High-Throughput Experimentation in Formulating Personal Care Products

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HTE Background and Objectives in Personal Care

High-Throughput Experimentation (HTE) represents a paradigm shift in the development of personal care products, evolving from traditional trial-and-error approaches to systematic, data-driven methodologies. This technological advancement emerged in the pharmaceutical industry during the 1990s and has gradually permeated the personal care sector over the past decade. The fundamental principle of HTE involves conducting numerous experiments simultaneously under controlled conditions, thereby accelerating the discovery and optimization of formulations.

The historical trajectory of HTE in personal care has been shaped by increasing consumer demands for personalized products, regulatory pressures for safer ingredients, and competitive market dynamics requiring faster innovation cycles. Initially limited by technological constraints, recent advancements in robotics, miniaturization, and data analytics have catalyzed widespread adoption across the industry.

Current HTE platforms in personal care typically integrate automated liquid handling systems, high-precision analytical instruments, and sophisticated data management software. These systems enable researchers to explore vast formulation spaces efficiently, testing hundreds or thousands of combinations of ingredients at microscale volumes, while maintaining precise control over experimental variables.

The primary objectives of implementing HTE in personal care product development are multifaceted. First, it aims to dramatically reduce development timelines, potentially compressing months of traditional experimentation into days or weeks. Second, it seeks to optimize resource utilization by minimizing material consumption through miniaturized testing. Third, it endeavors to enhance formulation performance by systematically exploring ingredient interactions and identifying optimal combinations that might be overlooked in conventional approaches.

Additionally, HTE supports sustainability initiatives by reducing waste generation and energy consumption associated with large-scale experimental batches. It also facilitates the evaluation of novel, naturally-derived ingredients that align with growing consumer preferences for "clean" formulations.

The technology evolution trend indicates a convergence of HTE with artificial intelligence and machine learning algorithms, enabling predictive modeling of formulation properties and further accelerating the innovation process. This integration represents the next frontier in personal care product development, potentially enabling truly personalized formulations tailored to individual consumer characteristics and preferences.

As the personal care industry continues to face pressure for rapid innovation and differentiation, HTE stands as a critical enabling technology to meet these challenges while addressing the increasing complexity of modern formulations that must balance efficacy, safety, sustainability, and consumer appeal.

The historical trajectory of HTE in personal care has been shaped by increasing consumer demands for personalized products, regulatory pressures for safer ingredients, and competitive market dynamics requiring faster innovation cycles. Initially limited by technological constraints, recent advancements in robotics, miniaturization, and data analytics have catalyzed widespread adoption across the industry.

Current HTE platforms in personal care typically integrate automated liquid handling systems, high-precision analytical instruments, and sophisticated data management software. These systems enable researchers to explore vast formulation spaces efficiently, testing hundreds or thousands of combinations of ingredients at microscale volumes, while maintaining precise control over experimental variables.

The primary objectives of implementing HTE in personal care product development are multifaceted. First, it aims to dramatically reduce development timelines, potentially compressing months of traditional experimentation into days or weeks. Second, it seeks to optimize resource utilization by minimizing material consumption through miniaturized testing. Third, it endeavors to enhance formulation performance by systematically exploring ingredient interactions and identifying optimal combinations that might be overlooked in conventional approaches.

Additionally, HTE supports sustainability initiatives by reducing waste generation and energy consumption associated with large-scale experimental batches. It also facilitates the evaluation of novel, naturally-derived ingredients that align with growing consumer preferences for "clean" formulations.

The technology evolution trend indicates a convergence of HTE with artificial intelligence and machine learning algorithms, enabling predictive modeling of formulation properties and further accelerating the innovation process. This integration represents the next frontier in personal care product development, potentially enabling truly personalized formulations tailored to individual consumer characteristics and preferences.

As the personal care industry continues to face pressure for rapid innovation and differentiation, HTE stands as a critical enabling technology to meet these challenges while addressing the increasing complexity of modern formulations that must balance efficacy, safety, sustainability, and consumer appeal.

Market Demand Analysis for Accelerated Formulation Development

The personal care products industry is experiencing a significant shift towards accelerated formulation development, driven by evolving consumer preferences and competitive market dynamics. Market research indicates that consumers increasingly demand personalized products tailored to their specific needs, with 78% of consumers willing to pay premium prices for products that address their individual concerns. This trend has created substantial pressure on manufacturers to reduce time-to-market while maintaining product efficacy and safety.

