High-Throughput Experimentation in Metal Alloys for Aerospace

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Alloy HTE Background and Objectives

High-Throughput Experimentation (HTE) in metal alloys represents a paradigm shift in materials science research methodology, particularly for aerospace applications where performance requirements are exceptionally demanding. The evolution of aerospace alloy development has historically been characterized by time-intensive trial-and-error approaches, with each iteration requiring months or even years of testing. This conventional approach has significantly limited innovation pace in an industry where material performance directly impacts safety, efficiency, and environmental sustainability.

The emergence of HTE techniques in the early 2000s began transforming materials research across multiple industries, but aerospace adoption has been relatively recent. This acceleration comes in response to increasing demands for lighter, stronger, and more heat-resistant materials capable of withstanding extreme operational conditions while reducing fuel consumption and emissions. The convergence of computational modeling, robotics, and advanced characterization techniques has enabled the parallel synthesis and evaluation of hundreds or thousands of alloy compositions simultaneously.

Current technological trajectories indicate a growing integration of artificial intelligence and machine learning algorithms with HTE platforms, creating unprecedented opportunities to discover novel aerospace alloys with optimized property combinations. These developments are occurring against a backdrop of increasing global competition in aerospace manufacturing and mounting pressure to reduce the environmental impact of air travel.

The primary objectives of HTE implementation in aerospace alloy development are multifaceted. First, to dramatically compress the innovation timeline from concept to qualification, reducing development cycles from decades to years or even months. Second, to expand the compositional exploration space beyond traditional alloy systems, enabling the discovery of non-intuitive material solutions. Third, to establish predictive capabilities that can accurately forecast alloy performance under various operational conditions without extensive physical testing.

Additionally, HTE aims to democratize advanced materials development by reducing the resource barriers to entry, potentially enabling smaller organizations to contribute meaningfully to aerospace innovation. The ultimate goal is to create a self-improving ecosystem where each experimental iteration generates data that enhances the predictive power of subsequent experiments, creating a virtuous cycle of accelerating discovery rates.

The technological evolution in this field is increasingly focused on developing specialized HTE equipment and protocols specifically tailored to the unique requirements of aerospace alloys, including the ability to simulate extreme temperatures, pressures, and mechanical stresses that characterize aerospace operating environments.

The emergence of HTE techniques in the early 2000s began transforming materials research across multiple industries, but aerospace adoption has been relatively recent. This acceleration comes in response to increasing demands for lighter, stronger, and more heat-resistant materials capable of withstanding extreme operational conditions while reducing fuel consumption and emissions. The convergence of computational modeling, robotics, and advanced characterization techniques has enabled the parallel synthesis and evaluation of hundreds or thousands of alloy compositions simultaneously.

Current technological trajectories indicate a growing integration of artificial intelligence and machine learning algorithms with HTE platforms, creating unprecedented opportunities to discover novel aerospace alloys with optimized property combinations. These developments are occurring against a backdrop of increasing global competition in aerospace manufacturing and mounting pressure to reduce the environmental impact of air travel.

The primary objectives of HTE implementation in aerospace alloy development are multifaceted. First, to dramatically compress the innovation timeline from concept to qualification, reducing development cycles from decades to years or even months. Second, to expand the compositional exploration space beyond traditional alloy systems, enabling the discovery of non-intuitive material solutions. Third, to establish predictive capabilities that can accurately forecast alloy performance under various operational conditions without extensive physical testing.

Additionally, HTE aims to democratize advanced materials development by reducing the resource barriers to entry, potentially enabling smaller organizations to contribute meaningfully to aerospace innovation. The ultimate goal is to create a self-improving ecosystem where each experimental iteration generates data that enhances the predictive power of subsequent experiments, creating a virtuous cycle of accelerating discovery rates.

The technological evolution in this field is increasingly focused on developing specialized HTE equipment and protocols specifically tailored to the unique requirements of aerospace alloys, including the ability to simulate extreme temperatures, pressures, and mechanical stresses that characterize aerospace operating environments.

Market Demand Analysis for Advanced Aerospace Materials

The aerospace materials market is experiencing unprecedented growth, driven by increasing demand for fuel-efficient aircraft and the expansion of commercial aviation and space exploration sectors. Current market valuations place the advanced aerospace materials segment at approximately $5.9 billion, with projections indicating a compound annual growth rate of 6.7% through 2028. This growth trajectory is primarily fueled by the aviation industry's push toward lightweight, high-performance materials that can withstand extreme conditions while reducing overall aircraft weight and fuel consumption.

