High-Throughput Experimentation in Ceramic-Based Device Manufacturing

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic HTE Background and Objectives

High-Throughput Experimentation (HTE) represents a paradigm shift in ceramic-based device manufacturing, evolving from traditional trial-and-error approaches to systematic, data-driven methodologies. This technological evolution began in the pharmaceutical industry during the 1990s and has gradually expanded into materials science over the past two decades, with ceramic applications emerging as a frontier area in the last 5-7 years.

The historical development of ceramic manufacturing has been characterized by labor-intensive processes and empirical knowledge accumulation. Traditional ceramic processing typically involves lengthy iteration cycles, with each experimental modification requiring weeks or months to evaluate. This time-intensive approach has significantly limited innovation rates and material discovery in the ceramic sector compared to other materials classes.

HTE in ceramics aims to accelerate the discovery, optimization, and implementation of novel ceramic materials and manufacturing processes by orders of magnitude. The core technological objective is to establish parallel processing methodologies that enable simultaneous evaluation of multiple compositional, structural, and processing variables. This parallelization is expected to reduce development cycles from years to months or even weeks.

Current technological trends indicate a convergence of robotics, advanced characterization techniques, and artificial intelligence to enable truly autonomous materials discovery platforms. The integration of machine learning algorithms with HTE hardware systems represents a particularly promising direction, allowing for intelligent experimental design and predictive capabilities that further enhance efficiency.

The primary objectives of ceramic HTE technology development include: establishing standardized protocols for high-throughput synthesis of ceramic materials; developing rapid characterization methods suitable for ceramic properties; creating robust data management systems for handling the massive datasets generated; and building predictive models that can accelerate future development cycles.

Beyond technical goals, ceramic HTE aims to address critical industry challenges such as reducing energy consumption in manufacturing processes, identifying lead-free alternatives for electronic ceramics, developing sustainable processing routes, and discovering novel compositions with enhanced functional properties for emerging applications in energy storage, electronics, and healthcare.

The ultimate vision for ceramic HTE technology is to establish a self-improving discovery platform that continuously leverages accumulated data to refine experimental approaches and accelerate innovation cycles, thereby transforming ceramic manufacturing from an art form to a data-driven science. This transformation is expected to enable rapid response to market demands and facilitate the development of customized ceramic solutions for specific applications.

The historical development of ceramic manufacturing has been characterized by labor-intensive processes and empirical knowledge accumulation. Traditional ceramic processing typically involves lengthy iteration cycles, with each experimental modification requiring weeks or months to evaluate. This time-intensive approach has significantly limited innovation rates and material discovery in the ceramic sector compared to other materials classes.

HTE in ceramics aims to accelerate the discovery, optimization, and implementation of novel ceramic materials and manufacturing processes by orders of magnitude. The core technological objective is to establish parallel processing methodologies that enable simultaneous evaluation of multiple compositional, structural, and processing variables. This parallelization is expected to reduce development cycles from years to months or even weeks.

Current technological trends indicate a convergence of robotics, advanced characterization techniques, and artificial intelligence to enable truly autonomous materials discovery platforms. The integration of machine learning algorithms with HTE hardware systems represents a particularly promising direction, allowing for intelligent experimental design and predictive capabilities that further enhance efficiency.

The primary objectives of ceramic HTE technology development include: establishing standardized protocols for high-throughput synthesis of ceramic materials; developing rapid characterization methods suitable for ceramic properties; creating robust data management systems for handling the massive datasets generated; and building predictive models that can accelerate future development cycles.

Beyond technical goals, ceramic HTE aims to address critical industry challenges such as reducing energy consumption in manufacturing processes, identifying lead-free alternatives for electronic ceramics, developing sustainable processing routes, and discovering novel compositions with enhanced functional properties for emerging applications in energy storage, electronics, and healthcare.

The ultimate vision for ceramic HTE technology is to establish a self-improving discovery platform that continuously leverages accumulated data to refine experimental approaches and accelerate innovation cycles, thereby transforming ceramic manufacturing from an art form to a data-driven science. This transformation is expected to enable rapid response to market demands and facilitate the development of customized ceramic solutions for specific applications.