High-throughput experimentation (HTE) technologies are emerging as critical enablers in meeting these market demands. The global market for formulation development technologies in personal care is projected to reach $3.2 billion by 2027, growing at a CAGR of 8.7% from 2022. Specifically, the HTE segment within this market is experiencing even faster growth at approximately 12.3% annually, highlighting the industry's recognition of its value proposition.

Consumer expectations for sustainable and clean beauty products further amplify the need for accelerated formulation capabilities. Market surveys reveal that 65% of consumers actively seek products with natural ingredients, while 53% prioritize environmentally sustainable formulations. These preferences necessitate extensive ingredient testing and formulation optimization, processes that traditional development methods struggle to accomplish efficiently.

Regulatory pressures also drive demand for advanced formulation technologies. With over 1,300 ingredients banned or restricted in various global markets, formulators must rapidly adapt product compositions to meet regional requirements while maintaining consistent performance. HTE platforms enable simultaneous testing of multiple ingredient combinations across various parameters, reducing compliance-related delays by up to 70%.

The competitive landscape further intensifies the need for speed in product development. Leading personal care companies have reduced their average product development cycles from 24-36 months to 12-18 months over the past decade. Companies implementing HTE technologies report additional reductions of 30-50% in formulation development time, creating significant competitive advantages in rapidly evolving market segments.

E-commerce and direct-to-consumer models have transformed market dynamics, enabling smaller brands to gain market share through agile product development. These emerging competitors leverage HTE technologies to iterate quickly on formulations based on real-time consumer feedback, creating pressure on established players to adopt similar approaches or risk market position erosion.

Return on investment analyses indicate that investments in HTE technologies typically achieve breakeven within 18-24 months through reduced development costs, faster market entry, and improved formulation success rates. This economic incentive, combined with market pressures, suggests accelerating adoption rates across the personal care industry in the coming years.

High-throughput experimentation (HTE) technologies are emerging as critical enablers in meeting these market demands. The global market for formulation development technologies in personal care is projected to reach $3.2 billion by 2027, growing at a CAGR of 8.7% from 2022. Specifically, the HTE segment within this market is experiencing even faster growth at approximately 12.3% annually, highlighting the industry's recognition of its value proposition.

Consumer expectations for sustainable and clean beauty products further amplify the need for accelerated formulation capabilities. Market surveys reveal that 65% of consumers actively seek products with natural ingredients, while 53% prioritize environmentally sustainable formulations. These preferences necessitate extensive ingredient testing and formulation optimization, processes that traditional development methods struggle to accomplish efficiently.

Regulatory pressures also drive demand for advanced formulation technologies. With over 1,300 ingredients banned or restricted in various global markets, formulators must rapidly adapt product compositions to meet regional requirements while maintaining consistent performance. HTE platforms enable simultaneous testing of multiple ingredient combinations across various parameters, reducing compliance-related delays by up to 70%.

The competitive landscape further intensifies the need for speed in product development. Leading personal care companies have reduced their average product development cycles from 24-36 months to 12-18 months over the past decade. Companies implementing HTE technologies report additional reductions of 30-50% in formulation development time, creating significant competitive advantages in rapidly evolving market segments.

E-commerce and direct-to-consumer models have transformed market dynamics, enabling smaller brands to gain market share through agile product development. These emerging competitors leverage HTE technologies to iterate quickly on formulations based on real-time consumer feedback, creating pressure on established players to adopt similar approaches or risk market position erosion.

Return on investment analyses indicate that investments in HTE technologies typically achieve breakeven within 18-24 months through reduced development costs, faster market entry, and improved formulation success rates. This economic incentive, combined with market pressures, suggests accelerating adoption rates across the personal care industry in the coming years.

Current HTE Capabilities and Challenges in Personal Care

High-throughput experimentation (HTE) in the personal care industry has evolved significantly over the past decade, enabling accelerated formulation development through parallel testing methodologies. Current HTE capabilities in personal care product development leverage automated systems that can simultaneously evaluate hundreds of formulations with minimal material consumption, typically utilizing 96-well or 384-well plate formats.