Metal alloys represent a significant portion of this market, with titanium alloys, aluminum-lithium alloys, and nickel-based superalloys commanding particular attention. The demand for these materials is especially pronounced in critical components such as engine parts, structural elements, and landing gear systems where performance requirements are exceptionally stringent.

Commercial aircraft manufacturers are increasingly prioritizing materials that offer superior strength-to-weight ratios, with Boeing and Airbus collectively forecasting delivery of over 40,000 new aircraft in the next two decades. This production volume necessitates more efficient material development processes, making high-throughput experimentation (HTE) technologies particularly valuable.

Defense aerospace applications present another substantial market segment, with military aircraft and spacecraft requiring materials that deliver enhanced performance under extreme operational conditions. The U.S. Department of Defense alone allocates billions annually toward advanced materials research, with similar investments being made by defense departments worldwide.

Emerging markets in Asia-Pacific, particularly China and India, are rapidly expanding their aerospace manufacturing capabilities, creating new demand centers for advanced alloys. These regions are expected to account for nearly 40% of global aerospace material consumption by 2030, representing a significant shift in market dynamics.

The space exploration sector, bolstered by both government initiatives and private ventures like SpaceX and Blue Origin, is generating demand for specialized alloys that can withstand the harsh conditions of space. This segment is growing at nearly 8.5% annually, outpacing the broader aerospace materials market.

Sustainability considerations are also reshaping market demands, with increasing pressure for materials that enable reduced emissions throughout the aircraft lifecycle. This trend is driving interest in alloys that not only deliver performance benefits but also offer improved recyclability and reduced environmental impact during production.

The COVID-19 pandemic temporarily disrupted market growth, but recovery has been robust, with demand now exceeding pre-pandemic levels in many segments. This recovery pattern underscores the resilience of the aerospace sector and the fundamental importance of advanced materials to its continued development.

Metal alloys represent a significant portion of this market, with titanium alloys, aluminum-lithium alloys, and nickel-based superalloys commanding particular attention. The demand for these materials is especially pronounced in critical components such as engine parts, structural elements, and landing gear systems where performance requirements are exceptionally stringent.

Commercial aircraft manufacturers are increasingly prioritizing materials that offer superior strength-to-weight ratios, with Boeing and Airbus collectively forecasting delivery of over 40,000 new aircraft in the next two decades. This production volume necessitates more efficient material development processes, making high-throughput experimentation (HTE) technologies particularly valuable.

Defense aerospace applications present another substantial market segment, with military aircraft and spacecraft requiring materials that deliver enhanced performance under extreme operational conditions. The U.S. Department of Defense alone allocates billions annually toward advanced materials research, with similar investments being made by defense departments worldwide.

Emerging markets in Asia-Pacific, particularly China and India, are rapidly expanding their aerospace manufacturing capabilities, creating new demand centers for advanced alloys. These regions are expected to account for nearly 40% of global aerospace material consumption by 2030, representing a significant shift in market dynamics.

The space exploration sector, bolstered by both government initiatives and private ventures like SpaceX and Blue Origin, is generating demand for specialized alloys that can withstand the harsh conditions of space. This segment is growing at nearly 8.5% annually, outpacing the broader aerospace materials market.

Sustainability considerations are also reshaping market demands, with increasing pressure for materials that enable reduced emissions throughout the aircraft lifecycle. This trend is driving interest in alloys that not only deliver performance benefits but also offer improved recyclability and reduced environmental impact during production.

The COVID-19 pandemic temporarily disrupted market growth, but recovery has been robust, with demand now exceeding pre-pandemic levels in many segments. This recovery pattern underscores the resilience of the aerospace sector and the fundamental importance of advanced materials to its continued development.

Current Status and Challenges in Metal Alloy HTE

High-throughput experimentation (HTE) in metal alloys for aerospace applications has seen significant advancements globally, yet faces substantial technical and implementation challenges. Currently, the United States, Germany, China, and Japan lead in this field, with major research institutions and aerospace manufacturers establishing dedicated HTE facilities. These centers typically employ combinatorial materials science approaches, allowing for the simultaneous synthesis and characterization of hundreds to thousands of compositionally distinct samples.

