High-Throughput Experimentation in Bio-based Material Innovation

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Materials HTE Background and Objectives

High-throughput experimentation (HTE) has emerged as a transformative approach in materials science, enabling rapid synthesis, characterization, and testing of multiple material variants simultaneously. In the context of bio-based materials, this methodology represents a paradigm shift from traditional trial-and-error approaches that have historically dominated the field. The evolution of HTE in bio-based materials research can be traced back to early automated systems in the pharmaceutical industry, which have been progressively adapted for materials science applications over the past two decades.

The bio-based materials sector has witnessed significant growth driven by increasing environmental concerns, regulatory pressures, and consumer demand for sustainable alternatives to petroleum-derived products. However, the inherent complexity and variability of biological feedstocks present unique challenges that conventional research methodologies struggle to address efficiently. The development timeline for new bio-based materials has traditionally been lengthy, often requiring 5-10 years from concept to commercialization.

HTE technologies offer a promising solution by enabling researchers to explore vast compositional and processing parameter spaces at unprecedented speeds. The integration of robotics, advanced analytics, and machine learning algorithms has further enhanced the capabilities of HTE platforms, allowing for intelligent experimental design and data-driven decision making. Recent advancements in miniaturization and parallelization have made it possible to conduct thousands of experiments simultaneously while consuming minimal resources.

The primary objectives of implementing HTE in bio-based material innovation are multifaceted. First, to accelerate the discovery and optimization of novel bio-based materials with performance characteristics that match or exceed their petroleum-based counterparts. Second, to establish structure-property relationships that provide fundamental insights into how molecular architecture influences macroscopic properties in bio-based systems. Third, to develop predictive models that can guide future experimental efforts and reduce reliance on empirical approaches.

Additionally, HTE aims to address the scalability challenges that have historically plagued bio-based materials development. By rapidly identifying promising candidates and optimizing processing conditions at small scales, researchers can more confidently transition to pilot and industrial-scale production. This approach significantly reduces the resource investment required for scale-up efforts and increases the likelihood of successful commercialization.

The convergence of HTE with other emerging technologies, such as synthetic biology and advanced computational modeling, presents unprecedented opportunities for bio-based materials innovation. As these methodologies continue to evolve, they promise to revolutionize how we discover, develop, and deploy sustainable materials across various industrial sectors, from packaging and consumer goods to construction and transportation.

The bio-based materials sector has witnessed significant growth driven by increasing environmental concerns, regulatory pressures, and consumer demand for sustainable alternatives to petroleum-derived products. However, the inherent complexity and variability of biological feedstocks present unique challenges that conventional research methodologies struggle to address efficiently. The development timeline for new bio-based materials has traditionally been lengthy, often requiring 5-10 years from concept to commercialization.

HTE technologies offer a promising solution by enabling researchers to explore vast compositional and processing parameter spaces at unprecedented speeds. The integration of robotics, advanced analytics, and machine learning algorithms has further enhanced the capabilities of HTE platforms, allowing for intelligent experimental design and data-driven decision making. Recent advancements in miniaturization and parallelization have made it possible to conduct thousands of experiments simultaneously while consuming minimal resources.

The primary objectives of implementing HTE in bio-based material innovation are multifaceted. First, to accelerate the discovery and optimization of novel bio-based materials with performance characteristics that match or exceed their petroleum-based counterparts. Second, to establish structure-property relationships that provide fundamental insights into how molecular architecture influences macroscopic properties in bio-based systems. Third, to develop predictive models that can guide future experimental efforts and reduce reliance on empirical approaches.

Additionally, HTE aims to address the scalability challenges that have historically plagued bio-based materials development. By rapidly identifying promising candidates and optimizing processing conditions at small scales, researchers can more confidently transition to pilot and industrial-scale production. This approach significantly reduces the resource investment required for scale-up efforts and increases the likelihood of successful commercialization.

The convergence of HTE with other emerging technologies, such as synthetic biology and advanced computational modeling, presents unprecedented opportunities for bio-based materials innovation. As these methodologies continue to evolve, they promise to revolutionize how we discover, develop, and deploy sustainable materials across various industrial sectors, from packaging and consumer goods to construction and transportation.

