High-Throughput Experimentation in Textile Polymer Synthesis

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Textile Polymer Synthesis Evolution and Objectives

The evolution of textile polymer synthesis has undergone significant transformations since the early 20th century, transitioning from natural fiber dominance to synthetic polymer innovations. Initially, materials like cotton, wool, and silk dominated the textile landscape until the 1930s when nylon emerged as the first commercially successful synthetic polymer. This breakthrough catalyzed rapid development in polymer science, leading to the introduction of polyester in the 1940s and subsequent innovations in acrylic, spandex, and other synthetic fibers throughout the mid-20th century.

The 1970s and 1980s witnessed a paradigm shift with the development of high-performance technical textiles, incorporating advanced polymers with specialized properties such as flame resistance, enhanced durability, and moisture management capabilities. By the 1990s, the focus expanded to include environmentally sustainable approaches, addressing growing concerns about the ecological impact of synthetic polymer production and disposal.

The early 21st century has been characterized by the integration of nanotechnology into textile polymer synthesis, enabling unprecedented control over material properties at the molecular level. This period has also seen the emergence of smart textiles incorporating conductive polymers, shape-memory materials, and responsive elements that can adapt to environmental conditions or user needs.

Current technological objectives in textile polymer synthesis center on addressing several key challenges. Sustainability remains paramount, with significant research directed toward biodegradable polymers, bio-based feedstocks, and closed-loop recycling systems that minimize environmental impact while maintaining performance characteristics. Energy efficiency in manufacturing processes represents another critical goal, as traditional polymer synthesis often requires substantial energy inputs and generates considerable carbon emissions.

Functionality enhancement constitutes a major objective, with researchers pursuing polymers that offer multifunctional properties such as antimicrobial protection, UV resistance, thermoregulation, and self-cleaning capabilities. Scalability and cost-effectiveness remain essential considerations, as innovative materials must transition from laboratory success to commercial viability to achieve widespread adoption.

High-throughput experimentation (HTE) has emerged as a transformative approach to accelerate these objectives, enabling researchers to systematically explore vast chemical and process parameter spaces with unprecedented efficiency. The integration of robotics, advanced analytics, and machine learning with HTE methodologies promises to revolutionize polymer discovery and optimization, potentially reducing development timelines from years to months while expanding the accessible design space for next-generation textile materials.

The 1970s and 1980s witnessed a paradigm shift with the development of high-performance technical textiles, incorporating advanced polymers with specialized properties such as flame resistance, enhanced durability, and moisture management capabilities. By the 1990s, the focus expanded to include environmentally sustainable approaches, addressing growing concerns about the ecological impact of synthetic polymer production and disposal.

The early 21st century has been characterized by the integration of nanotechnology into textile polymer synthesis, enabling unprecedented control over material properties at the molecular level. This period has also seen the emergence of smart textiles incorporating conductive polymers, shape-memory materials, and responsive elements that can adapt to environmental conditions or user needs.

Current technological objectives in textile polymer synthesis center on addressing several key challenges. Sustainability remains paramount, with significant research directed toward biodegradable polymers, bio-based feedstocks, and closed-loop recycling systems that minimize environmental impact while maintaining performance characteristics. Energy efficiency in manufacturing processes represents another critical goal, as traditional polymer synthesis often requires substantial energy inputs and generates considerable carbon emissions.

Functionality enhancement constitutes a major objective, with researchers pursuing polymers that offer multifunctional properties such as antimicrobial protection, UV resistance, thermoregulation, and self-cleaning capabilities. Scalability and cost-effectiveness remain essential considerations, as innovative materials must transition from laboratory success to commercial viability to achieve widespread adoption.

High-throughput experimentation (HTE) has emerged as a transformative approach to accelerate these objectives, enabling researchers to systematically explore vast chemical and process parameter spaces with unprecedented efficiency. The integration of robotics, advanced analytics, and machine learning with HTE methodologies promises to revolutionize polymer discovery and optimization, potentially reducing development timelines from years to months while expanding the accessible design space for next-generation textile materials.

Market Demand Analysis for Advanced Textile Polymers

The global market for advanced textile polymers has witnessed substantial growth in recent years, driven by increasing demand for high-performance textiles across multiple industries. The compound annual growth rate (CAGR) for advanced textile polymers is projected to exceed 6% between 2023-2028, with the market value expected to reach approximately $25 billion by 2028. This growth trajectory is primarily fueled by expanding applications in sportswear, medical textiles, protective clothing, and technical textiles for industrial applications.

