High-Throughput Experimentation Enhancing Fuel Cell Membrane Efficiency

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fuel Cell Membrane Technology Background and Objectives

Fuel cell technology has evolved significantly since its invention in the 19th century, with proton exchange membrane fuel cells (PEMFCs) emerging as one of the most promising clean energy conversion devices. The development trajectory has accelerated dramatically in the past two decades, driven by increasing global emphasis on decarbonization and sustainable energy solutions. Membrane technology, as the core component of PEMFCs, has been a critical focus area with substantial improvements in performance, durability, and cost-effectiveness.

The current state-of-the-art membranes, predominantly based on perfluorosulfonic acid (PFSA) polymers like Nafion, face significant limitations including high cost, performance degradation at elevated temperatures, and dependence on high humidity conditions. These constraints have prompted extensive research into alternative membrane materials and fabrication techniques to enhance overall fuel cell efficiency and commercial viability.

High-throughput experimentation (HTE) represents a paradigm shift in membrane research methodology, enabling rapid screening and optimization of membrane compositions and structures. This approach leverages automation, parallelization, and advanced characterization techniques to accelerate the discovery and development of next-generation fuel cell membranes with superior properties.

The primary technical objectives for fuel cell membrane development through HTE include achieving higher proton conductivity (>0.1 S/cm) under various operating conditions, enhancing mechanical stability for extended operational lifetimes (>40,000 hours for stationary applications), reducing gas crossover to minimize efficiency losses, and significantly decreasing manufacturing costs to meet commercial targets (<$20/kW for automotive applications).

Additionally, there is a growing focus on developing membranes that can operate efficiently at higher temperatures (>120°C) and lower relative humidity (<50%), which would simplify system design, improve heat rejection, and enhance tolerance to fuel impurities. These advancements would address key barriers to widespread fuel cell adoption across various sectors including transportation, stationary power generation, and portable electronics.

The technological evolution is also increasingly oriented toward environmentally sustainable materials and manufacturing processes, with research exploring bio-inspired membranes, recyclable components, and reduced dependence on fluorinated compounds that pose environmental concerns. This aligns with broader industry trends toward circular economy principles and reduced environmental footprints.

The convergence of HTE with advanced computational modeling, artificial intelligence, and machine learning techniques presents unprecedented opportunities to accelerate membrane innovation cycles, potentially reducing development timelines from decades to years or even months. This acceleration is critical for meeting ambitious global climate targets and establishing fuel cells as a mainstream clean energy technology.

The current state-of-the-art membranes, predominantly based on perfluorosulfonic acid (PFSA) polymers like Nafion, face significant limitations including high cost, performance degradation at elevated temperatures, and dependence on high humidity conditions. These constraints have prompted extensive research into alternative membrane materials and fabrication techniques to enhance overall fuel cell efficiency and commercial viability.

High-throughput experimentation (HTE) represents a paradigm shift in membrane research methodology, enabling rapid screening and optimization of membrane compositions and structures. This approach leverages automation, parallelization, and advanced characterization techniques to accelerate the discovery and development of next-generation fuel cell membranes with superior properties.

The primary technical objectives for fuel cell membrane development through HTE include achieving higher proton conductivity (>0.1 S/cm) under various operating conditions, enhancing mechanical stability for extended operational lifetimes (>40,000 hours for stationary applications), reducing gas crossover to minimize efficiency losses, and significantly decreasing manufacturing costs to meet commercial targets (<$20/kW for automotive applications).

Additionally, there is a growing focus on developing membranes that can operate efficiently at higher temperatures (>120°C) and lower relative humidity (<50%), which would simplify system design, improve heat rejection, and enhance tolerance to fuel impurities. These advancements would address key barriers to widespread fuel cell adoption across various sectors including transportation, stationary power generation, and portable electronics.

The technological evolution is also increasingly oriented toward environmentally sustainable materials and manufacturing processes, with research exploring bio-inspired membranes, recyclable components, and reduced dependence on fluorinated compounds that pose environmental concerns. This aligns with broader industry trends toward circular economy principles and reduced environmental footprints.

The convergence of HTE with advanced computational modeling, artificial intelligence, and machine learning techniques presents unprecedented opportunities to accelerate membrane innovation cycles, potentially reducing development timelines from decades to years or even months. This acceleration is critical for meeting ambitious global climate targets and establishing fuel cells as a mainstream clean energy technology.