Market Analysis for Bio-based Materials

The global market for bio-based materials has experienced significant growth in recent years, driven by increasing environmental concerns, regulatory pressures, and consumer demand for sustainable products. The market value reached approximately $95 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.2% through 2030, potentially reaching $160 billion by the end of the decade.

Several key sectors are driving this growth. The packaging industry represents the largest application segment, accounting for nearly 30% of the bio-based materials market. This is followed by construction materials (22%), automotive components (18%), consumer goods (15%), and other applications including agriculture, electronics, and medical devices making up the remainder.

Regionally, Europe leads the market with approximately 35% share, supported by stringent regulations promoting sustainable materials and circular economy principles. North America follows at 28%, while Asia-Pacific represents the fastest-growing region with a CAGR exceeding 9%, driven primarily by rapid industrialization in China, Japan, and South Korea.

Consumer preferences are shifting dramatically toward sustainable products, with recent surveys indicating that over 65% of global consumers are willing to pay premium prices for environmentally friendly alternatives. This trend is particularly pronounced among millennials and Gen Z consumers, who demonstrate the highest preference for bio-based products.

Regulatory frameworks worldwide are increasingly favorable for bio-based materials. The European Union's Circular Economy Action Plan and Bioeconomy Strategy have established targets for reducing plastic waste and promoting bio-based alternatives. Similarly, the United States has implemented tax incentives for companies developing sustainable materials, while China's 14th Five-Year Plan emphasizes green development including bio-based material innovation.

Investment in the sector has surged, with venture capital funding for bio-based material startups reaching $3.2 billion in 2022, a 40% increase from the previous year. Major chemical and material companies are also reallocating R&D budgets toward bio-based innovations, with an average increase of 15-20% in sustainable material research spending.

Despite positive growth indicators, challenges remain. Price competitiveness continues to be a significant barrier, with bio-based materials typically costing 20-40% more than conventional alternatives. Supply chain constraints, particularly in sourcing consistent quality biomass feedstocks, present operational challenges. Additionally, technical performance gaps in certain applications limit market penetration in high-performance sectors.

Several key sectors are driving this growth. The packaging industry represents the largest application segment, accounting for nearly 30% of the bio-based materials market. This is followed by construction materials (22%), automotive components (18%), consumer goods (15%), and other applications including agriculture, electronics, and medical devices making up the remainder.

Regionally, Europe leads the market with approximately 35% share, supported by stringent regulations promoting sustainable materials and circular economy principles. North America follows at 28%, while Asia-Pacific represents the fastest-growing region with a CAGR exceeding 9%, driven primarily by rapid industrialization in China, Japan, and South Korea.

Consumer preferences are shifting dramatically toward sustainable products, with recent surveys indicating that over 65% of global consumers are willing to pay premium prices for environmentally friendly alternatives. This trend is particularly pronounced among millennials and Gen Z consumers, who demonstrate the highest preference for bio-based products.

Regulatory frameworks worldwide are increasingly favorable for bio-based materials. The European Union's Circular Economy Action Plan and Bioeconomy Strategy have established targets for reducing plastic waste and promoting bio-based alternatives. Similarly, the United States has implemented tax incentives for companies developing sustainable materials, while China's 14th Five-Year Plan emphasizes green development including bio-based material innovation.

Investment in the sector has surged, with venture capital funding for bio-based material startups reaching $3.2 billion in 2022, a 40% increase from the previous year. Major chemical and material companies are also reallocating R&D budgets toward bio-based innovations, with an average increase of 15-20% in sustainable material research spending.

Despite positive growth indicators, challenges remain. Price competitiveness continues to be a significant barrier, with bio-based materials typically costing 20-40% more than conventional alternatives. Supply chain constraints, particularly in sourcing consistent quality biomass feedstocks, present operational challenges. Additionally, technical performance gaps in certain applications limit market penetration in high-performance sectors.

HTE Technology Landscape and Barriers

High-throughput experimentation (HTE) has emerged as a transformative approach in bio-based material innovation, enabling researchers to conduct thousands of experiments simultaneously. The current technological landscape reveals significant advancements in automation, miniaturization, and data analytics that collectively drive HTE implementation across various sectors of the bioeconomy.