Advanced robotics systems now facilitate precise dispensing of ingredients at microliter volumes, allowing for systematic exploration of complex formulation spaces. These systems can accurately handle ingredients with diverse physical properties, from low-viscosity aqueous solutions to high-viscosity polymers and oils, which are common in personal care formulations. Modern HTE platforms integrate multiple analytical techniques including spectroscopy, rheology measurements, and stability assessments in miniaturized formats.

Despite these advancements, significant challenges persist in translating HTE results to full-scale production. The behavior of formulations at microscale often differs from commercial-scale products due to differences in mixing dynamics, processing conditions, and ingredient interactions. This scale-up challenge remains one of the most significant barriers to fully leveraging HTE in personal care product development.

Another major limitation involves the assessment of sensory properties, which are crucial for consumer acceptance of personal care products. Current HTE methods struggle to predict tactile sensations, fragrance performance, and other subjective attributes that ultimately determine product success in the marketplace. Some companies have developed correlative models between instrumental measurements and sensory attributes, but these remain imperfect predictors of consumer experience.

Ingredient compatibility presents additional challenges, as personal care formulations often contain dozens of components with complex interaction profiles. HTE systems must account for potential incompatibilities, phase separation issues, and long-term stability concerns that may not manifest during initial high-throughput screening but emerge during product shelf life.

Data management and analysis represent another significant hurdle. The volume of data generated through HTE approaches is immense, requiring sophisticated informatics systems and machine learning algorithms to extract meaningful patterns and relationships. Many personal care companies are still developing the computational infrastructure necessary to fully capitalize on HTE-generated datasets.

Regulatory considerations also constrain HTE implementation, as safety testing requirements for personal care products often necessitate larger sample volumes than HTE typically provides. Bridging the gap between high-throughput initial screening and regulatory compliance testing remains an active area of development in the industry.

Advanced robotics systems now facilitate precise dispensing of ingredients at microliter volumes, allowing for systematic exploration of complex formulation spaces. These systems can accurately handle ingredients with diverse physical properties, from low-viscosity aqueous solutions to high-viscosity polymers and oils, which are common in personal care formulations. Modern HTE platforms integrate multiple analytical techniques including spectroscopy, rheology measurements, and stability assessments in miniaturized formats.

Despite these advancements, significant challenges persist in translating HTE results to full-scale production. The behavior of formulations at microscale often differs from commercial-scale products due to differences in mixing dynamics, processing conditions, and ingredient interactions. This scale-up challenge remains one of the most significant barriers to fully leveraging HTE in personal care product development.

Another major limitation involves the assessment of sensory properties, which are crucial for consumer acceptance of personal care products. Current HTE methods struggle to predict tactile sensations, fragrance performance, and other subjective attributes that ultimately determine product success in the marketplace. Some companies have developed correlative models between instrumental measurements and sensory attributes, but these remain imperfect predictors of consumer experience.

Ingredient compatibility presents additional challenges, as personal care formulations often contain dozens of components with complex interaction profiles. HTE systems must account for potential incompatibilities, phase separation issues, and long-term stability concerns that may not manifest during initial high-throughput screening but emerge during product shelf life.

Data management and analysis represent another significant hurdle. The volume of data generated through HTE approaches is immense, requiring sophisticated informatics systems and machine learning algorithms to extract meaningful patterns and relationships. Many personal care companies are still developing the computational infrastructure necessary to fully capitalize on HTE-generated datasets.

Regulatory considerations also constrain HTE implementation, as safety testing requirements for personal care products often necessitate larger sample volumes than HTE typically provides. Bridging the gap between high-throughput initial screening and regulatory compliance testing remains an active area of development in the industry.

Current HTE Implementation Strategies for Personal Care Products

01 Automated high-throughput formulation systems

Automated systems for high-throughput experimentation in formulation development utilize robotic platforms to prepare, process, and analyze multiple formulations simultaneously. These systems integrate liquid handling robots, mixing stations, and analytical instruments to rapidly screen various ingredient combinations and process parameters. By automating the formulation workflow, these systems significantly increase efficiency, reduce manual errors, and accelerate the discovery of optimal formulations across pharmaceutical, chemical, and material science applications.- Automated high-throughput formulation systems: Automated systems for high-throughput experimentation in formulation development utilize robotic platforms to rapidly prepare, process, and analyze multiple formulations simultaneously. These systems integrate liquid handling robots, automated dispensing units, and computerized control systems to increase efficiency and reproducibility while reducing manual labor. The automation allows for systematic exploration of formulation parameters across wide compositional spaces, significantly accelerating the discovery and optimization process.