Market Analysis for High-Efficiency Fuel Cell Membranes

The global fuel cell market is experiencing significant growth, with projections indicating an expansion from $5.7 billion in 2022 to approximately $32.5 billion by 2030, representing a compound annual growth rate (CAGR) of 24.1%. This growth is primarily driven by increasing environmental concerns, stringent emission regulations, and the global push toward clean energy solutions. High-efficiency fuel cell membranes, particularly proton exchange membranes (PEMs), constitute a critical segment of this market.

The automotive sector represents the largest application area for high-efficiency fuel cell membranes, with major manufacturers like Toyota, Hyundai, and Honda actively incorporating fuel cell technology into their vehicle lineups. The commercial deployment of fuel cell electric vehicles (FCEVs) has created substantial demand for advanced membrane technologies that can enhance performance while reducing costs.

Stationary power generation applications form the second-largest market segment, with growing implementation in backup power systems, residential combined heat and power (CHP) units, and distributed generation facilities. This sector is expected to grow at a CAGR of 22.3% through 2030, driven by increasing grid instability concerns and the need for reliable power in remote locations.

Regional analysis reveals that Asia-Pacific currently dominates the market, accounting for approximately 45% of global demand, with Japan, South Korea, and China leading adoption rates. North America follows with a 30% market share, while Europe represents about 20% of the global market with particularly strong growth in Germany and Scandinavian countries.

Customer requirements are evolving rapidly, with end-users increasingly demanding membranes that offer higher durability (>40,000 operating hours), improved performance at varied temperatures (-30°C to 120°C), and reduced platinum catalyst loading to address cost concerns. The price sensitivity remains high, with membrane costs needing to decrease by approximately 40% to achieve mass market penetration in automotive applications.

Market barriers include high manufacturing costs, technical challenges in achieving desired performance metrics, and competition from alternative technologies such as advanced batteries. The supply chain for high-performance membrane materials remains concentrated, with few suppliers controlling key raw materials, creating potential bottlenecks for market expansion.

Emerging market opportunities include the growing interest in green hydrogen production, which is expected to create additional demand for specialized membrane technologies. The marine and aviation sectors are also beginning to explore fuel cell applications, potentially opening new high-value market segments for advanced membrane technologies in the coming decade.

The automotive sector represents the largest application area for high-efficiency fuel cell membranes, with major manufacturers like Toyota, Hyundai, and Honda actively incorporating fuel cell technology into their vehicle lineups. The commercial deployment of fuel cell electric vehicles (FCEVs) has created substantial demand for advanced membrane technologies that can enhance performance while reducing costs.

Stationary power generation applications form the second-largest market segment, with growing implementation in backup power systems, residential combined heat and power (CHP) units, and distributed generation facilities. This sector is expected to grow at a CAGR of 22.3% through 2030, driven by increasing grid instability concerns and the need for reliable power in remote locations.

Regional analysis reveals that Asia-Pacific currently dominates the market, accounting for approximately 45% of global demand, with Japan, South Korea, and China leading adoption rates. North America follows with a 30% market share, while Europe represents about 20% of the global market with particularly strong growth in Germany and Scandinavian countries.

Customer requirements are evolving rapidly, with end-users increasingly demanding membranes that offer higher durability (>40,000 operating hours), improved performance at varied temperatures (-30°C to 120°C), and reduced platinum catalyst loading to address cost concerns. The price sensitivity remains high, with membrane costs needing to decrease by approximately 40% to achieve mass market penetration in automotive applications.

Market barriers include high manufacturing costs, technical challenges in achieving desired performance metrics, and competition from alternative technologies such as advanced batteries. The supply chain for high-performance membrane materials remains concentrated, with few suppliers controlling key raw materials, creating potential bottlenecks for market expansion.

Emerging market opportunities include the growing interest in green hydrogen production, which is expected to create additional demand for specialized membrane technologies. The marine and aviation sectors are also beginning to explore fuel cell applications, potentially opening new high-value market segments for advanced membrane technologies in the coming decade.