Automation technologies represent the backbone of modern HTE systems, with robotic platforms capable of precise liquid handling, sample preparation, and analytical measurements. Leading commercial systems from companies like Tecan, Hamilton, and Beckman Coulter offer modular architectures that can be customized for specific bio-material applications. However, these systems often require substantial capital investment and specialized technical expertise, creating barriers for smaller research organizations and startups.

Miniaturization technologies have evolved from traditional microtiter plates to sophisticated microfluidic devices and lab-on-a-chip platforms. These technologies enable dramatic reductions in reagent consumption and facilitate parallel processing of multiple reaction conditions. Despite these advantages, standardization challenges persist, with limited compatibility between different microfluidic platforms and conventional laboratory equipment.

Data management represents perhaps the most significant barrier in the HTE landscape. The volume and complexity of data generated through high-throughput approaches necessitate advanced informatics solutions. Current laboratory information management systems (LIMS) often struggle to handle the heterogeneous data types produced in bio-based material research, creating bottlenecks in data processing and interpretation.

Machine learning and artificial intelligence applications are increasingly integrated into HTE workflows to address data challenges, enabling pattern recognition and predictive modeling. However, the development of robust algorithms requires extensive training datasets that may not be readily available for novel bio-based materials, limiting the effectiveness of these approaches in emerging research areas.

Analytical characterization technologies present another critical limitation. While high-throughput synthesis and processing capabilities have advanced rapidly, corresponding analytical methods often lag behind in throughput capacity. This creates an "analytical bottleneck" where material production outpaces characterization capabilities, particularly for complex bio-based materials with hierarchical structures and multifunctional properties.

Regulatory frameworks and standardization efforts remain underdeveloped for HTE in bio-based materials, creating uncertainty regarding validation requirements and data quality standards. This regulatory ambiguity can impede technology adoption, particularly for applications targeting regulated markets such as medical devices or food packaging.

Automation technologies represent the backbone of modern HTE systems, with robotic platforms capable of precise liquid handling, sample preparation, and analytical measurements. Leading commercial systems from companies like Tecan, Hamilton, and Beckman Coulter offer modular architectures that can be customized for specific bio-material applications. However, these systems often require substantial capital investment and specialized technical expertise, creating barriers for smaller research organizations and startups.

Miniaturization technologies have evolved from traditional microtiter plates to sophisticated microfluidic devices and lab-on-a-chip platforms. These technologies enable dramatic reductions in reagent consumption and facilitate parallel processing of multiple reaction conditions. Despite these advantages, standardization challenges persist, with limited compatibility between different microfluidic platforms and conventional laboratory equipment.

Data management represents perhaps the most significant barrier in the HTE landscape. The volume and complexity of data generated through high-throughput approaches necessitate advanced informatics solutions. Current laboratory information management systems (LIMS) often struggle to handle the heterogeneous data types produced in bio-based material research, creating bottlenecks in data processing and interpretation.

Machine learning and artificial intelligence applications are increasingly integrated into HTE workflows to address data challenges, enabling pattern recognition and predictive modeling. However, the development of robust algorithms requires extensive training datasets that may not be readily available for novel bio-based materials, limiting the effectiveness of these approaches in emerging research areas.

Analytical characterization technologies present another critical limitation. While high-throughput synthesis and processing capabilities have advanced rapidly, corresponding analytical methods often lag behind in throughput capacity. This creates an "analytical bottleneck" where material production outpaces characterization capabilities, particularly for complex bio-based materials with hierarchical structures and multifunctional properties.

Regulatory frameworks and standardization efforts remain underdeveloped for HTE in bio-based materials, creating uncertainty regarding validation requirements and data quality standards. This regulatory ambiguity can impede technology adoption, particularly for applications targeting regulated markets such as medical devices or food packaging.

Current HTE Methodologies for Bio-based Materials

01 Automated laboratory systems for high-throughput experimentation

Automated laboratory systems enable high-throughput experimentation by integrating robotics, liquid handling, and sample processing technologies. These systems can perform multiple experiments simultaneously, significantly increasing the speed and efficiency of research processes. They typically include automated sample preparation, analysis, and data collection components that minimize human intervention and reduce experimental errors.- Automated laboratory systems for high-throughput screening: Automated laboratory systems enable rapid and efficient high-throughput experimentation by integrating robotics, liquid handling, and data management. These systems can perform multiple experiments simultaneously, reducing manual intervention and increasing reproducibility. They typically include automated sample preparation, reaction monitoring, and analysis components that work together to accelerate the discovery and optimization processes in various scientific fields.