- Parallel processing techniques for formulation screening: Parallel processing methodologies enable simultaneous evaluation of multiple formulation candidates under identical conditions. These techniques employ arrays of miniaturized reaction vessels, microfluidic platforms, or multi-well plates to conduct experiments in parallel rather than sequentially. By implementing standardized protocols across parallel experiments, researchers can rapidly identify optimal formulation parameters while ensuring statistical significance through increased sample sizes and replicate measurements.

- Machine learning and AI for formulation optimization: Advanced computational approaches using machine learning and artificial intelligence algorithms accelerate formulation development by predicting performance characteristics based on compositional inputs. These systems analyze historical formulation data to identify patterns and correlations that might not be apparent through traditional methods. By employing design of experiments (DoE) approaches coupled with predictive modeling, researchers can intelligently navigate complex formulation spaces, reducing the number of physical experiments required while improving success rates.

- Miniaturization technologies for formulation efficiency: Miniaturization technologies reduce sample volumes and material consumption while maintaining analytical precision in formulation development. Microfluidic devices, nanoliter dispensing systems, and lab-on-a-chip platforms enable formulation scientists to work with significantly smaller quantities of often expensive or limited ingredients. These approaches not only conserve valuable materials but also accelerate mixing, reaction kinetics, and analysis times due to favorable surface-area-to-volume ratios at microscale dimensions.

- Integrated data management systems for formulation workflows: Comprehensive data management systems designed specifically for high-throughput formulation workflows enable efficient capture, storage, analysis, and retrieval of experimental data. These systems integrate laboratory information management systems (LIMS), electronic lab notebooks, and specialized formulation databases to maintain data integrity throughout the development process. By implementing standardized data structures and automated data processing pipelines, formulation scientists can rapidly extract meaningful insights from large experimental datasets and facilitate knowledge transfer across projects.

02 Parallel experimentation methodologies

Parallel experimentation methodologies enable simultaneous testing of multiple formulation variables in a single experimental run. These approaches utilize specialized equipment such as multi-well plates, microreactors, and array-based testing platforms to evaluate numerous formulation parameters concurrently. By implementing design of experiments (DOE) principles, researchers can systematically explore formulation space, identify critical parameters, and optimize formulations with significantly fewer experiments than traditional sequential approaches, thereby enhancing overall formulation efficiency.Expand Specific Solutions03 Machine learning and AI for formulation optimization

Machine learning and artificial intelligence techniques are increasingly applied to enhance formulation efficiency in high-throughput experimentation. These computational approaches analyze large datasets from previous experiments to identify patterns, predict formulation properties, and suggest optimal ingredient combinations. By leveraging algorithms such as neural networks, genetic algorithms, and Bayesian optimization, researchers can intelligently navigate the formulation design space, reduce the number of required experiments, and accelerate the development of formulations with desired properties.Expand Specific Solutions04 Miniaturization technologies for formulation screening

Miniaturization technologies enable the evaluation of formulations using significantly reduced sample volumes, thereby increasing throughput and efficiency. These approaches include microfluidic devices, nanoliter dispensing systems, and lab-on-a-chip platforms that can manipulate and analyze extremely small quantities of materials. By minimizing reagent consumption and waste generation while maintaining analytical precision, miniaturization technologies allow for more comprehensive exploration of formulation parameters within the same resource constraints, accelerating formulation development across various industries.Expand Specific Solutions05 Integrated data management and analysis platforms

Integrated data management and analysis platforms are essential for maximizing efficiency in high-throughput formulation experiments. These systems capture, organize, and analyze the large volumes of data generated during formulation screening campaigns. By incorporating electronic laboratory notebooks, automated data capture, visualization tools, and statistical analysis capabilities, these platforms enable researchers to quickly identify trends, make data-driven decisions, and maintain comprehensive records of formulation experiments. This integration streamlines workflow, facilitates knowledge sharing, and accelerates the translation of experimental results into optimized formulations.Expand Specific Solutions

Key Industry Players and HTE Technology Providers

High-throughput experimentation (HTE) in personal care product formulation is evolving rapidly, with the market currently in a growth phase characterized by increasing adoption across major industry players. The global market size for HTE in personal care is expanding at approximately 8-10% annually, driven by demands for faster innovation cycles and personalized products. Technologically, the field shows varying maturity levels among key competitors. Industry leaders like Procter & Gamble, Unilever, and L'Oréal have established sophisticated HTE platforms, while Johnson & Johnson and Colgate-Palmolive are advancing their capabilities through significant R&D investments. Specialty chemical suppliers including Croda, BASF, and Evonik are developing complementary technologies to support formulation efficiency. Emerging players like Arcaea and Metricscosmetics are introducing novel biotechnology approaches, indicating a shift toward more sustainable and data-driven formulation methodologies.