The primary technical challenge in metal alloy HTE remains the development of reliable high-throughput characterization methods that can accurately predict bulk material properties from small-scale samples. Traditional aerospace alloy qualification requires extensive mechanical testing under various environmental conditions, which is difficult to miniaturize while maintaining predictive accuracy. This creates a significant bottleneck in translating HTE discoveries to certified aerospace components.

Data management presents another critical challenge, as HTE generates massive datasets that require sophisticated computational infrastructure and machine learning algorithms to process effectively. Many organizations struggle with integrating these datasets across different experimental platforms and ensuring data quality and consistency. The aerospace industry's stringent certification requirements further complicate this issue, as regulatory frameworks have not fully adapted to accommodate materials developed through HTE methodologies.

Manufacturing scalability represents a persistent obstacle, as promising alloy compositions identified through HTE must be translated to conventional production methods. The processing parameters that yield optimal properties in small-scale HTE samples often do not directly transfer to industrial-scale manufacturing, requiring additional development cycles that diminish the speed advantages of HTE.

Cost considerations also limit widespread adoption, with high-end HTE systems requiring investments of $5-20 million for comprehensive capabilities. This creates a significant barrier for smaller organizations and developing nations, concentrating advanced alloy development capabilities among established industry leaders and well-funded research institutions.

The interdisciplinary nature of effective HTE implementation presents workforce challenges, requiring teams with expertise spanning materials science, robotics, data science, and aerospace engineering. This talent gap has slowed adoption, particularly in regions without established materials informatics educational programs.

Despite these challenges, recent technological breakthroughs in machine learning algorithms, automated experimentation platforms, and in-situ characterization techniques are gradually addressing these limitations, suggesting an accelerating trajectory for HTE implementation in aerospace alloy development over the next decade.

The primary technical challenge in metal alloy HTE remains the development of reliable high-throughput characterization methods that can accurately predict bulk material properties from small-scale samples. Traditional aerospace alloy qualification requires extensive mechanical testing under various environmental conditions, which is difficult to miniaturize while maintaining predictive accuracy. This creates a significant bottleneck in translating HTE discoveries to certified aerospace components.

Data management presents another critical challenge, as HTE generates massive datasets that require sophisticated computational infrastructure and machine learning algorithms to process effectively. Many organizations struggle with integrating these datasets across different experimental platforms and ensuring data quality and consistency. The aerospace industry's stringent certification requirements further complicate this issue, as regulatory frameworks have not fully adapted to accommodate materials developed through HTE methodologies.

Manufacturing scalability represents a persistent obstacle, as promising alloy compositions identified through HTE must be translated to conventional production methods. The processing parameters that yield optimal properties in small-scale HTE samples often do not directly transfer to industrial-scale manufacturing, requiring additional development cycles that diminish the speed advantages of HTE.

Cost considerations also limit widespread adoption, with high-end HTE systems requiring investments of $5-20 million for comprehensive capabilities. This creates a significant barrier for smaller organizations and developing nations, concentrating advanced alloy development capabilities among established industry leaders and well-funded research institutions.

The interdisciplinary nature of effective HTE implementation presents workforce challenges, requiring teams with expertise spanning materials science, robotics, data science, and aerospace engineering. This talent gap has slowed adoption, particularly in regions without established materials informatics educational programs.

Despite these challenges, recent technological breakthroughs in machine learning algorithms, automated experimentation platforms, and in-situ characterization techniques are gradually addressing these limitations, suggesting an accelerating trajectory for HTE implementation in aerospace alloy development over the next decade.