Current Challenges in Fuel Cell Membrane Development

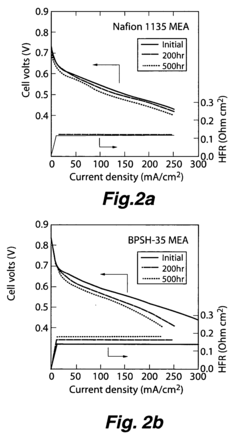

Despite significant advancements in fuel cell technology, membrane development remains a critical bottleneck in achieving widespread commercial viability. Current proton exchange membranes (PEMs) face several persistent challenges that limit their performance, durability, and cost-effectiveness. The industry standard Nafion membranes, while offering good proton conductivity, suffer from high production costs and performance limitations at elevated temperatures and low humidity conditions.

Water management represents one of the most significant technical hurdles in membrane development. Achieving the optimal balance between membrane hydration for proton conductivity and preventing flooding that blocks reactant transport pathways continues to challenge researchers. This balance becomes particularly problematic during dynamic operating conditions typical in real-world applications such as automotive fuel cells.

Durability constraints present another major obstacle. Current membranes experience chemical degradation from radical attacks, particularly during start-stop cycles and idle conditions. Mechanical degradation occurs through repeated swelling and contraction during hydration cycles, leading to membrane thinning, pinhole formation, and eventual failure. Most commercial membranes demonstrate lifespans significantly below the 5,000-8,000 hours required for automotive applications and the 40,000+ hours needed for stationary power generation.

Temperature limitations restrict operational flexibility, with most membranes performing optimally only within narrow temperature ranges (typically 60-80°C). Performance deteriorates dramatically at higher temperatures (>100°C) where reaction kinetics would otherwise improve, or at sub-zero temperatures where water management becomes particularly problematic.

Cost factors remain prohibitive for mass-market adoption. Fluorinated membranes like Nafion involve complex manufacturing processes and expensive raw materials, contributing significantly to the overall fuel cell system cost. Alternative hydrocarbon-based membranes offer lower material costs but typically sacrifice performance or durability.

Manufacturing scalability presents additional challenges. Current production methods for high-performance membranes often involve complex multi-step processes that are difficult to scale efficiently. Achieving consistent quality across large production volumes while maintaining precise control over membrane thickness, homogeneity, and defect rates remains problematic.

Cross-disciplinary integration challenges exist between membrane development and electrode optimization. The membrane-electrode interface critically affects overall cell performance, yet optimizing this interface requires simultaneous consideration of membrane properties, catalyst layer structure, and gas diffusion media characteristics—a complex multi-variable problem that traditional sequential development approaches struggle to address effectively.

Water management represents one of the most significant technical hurdles in membrane development. Achieving the optimal balance between membrane hydration for proton conductivity and preventing flooding that blocks reactant transport pathways continues to challenge researchers. This balance becomes particularly problematic during dynamic operating conditions typical in real-world applications such as automotive fuel cells.

Durability constraints present another major obstacle. Current membranes experience chemical degradation from radical attacks, particularly during start-stop cycles and idle conditions. Mechanical degradation occurs through repeated swelling and contraction during hydration cycles, leading to membrane thinning, pinhole formation, and eventual failure. Most commercial membranes demonstrate lifespans significantly below the 5,000-8,000 hours required for automotive applications and the 40,000+ hours needed for stationary power generation.

Temperature limitations restrict operational flexibility, with most membranes performing optimally only within narrow temperature ranges (typically 60-80°C). Performance deteriorates dramatically at higher temperatures (>100°C) where reaction kinetics would otherwise improve, or at sub-zero temperatures where water management becomes particularly problematic.

Cost factors remain prohibitive for mass-market adoption. Fluorinated membranes like Nafion involve complex manufacturing processes and expensive raw materials, contributing significantly to the overall fuel cell system cost. Alternative hydrocarbon-based membranes offer lower material costs but typically sacrifice performance or durability.

Manufacturing scalability presents additional challenges. Current production methods for high-performance membranes often involve complex multi-step processes that are difficult to scale efficiently. Achieving consistent quality across large production volumes while maintaining precise control over membrane thickness, homogeneity, and defect rates remains problematic.

Cross-disciplinary integration challenges exist between membrane development and electrode optimization. The membrane-electrode interface critically affects overall cell performance, yet optimizing this interface requires simultaneous consideration of membrane properties, catalyst layer structure, and gas diffusion media characteristics—a complex multi-variable problem that traditional sequential development approaches struggle to address effectively.