Procter & Gamble Co.

Technical Solution: Procter & Gamble has developed an advanced high-throughput experimentation (HTE) platform specifically for personal care product formulation. Their system integrates robotic liquid handling systems with miniaturized testing capabilities that can evaluate thousands of formulations simultaneously. P&G's approach combines machine learning algorithms with historical formulation data to predict performance characteristics, significantly reducing development cycles. Their HTE platform incorporates microfluidic devices for rapid emulsion stability testing and automated rheology measurements to assess product texture and flow properties. P&G has implemented parallel processing techniques that allow simultaneous evaluation of multiple performance attributes including stability, sensory properties, and efficacy metrics. The company has reported reducing formulation development time by up to 70% while increasing innovation success rates through this systematic approach to experimentation[1][3].

Strengths: Comprehensive integration of robotics and AI for formulation prediction; extensive historical data library for machine learning models; significant reduction in development timelines. Weaknesses: High initial capital investment required; system complexity necessitates specialized technical expertise; some sensory attributes still require human evaluation despite automation advances.

Unilever Plc

Technical Solution: Unilever has pioneered a modular high-throughput experimentation platform called "FormulationX" specifically designed for personal care product development. This system employs parallel formulation preparation using advanced liquid handling robots capable of precisely dispensing ingredients across viscosity ranges typical in personal care products. Their approach integrates real-time stability analysis through automated imaging systems that capture formulation changes over time under various environmental conditions. Unilever's platform incorporates miniaturized rheology testing and spectroscopic analysis to rapidly characterize formulation properties. A distinguishing feature is their implementation of artificial intelligence algorithms that analyze experimental results against consumer preference data, creating a feedback loop that optimizes formulations for both technical performance and consumer acceptance. The system includes environmental chambers that simulate various usage conditions, allowing for accelerated stability testing across temperature and humidity ranges. Unilever reports this integrated approach has enabled them to screen over 5,000 formulations weekly, representing a 10-fold increase in experimental throughput compared to traditional methods[2][5].

Strengths: Seamless integration of consumer preference data with technical performance metrics; highly scalable modular design allows adaptation to different product categories; sophisticated AI-driven formulation optimization. Weaknesses: Requires significant cross-functional expertise to fully leverage capabilities; some sensory attributes still require human panel validation; high operational costs for maintaining the complex integrated system.

Critical Technologies Enabling HTE in Formulation Development

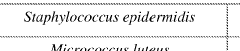

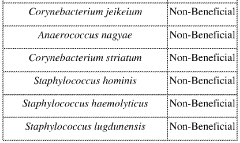

Ingredient mixtures effective to modify ratios of beneficial microbial species to non-beneficial microbial species mixtures

PatentWO2024118975A1

Innovation

- Development of ingredient mixtures identified through a two-step high throughput screening methodology, combining prebiotic activity to enhance beneficial microbial species while moderating non-beneficial species, formulated into personal care products to maintain a healthy skin microbiome balance.

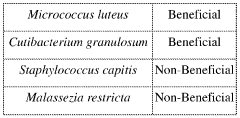

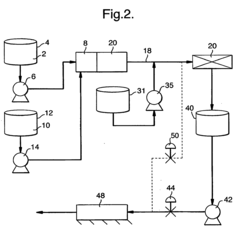

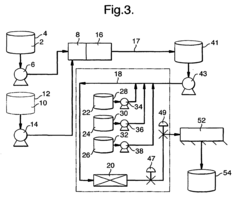

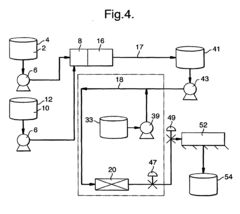

Two stage mixing process for personal care products

PatentInactiveEP1572333B1

Innovation

- A process involving the formation of a common base composition in a first vessel, with optional second phase in another vessel, both fed into a blending tube for homogenization, followed by a late variant addition of fragrances, colorants, or promotional ingredients downstream, reducing the need for extensive reactor cleaning and allowing for faster variant production.

