced experimentation platforms.

Corning, Inc.

Technical Solution: Corning has developed a high-throughput experimentation (HTE) platform specifically for ceramic surface fabrication that combines automated material synthesis, characterization, and data analytics. Their approach utilizes robotic systems capable of preparing hundreds of unique ceramic compositions daily with precise control over chemical gradients and processing parameters. The system incorporates in-line characterization tools including X-ray diffraction, spectroscopic techniques, and mechanical testing that provide immediate feedback on material properties. Corning's proprietary machine learning algorithms analyze the resulting data to identify promising ceramic surface compositions and processing conditions, significantly accelerating the traditional development cycle. This integrated approach has enabled Corning to develop specialized glass-ceramic surfaces with tailored properties for applications ranging from consumer electronics to architectural materials, reducing development time from years to months.

Strengths: Industry-leading automation capabilities and proprietary data analytics provide exceptional throughput; vertical integration allows seamless transition from research to manufacturing. Weaknesses: High capital investment requirements; system optimization primarily focused on Corning's specific material systems rather than general-purpose applications.

SCHOTT AG

Technical Solution: SCHOTT AG has implemented a comprehensive high-throughput experimentation system for ceramic surface development that combines parallel processing techniques with advanced characterization methods. Their approach utilizes multi-chamber deposition systems capable of creating compositional libraries with up to 100 distinct ceramic formulations per substrate. These libraries undergo automated thermal processing in specially designed gradient furnaces that can simultaneously expose samples to different temperature profiles. SCHOTT's system incorporates high-resolution imaging, spectroscopic mapping, and nano-indentation arrays to rapidly characterize surface properties across thousands of compositional variants. Their proprietary software platform integrates experimental data with theoretical models to guide formulation optimization. This methodology has been particularly successful in developing specialized glass-ceramic surfaces for technical applications, including CERAN® cooktop panels and pharmaceutical packaging with enhanced chemical durability.

Strengths: Exceptional precision in compositional control; sophisticated characterization capabilities for surface properties; proven track record of commercial implementation. Weaknesses: System requires significant expertise to operate effectively; optimization primarily focused on specialized glass-ceramic applications rather than broader ceramic categories.

Key Patents in Ceramic Surface HTE Technology

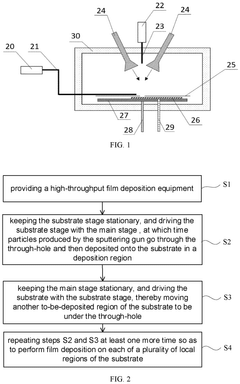

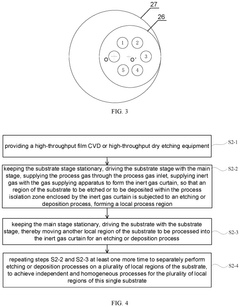

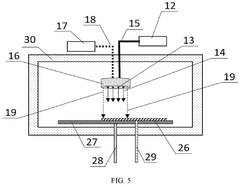

High-throughput thin film deposition apparatus, etching apparatus and etching method

PatentInactiveEP4484606A1

Innovation

- The development of high-throughput film deposition equipment featuring a reaction chamber, stage control apparatus, and process isolation apparatus, which includes a mask plate or inert gas curtain to isolate processes within a local region of the substrate, allowing for independent and uniform processing of multiple regions, enabling the equipment to achieve uniform film deposition and etching.

Materials Characterization Techniques for HTE

Materials characterization represents a critical component in high-throughput experimentation (HTE) for ceramic surface fabrication. Advanced characterization techniques enable researchers to rapidly analyze multiple samples with precision and efficiency, accelerating the discovery and optimization of novel ceramic materials and surface properties. X-ray diffraction (XRD) stands as a cornerstone technique, allowing for rapid phase identification and crystallographic analysis across sample libraries. Modern HTE-adapted XRD systems incorporate automated sample handling and parallel detection capabilities, enabling hundreds of measurements per day with minimal human intervention.