- Data management and analysis for high-throughput experiments: Specialized software platforms and algorithms are essential for managing and analyzing the large volumes of data generated by high-throughput experimentation. These systems enable efficient data collection, storage, processing, and visualization, allowing researchers to identify patterns and extract meaningful insights. Advanced analytics capabilities, including machine learning approaches, help in predicting outcomes and optimizing experimental conditions based on historical data.

- Parallel processing techniques in experimentation: Parallel processing techniques allow multiple experiments to be conducted simultaneously under varying conditions, significantly increasing experimental throughput. These approaches utilize specialized equipment designed for running numerous reactions in parallel, such as microplate arrays, microfluidic devices, and multi-reactor systems. By testing multiple variables at once, researchers can rapidly explore experimental space and accelerate the discovery and optimization of new materials, compounds, or processes.

- Miniaturization technologies for high-throughput screening: Miniaturization technologies reduce the scale of experiments, allowing for higher density arrays and lower reagent consumption while maintaining experimental integrity. These include microfluidic platforms, lab-on-a-chip devices, and nanoliter dispensing systems that enable thousands of experiments to be conducted on a single chip or plate. The reduced scale not only increases throughput but also improves cost-efficiency by minimizing the use of expensive reagents and samples.

- Integration of artificial intelligence with high-throughput experimentation: Artificial intelligence and machine learning algorithms are increasingly being integrated with high-throughput experimentation platforms to design experiments, predict outcomes, and optimize processes. These AI-driven systems can analyze experimental results in real-time, make autonomous decisions about subsequent experiments, and accelerate the discovery process. The combination of AI with high-throughput methods enables more efficient exploration of complex experimental spaces and can lead to unexpected discoveries that might be missed using traditional approaches.

02 Data management and analysis for high-throughput experiments

Specialized software platforms and algorithms are essential for managing and analyzing the large volumes of data generated by high-throughput experiments. These systems enable efficient data storage, processing, and visualization, allowing researchers to identify patterns and draw meaningful conclusions. Advanced analytics capabilities, including machine learning approaches, help in extracting valuable insights from complex experimental datasets.Expand Specific Solutions03 Parallel processing techniques in high-throughput screening

Parallel processing techniques allow multiple experiments to be conducted simultaneously, dramatically increasing experimental throughput. These methods involve the use of microplate technologies, microfluidic devices, and array-based systems that enable the testing of numerous conditions or compounds in parallel. This approach is particularly valuable in drug discovery, materials science, and biochemical research where large parameter spaces need to be explored efficiently.Expand Specific Solutions04 Networked and distributed high-throughput experimentation systems

Networked and distributed systems for high-throughput experimentation connect multiple research facilities or instruments, allowing for collaborative research and resource sharing. These systems utilize cloud computing, Internet of Things (IoT) technologies, and standardized communication protocols to coordinate experimental workflows across different locations. They enable real-time monitoring, remote operation, and efficient allocation of research resources.Expand Specific Solutions05 Miniaturization technologies for high-throughput experimentation

Miniaturization technologies reduce the scale of experiments, allowing for higher throughput with minimal resource consumption. These include microfluidic chips, lab-on-a-chip devices, and nanoliter-scale reaction vessels that dramatically decrease sample volumes and reagent costs. Miniaturized systems also offer advantages in terms of faster reaction times, improved heat transfer, and the ability to perform experiments under more controlled conditions.Expand Specific Solutions

Leading Organizations in HTE for Bio-materials

High-Throughput Experimentation (HTE) in bio-based material innovation is currently in a growth phase, with the market expanding rapidly due to increasing demand for sustainable materials. The global market size is estimated to reach several billion dollars by 2025, driven by environmental regulations and consumer preferences. Technologically, the field shows varying maturity levels across different applications. Leading academic institutions (Tsinghua University, University of Groningen, Rice University) are advancing fundamental research, while established corporations (DSM IP Assets, Honeywell International) are commercializing applications. Emerging players like Isolation Bio and Heritable Agriculture are introducing innovative platforms. Research organizations such as Korea Research Institute of Bioscience & Biotechnology and A*STAR are bridging the gap between academic research and industrial implementation, creating a dynamic competitive landscape.