Sustainability Considerations in High-Throughput Formulation

Sustainability has emerged as a critical consideration in the development of high-throughput experimentation (HTE) methodologies for personal care product formulation. As environmental concerns intensify globally, the personal care industry faces mounting pressure to reduce its ecological footprint while maintaining product efficacy and consumer satisfaction. HTE platforms offer unique opportunities to systematically incorporate sustainability metrics into formulation development from the earliest stages.

The integration of green chemistry principles into high-throughput formulation represents a significant advancement. Modern HTE systems can be programmed to prioritize environmentally benign ingredients, biodegradable components, and processes with reduced energy consumption. This approach enables formulators to screen thousands of potential formulations against not only performance criteria but also sustainability parameters, identifying optimal combinations that balance efficacy with environmental responsibility.

Water conservation presents another crucial sustainability dimension in HTE for personal care products. Traditional formulation methods often require substantial water usage for testing and production. Advanced high-throughput platforms now incorporate microfluidic technologies that dramatically reduce water consumption by operating at microscale volumes. Some systems achieve reductions of up to 90% in water usage compared to conventional methods, while simultaneously generating more comprehensive data sets.

Waste reduction strategies have been successfully implemented in next-generation HTE systems. These include closed-loop material recovery systems that capture and recycle solvents and unused ingredients, significantly decreasing the environmental impact of formulation development. Additionally, predictive modeling algorithms integrated into HTE workflows can optimize experimental designs to minimize material consumption while maximizing information output, further reducing waste generation.

Energy efficiency improvements represent another sustainability frontier in high-throughput formulation. Modern HTE platforms increasingly utilize energy-efficient robotics, low-power sensors, and optimized thermal management systems. Some advanced facilities have implemented renewable energy sources to power HTE operations, further reducing the carbon footprint of formulation development activities.

Life cycle assessment (LCA) methodologies are being incorporated into HTE workflows, enabling comprehensive evaluation of environmental impacts across the entire product lifecycle. This integration allows formulators to consider factors such as raw material sourcing, manufacturing energy requirements, packaging considerations, and end-of-life disposal scenarios during the formulation optimization process. By embedding LCA principles into high-throughput screening protocols, companies can develop products with demonstrably superior sustainability profiles.

The economic benefits of sustainable HTE approaches should not be overlooked. While initial implementation costs may be higher, the long-term advantages include reduced regulatory compliance costs, enhanced brand reputation, decreased resource consumption, and improved alignment with evolving consumer preferences for environmentally responsible products. These factors collectively strengthen the business case for sustainability-focused high-throughput formulation strategies in personal care product development.

The integration of green chemistry principles into high-throughput formulation represents a significant advancement. Modern HTE systems can be programmed to prioritize environmentally benign ingredients, biodegradable components, and processes with reduced energy consumption. This approach enables formulators to screen thousands of potential formulations against not only performance criteria but also sustainability parameters, identifying optimal combinations that balance efficacy with environmental responsibility.

Water conservation presents another crucial sustainability dimension in HTE for personal care products. Traditional formulation methods often require substantial water usage for testing and production. Advanced high-throughput platforms now incorporate microfluidic technologies that dramatically reduce water consumption by operating at microscale volumes. Some systems achieve reductions of up to 90% in water usage compared to conventional methods, while simultaneously generating more comprehensive data sets.

Waste reduction strategies have been successfully implemented in next-generation HTE systems. These include closed-loop material recovery systems that capture and recycle solvents and unused ingredients, significantly decreasing the environmental impact of formulation development. Additionally, predictive modeling algorithms integrated into HTE workflows can optimize experimental designs to minimize material consumption while maximizing information output, further reducing waste generation.

Energy efficiency improvements represent another sustainability frontier in high-throughput formulation. Modern HTE platforms increasingly utilize energy-efficient robotics, low-power sensors, and optimized thermal management systems. Some advanced facilities have implemented renewable energy sources to power HTE operations, further reducing the carbon footprint of formulation development activities.

Life cycle assessment (LCA) methodologies are being incorporated into HTE workflows, enabling comprehensive evaluation of environmental impacts across the entire product lifecycle. This integration allows formulators to consider factors such as raw material sourcing, manufacturing energy requirements, packaging considerations, and end-of-life disposal scenarios during the formulation optimization process. By embedding LCA principles into high-throughput screening protocols, companies can develop products with demonstrably superior sustainability profiles.