Current HTE Methodologies for Metal Alloy Discovery

01 Composition and manufacturing of lightweight metal alloys

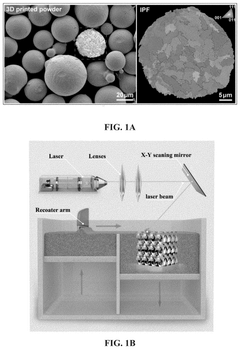

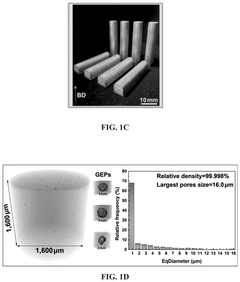

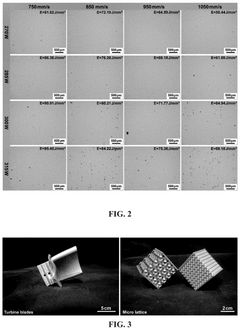

Lightweight metal alloys, particularly those based on aluminum, magnesium, and titanium, are designed for applications requiring high strength-to-weight ratios. These alloys are manufactured through various processes including casting, forging, and powder metallurgy techniques. The composition typically includes primary metals with specific additives to enhance properties such as corrosion resistance, ductility, and thermal stability. Advanced manufacturing methods allow for precise control of microstructure, resulting in optimized mechanical properties for aerospace, automotive, and other high-performance applications.- Composition and properties of metal alloys: Metal alloys are composed of specific combinations of elements to achieve desired properties. These compositions are carefully formulated to enhance characteristics such as strength, corrosion resistance, and thermal stability. The specific ratios of elements in the alloy determine its mechanical and physical properties, making them suitable for various industrial applications.

- Manufacturing processes for metal alloys: Various manufacturing techniques are employed to produce metal alloys with specific characteristics. These processes include casting, forging, powder metallurgy, and heat treatment. Each manufacturing method affects the microstructure and properties of the resulting alloy, allowing for customization based on intended applications.

- High-temperature resistant alloys: Specialized metal alloys designed to withstand extreme temperatures while maintaining structural integrity and performance. These alloys typically contain elements such as nickel, cobalt, and chromium, which provide resistance to oxidation and thermal fatigue. They are crucial for applications in aerospace, power generation, and other industries where components are exposed to high-temperature environments.

- Lightweight and high-strength alloys: Advanced metal alloys that combine low density with high mechanical strength. These alloys often incorporate elements like aluminum, titanium, or magnesium as base materials, with various alloying elements added to enhance specific properties. The development of these materials has been particularly important for transportation industries where weight reduction leads to improved fuel efficiency without compromising structural integrity.

- Corrosion-resistant alloy systems: Metal alloys specifically engineered to resist degradation in aggressive environments. These alloys typically contain elements such as chromium, molybdenum, or nickel that form protective oxide layers on the surface. The composition and microstructure are optimized to prevent various forms of corrosion, including galvanic, pitting, and stress corrosion cracking, making them essential for marine, chemical processing, and medical applications.

02 Heat treatment processes for metal alloys

Heat treatment processes are essential for modifying the properties of metal alloys. These processes include annealing, quenching, tempering, and aging treatments that alter the microstructure of the alloy. By controlling temperature, time, and cooling rates, specific mechanical properties such as hardness, strength, and ductility can be achieved. Solution treatment followed by precipitation hardening is particularly important for aluminum and nickel-based alloys, while normalizing and tempering are crucial for steel alloys. These treatments enable customization of alloy properties for specific industrial applications.Expand Specific Solutions03 Joining and welding techniques for metal alloys

Various joining and welding techniques have been developed for metal alloys, including fusion welding, solid-state welding, brazing, and soldering. These methods address challenges such as thermal distortion, cracking, and formation of brittle intermetallic compounds. Advanced techniques like friction stir welding, laser welding, and diffusion bonding offer advantages for joining dissimilar metals and alloys with minimal heat-affected zones. The selection of appropriate joining method depends on the alloy composition, thickness, and intended application, with considerations for mechanical strength, corrosion resistance, and service conditions.Expand Specific Solutions04 Corrosion-resistant alloy formulations

Corrosion-resistant alloys are formulated with specific elements to enhance their resistance to various corrosive environments. Stainless steels containing chromium and nickel form passive oxide layers that protect against atmospheric and chemical corrosion. Nickel-based alloys with additions of chromium, molybdenum, and tungsten offer exceptional resistance to high-temperature oxidation and aqueous corrosion. Aluminum alloys can be modified with magnesium, silicon, and zinc to improve their corrosion behavior. Surface treatments and coatings further enhance the corrosion resistance of these alloys for applications in marine environments, chemical processing, and medical implants.Expand Specific Solutions05 High-temperature resistant superalloys

Superalloys are specialized metal alloys designed to maintain structural integrity and resist deformation at extremely high temperatures. These alloys, typically based on nickel, cobalt, or iron, contain carefully balanced additions of elements such as chromium, aluminum, titanium, and refractory metals. They exhibit exceptional creep resistance, oxidation resistance, and thermal stability at temperatures exceeding 1000°C. Advanced processing techniques including directional solidification and single crystal growth further enhance their high-temperature capabilities. These materials are critical for gas turbine engines, power generation equipment, and other applications requiring strength and stability under extreme thermal conditions.Expand Specific Solutions