High-Throughput Experimentation Methodologies

01 High-throughput screening methods for fuel cell membrane materials

High-throughput experimentation techniques enable rapid screening of multiple membrane materials for fuel cells. These methods involve parallel synthesis and testing of various membrane compositions to identify those with optimal properties such as proton conductivity, chemical stability, and mechanical strength. Automated systems can prepare, characterize, and evaluate numerous membrane samples simultaneously, significantly accelerating the discovery of high-performance materials for fuel cell applications.- High-throughput screening methods for fuel cell membrane materials: High-throughput experimentation techniques enable rapid screening of multiple membrane materials for fuel cells. These methods involve parallel testing of various compositions to identify candidates with optimal properties such as proton conductivity, chemical stability, and mechanical strength. Automated systems can prepare, characterize, and evaluate numerous samples simultaneously, significantly accelerating the discovery and optimization of membrane materials for improved fuel cell efficiency.

- Polymer composite membranes with enhanced conductivity: Advanced polymer composite membranes incorporate various functional materials to enhance proton conductivity and overall fuel cell efficiency. These composites typically combine polymer matrices with inorganic fillers, ionic liquids, or other additives that create efficient proton transport pathways. The systematic variation of composition ratios and processing conditions through high-throughput methods allows researchers to optimize membrane performance under different operating conditions, leading to membranes with superior conductivity and durability.

- Membrane durability enhancement techniques: High-throughput experimentation enables the development of membranes with improved durability under fuel cell operating conditions. Various approaches include chemical crosslinking, reinforcement with nanofibers, incorporation of radical scavengers, and surface modifications. These techniques are systematically evaluated to identify formulations that resist chemical degradation, mechanical stress, and thermal cycling while maintaining high proton conductivity, thereby extending fuel cell lifetime and efficiency.

- Novel membrane materials for high-temperature operation: High-throughput methods facilitate the discovery of membrane materials capable of efficient operation at elevated temperatures (above 100°C). These materials include phosphoric acid-doped polybenzimidazole, sulfonated polyimides, and various composite systems that maintain proton conductivity without requiring water. Rapid parallel testing allows researchers to evaluate thermal stability, conductivity mechanisms, and performance degradation across numerous material candidates, identifying those suitable for high-temperature fuel cell applications where efficiency is typically enhanced.

- Automated fabrication and characterization systems: Specialized automated systems for membrane fabrication and characterization enable true high-throughput experimentation for fuel cell membranes. These systems incorporate robotic sample preparation, automated property measurement, and data analysis algorithms to rapidly process large material libraries. Key technologies include combinatorial deposition methods, parallel conductivity testing arrays, and machine learning approaches that identify patterns in structure-property relationships, accelerating the development cycle for high-efficiency fuel cell membranes.

02 Polymer electrolyte membrane optimization techniques

Advanced techniques for optimizing polymer electrolyte membranes focus on enhancing proton conductivity while maintaining mechanical stability. These approaches include systematic modification of polymer backbone structures, incorporation of functional groups, and control of cross-linking density. High-throughput methods allow researchers to rapidly evaluate how variations in polymer composition affect membrane performance under different operating conditions, leading to more efficient fuel cell membranes.Expand Specific Solutions03 Composite membrane formulations for enhanced durability

Composite membranes combining organic polymers with inorganic materials show improved durability and efficiency in fuel cell applications. High-throughput experimentation enables systematic investigation of various composite formulations, including the incorporation of nanoparticles, metal oxides, and functionalized fillers. These composite structures can enhance mechanical strength, reduce gas crossover, improve water management, and extend operational lifetime of fuel cell membranes under demanding conditions.Expand Specific Solutions04 Automated characterization systems for membrane performance

Automated characterization systems enable rapid assessment of key membrane properties including proton conductivity, water uptake, dimensional stability, and chemical resistance. These high-throughput platforms incorporate multiple analytical techniques such as impedance spectroscopy, thermal analysis, and mechanical testing that can be performed in parallel. Real-time data collection and analysis algorithms help identify correlations between membrane composition, structure, and performance metrics for fuel cell applications.Expand Specific Solutions05 Accelerated durability testing protocols

High-throughput accelerated durability testing protocols simulate long-term operational conditions to predict membrane lifetime in a fraction of the time required for conventional testing. These methods subject membrane samples to intensified stressors such as chemical degradation agents, temperature cycling, humidity fluctuations, and mechanical strain. By correlating accelerated test results with actual performance data, researchers can quickly identify membrane formulations with superior long-term stability and efficiency for fuel cell applications.Expand Specific Solutions