Market Analysis for Ceramic-Based Devices

The global market for ceramic-based devices has experienced significant growth in recent years, driven by advancements in material science and increasing demand across multiple industries. The market size for advanced ceramics reached approximately $75 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 6.2% through 2030. This growth trajectory is particularly evident in electronic components, where ceramic substrates and packages are essential for high-performance applications.

The healthcare sector represents one of the fastest-growing segments for ceramic-based devices, with bioceramics used in implants, dental applications, and diagnostic equipment showing market expansion at 8.5% annually. This acceleration is primarily attributed to the aging global population and increasing prevalence of chronic conditions requiring medical interventions. Ceramic materials offer superior biocompatibility and durability compared to traditional alternatives, driving their adoption in medical technology.

In the electronics industry, ceramic substrates and packages account for approximately 35% of the total ceramic devices market. The miniaturization trend in consumer electronics and the expansion of 5G infrastructure have created substantial demand for high-performance ceramic components that can withstand extreme conditions while maintaining signal integrity. The automotive sector has also emerged as a significant consumer, with ceramic components increasingly utilized in sensors, catalytic converters, and emerging battery technologies.

Regionally, Asia-Pacific dominates the ceramic devices manufacturing landscape, accounting for over 45% of global production capacity. China, Japan, and South Korea have established robust manufacturing ecosystems, benefiting from government initiatives supporting advanced materials development. North America and Europe maintain significant market shares, particularly in high-value applications requiring specialized ceramic formulations and precision manufacturing.

The integration of high-throughput experimentation (HTE) methodologies in ceramic device manufacturing represents a critical inflection point for the industry. Market analysis indicates that manufacturers implementing HTE techniques can reduce development cycles by 40-60% while simultaneously exploring a broader range of material compositions and processing parameters. This efficiency gain translates to faster time-to-market and enhanced product performance, creating competitive advantages in rapidly evolving markets.

Customer demand patterns show increasing requirements for customized ceramic solutions with specific performance characteristics, driving manufacturers toward more agile and responsive development approaches. The ability to rapidly iterate through material formulations and processing conditions using HTE methodologies directly addresses this market need, potentially unlocking new application areas previously constrained by lengthy development timelines.

The healthcare sector represents one of the fastest-growing segments for ceramic-based devices, with bioceramics used in implants, dental applications, and diagnostic equipment showing market expansion at 8.5% annually. This acceleration is primarily attributed to the aging global population and increasing prevalence of chronic conditions requiring medical interventions. Ceramic materials offer superior biocompatibility and durability compared to traditional alternatives, driving their adoption in medical technology.

In the electronics industry, ceramic substrates and packages account for approximately 35% of the total ceramic devices market. The miniaturization trend in consumer electronics and the expansion of 5G infrastructure have created substantial demand for high-performance ceramic components that can withstand extreme conditions while maintaining signal integrity. The automotive sector has also emerged as a significant consumer, with ceramic components increasingly utilized in sensors, catalytic converters, and emerging battery technologies.

Regionally, Asia-Pacific dominates the ceramic devices manufacturing landscape, accounting for over 45% of global production capacity. China, Japan, and South Korea have established robust manufacturing ecosystems, benefiting from government initiatives supporting advanced materials development. North America and Europe maintain significant market shares, particularly in high-value applications requiring specialized ceramic formulations and precision manufacturing.

The integration of high-throughput experimentation (HTE) methodologies in ceramic device manufacturing represents a critical inflection point for the industry. Market analysis indicates that manufacturers implementing HTE techniques can reduce development cycles by 40-60% while simultaneously exploring a broader range of material compositions and processing parameters. This efficiency gain translates to faster time-to-market and enhanced product performance, creating competitive advantages in rapidly evolving markets.

Customer demand patterns show increasing requirements for customized ceramic solutions with specific performance characteristics, driving manufacturers toward more agile and responsive development approaches. The ability to rapidly iterate through material formulations and processing conditions using HTE methodologies directly addresses this market need, potentially unlocking new application areas previously constrained by lengthy development timelines.