Key Industry Players in Aerospace Alloy Development

High-Throughput Experimentation (HTE) in metal alloys for aerospace is currently in a growth phase, with increasing adoption across research institutions and industry. The market is expanding rapidly, driven by the need for accelerated materials development and reduced costs in aerospace applications. Major players include established aerospace manufacturers like Boeing and United Technologies, who are investing in HTE capabilities to maintain competitive advantage. Research institutions, particularly in China (Harbin Institute of Technology, Institute of Metal Research CAS) and the US, are advancing fundamental HTE methodologies. Specialized materials companies like ALD Vacuum Technologies and Universal Alloy are developing tailored HTE solutions for aerospace alloys. The technology is approaching maturity in research settings but remains in early commercial implementation phases, with significant potential for further integration into industrial workflows.

The Boeing Co.

Technical Solution: Boeing has developed an advanced high-throughput experimentation (HTE) platform specifically for aerospace alloy development. Their system integrates robotic sample preparation, automated testing, and machine learning algorithms to rapidly screen thousands of alloy compositions. Boeing's approach includes multi-scale characterization techniques that evaluate mechanical properties, corrosion resistance, and microstructural features simultaneously. Their Materials Technology Center employs parallel processing methods where multiple small-scale samples with systematically varied compositions are fabricated and tested under identical conditions, enabling direct comparison across a wide compositional space. Boeing has also implemented digital twins of their alloy development process, allowing virtual experimentation to complement physical testing and further accelerate discovery cycles. The company's integrated data management system captures all experimental results in a structured database that feeds into predictive models for next-generation aerospace alloys.

Strengths: Boeing's integrated approach combines physical testing with computational modeling, creating a powerful feedback loop that accelerates development cycles. Their extensive aerospace application knowledge ensures relevance of testing protocols. Weaknesses: The proprietary nature of their systems limits collaboration with external researchers, and their focus on specific aerospace applications may narrow the exploration of novel alloy compositions outside traditional aerospace requirements.

Institute of Metal Research Chinese Academy of Sciences

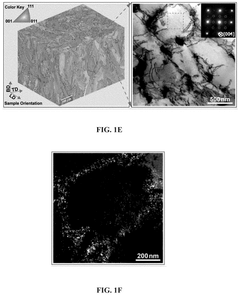

Technical Solution: The Institute of Metal Research (IMR) has established a comprehensive high-throughput experimentation platform for aerospace alloys that combines physical metallurgy with computational approaches. Their system features parallel synthesis capabilities including diffusion multiples, laser additive manufacturing with powder mixing gradients, and thin film deposition with composition spreads. IMR employs automated characterization techniques including high-speed EBSD mapping, synchrotron-based X-ray diffraction arrays, and mechanical property mapping via instrumented indentation. A distinctive aspect of their approach is the integration of high-throughput corrosion testing facilities that can evaluate environmental degradation across hundreds of compositions simultaneously. IMR has developed specialized high-temperature mechanical testing arrays for evaluating creep, fatigue, and oxidation resistance—critical properties for aerospace applications. Their platform incorporates advanced data analytics including machine learning algorithms that identify composition-processing-property relationships and guide experimental design. IMR has also implemented digital knowledge management systems that capture both successful and unsuccessful experiments to build comprehensive materials design rules.

Strengths: IMR's platform demonstrates exceptional capabilities in correlating microstructural features with mechanical properties across compositional gradients, enabling fundamental understanding of structure-property relationships. Their integration with China's advanced characterization infrastructure (synchrotrons, neutron sources) provides unique analytical capabilities. Weaknesses: Their system may have limitations in scaling up promising compositions to production volumes, and their focus on fundamental science sometimes extends development timelines compared to more application-driven approaches.

Critical Technologies in Aerospace Alloy HTE

Multi-component high entropy alloy with nanoscale atomic self-ordering structure and preparation methods thereof

PatentPendingUS20240344183A1

Innovation

- A multi-component high entropy alloy with a composition of Co, Ni, Cr, Al, Ti, Mo, and Nb is developed, featuring a nanoscale atomic self-ordering structure and a method involving selective laser melting to achieve high density and isotropic mechanical properties, overcoming the limitations of traditional superalloys.