Consumer preferences are shifting dramatically toward sustainable, multifunctional, and high-performance textile products. Market research indicates that 67% of consumers are willing to pay premium prices for textiles with enhanced properties such as moisture-wicking, antimicrobial protection, or improved durability. This consumer behavior has created significant market pull for innovative polymer solutions that can deliver these advanced functionalities while maintaining comfort and aesthetic appeal.

The medical and healthcare sector represents one of the fastest-growing segments for advanced textile polymers, with an estimated CAGR of 7.8%. The COVID-19 pandemic has accelerated this trend, creating unprecedented demand for antimicrobial textiles, personal protective equipment (PPE), and specialized medical textiles. Additionally, the aging population in developed economies has increased the need for medical textiles with properties such as biocompatibility, controlled drug release, and wound healing capabilities.

In the sportswear and athleisure segment, market demand is being driven by performance-enhancing properties. Leading brands are actively seeking textile polymers that can provide compression, thermal regulation, odor control, and UV protection. This segment is expected to grow at 5.9% annually, with particularly strong demand in North America, Europe, and emerging Asian markets where fitness culture is rapidly expanding.

The technical textiles sector, encompassing automotive, aerospace, construction, and industrial applications, presents substantial growth opportunities for advanced polymer solutions. Lightweight, high-strength materials that can replace traditional components while reducing weight and improving performance are particularly sought after. The automotive industry alone is expected to increase its consumption of advanced textile polymers by 22% over the next five years as manufacturers strive to meet fuel efficiency and sustainability targets.

Sustainability has emerged as a critical market driver, with regulatory pressures and consumer demand pushing manufacturers toward eco-friendly alternatives. Biodegradable polymers, recycled materials, and bio-based alternatives are experiencing growth rates nearly double those of conventional synthetic polymers. This trend is particularly pronounced in European markets, where stringent environmental regulations are accelerating the transition toward sustainable textile solutions.

Consumer preferences are shifting dramatically toward sustainable, multifunctional, and high-performance textile products. Market research indicates that 67% of consumers are willing to pay premium prices for textiles with enhanced properties such as moisture-wicking, antimicrobial protection, or improved durability. This consumer behavior has created significant market pull for innovative polymer solutions that can deliver these advanced functionalities while maintaining comfort and aesthetic appeal.

The medical and healthcare sector represents one of the fastest-growing segments for advanced textile polymers, with an estimated CAGR of 7.8%. The COVID-19 pandemic has accelerated this trend, creating unprecedented demand for antimicrobial textiles, personal protective equipment (PPE), and specialized medical textiles. Additionally, the aging population in developed economies has increased the need for medical textiles with properties such as biocompatibility, controlled drug release, and wound healing capabilities.

In the sportswear and athleisure segment, market demand is being driven by performance-enhancing properties. Leading brands are actively seeking textile polymers that can provide compression, thermal regulation, odor control, and UV protection. This segment is expected to grow at 5.9% annually, with particularly strong demand in North America, Europe, and emerging Asian markets where fitness culture is rapidly expanding.

The technical textiles sector, encompassing automotive, aerospace, construction, and industrial applications, presents substantial growth opportunities for advanced polymer solutions. Lightweight, high-strength materials that can replace traditional components while reducing weight and improving performance are particularly sought after. The automotive industry alone is expected to increase its consumption of advanced textile polymers by 22% over the next five years as manufacturers strive to meet fuel efficiency and sustainability targets.

Sustainability has emerged as a critical market driver, with regulatory pressures and consumer demand pushing manufacturers toward eco-friendly alternatives. Biodegradable polymers, recycled materials, and bio-based alternatives are experiencing growth rates nearly double those of conventional synthetic polymers. This trend is particularly pronounced in European markets, where stringent environmental regulations are accelerating the transition toward sustainable textile solutions.

Current HTE Implementation Status and Barriers

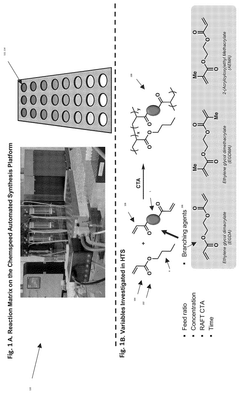

High-throughput experimentation (HTE) in textile polymer synthesis has seen significant implementation across various research institutions and industrial settings, though with varying degrees of sophistication and integration. Currently, the most advanced HTE platforms in this domain incorporate automated synthesis reactors capable of conducting up to 96 parallel reactions under controlled conditions of temperature, pressure, and stirring rates.