Current HTE Challenges in Ceramic Manufacturing

Despite significant advancements in High-Throughput Experimentation (HTE) methodologies, ceramic-based device manufacturing faces several persistent challenges that limit widespread industrial adoption. The inherent complexity of ceramic materials, characterized by diverse compositions and processing parameters, creates a multidimensional experimental space that is difficult to navigate efficiently. Traditional HTE approaches developed for other materials often fail when applied to ceramics due to their unique sintering requirements and temperature-dependent phase transformations.

Sample preparation represents a major bottleneck in ceramic HTE workflows. The necessity for precise powder processing, including milling, mixing, and homogenization steps, is difficult to miniaturize and parallelize without compromising sample quality. Current automated systems struggle with the viscosity variations in ceramic slurries and pastes, leading to inconsistent sample preparation that undermines experimental reproducibility.

High-temperature processing requirements pose another significant challenge. Ceramics typically require sintering at temperatures ranging from 800°C to 1700°C, with precise control of heating rates, dwell times, and atmospheric conditions. Existing HTE equipment often lacks the capability to process multiple samples under such demanding and varied thermal conditions while maintaining sample integrity and preventing cross-contamination.

Characterization throughput lags significantly behind sample preparation capabilities. Non-destructive evaluation of ceramic properties such as density, porosity, phase composition, and microstructure remains time-intensive. Advanced techniques like X-ray diffraction and electron microscopy, while informative, create bottlenecks in the HTE workflow due to their sequential nature and complex data interpretation requirements.

Data management and analysis present additional hurdles. The heterogeneous nature of ceramic materials generates complex datasets that are difficult to standardize and interpret. Current machine learning algorithms struggle with the non-linear relationships between processing parameters and material properties in ceramics, limiting predictive capabilities and automated decision-making in experimental design.

Scale-up challenges further complicate HTE implementation. Findings from miniaturized experiments often fail to translate directly to production scales due to differences in thermal gradients, mass transport phenomena, and interfacial effects. This disconnect between HTE results and manufacturing outcomes reduces industry confidence in HTE methodologies for ceramic development.

Regulatory and quality control considerations add another layer of complexity, particularly for ceramics used in critical applications such as medical devices, electronics, and aerospace components. Validation protocols for HTE-developed ceramics remain underdeveloped, creating uncertainty in regulatory approval pathways and slowing industrial adoption.

Sample preparation represents a major bottleneck in ceramic HTE workflows. The necessity for precise powder processing, including milling, mixing, and homogenization steps, is difficult to miniaturize and parallelize without compromising sample quality. Current automated systems struggle with the viscosity variations in ceramic slurries and pastes, leading to inconsistent sample preparation that undermines experimental reproducibility.

High-temperature processing requirements pose another significant challenge. Ceramics typically require sintering at temperatures ranging from 800°C to 1700°C, with precise control of heating rates, dwell times, and atmospheric conditions. Existing HTE equipment often lacks the capability to process multiple samples under such demanding and varied thermal conditions while maintaining sample integrity and preventing cross-contamination.

Characterization throughput lags significantly behind sample preparation capabilities. Non-destructive evaluation of ceramic properties such as density, porosity, phase composition, and microstructure remains time-intensive. Advanced techniques like X-ray diffraction and electron microscopy, while informative, create bottlenecks in the HTE workflow due to their sequential nature and complex data interpretation requirements.

Data management and analysis present additional hurdles. The heterogeneous nature of ceramic materials generates complex datasets that are difficult to standardize and interpret. Current machine learning algorithms struggle with the non-linear relationships between processing parameters and material properties in ceramics, limiting predictive capabilities and automated decision-making in experimental design.

Scale-up challenges further complicate HTE implementation. Findings from miniaturized experiments often fail to translate directly to production scales due to differences in thermal gradients, mass transport phenomena, and interfacial effects. This disconnect between HTE results and manufacturing outcomes reduces industry confidence in HTE methodologies for ceramic development.