High throughput screening method and apparatus for analysing interactions between surfaces with different topography and the environment

PatentInactiveEP2210096A1

Innovation

- A high-throughput screening method using a micro-array with multiple units of varying topography to analyze interactions between materials and environments, allowing for quick and efficient screening of materials and surface topographies for cellular and tissue compatibility, employing biocompatible materials like polymers and ceramics, and varying surface features such as porosity, roughness, and hydrophobicity.

Material Certification Standards for Aerospace Applications

The aerospace industry maintains exceptionally rigorous material certification standards due to the critical safety requirements and extreme operating conditions of aircraft components. For high-throughput experimentation (HTE) in metal alloys to gain acceptance in aerospace applications, compliance with these standards is non-negotiable. Currently, aerospace materials must meet specifications set by organizations such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), SAE International, and ASTM International.

These certification standards typically require extensive documentation of material properties, processing methods, and quality control measures. For instance, AMS (Aerospace Material Specifications) and MMPDS (Metallic Materials Properties Development and Standardization) provide detailed requirements for material qualification. The challenge for HTE approaches lies in demonstrating that rapidly developed alloys meet these stringent requirements, which traditionally involve time-consuming testing protocols.

Certification processes generally include mechanical property testing (tensile, fatigue, fracture toughness), environmental exposure tests (corrosion, temperature extremes), and microstructural analysis. These tests must be performed on statistically significant sample sizes and often require multiple production lots to establish consistency. HTE methods, which typically produce small sample volumes, face significant hurdles in generating sufficient material for these comprehensive test regimes.

Recent developments show promising pathways for integrating HTE with certification requirements. Digital certification approaches using computational models validated by targeted physical testing are gaining traction. Organizations like NASA and the Air Force Research Laboratory have initiated programs to accelerate material qualification through integrated computational materials engineering (ICME) approaches combined with strategic experimental validation.

Several aerospace primes, including Boeing and Airbus, have established internal protocols for evaluating materials developed through accelerated methods. These protocols typically involve correlation studies between traditional and accelerated testing methodologies to establish equivalence. Additionally, standards organizations are beginning to develop guidelines specifically addressing materials developed through combinatorial approaches.

For HTE to achieve broader acceptance, researchers must develop robust correlations between small-scale test results and full-scale component performance. This includes establishing clear traceability between high-throughput screening data and traditional certification metrics. Furthermore, statistical methods must be developed to quantify uncertainty in accelerated testing approaches, ensuring that safety margins remain conservative despite reduced testing volumes.

These certification standards typically require extensive documentation of material properties, processing methods, and quality control measures. For instance, AMS (Aerospace Material Specifications) and MMPDS (Metallic Materials Properties Development and Standardization) provide detailed requirements for material qualification. The challenge for HTE approaches lies in demonstrating that rapidly developed alloys meet these stringent requirements, which traditionally involve time-consuming testing protocols.

Certification processes generally include mechanical property testing (tensile, fatigue, fracture toughness), environmental exposure tests (corrosion, temperature extremes), and microstructural analysis. These tests must be performed on statistically significant sample sizes and often require multiple production lots to establish consistency. HTE methods, which typically produce small sample volumes, face significant hurdles in generating sufficient material for these comprehensive test regimes.

Recent developments show promising pathways for integrating HTE with certification requirements. Digital certification approaches using computational models validated by targeted physical testing are gaining traction. Organizations like NASA and the Air Force Research Laboratory have initiated programs to accelerate material qualification through integrated computational materials engineering (ICME) approaches combined with strategic experimental validation.

Several aerospace primes, including Boeing and Airbus, have established internal protocols for evaluating materials developed through accelerated methods. These protocols typically involve correlation studies between traditional and accelerated testing methodologies to establish equivalence. Additionally, standards organizations are beginning to develop guidelines specifically addressing materials developed through combinatorial approaches.

For HTE to achieve broader acceptance, researchers must develop robust correlations between small-scale test results and full-scale component performance. This includes establishing clear traceability between high-throughput screening data and traditional certification metrics. Furthermore, statistical methods must be developed to quantify uncertainty in accelerated testing approaches, ensuring that safety margins remain conservative despite reduced testing volumes.