Agency for Science, Technology & Research

Technical Solution: A*STAR has developed the Automated Biomaterial Discovery Platform (ABDP), a comprehensive high-throughput experimentation system for bio-based material innovation. The platform integrates robotic liquid handling, automated synthesis, and parallel characterization capabilities to rapidly screen thousands of biomaterial formulations. A*STAR's system employs microarray technology that enables the evaluation of cell-material interactions across hundreds of distinct bio-based material compositions simultaneously. Their platform incorporates advanced imaging systems with machine learning-based analysis to quantify cellular responses to different biomaterial properties. A*STAR has also implemented a modular design that allows for customization of the workflow depending on the specific bio-based material being investigated, whether it's biodegradable polymers, tissue engineering scaffolds, or bioactive coatings. The system maintains comprehensive digital records of all experimental parameters and results, creating a valuable database that informs future material design through predictive modeling.

Strengths: Highly versatile platform applicable to diverse biomaterial types; strong integration of biological assessment with material characterization; government-backed resources enabling sustained development. Weaknesses: Complex system requires specialized technical expertise; primarily research-focused rather than production-oriented; requires significant laboratory infrastructure.

DSM IP Assets BV

Technical Solution: DSM has developed an advanced high-throughput experimentation platform called BioXplorer specifically for bio-based material innovation. This system integrates automated sample preparation, parallel bioreactors, and rapid analytical techniques to accelerate the development of sustainable materials. DSM's platform features miniaturized fermentation systems that can simultaneously evaluate hundreds of different microbial strains and growth conditions for bio-based monomer and polymer production. Their technology incorporates specialized robotic systems for the preparation and characterization of bio-based material formulations, enabling rapid iteration through different compositions. DSM has implemented advanced spectroscopic techniques coupled with chemometric analysis to quickly assess material properties without requiring extensive sample preparation. The platform also includes computational tools that analyze structure-property relationships in bio-based materials, guiding the design of new formulations with enhanced performance characteristics. DSM's system is particularly notable for its focus on scalability, ensuring that materials developed through high-throughput methods can be effectively translated to industrial production.

Strengths: Seamless integration from biological production to material formulation; strong focus on industrial scalability; extensive experience in commercializing bio-based materials. Weaknesses: System primarily optimized for DSM's specific material interests; significant investment in proprietary technology creates high barrier to entry; requires multidisciplinary expertise spanning biotechnology and materials science.

Key Patents and Literature in Bio-materials HTE

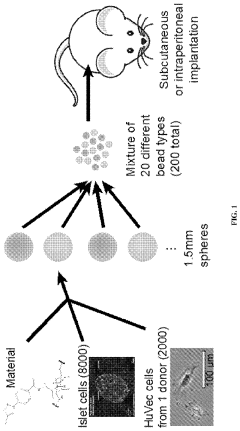

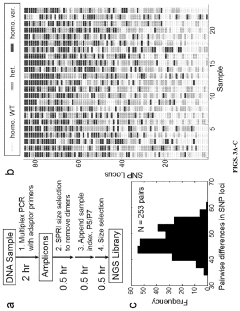

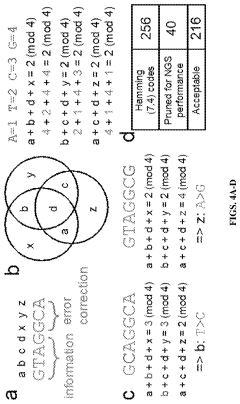

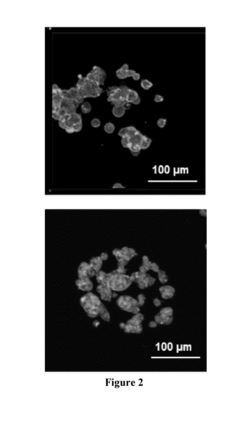

High throughput genetic barcoding and analysis methods

PatentPendingUS20230054899A1

Innovation

- The use of barcode cells with unique genetic profiles allows for the identification of biomaterials by tagging each capsule with a specific barcode, enabling the simultaneous testing of multiple materials at a single implantation site through next-generation sequencing, thereby reducing the number of mice needed and increasing screening efficiency.