Spectroscopic methods, particularly X-ray photoelectron spectroscopy (XPS) and Raman spectroscopy, provide essential information about surface chemistry and bonding states in ceramic materials. These techniques have been successfully adapted for high-throughput workflows through the implementation of automated mapping functions and rapid data acquisition protocols. For instance, confocal Raman systems can now perform compositional mapping of ceramic surface libraries at speeds previously unattainable, reducing characterization bottlenecks.

Microscopy techniques have undergone significant evolution to meet HTE requirements. Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) delivers morphological and elemental composition data across gradient libraries of ceramic surfaces. Automated stage control and image analysis algorithms enable systematic characterization of large sample arrays, with machine learning approaches increasingly employed to identify patterns and anomalies across extensive datasets.

Mechanical and tribological property assessment has also been adapted for high-throughput workflows. Nanoindentation arrays can rapidly map hardness and elastic modulus variations across ceramic surface libraries, while automated scratch testing provides insights into adhesion and wear resistance. These techniques are particularly valuable for ceramic coatings where performance metrics must be evaluated across compositional gradients.

Thermal analysis methods, including differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), have been miniaturized and parallelized to accommodate HTE requirements. These adaptations allow researchers to efficiently investigate phase transitions, thermal stability, and decomposition behaviors across multiple ceramic compositions simultaneously, significantly accelerating materials optimization cycles.

The integration of these characterization techniques with advanced data management systems represents a crucial development in HTE for ceramics. Automated data processing pipelines, incorporating machine learning algorithms for feature extraction and pattern recognition, enable researchers to rapidly identify promising candidates from vast experimental spaces. This integration transforms raw characterization data into actionable insights, driving accelerated discovery cycles in ceramic surface engineering.

Spectroscopic methods, particularly X-ray photoelectron spectroscopy (XPS) and Raman spectroscopy, provide essential information about surface chemistry and bonding states in ceramic materials. These techniques have been successfully adapted for high-throughput workflows through the implementation of automated mapping functions and rapid data acquisition protocols. For instance, confocal Raman systems can now perform compositional mapping of ceramic surface libraries at speeds previously unattainable, reducing characterization bottlenecks.

Microscopy techniques have undergone significant evolution to meet HTE requirements. Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) delivers morphological and elemental composition data across gradient libraries of ceramic surfaces. Automated stage control and image analysis algorithms enable systematic characterization of large sample arrays, with machine learning approaches increasingly employed to identify patterns and anomalies across extensive datasets.

Mechanical and tribological property assessment has also been adapted for high-throughput workflows. Nanoindentation arrays can rapidly map hardness and elastic modulus variations across ceramic surface libraries, while automated scratch testing provides insights into adhesion and wear resistance. These techniques are particularly valuable for ceramic coatings where performance metrics must be evaluated across compositional gradients.

Thermal analysis methods, including differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), have been miniaturized and parallelized to accommodate HTE requirements. These adaptations allow researchers to efficiently investigate phase transitions, thermal stability, and decomposition behaviors across multiple ceramic compositions simultaneously, significantly accelerating materials optimization cycles.

The integration of these characterization techniques with advanced data management systems represents a crucial development in HTE for ceramics. Automated data processing pipelines, incorporating machine learning algorithms for feature extraction and pattern recognition, enable researchers to rapidly identify promising candidates from vast experimental spaces. This integration transforms raw characterization data into actionable insights, driving accelerated discovery cycles in ceramic surface engineering.

Sustainability Aspects of Ceramic HTE Processes

The integration of sustainability principles into High-Throughput Experimentation (HTE) for ceramic surface fabrication represents a critical evolution in materials science. As environmental concerns gain prominence globally, ceramic HTE processes must adapt to minimize ecological footprints while maintaining efficiency and innovation capabilities.

Energy consumption remains one of the most significant sustainability challenges in ceramic HTE. Traditional ceramic processing typically requires high-temperature firing, consuming substantial energy resources. Advanced HTE platforms are now incorporating energy-efficient technologies such as microwave-assisted processing, laser-based techniques, and optimized thermal management systems that can reduce energy requirements by 30-45% compared to conventional methods.