Leading research centers have developed specialized robotic systems that can prepare polymer formulations with precise control over monomer ratios, catalyst concentrations, and reaction conditions. These systems typically integrate liquid handling robots, parallel reactors, and automated sampling devices that enable rapid synthesis and characterization of textile polymers with diverse properties.

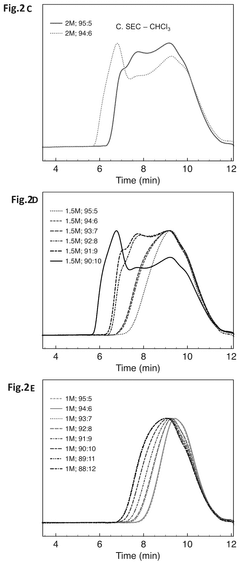

Analytical techniques have been successfully coupled with HTE workflows, including high-throughput FTIR spectroscopy, rapid GPC (Gel Permeation Chromatography), and automated DSC (Differential Scanning Calorimetry) for thermal property assessment. Some advanced facilities have implemented machine learning algorithms to analyze the large datasets generated and guide subsequent experimental designs.

Despite these advancements, significant barriers impede the widespread adoption of HTE in textile polymer synthesis. The high initial investment cost for establishing comprehensive HTE platforms remains prohibitive for many organizations, particularly small and medium enterprises. Complete HTE systems with integrated synthesis and characterization capabilities typically require investments exceeding $1-2 million.

Technical challenges persist in miniaturizing certain textile polymer synthesis processes that traditionally require specific processing conditions difficult to replicate at small scales. Viscosity control, phase separation monitoring, and fiber formation assessment present particular difficulties in high-throughput formats.

Data management represents another substantial barrier, as the volume of information generated through HTE approaches often overwhelms traditional laboratory information management systems. The lack of standardized data formats and protocols for textile polymer characterization further complicates cross-laboratory comparisons and knowledge sharing.

Workforce limitations also hinder implementation, as operating advanced HTE systems requires specialized training in both polymer chemistry and automation technologies. Many organizations lack personnel with this interdisciplinary expertise, creating operational bottlenecks even when equipment is available.

Regulatory considerations present additional challenges, particularly for textile polymers intended for specific applications like medical textiles or protective equipment, where validation of high-throughput methods against traditional approaches is required by regulatory bodies before implementation in product development pipelines.

Leading research centers have developed specialized robotic systems that can prepare polymer formulations with precise control over monomer ratios, catalyst concentrations, and reaction conditions. These systems typically integrate liquid handling robots, parallel reactors, and automated sampling devices that enable rapid synthesis and characterization of textile polymers with diverse properties.

Analytical techniques have been successfully coupled with HTE workflows, including high-throughput FTIR spectroscopy, rapid GPC (Gel Permeation Chromatography), and automated DSC (Differential Scanning Calorimetry) for thermal property assessment. Some advanced facilities have implemented machine learning algorithms to analyze the large datasets generated and guide subsequent experimental designs.

Despite these advancements, significant barriers impede the widespread adoption of HTE in textile polymer synthesis. The high initial investment cost for establishing comprehensive HTE platforms remains prohibitive for many organizations, particularly small and medium enterprises. Complete HTE systems with integrated synthesis and characterization capabilities typically require investments exceeding $1-2 million.

Technical challenges persist in miniaturizing certain textile polymer synthesis processes that traditionally require specific processing conditions difficult to replicate at small scales. Viscosity control, phase separation monitoring, and fiber formation assessment present particular difficulties in high-throughput formats.

Data management represents another substantial barrier, as the volume of information generated through HTE approaches often overwhelms traditional laboratory information management systems. The lack of standardized data formats and protocols for textile polymer characterization further complicates cross-laboratory comparisons and knowledge sharing.

Workforce limitations also hinder implementation, as operating advanced HTE systems requires specialized training in both polymer chemistry and automation technologies. Many organizations lack personnel with this interdisciplinary expertise, creating operational bottlenecks even when equipment is available.

Regulatory considerations present additional challenges, particularly for textile polymers intended for specific applications like medical textiles or protective equipment, where validation of high-throughput methods against traditional approaches is required by regulatory bodies before implementation in product development pipelines.