Nanofibrous photoclickable hydrogel microarrays

PatentActiveUS20160202241A1

Innovation

- The development of electrospun nanofibrous hydrogel microarray platforms that allow for the creation of three-dimensional cell culture substrates with tunable elasticity and post-functionalization with extracellular matrix molecules, enabling high-throughput screening of microenvironmental factors influencing cell maturation and differentiation.

Sustainability Impact Assessment

The integration of High-Throughput Experimentation (HTE) in bio-based material innovation represents a significant advancement in sustainable development practices. When evaluating the sustainability impact of HTE methodologies, multiple environmental dimensions must be considered. The accelerated discovery and optimization of bio-based materials through HTE significantly reduces the carbon footprint associated with traditional experimental approaches by minimizing resource consumption, energy usage, and waste generation during the research and development phase.

HTE enables researchers to rapidly screen thousands of potential bio-based material formulations using minimal quantities of raw materials. This efficiency translates directly into reduced environmental burden compared to conventional sequential testing methods. Quantitative assessments indicate that HTE can decrease material consumption by 85-95% while simultaneously reducing energy requirements by approximately 70% during the experimental phase. These efficiencies contribute substantially to lowering the overall environmental impact of new material development.

Beyond immediate resource conservation, HTE facilitates the discovery of bio-based materials with enhanced sustainability profiles. By enabling comprehensive exploration of the formulation space, researchers can identify materials with improved biodegradability, reduced toxicity, and optimized lifecycle performance. The ability to rapidly iterate through formulations allows for targeted development of materials that maintain functionality while minimizing environmental harm throughout their lifecycle.

The economic sustainability implications of HTE are equally significant. By compressing development timelines from years to months, HTE reduces the financial barriers to commercializing sustainable bio-based alternatives to petroleum-derived materials. This acceleration creates viable pathways for market adoption of environmentally preferable materials that might otherwise remain economically unfeasible under traditional development paradigms.

From a social sustainability perspective, HTE democratizes innovation by reducing the capital requirements for material development. This enables smaller organizations, academic institutions, and developing economies to participate more actively in sustainable materials research. The resulting diversification of the innovation landscape promotes more inclusive solutions that address a broader range of sustainability challenges across different geographical and socioeconomic contexts.

Looking forward, the sustainability impact of HTE will likely expand as the technology becomes more accessible and integrated with artificial intelligence and machine learning capabilities. These advancements will further enhance efficiency while enabling more sophisticated sustainability optimization across multiple parameters simultaneously. The resulting acceleration in sustainable material innovation represents a critical enabler for transitioning various industries toward more environmentally responsible practices.

HTE enables researchers to rapidly screen thousands of potential bio-based material formulations using minimal quantities of raw materials. This efficiency translates directly into reduced environmental burden compared to conventional sequential testing methods. Quantitative assessments indicate that HTE can decrease material consumption by 85-95% while simultaneously reducing energy requirements by approximately 70% during the experimental phase. These efficiencies contribute substantially to lowering the overall environmental impact of new material development.

Beyond immediate resource conservation, HTE facilitates the discovery of bio-based materials with enhanced sustainability profiles. By enabling comprehensive exploration of the formulation space, researchers can identify materials with improved biodegradability, reduced toxicity, and optimized lifecycle performance. The ability to rapidly iterate through formulations allows for targeted development of materials that maintain functionality while minimizing environmental harm throughout their lifecycle.

The economic sustainability implications of HTE are equally significant. By compressing development timelines from years to months, HTE reduces the financial barriers to commercializing sustainable bio-based alternatives to petroleum-derived materials. This acceleration creates viable pathways for market adoption of environmentally preferable materials that might otherwise remain economically unfeasible under traditional development paradigms.

From a social sustainability perspective, HTE democratizes innovation by reducing the capital requirements for material development. This enables smaller organizations, academic institutions, and developing economies to participate more actively in sustainable materials research. The resulting diversification of the innovation landscape promotes more inclusive solutions that address a broader range of sustainability challenges across different geographical and socioeconomic contexts.