Regulatory and quality control considerations add another layer of complexity, particularly for ceramics used in critical applications such as medical devices, electronics, and aerospace components. Validation protocols for HTE-developed ceramics remain underdeveloped, creating uncertainty in regulatory approval pathways and slowing industrial adoption.

Current HTE Methodologies for Ceramics

01 Automated laboratory systems for high-throughput experimentation

Automated laboratory systems enable high-throughput experimentation by integrating robotics, sample handling, and data acquisition components. These systems can perform multiple experiments simultaneously, significantly increasing experimental throughput compared to traditional methods. They typically include automated liquid handling, sample preparation, and analysis capabilities that minimize human intervention and reduce experimental cycle times.- Automated laboratory systems for high-throughput experimentation: Automated laboratory systems can significantly increase experimental throughput by integrating robotics, liquid handling systems, and computerized control. These systems enable parallel processing of multiple samples simultaneously, reducing manual intervention and increasing efficiency. Advanced automation platforms can operate continuously, performing standardized protocols with precision and consistency, which is essential for high-throughput screening applications in drug discovery, materials science, and biotechnology.

- Data processing and analysis methods for high-throughput experiments: Specialized data processing algorithms and analysis methods are crucial for handling the large volumes of data generated in high-throughput experimentation. These computational approaches enable rapid processing, pattern recognition, and extraction of meaningful insights from experimental results. Machine learning and artificial intelligence techniques can be applied to identify correlations and predict outcomes, further enhancing the efficiency and value of high-throughput screening campaigns.

- Microfluidic and miniaturized systems for enhanced throughput: Microfluidic technologies and miniaturized experimental platforms enable significant increases in throughput by reducing sample volumes and reaction times while allowing for massive parallelization. These systems can perform thousands of experiments simultaneously on a single chip or plate, dramatically increasing experimental capacity while reducing reagent consumption. Integration of sensors and detection systems within these platforms allows for real-time monitoring and analysis of experimental outcomes.

- Networked and distributed computing for high-throughput experimentation: Networked laboratory systems and distributed computing architectures enable coordination of multiple experimental platforms and resources across different locations. Cloud-based systems allow for remote monitoring, control, and data sharing, facilitating collaborative research and maximizing resource utilization. These approaches can significantly increase overall experimental throughput by optimizing workflow management and enabling continuous operation across time zones and geographical boundaries.

- Experimental design optimization for maximum throughput: Advanced experimental design strategies can optimize throughput by employing statistical methods such as Design of Experiments (DoE) and adaptive sampling approaches. These methodologies enable researchers to extract maximum information from minimal experimental runs, reducing redundancy and focusing resources on the most informative experiments. Optimization algorithms can dynamically adjust experimental parameters based on real-time results, further enhancing efficiency and accelerating discovery processes.

02 Parallel processing techniques for data analysis

Parallel processing techniques enhance high-throughput experimentation by distributing computational tasks across multiple processors or computing nodes. These methods enable simultaneous analysis of large experimental datasets, reducing processing time and increasing overall throughput. Advanced algorithms optimize resource allocation and task scheduling to maximize computational efficiency in handling complex experimental data.Expand Specific Solutions03 Microfluidic platforms for accelerated experimentation

Microfluidic platforms facilitate high-throughput experimentation by miniaturizing reaction volumes and enabling parallel processing of multiple samples. These systems reduce reagent consumption while increasing experimental density and throughput. Advanced microfluidic designs incorporate integrated sensors, controlled reaction environments, and automated sample handling to maximize experimental efficiency and data quality.Expand Specific Solutions04 Machine learning for experimental optimization

Machine learning algorithms enhance high-throughput experimentation by optimizing experimental design and predicting outcomes. These approaches analyze patterns in experimental data to identify optimal conditions, reduce the number of required experiments, and accelerate discovery processes. Predictive models help researchers focus on promising experimental paths, significantly increasing effective throughput by eliminating unnecessary experiments.Expand Specific Solutions05 Integrated data management systems