Contemporary HTE Methodologies for Polymer Development

01 Automated high-throughput polymer synthesis platforms

Advanced automated platforms designed specifically for high-throughput synthesis of textile polymers, featuring robotic systems, parallel reactors, and integrated analytical tools. These systems enable simultaneous synthesis of multiple polymer variants under controlled conditions, significantly increasing experimental throughput while maintaining precision and reproducibility. The platforms typically incorporate automated sampling, mixing, and temperature control to optimize polymer synthesis parameters efficiently.- Automated high-throughput polymer synthesis platforms: Advanced automated platforms designed specifically for high-throughput synthesis of textile polymers, featuring robotic systems, parallel reactors, and integrated analysis capabilities. These systems enable simultaneous synthesis of multiple polymer variants under controlled conditions, significantly increasing experimental throughput while maintaining precision. The platforms incorporate automated sample handling, precise temperature and pressure control, and can be programmed to execute complex synthesis protocols with minimal human intervention.

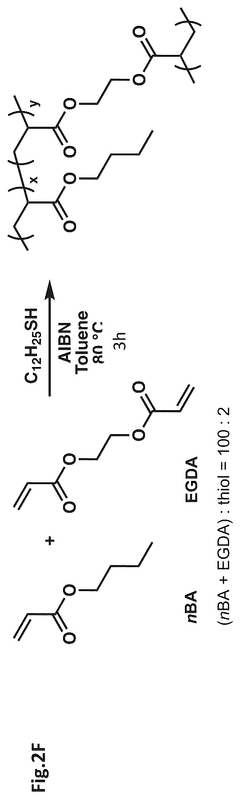

- Combinatorial methods for textile polymer development: Combinatorial approaches that systematically explore diverse monomer combinations, catalyst systems, and reaction conditions to rapidly identify optimal textile polymer formulations. These methods employ design of experiments (DOE) techniques to efficiently map the parameter space with minimal experimental runs. By systematically varying multiple synthesis parameters simultaneously, researchers can quickly identify promising polymer candidates with desired properties such as strength, elasticity, or thermal stability for textile applications.

- Integrated analysis and characterization systems: High-throughput characterization technologies that rapidly analyze key properties of synthesized textile polymers, including molecular weight distribution, thermal properties, mechanical strength, and surface characteristics. These systems integrate multiple analytical techniques such as automated spectroscopy, chromatography, thermal analysis, and mechanical testing to provide comprehensive polymer characterization. Real-time data collection and analysis capabilities enable rapid feedback loops that accelerate the polymer development process.

- Machine learning and AI for polymer synthesis optimization: Application of machine learning algorithms and artificial intelligence to optimize textile polymer synthesis processes and predict polymer properties. These computational approaches analyze large datasets from high-throughput experiments to identify patterns and correlations between synthesis parameters and resulting polymer characteristics. Predictive models enable researchers to focus experimental efforts on the most promising parameter combinations, reducing the number of physical experiments required and accelerating the discovery of novel textile polymers with enhanced properties.

- Sustainable and eco-friendly high-throughput polymer synthesis: High-throughput methodologies specifically designed for developing sustainable textile polymers using bio-based feedstocks, environmentally friendly catalysts, and energy-efficient processes. These approaches enable rapid screening of renewable monomers, green solvents, and biodegradable polymer formulations. The high-throughput platforms incorporate sustainability metrics into the evaluation process, allowing researchers to simultaneously optimize for both performance characteristics and environmental impact when developing next-generation textile materials.

02 Combinatorial methods for textile polymer development

Combinatorial approaches that systematically explore multiple variables in textile polymer synthesis simultaneously. These methods involve creating libraries of polymer variants by systematically varying parameters such as monomer ratios, catalysts, reaction conditions, and additives. The combinatorial approach enables rapid screening of numerous polymer formulations to identify optimal compositions with desired textile properties, significantly accelerating the discovery and development process for new textile materials.Expand Specific Solutions03 Machine learning and AI-driven polymer design

Integration of artificial intelligence and machine learning algorithms to optimize textile polymer synthesis processes. These computational approaches analyze large datasets from high-throughput experiments to identify patterns and correlations between synthesis parameters and polymer properties. Machine learning models can predict optimal reaction conditions, suggest novel polymer structures, and guide experimental design, thereby reducing the number of physical experiments required and accelerating the development of textile polymers with targeted properties.Expand Specific Solutions04 Microfluidic and flow chemistry systems for polymer synthesis