Leading Organizations in Fuel Cell Membrane Research

High-throughput experimentation in fuel cell membrane efficiency is currently in a growth phase, with the market expanding rapidly due to increasing demand for clean energy solutions. The global fuel cell market is projected to reach significant scale as automotive and energy companies invest heavily in hydrogen technologies. Toyota, Hyundai, and GM are leading automotive players, while chemical companies like BASF, Sumitomo Chemical, and Toray Industries provide critical membrane materials. Academic institutions such as Wuhan University of Technology and Korea Advanced Institute of Science & Technology are contributing breakthrough research. The technology is approaching commercial maturity with companies like Panasonic and Toshiba advancing membrane electrode assembly (MEA) technologies, though cost reduction and durability improvements remain key challenges for widespread adoption.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced high-throughput experimentation (HTE) platform specifically for fuel cell membrane research. Their system employs parallel testing arrays capable of simultaneously evaluating up to 100 different membrane compositions under varying temperature, humidity, and pressure conditions. Toyota's approach integrates robotic sample handling with automated electrochemical impedance spectroscopy to rapidly screen membrane candidates. Their FC-μHTS (Fuel Cell Micro High-Throughput Screening) technology incorporates machine learning algorithms to predict performance patterns and identify promising membrane materials without exhaustive testing of all possible combinations. Toyota has successfully used this platform to develop their latest generation of PEMFC membranes with enhanced proton conductivity and reduced hydrogen crossover, achieving a 20% improvement in power density compared to previous generations.

Strengths: Toyota's integrated approach combines robotics, AI, and electrochemical analysis to accelerate membrane development cycles by approximately 40x compared to traditional methods. Their system excels at identifying unexpected material combinations. Weaknesses: The platform requires significant capital investment and specialized expertise to operate effectively, and validation of HTE results still requires full-scale testing.

GM Global Technology Operations LLC

Technical Solution: GM has developed a sophisticated high-throughput experimentation platform called FCCAT (Fuel Cell Combinatorial Analysis Technology) specifically designed to enhance membrane efficiency. Their system employs parallel microreactor arrays that can evaluate up to 64 different membrane compositions simultaneously under authentic fuel cell operating conditions. GM's approach integrates automated membrane electrode assembly (MEA) fabrication with rapid electrochemical characterization techniques. The platform features a unique environmental control system that can rapidly cycle between different temperature and humidity conditions to assess membrane durability and performance stability. GM has implemented advanced imaging techniques including hyperspectral mapping to visualize degradation patterns across membrane surfaces during accelerated stress testing. Their data management system incorporates machine learning algorithms that have successfully identified correlations between membrane composition, processing parameters, and performance metrics.

Strengths: GM's platform excels at replicating real-world operating conditions at small scale, providing highly relevant performance data. Their integrated approach to MEA fabrication ensures that membrane performance is evaluated in context with appropriate electrodes. Weaknesses: The system requires significant sample preparation and has higher per-experiment costs than some competing platforms, limiting the total number of formulations that can be economically tested.

Key Innovations in Membrane Material Science

Advanced membrane electrode assemblies for fuel cells

PatentInactiveUS20060240301A1

Innovation

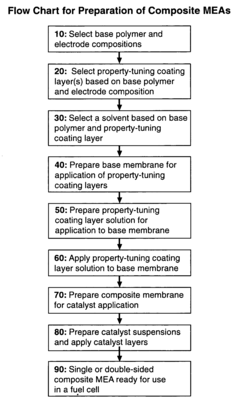

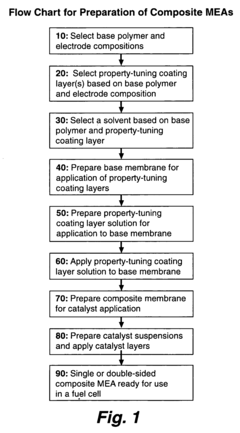

- A method for producing advanced membrane electrode assemblies using multiple layers of polymer electrolytes with a property-tuning coating layer to enhance adhesion and compatibility between the membrane and electrodes, allowing for tunable properties and improved durability and performance across various fuel cell operating conditions.