Material utilization efficiency has dramatically improved through precision deposition technologies and combinatorial approaches. Modern ceramic HTE systems can operate with nanogram to microgram quantities of raw materials, representing a 100-fold reduction compared to traditional experimental methods. This miniaturization not only conserves valuable resources but also minimizes waste generation throughout the experimental lifecycle.

Water conservation strategies have become increasingly important in sustainable ceramic HTE. Closed-loop water systems, dry processing techniques, and water-free alternative methods are being implemented across research facilities. These innovations have demonstrated potential water usage reductions of up to 80% in certain ceramic surface fabrication processes.

Chemical safety and toxicity reduction represent another crucial sustainability dimension. The transition toward greener chemistry principles in ceramic HTE includes substituting hazardous substances with environmentally benign alternatives, implementing safer synthesis routes, and developing non-toxic ceramic formulations that maintain desired performance characteristics.

Life cycle assessment (LCA) methodologies are now being systematically applied to ceramic HTE processes, enabling comprehensive evaluation of environmental impacts from raw material extraction through manufacturing to end-of-life scenarios. This holistic approach identifies optimization opportunities across the entire value chain and guides sustainable innovation pathways.

Circular economy principles are increasingly influencing ceramic HTE research directions. Investigations into recyclable ceramic formulations, biodegradable temporary components, and waste-derived raw materials are expanding. Some pioneering facilities have achieved up to 60% incorporation of recycled content in experimental ceramic compositions without compromising performance properties.

The economic sustainability of ceramic HTE processes has improved through automation, parallelization, and machine learning optimization. These advancements reduce labor requirements, accelerate discovery timelines, and enhance resource efficiency, creating a positive feedback loop where environmental and economic benefits reinforce each other.

Energy consumption remains one of the most significant sustainability challenges in ceramic HTE. Traditional ceramic processing typically requires high-temperature firing, consuming substantial energy resources. Advanced HTE platforms are now incorporating energy-efficient technologies such as microwave-assisted processing, laser-based techniques, and optimized thermal management systems that can reduce energy requirements by 30-45% compared to conventional methods.

Material utilization efficiency has dramatically improved through precision deposition technologies and combinatorial approaches. Modern ceramic HTE systems can operate with nanogram to microgram quantities of raw materials, representing a 100-fold reduction compared to traditional experimental methods. This miniaturization not only conserves valuable resources but also minimizes waste generation throughout the experimental lifecycle.

Water conservation strategies have become increasingly important in sustainable ceramic HTE. Closed-loop water systems, dry processing techniques, and water-free alternative methods are being implemented across research facilities. These innovations have demonstrated potential water usage reductions of up to 80% in certain ceramic surface fabrication processes.

Chemical safety and toxicity reduction represent another crucial sustainability dimension. The transition toward greener chemistry principles in ceramic HTE includes substituting hazardous substances with environmentally benign alternatives, implementing safer synthesis routes, and developing non-toxic ceramic formulations that maintain desired performance characteristics.

Life cycle assessment (LCA) methodologies are now being systematically applied to ceramic HTE processes, enabling comprehensive evaluation of environmental impacts from raw material extraction through manufacturing to end-of-life scenarios. This holistic approach identifies optimization opportunities across the entire value chain and guides sustainable innovation pathways.

Circular economy principles are increasingly influencing ceramic HTE research directions. Investigations into recyclable ceramic formulations, biodegradable temporary components, and waste-derived raw materials are expanding. Some pioneering facilities have achieved up to 60% incorporation of recycled content in experimental ceramic compositions without compromising performance properties.

The economic sustainability of ceramic HTE processes has improved through automation, parallelization, and machine learning optimization. These advancements reduce labor requirements, accelerate discovery timelines, and enhance resource efficiency, creating a positive feedback loop where environmental and economic benefits reinforce each other.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!