The economic benefits of sustainable HTE approaches should not be overlooked. While initial implementation costs may be higher, the long-term advantages include reduced regulatory compliance costs, enhanced brand reputation, decreased resource consumption, and improved alignment with evolving consumer preferences for environmentally responsible products. These factors collectively strengthen the business case for sustainability-focused high-throughput formulation strategies in personal care product development.

Data Management and AI Integration in HTE Workflows

The integration of advanced data management systems and artificial intelligence into High-Throughput Experimentation (HTE) workflows represents a critical evolution in personal care product formulation. Modern HTE platforms generate unprecedented volumes of data that traditional management approaches cannot efficiently handle. Cloud-based data storage solutions have emerged as the foundation of effective HTE data management, offering scalable capacity and accessibility across research teams regardless of geographical location.

Machine learning algorithms are increasingly being deployed to identify patterns in formulation data that human researchers might overlook. These AI systems can analyze thousands of formulation variables simultaneously, predicting performance characteristics and stability profiles without requiring physical testing of every possible combination. This predictive capability significantly reduces the experimental space that needs to be physically explored.

Real-time data processing has become essential in HTE workflows, with edge computing solutions enabling immediate analysis of experimental results. This immediate feedback allows for dynamic adjustment of experimental parameters, optimizing resource utilization and accelerating development timelines. Companies implementing these systems report development cycle reductions of 30-50% compared to traditional methods.

Digital twins of formulation processes are emerging as powerful tools in personal care product development. These virtual models simulate physical formulation behaviors, allowing researchers to conduct thousands of virtual experiments before committing resources to physical testing. The accuracy of these models improves continuously as they are trained on expanding datasets from physical experiments.

Natural language processing (NLP) technologies are being integrated to extract valuable insights from unstructured data sources such as research papers, patents, and consumer reviews. These systems can automatically identify emerging trends in consumer preferences or competitive formulation approaches, informing the direction of HTE campaigns.

Automated decision-making algorithms are beginning to guide experimental design in HTE workflows. These systems can autonomously determine the most informative next experiments to conduct, optimizing the exploration of formulation space based on previous results and desired product attributes. This represents a shift from traditional Design of Experiments approaches to more adaptive, AI-driven experimental design.

Interoperability between different data systems remains a significant challenge, with many organizations working to establish standardized data formats and protocols specific to personal care formulation. Industry consortia are developing open standards to facilitate seamless data exchange between equipment, analysis platforms, and research databases, enhancing collaborative innovation potential.

Machine learning algorithms are increasingly being deployed to identify patterns in formulation data that human researchers might overlook. These AI systems can analyze thousands of formulation variables simultaneously, predicting performance characteristics and stability profiles without requiring physical testing of every possible combination. This predictive capability significantly reduces the experimental space that needs to be physically explored.

Real-time data processing has become essential in HTE workflows, with edge computing solutions enabling immediate analysis of experimental results. This immediate feedback allows for dynamic adjustment of experimental parameters, optimizing resource utilization and accelerating development timelines. Companies implementing these systems report development cycle reductions of 30-50% compared to traditional methods.

Digital twins of formulation processes are emerging as powerful tools in personal care product development. These virtual models simulate physical formulation behaviors, allowing researchers to conduct thousands of virtual experiments before committing resources to physical testing. The accuracy of these models improves continuously as they are trained on expanding datasets from physical experiments.

Natural language processing (NLP) technologies are being integrated to extract valuable insights from unstructured data sources such as research papers, patents, and consumer reviews. These systems can automatically identify emerging trends in consumer preferences or competitive formulation approaches, informing the direction of HTE campaigns.

Automated decision-making algorithms are beginning to guide experimental design in HTE workflows. These systems can autonomously determine the most informative next experiments to conduct, optimizing the exploration of formulation space based on previous results and desired product attributes. This represents a shift from traditional Design of Experiments approaches to more adaptive, AI-driven experimental design.

Interoperability between different data systems remains a significant challenge, with many organizations working to establish standardized data formats and protocols specific to personal care formulation. Industry consortia are developing open standards to facilitate seamless data exchange between equipment, analysis platforms, and research databases, enhancing collaborative innovation potential.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!