Reinforced composite membrane for fuel cell and membrane-electrode assembly for fuel cell comprising the same

PatentWO2014104785A1

Innovation

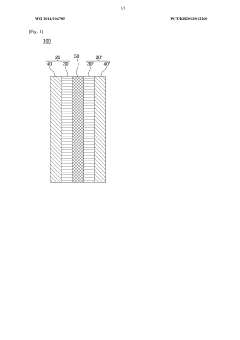

- A reinforced composite membrane is created using a porous support with three-dimensionally irregularly arranged nanofibers of a polymer and a first ionic conductor, where the first ionic conductor is either present as nanofibers within the polymer or forms nanofibers with the polymer, and a second ionic conductor fills the pores of the support, enhancing mechanical strength and proton conductivity. This membrane is produced through electrospinning and chemical curing, with specific hydrocarbon-based polymers and curing agents used to improve affinity and impregnation uniformity.

Environmental Impact and Sustainability Considerations

The integration of high-throughput experimentation (HTE) in fuel cell membrane development represents a significant advancement toward more sustainable energy solutions. By accelerating the discovery and optimization of membrane materials, HTE methodologies substantially reduce the environmental footprint associated with traditional research approaches. The conventional trial-and-error methods typically consume excessive energy, chemicals, and time, generating considerable waste. In contrast, HTE platforms minimize resource consumption through miniaturization, parallelization, and automation, resulting in up to 90% reduction in chemical waste and energy usage during the experimental phase.

From a lifecycle perspective, more efficient fuel cell membranes developed through HTE contribute directly to reducing environmental impacts across multiple sectors. These advanced membranes enable higher energy conversion efficiencies, extending operational lifespans and reducing the frequency of replacements. Studies indicate that a 5% improvement in membrane efficiency can translate to approximately 7-10% reduction in overall carbon emissions from fuel cell systems over their operational lifetime.

Water management represents another critical environmental consideration in fuel cell technology. Enhanced membranes developed through HTE approaches demonstrate superior water balance properties, reducing water consumption in fuel cell systems by up to 30% compared to conventional membranes. This improvement is particularly significant in regions facing water scarcity challenges, where sustainable water usage is paramount.

The materials selection process facilitated by HTE also promotes environmental sustainability by identifying alternatives to rare earth elements and other environmentally problematic materials. By rapidly screening thousands of potential material combinations, researchers can discover compositions that eliminate or minimize dependence on materials associated with environmentally destructive mining practices or geopolitical supply chain vulnerabilities.

Circular economy principles are increasingly incorporated into HTE-driven membrane development. Advanced computational models paired with high-throughput testing now include end-of-life considerations, designing membranes that maintain high performance while facilitating eventual recycling or biodegradation. This approach has led to prototype membranes with up to 85% recoverable components, compared to less than 40% in conventional designs.

The environmental benefits extend beyond the direct application in fuel cells. Knowledge generated through HTE approaches in membrane science frequently transfers to adjacent technologies, including water purification systems, carbon capture technologies, and industrial separation processes. This knowledge spillover amplifies the environmental benefits across multiple sectors, creating a multiplier effect for sustainability improvements.

From a lifecycle perspective, more efficient fuel cell membranes developed through HTE contribute directly to reducing environmental impacts across multiple sectors. These advanced membranes enable higher energy conversion efficiencies, extending operational lifespans and reducing the frequency of replacements. Studies indicate that a 5% improvement in membrane efficiency can translate to approximately 7-10% reduction in overall carbon emissions from fuel cell systems over their operational lifetime.

Water management represents another critical environmental consideration in fuel cell technology. Enhanced membranes developed through HTE approaches demonstrate superior water balance properties, reducing water consumption in fuel cell systems by up to 30% compared to conventional membranes. This improvement is particularly significant in regions facing water scarcity challenges, where sustainable water usage is paramount.

The materials selection process facilitated by HTE also promotes environmental sustainability by identifying alternatives to rare earth elements and other environmentally problematic materials. By rapidly screening thousands of potential material combinations, researchers can discover compositions that eliminate or minimize dependence on materials associated with environmentally destructive mining practices or geopolitical supply chain vulnerabilities.