Integrated data management systems are essential for high-throughput experimentation, enabling efficient collection, storage, and analysis of large experimental datasets. These systems provide real-time monitoring of experiments, automated data capture, and standardized formats for data exchange. By streamlining data workflows and enabling rapid access to experimental results, these platforms significantly increase overall experimental throughput and knowledge extraction.Expand Specific Solutions

Leading Companies in Ceramic HTE Solutions

High-throughput experimentation in ceramic-based device manufacturing is currently in a growth phase, with the market expanding rapidly due to increasing demand for advanced ceramic components in electronics, automotive, and energy sectors. The global market size is estimated to reach significant scale as industries seek more efficient production methods. Technologically, the field is maturing with companies like Corning, NGK Insulators, and IBIDEN leading innovation in high-performance ceramics manufacturing. TDK, Sumitomo Electric, and Taiyo Yuden are advancing ceramic applications in electronic components, while research institutions like the Agency for Science, Technology & Research and various technical institutes are developing next-generation ceramic processing techniques. General Electric and Rolls-Royce are implementing these technologies in industrial applications, creating a competitive landscape balanced between established manufacturers and emerging specialized solution providers.

Corning, Inc.

Technical Solution: Corning has developed an advanced high-throughput experimentation (HTE) platform specifically for ceramic-based device manufacturing. Their system integrates robotic sample preparation, automated characterization tools, and machine learning algorithms to rapidly screen thousands of ceramic material compositions. The platform utilizes parallel synthesis methods where multiple ceramic formulations are simultaneously prepared using precision dispensing systems capable of handling various precursors including metal oxides, nitrates, and organometallics. Corning's approach incorporates in-situ monitoring during sintering processes using specialized sensors that track phase transformations and microstructural development in real-time. Their data management infrastructure connects experimental parameters with measured properties through a centralized database, enabling AI-driven predictive modeling to identify promising ceramic compositions for specific applications such as display glass, optical communications, and environmental technologies. The system has reportedly reduced development cycles from years to months for new ceramic materials with tailored properties.

Strengths: Extensive experience in glass and ceramic manufacturing; proprietary characterization techniques; established infrastructure for scaling successful formulations to production. Weaknesses: System primarily optimized for Corning's specific product categories; high capital investment requirements; potential limitations in handling certain specialized ceramic compositions requiring extreme processing conditions.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has implemented a comprehensive high-throughput experimentation system for ceramic manufacturing that focuses on functional ceramics for energy and environmental applications. Their approach combines combinatorial synthesis methods with high-speed evaluation techniques to accelerate the development of advanced ceramic components. The system features gradient material libraries where composition and processing parameters systematically vary across sample arrays, allowing simultaneous evaluation of numerous formulations. NGK's platform incorporates specialized high-temperature testing equipment that can rapidly assess electrical, thermal, and mechanical properties under simulated operating conditions. A key innovation is their multi-stage screening process that progressively narrows candidate materials through increasingly rigorous testing protocols. The company has developed custom software tools that integrate manufacturing process data with material performance metrics to identify optimal processing windows. This system has been particularly successful in developing ceramic materials for battery separators, automotive sensors, and pollution control devices, reducing development time by approximately 60% compared to conventional methods.

Strengths: Specialized expertise in functional ceramics for harsh environments; established manufacturing infrastructure for scaling promising materials; strong capabilities in electrical and electrochemical property testing. Weaknesses: System heavily focused on specific application areas; requires significant expertise to operate effectively; limited flexibility for adapting to entirely new ceramic material classes.