Looking forward, the sustainability impact of HTE will likely expand as the technology becomes more accessible and integrated with artificial intelligence and machine learning capabilities. These advancements will further enhance efficiency while enabling more sophisticated sustainability optimization across multiple parameters simultaneously. The resulting acceleration in sustainable material innovation represents a critical enabler for transitioning various industries toward more environmentally responsible practices.

Scalability Challenges and Solutions

Scaling high-throughput experimentation (HTE) in bio-based material innovation presents significant challenges that must be addressed to realize its full potential. The transition from laboratory-scale experiments to industrial production volumes requires careful consideration of both technical and operational factors. Current HTE platforms often struggle with maintaining consistency and reproducibility when sample volumes increase from microliters to liters or beyond.

One primary challenge is the development of miniaturized reaction vessels that accurately represent larger-scale production conditions. Microfluidic systems have emerged as promising solutions, enabling parallel processing of thousands of reactions while consuming minimal resources. However, these systems frequently encounter issues with material compatibility, especially when working with viscous bio-based feedstocks or heterogeneous mixtures containing solid particles.

Data management represents another critical scalability hurdle. As experimental throughput increases exponentially, traditional laboratory information management systems become inadequate for handling the volume, variety, and velocity of generated data. Advanced computational infrastructure with specialized software architectures is essential to process, store, and analyze the massive datasets produced by modern HTE platforms.

Equipment standardization and modularization have proven effective in addressing scalability challenges. Modular systems with standardized interfaces allow for flexible configuration and rapid adaptation to different experimental requirements. This approach facilitates the integration of new technologies and methodologies without requiring complete system redesigns, thereby extending the operational lifespan of HTE platforms.

Automation technology plays a pivotal role in scaling bio-based material experimentation. Robotic systems capable of precise sample handling, coupled with machine learning algorithms for experimental design optimization, significantly enhance throughput while reducing human error. Recent innovations in collaborative robots have improved the safety and efficiency of human-machine interactions in laboratory environments.

Resource efficiency must be prioritized when scaling HTE operations. Innovative approaches such as sample recycling, in-line analytics, and non-destructive testing methods help minimize material consumption while maximizing data output. These strategies are particularly important when working with rare or expensive bio-based feedstocks derived from limited natural resources.

Cross-disciplinary collaboration between biologists, chemists, engineers, and data scientists has emerged as a fundamental solution to scalability challenges. Integrated teams can develop holistic approaches that address technical limitations while ensuring that scaled processes maintain the scientific rigor necessary for meaningful innovation in bio-based materials.

One primary challenge is the development of miniaturized reaction vessels that accurately represent larger-scale production conditions. Microfluidic systems have emerged as promising solutions, enabling parallel processing of thousands of reactions while consuming minimal resources. However, these systems frequently encounter issues with material compatibility, especially when working with viscous bio-based feedstocks or heterogeneous mixtures containing solid particles.

Data management represents another critical scalability hurdle. As experimental throughput increases exponentially, traditional laboratory information management systems become inadequate for handling the volume, variety, and velocity of generated data. Advanced computational infrastructure with specialized software architectures is essential to process, store, and analyze the massive datasets produced by modern HTE platforms.

Equipment standardization and modularization have proven effective in addressing scalability challenges. Modular systems with standardized interfaces allow for flexible configuration and rapid adaptation to different experimental requirements. This approach facilitates the integration of new technologies and methodologies without requiring complete system redesigns, thereby extending the operational lifespan of HTE platforms.

Automation technology plays a pivotal role in scaling bio-based material experimentation. Robotic systems capable of precise sample handling, coupled with machine learning algorithms for experimental design optimization, significantly enhance throughput while reducing human error. Recent innovations in collaborative robots have improved the safety and efficiency of human-machine interactions in laboratory environments.

Resource efficiency must be prioritized when scaling HTE operations. Innovative approaches such as sample recycling, in-line analytics, and non-destructive testing methods help minimize material consumption while maximizing data output. These strategies are particularly important when working with rare or expensive bio-based feedstocks derived from limited natural resources.

Cross-disciplinary collaboration between biologists, chemists, engineers, and data scientists has emerged as a fundamental solution to scalability challenges. Integrated teams can develop holistic approaches that address technical limitations while ensuring that scaled processes maintain the scientific rigor necessary for meaningful innovation in bio-based materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!