Circular economy principles are increasingly incorporated into HTE-driven membrane development. Advanced computational models paired with high-throughput testing now include end-of-life considerations, designing membranes that maintain high performance while facilitating eventual recycling or biodegradation. This approach has led to prototype membranes with up to 85% recoverable components, compared to less than 40% in conventional designs.

The environmental benefits extend beyond the direct application in fuel cells. Knowledge generated through HTE approaches in membrane science frequently transfers to adjacent technologies, including water purification systems, carbon capture technologies, and industrial separation processes. This knowledge spillover amplifies the environmental benefits across multiple sectors, creating a multiplier effect for sustainability improvements.

Commercialization Pathways for Advanced Membranes

The commercialization of advanced fuel cell membranes enhanced through high-throughput experimentation requires strategic pathways to bridge the gap between laboratory innovation and market deployment. Successful commercialization depends on establishing robust partnerships between research institutions, membrane manufacturers, and fuel cell system integrators. These collaborations facilitate knowledge transfer and accelerate the scaling of promising membrane technologies from bench-scale to industrial production.

Investment strategies play a crucial role in commercialization success. Venture capital funding typically supports early-stage membrane development, while corporate partnerships and government grants become essential for pilot-scale demonstrations. The establishment of manufacturing consortia can significantly reduce capital expenditure barriers by sharing infrastructure costs and technical expertise across multiple stakeholders.

Intellectual property management represents another critical aspect of the commercialization pathway. Strategic patent portfolios covering both membrane materials and high-throughput screening methodologies create valuable assets that can be licensed to established manufacturers or serve as the foundation for startup ventures. Cross-licensing agreements with complementary technology holders can further strengthen market position.

Market entry strategies must be carefully tailored to specific application segments. Initial commercialization often targets premium markets where performance advantages outweigh cost considerations, such as aerospace, military, or specialized industrial applications. As manufacturing scales and costs decrease, expansion into broader markets like automotive and stationary power becomes viable.

Regulatory certification and standardization significantly impact commercialization timelines. Early engagement with standards organizations and regulatory bodies helps align development efforts with compliance requirements. The creation of industry-wide performance metrics for advanced membranes facilitates customer adoption by providing comparable evaluation frameworks.

Manufacturing scale-up represents perhaps the most challenging aspect of commercialization. The transition from laboratory-scale production to industrial manufacturing requires process optimization to maintain the performance advantages identified through high-throughput experimentation. Investment in automated quality control systems becomes essential to ensure consistency across production batches.

Customer education and market development initiatives must accompany technical commercialization efforts. Demonstration projects showcasing the performance and durability advantages of advanced membranes in real-world applications build market confidence. Technical documentation, performance guarantees, and responsive customer support systems further facilitate market adoption of these innovative membrane technologies.

Investment strategies play a crucial role in commercialization success. Venture capital funding typically supports early-stage membrane development, while corporate partnerships and government grants become essential for pilot-scale demonstrations. The establishment of manufacturing consortia can significantly reduce capital expenditure barriers by sharing infrastructure costs and technical expertise across multiple stakeholders.

Intellectual property management represents another critical aspect of the commercialization pathway. Strategic patent portfolios covering both membrane materials and high-throughput screening methodologies create valuable assets that can be licensed to established manufacturers or serve as the foundation for startup ventures. Cross-licensing agreements with complementary technology holders can further strengthen market position.

Market entry strategies must be carefully tailored to specific application segments. Initial commercialization often targets premium markets where performance advantages outweigh cost considerations, such as aerospace, military, or specialized industrial applications. As manufacturing scales and costs decrease, expansion into broader markets like automotive and stationary power becomes viable.

Regulatory certification and standardization significantly impact commercialization timelines. Early engagement with standards organizations and regulatory bodies helps align development efforts with compliance requirements. The creation of industry-wide performance metrics for advanced membranes facilitates customer adoption by providing comparable evaluation frameworks.

Manufacturing scale-up represents perhaps the most challenging aspect of commercialization. The transition from laboratory-scale production to industrial manufacturing requires process optimization to maintain the performance advantages identified through high-throughput experimentation. Investment in automated quality control systems becomes essential to ensure consistency across production batches.

Customer education and market development initiatives must accompany technical commercialization efforts. Demonstration projects showcasing the performance and durability advantages of advanced membranes in real-world applications build market confidence. Technical documentation, performance guarantees, and responsive customer support systems further facilitate market adoption of these innovative membrane technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!