Key Innovations in Ceramic Characterization

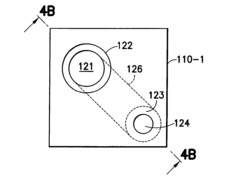

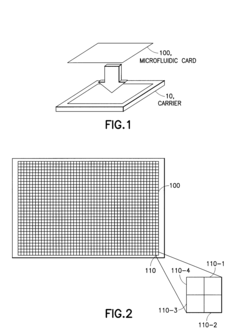

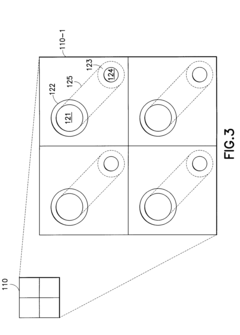

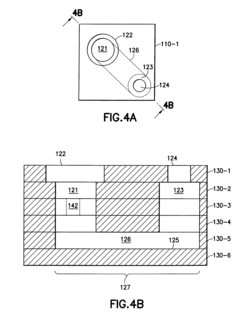

Microfluidics Packaging

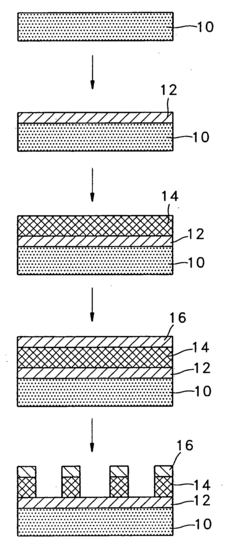

PatentInactiveUS20050069462A1

Innovation

- A ceramic device with micro wells and channels is developed, utilizing laminated personalized green sheets to create U-shaped channels with controlled fluid delivery through engineered geometries and surface features, enabling self-metering of fluid volumes via differential capillary forces and capillary retention valves.

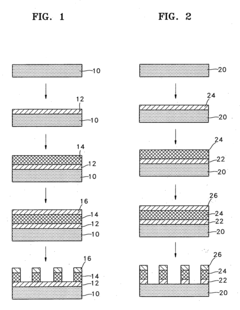

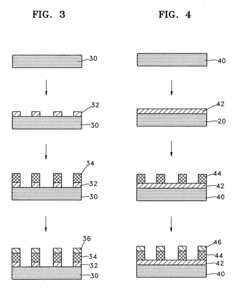

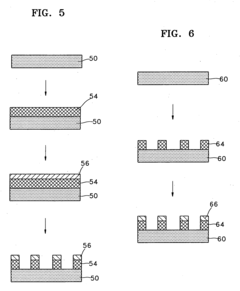

Manufacturing method of ceramic device using mixture with photosensitive resin

PatentInactiveUS20040055128A1

Innovation

- A manufacturing method using a mixture of photosensitive resin with metal or ceramic, where layers are formed and patterned simultaneously or sequentially through light exposure, allowing for precise control of layer arrangement and preventing short circuits between electrodes.

Materials Informatics Integration

Materials Informatics Integration represents a transformative approach in ceramic-based device manufacturing, combining data science with materials science to accelerate innovation. This integration leverages machine learning algorithms, statistical methods, and computational modeling to extract meaningful patterns from high-throughput experimentation data, enabling more efficient materials discovery and optimization.

The integration process begins with comprehensive data collection from multiple sources, including experimental results, characterization techniques, and historical manufacturing data. These diverse datasets are then standardized and organized into structured databases that facilitate cross-referencing and pattern recognition. Advanced data mining techniques subsequently identify correlations between processing parameters, microstructural features, and functional properties of ceramic materials.

Machine learning models, particularly deep neural networks and Bayesian optimization algorithms, have demonstrated remarkable success in predicting ceramic material properties based on compositional and processing variables. These predictive models significantly reduce the experimental iterations required to achieve desired performance metrics, cutting development time by up to 70% in some reported cases.

Materials informatics platforms specifically designed for ceramic manufacturing incorporate physics-based models alongside data-driven approaches, creating hybrid systems that respect fundamental materials science principles while leveraging the pattern-recognition capabilities of artificial intelligence. This synergy enables researchers to explore vast compositional spaces that would be impractical to investigate through traditional experimental methods alone.

Real-time data analytics integration with high-throughput experimentation equipment creates feedback loops that continuously refine experimental parameters. This adaptive experimentation approach maximizes information gain from each experimental cycle, optimizing resource utilization and accelerating the discovery process.

Several challenges remain in materials informatics integration, including the need for standardized data formats, methods to handle sparse and noisy experimental data, and techniques for quantifying uncertainty in predictions. Additionally, developing interpretable models that provide mechanistic insights, rather than merely predictive capabilities, represents a frontier research area critical for advancing fundamental understanding of ceramic materials behavior.