Microfluidic devices and continuous flow reactors designed for rapid, small-scale polymer synthesis with precise control over reaction parameters. These systems enable efficient mixing, heat transfer, and reaction monitoring in miniaturized environments, allowing for parallel processing of multiple polymer formulations with minimal material consumption. The continuous flow approach provides consistent reaction conditions, improved safety for exothermic reactions, and seamless integration with inline analytical techniques for real-time polymer characterization.Expand Specific Solutions05 High-throughput characterization and testing of textile polymers

Advanced analytical methods and automated testing systems designed to rapidly evaluate the properties and performance of synthesized textile polymers. These include automated spectroscopic techniques, mechanical property testing, thermal analysis, and durability assessments specifically adapted for high-throughput workflows. The integration of these characterization methods with synthesis platforms creates a comprehensive system for quickly identifying promising polymer candidates with desired textile properties such as strength, elasticity, moisture management, and colorfastness.Expand Specific Solutions

Leading Organizations in HTE Textile Research

High-Throughput Experimentation (HTE) in textile polymer synthesis is currently in a growth phase, with the market expanding as industries seek more efficient R&D methods. The global market is estimated to reach significant scale as textile manufacturers adopt advanced experimentation techniques. Technologically, the field shows moderate maturity with key players demonstrating varying levels of expertise. Companies like Dow Silicones and Braskem SA lead in industrial applications, while UOP LLC and Reliance Industries contribute significant innovations. Academic institutions such as Donghua University and Beijing University of Chemical Technology provide research foundations. Specialized firms like Ningbo Galaxy Materials Technology offer dedicated HTE platforms, while traditional chemical companies including Daicel, SABIC, and Unilever are integrating these methodologies into their polymer development processes.

Dow Silicones Corp.

Technical Solution: Dow Silicones has developed an advanced high-throughput experimentation platform specifically optimized for silicone-based textile polymers. Their system features parallel reactor arrays capable of handling 96 reactions simultaneously under precisely controlled temperature and atmosphere conditions. A distinguishing feature is their proprietary "gradient technology" that creates systematic variations in monomer ratios, catalyst concentrations, and processing parameters across reaction arrays. The platform incorporates automated sampling and analysis systems including rapid GPC, rheological testing, and surface property characterization specifically designed for silicone polymers. Dow's system includes specialized modules for evaluating textile-specific properties such as hand feel, drape, and elasticity recovery through miniaturized mechanical testing. Their data management system employs advanced statistical tools and machine learning algorithms to identify optimal formulations and process conditions. This technology has enabled Dow to develop novel silicone elastomers for performance textiles with enhanced comfort, durability and sustainability profiles, reducing development time by approximately 70% compared to conventional methods.

Strengths: Specialized expertise in silicone chemistry; excellent integration of textile-specific testing; sophisticated data analysis capabilities. Weaknesses: Limited to silicone-based polymers; high operational costs; requires significant expertise in silicone chemistry.

Celanese Services Germany GmbH

Technical Solution: Celanese has developed a sophisticated high-throughput experimentation platform specifically designed for textile polymer synthesis focusing on acetyl-based polymers and polyesters. Their system features parallel pressure reactors with individual control of temperature, pressure, and mixing parameters, capable of handling up to 48 reactions simultaneously. A distinctive aspect is their "formulation gradient" technology that systematically varies monomer ratios, catalyst types, and additives across reaction arrays to rapidly identify optimal compositions. The platform incorporates automated inline monitoring via FTIR and viscometry to track polymerization kinetics in real-time. Celanese's system includes specialized modules for evaluating textile-relevant properties such as dyeability, moisture management, and dimensional stability through miniaturized testing protocols. Their data management system employs advanced statistical design of experiments (DoE) and machine learning algorithms to navigate complex formulation spaces efficiently. This technology has enabled Celanese to develop novel acetate-based fibers with enhanced sustainability profiles and performance characteristics, reducing development timelines from years to months while significantly expanding the explored chemical space.

Strengths: Deep expertise in acetyl chemistry and polyesters; excellent integration of textile-specific property testing; sophisticated experimental design capabilities. Weaknesses: More limited in polymer diversity than some competitors; complex system maintenance requirements; higher operational costs.