Sustainability Considerations in Advanced Alloy Development

Sustainability has emerged as a critical consideration in the development of advanced metal alloys for aerospace applications, particularly as the industry faces increasing pressure to reduce environmental impact while maintaining performance standards. High-throughput experimentation (HTE) methodologies offer unique opportunities to incorporate sustainability metrics into alloy design and optimization processes from the earliest stages of development.

The aerospace industry's material sustainability challenges stem from multiple factors: resource scarcity of critical elements like rhenium and cobalt, energy-intensive manufacturing processes, and end-of-life recycling complexities. HTE platforms can systematically evaluate alternative compositions that reduce or eliminate critical raw materials while maintaining essential performance characteristics. This approach enables researchers to rapidly screen hundreds of compositions with varying percentages of more abundant and less environmentally problematic elements.

Energy consumption represents another significant sustainability concern in aerospace alloy production. HTE techniques allow for the optimization of processing parameters that minimize energy requirements during manufacturing. By creating processing-structure-property relationship maps across numerous compositions simultaneously, researchers can identify alloys that require lower melting temperatures, shorter heat treatment cycles, or fewer processing steps, thereby reducing the carbon footprint of production operations.

Recyclability and circular economy principles are increasingly integrated into aerospace materials development. HTE methodologies facilitate the evaluation of alloy designs specifically optimized for disassembly and material recovery. This includes testing compositions with reduced number of alloying elements or avoiding combinations that make separation difficult during recycling. The ability to rapidly test recycled material feedstock performance across multiple composition variants represents a particularly valuable application of HTE in sustainability-focused research.

Life cycle assessment (LCA) metrics can be incorporated into HTE screening protocols, allowing sustainability factors to be weighted alongside traditional performance parameters. This holistic approach ensures that environmental considerations become selection criteria rather than afterthoughts. Advanced data analytics and machine learning algorithms applied to HTE datasets can identify unexpected correlations between composition, processing, performance, and sustainability metrics, potentially revealing novel eco-friendly alloy solutions that might otherwise remain undiscovered.

The integration of sustainability considerations into HTE frameworks requires collaborative efforts between materials scientists, environmental engineers, and aerospace industry stakeholders. Standardized sustainability metrics specific to aerospace alloys are being developed to enable meaningful comparisons across different material systems and processing routes. As these metrics mature, they will increasingly guide high-throughput experimentation campaigns toward more environmentally responsible innovation pathways in advanced aerospace alloy development.

The aerospace industry's material sustainability challenges stem from multiple factors: resource scarcity of critical elements like rhenium and cobalt, energy-intensive manufacturing processes, and end-of-life recycling complexities. HTE platforms can systematically evaluate alternative compositions that reduce or eliminate critical raw materials while maintaining essential performance characteristics. This approach enables researchers to rapidly screen hundreds of compositions with varying percentages of more abundant and less environmentally problematic elements.

Energy consumption represents another significant sustainability concern in aerospace alloy production. HTE techniques allow for the optimization of processing parameters that minimize energy requirements during manufacturing. By creating processing-structure-property relationship maps across numerous compositions simultaneously, researchers can identify alloys that require lower melting temperatures, shorter heat treatment cycles, or fewer processing steps, thereby reducing the carbon footprint of production operations.

Recyclability and circular economy principles are increasingly integrated into aerospace materials development. HTE methodologies facilitate the evaluation of alloy designs specifically optimized for disassembly and material recovery. This includes testing compositions with reduced number of alloying elements or avoiding combinations that make separation difficult during recycling. The ability to rapidly test recycled material feedstock performance across multiple composition variants represents a particularly valuable application of HTE in sustainability-focused research.

Life cycle assessment (LCA) metrics can be incorporated into HTE screening protocols, allowing sustainability factors to be weighted alongside traditional performance parameters. This holistic approach ensures that environmental considerations become selection criteria rather than afterthoughts. Advanced data analytics and machine learning algorithms applied to HTE datasets can identify unexpected correlations between composition, processing, performance, and sustainability metrics, potentially revealing novel eco-friendly alloy solutions that might otherwise remain undiscovered.

The integration of sustainability considerations into HTE frameworks requires collaborative efforts between materials scientists, environmental engineers, and aerospace industry stakeholders. Standardized sustainability metrics specific to aerospace alloys are being developed to enable meaningful comparisons across different material systems and processing routes. As these metrics mature, they will increasingly guide high-throughput experimentation campaigns toward more environmentally responsible innovation pathways in advanced aerospace alloy development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!