Critical Innovations in Parallel Synthesis Techniques

Synthesis of highly branched polymers via high throughput screening

PatentPendingUS20250236694A1

Innovation

- The use of high throughput screening (HTS) techniques in combination with the Strathclyde method to optimize reaction conditions, allowing for the rapid production of soluble, highly branched polymers with controlled molecular weight and degree of branching, using monofunctional and multifunctional (meth)acrylic acid alkyl esters.

Sustainability Considerations in HTE Textile Development

The integration of sustainability principles into High-Throughput Experimentation (HTE) for textile polymer synthesis represents a critical evolution in responsible materials development. As environmental concerns intensify globally, the textile industry faces mounting pressure to reduce its ecological footprint while maintaining economic viability. HTE methodologies offer unique opportunities to accelerate the discovery and optimization of sustainable textile polymers through their inherent efficiency advantages.

Energy consumption optimization stands as a primary sustainability consideration in HTE textile development. Advanced automation systems and miniaturized reaction platforms significantly reduce energy requirements per experiment compared to traditional methods. Recent implementations have demonstrated energy savings of 40-65% through parallel processing techniques and optimized heating/cooling cycles, effectively lowering the carbon footprint of polymer research activities.

Water conservation represents another crucial dimension, particularly relevant to textile manufacturing's historically high water demands. HTE approaches enable dramatic reductions in solvent and water usage through microscale experimentation, with some platforms achieving up to 90% reduction in liquid consumption compared to conventional methods. Additionally, closed-loop solvent recovery systems integrated into modern HTE workflows further minimize waste generation.

Raw material efficiency is substantially enhanced through HTE methodologies. Precise dispensing technologies reduce material waste, while rapid screening capabilities accelerate the identification of bio-based and recycled polymer formulations with performance characteristics matching or exceeding conventional synthetic materials. This capability directly supports circular economy principles by facilitating the development of polymers designed for eventual biodegradation or recycling.

Life cycle assessment (LCA) integration into HTE workflows represents an emerging practice with significant sustainability implications. By incorporating environmental impact metrics into experimental design and data analysis, researchers can prioritize polymer candidates with reduced ecological footprints from the earliest development stages. Several leading textile research institutions have pioneered computational models that predict environmental impacts alongside performance characteristics.

Green chemistry principles increasingly guide HTE textile polymer development, with particular emphasis on reducing hazardous substances. Automated systems enable safer handling of potentially harmful reagents while facilitating the exploration of benign alternatives. The high-throughput approach allows comprehensive testing of catalysts that function effectively under milder conditions, reducing energy requirements and hazardous waste generation.

The economic sustainability of textile innovation benefits substantially from HTE approaches. By accelerating development timelines and reducing material costs, these methodologies make sustainable textile research more financially viable. This economic advantage proves particularly valuable for smaller manufacturers seeking to transition toward greener production methods without prohibitive R&D investments.

Energy consumption optimization stands as a primary sustainability consideration in HTE textile development. Advanced automation systems and miniaturized reaction platforms significantly reduce energy requirements per experiment compared to traditional methods. Recent implementations have demonstrated energy savings of 40-65% through parallel processing techniques and optimized heating/cooling cycles, effectively lowering the carbon footprint of polymer research activities.

Water conservation represents another crucial dimension, particularly relevant to textile manufacturing's historically high water demands. HTE approaches enable dramatic reductions in solvent and water usage through microscale experimentation, with some platforms achieving up to 90% reduction in liquid consumption compared to conventional methods. Additionally, closed-loop solvent recovery systems integrated into modern HTE workflows further minimize waste generation.

Raw material efficiency is substantially enhanced through HTE methodologies. Precise dispensing technologies reduce material waste, while rapid screening capabilities accelerate the identification of bio-based and recycled polymer formulations with performance characteristics matching or exceeding conventional synthetic materials. This capability directly supports circular economy principles by facilitating the development of polymers designed for eventual biodegradation or recycling.

Life cycle assessment (LCA) integration into HTE workflows represents an emerging practice with significant sustainability implications. By incorporating environmental impact metrics into experimental design and data analysis, researchers can prioritize polymer candidates with reduced ecological footprints from the earliest development stages. Several leading textile research institutions have pioneered computational models that predict environmental impacts alongside performance characteristics.

Green chemistry principles increasingly guide HTE textile polymer development, with particular emphasis on reducing hazardous substances. Automated systems enable safer handling of potentially harmful reagents while facilitating the exploration of benign alternatives. The high-throughput approach allows comprehensive testing of catalysts that function effectively under milder conditions, reducing energy requirements and hazardous waste generation.

The economic sustainability of textile innovation benefits substantially from HTE approaches. By accelerating development timelines and reducing material costs, these methodologies make sustainable textile research more financially viable. This economic advantage proves particularly valuable for smaller manufacturers seeking to transition toward greener production methods without prohibitive R&D investments.

Economic Impact Assessment of HTE Implementation

The implementation of High-Throughput Experimentation (HTE) in textile polymer synthesis represents a significant economic inflection point for the industry. Initial cost-benefit analyses indicate that while the upfront investment in HTE infrastructure ranges from $2-5 million for comprehensive laboratory setups, the return on investment typically materializes within 24-36 months through accelerated product development cycles. Companies implementing HTE have reported reductions in R&D timelines by 40-60%, translating to millions in saved development costs and earlier market entry advantages.

From a manufacturing economics perspective, HTE enables more efficient resource utilization, with studies showing material waste reduction of 30-45% during the development phase. This efficiency extends to energy consumption, which decreases by approximately 25% compared to traditional sequential experimentation methods. The ability to rapidly screen multiple polymer formulations simultaneously reduces the per-experiment cost by an estimated 65-75% when amortized across large experimental sets.

Labor economics also transform under HTE implementation. While specialized personnel requirements increase initially, the overall labor cost per successful formulation decreases substantially. Industry data suggests that a single researcher utilizing HTE platforms can accomplish the equivalent work of 5-7 researchers using conventional methods, though this requires upskilling and training investments of approximately $50,000-75,000 per technical staff member.

Market opportunity costs represent perhaps the most compelling economic argument for HTE adoption. The textile industry's increasingly compressed product lifecycles mean that reaching market even three months earlier can capture an additional 15-20% of a product's lifetime revenue. Companies implementing HTE report average time-to-market reductions of 7-9 months for complex polymer-based textile innovations, potentially translating to millions in additional revenue per product.

Risk mitigation economics also favor HTE implementation. The parallel testing approach reduces the financial impact of individual experimental failures, with data indicating a 50-60% reduction in costs associated with failed development pathways. This risk distribution model proves particularly valuable for smaller enterprises with limited R&D budgets, potentially democratizing innovation capabilities across the industry spectrum.

Long-term economic modeling suggests that widespread HTE adoption could reshape competitive dynamics in the textile polymer sector, potentially creating a bifurcated market between HTE-enabled rapid innovators and traditional manufacturers. Economic forecasts project that by 2030, companies without HTE capabilities may face cost disadvantages of 30-40% in bringing new textile polymers to market, potentially restructuring industry profit pools and investment patterns.

From a manufacturing economics perspective, HTE enables more efficient resource utilization, with studies showing material waste reduction of 30-45% during the development phase. This efficiency extends to energy consumption, which decreases by approximately 25% compared to traditional sequential experimentation methods. The ability to rapidly screen multiple polymer formulations simultaneously reduces the per-experiment cost by an estimated 65-75% when amortized across large experimental sets.

Labor economics also transform under HTE implementation. While specialized personnel requirements increase initially, the overall labor cost per successful formulation decreases substantially. Industry data suggests that a single researcher utilizing HTE platforms can accomplish the equivalent work of 5-7 researchers using conventional methods, though this requires upskilling and training investments of approximately $50,000-75,000 per technical staff member.

Market opportunity costs represent perhaps the most compelling economic argument for HTE adoption. The textile industry's increasingly compressed product lifecycles mean that reaching market even three months earlier can capture an additional 15-20% of a product's lifetime revenue. Companies implementing HTE report average time-to-market reductions of 7-9 months for complex polymer-based textile innovations, potentially translating to millions in additional revenue per product.

Risk mitigation economics also favor HTE implementation. The parallel testing approach reduces the financial impact of individual experimental failures, with data indicating a 50-60% reduction in costs associated with failed development pathways. This risk distribution model proves particularly valuable for smaller enterprises with limited R&D budgets, potentially democratizing innovation capabilities across the industry spectrum.

Long-term economic modeling suggests that widespread HTE adoption could reshape competitive dynamics in the textile polymer sector, potentially creating a bifurcated market between HTE-enabled rapid innovators and traditional manufacturers. Economic forecasts project that by 2030, companies without HTE capabilities may face cost disadvantages of 30-40% in bringing new textile polymers to market, potentially restructuring industry profit pools and investment patterns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!