The future trajectory of materials informatics in ceramic manufacturing points toward autonomous research systems that combine robotic experimentation platforms with self-improving AI algorithms. These systems promise to revolutionize the development of next-generation ceramic devices by dramatically compressing innovation cycles and enabling the discovery of non-intuitive material compositions and processing routes that human researchers might overlook.

The integration process begins with comprehensive data collection from multiple sources, including experimental results, characterization techniques, and historical manufacturing data. These diverse datasets are then standardized and organized into structured databases that facilitate cross-referencing and pattern recognition. Advanced data mining techniques subsequently identify correlations between processing parameters, microstructural features, and functional properties of ceramic materials.

Machine learning models, particularly deep neural networks and Bayesian optimization algorithms, have demonstrated remarkable success in predicting ceramic material properties based on compositional and processing variables. These predictive models significantly reduce the experimental iterations required to achieve desired performance metrics, cutting development time by up to 70% in some reported cases.

Materials informatics platforms specifically designed for ceramic manufacturing incorporate physics-based models alongside data-driven approaches, creating hybrid systems that respect fundamental materials science principles while leveraging the pattern-recognition capabilities of artificial intelligence. This synergy enables researchers to explore vast compositional spaces that would be impractical to investigate through traditional experimental methods alone.

Real-time data analytics integration with high-throughput experimentation equipment creates feedback loops that continuously refine experimental parameters. This adaptive experimentation approach maximizes information gain from each experimental cycle, optimizing resource utilization and accelerating the discovery process.

Several challenges remain in materials informatics integration, including the need for standardized data formats, methods to handle sparse and noisy experimental data, and techniques for quantifying uncertainty in predictions. Additionally, developing interpretable models that provide mechanistic insights, rather than merely predictive capabilities, represents a frontier research area critical for advancing fundamental understanding of ceramic materials behavior.

The future trajectory of materials informatics in ceramic manufacturing points toward autonomous research systems that combine robotic experimentation platforms with self-improving AI algorithms. These systems promise to revolutionize the development of next-generation ceramic devices by dramatically compressing innovation cycles and enabling the discovery of non-intuitive material compositions and processing routes that human researchers might overlook.

Sustainability Considerations in Ceramic Manufacturing

The integration of sustainability principles into ceramic manufacturing processes has become increasingly critical as environmental regulations tighten and consumer demand for eco-friendly products grows. High-throughput experimentation (HTE) methodologies present unique opportunities to advance sustainable practices in ceramic-based device manufacturing through systematic optimization of resource utilization and environmental impact reduction.

Energy consumption represents one of the most significant sustainability challenges in ceramic manufacturing, with traditional firing processes requiring temperatures exceeding 1000°C for extended periods. HTE enables rapid screening of alternative formulations and processing conditions that can lower firing temperatures while maintaining product integrity. Recent experiments have demonstrated that certain dopants and composite structures identified through HTE can reduce sintering temperatures by 100-200°C, potentially decreasing energy consumption by 15-30%.

Raw material efficiency constitutes another critical sustainability dimension where HTE provides substantial benefits. By systematically exploring diverse material combinations and proportions, manufacturers can identify formulations that minimize the use of rare or environmentally problematic elements. For instance, HTE has facilitated the development of lead-free piezoelectric ceramics that maintain performance comparable to traditional lead-containing variants, addressing both environmental and regulatory concerns.

Water usage optimization in ceramic processing has been revolutionized through HTE approaches. Parallel testing of various dispersants, binders, and processing aids has identified combinations that maintain rheological properties while reducing water requirements by up to 40% in some slurry formulations. These improvements directly translate to reduced energy needs for drying stages and decreased wastewater treatment demands.

Waste reduction strategies have similarly benefited from HTE methodologies. Rapid screening of recycled material incorporation has established viable pathways for utilizing manufacturing scrap and end-of-life ceramic products as raw material inputs. Some HTE-optimized formulations can now incorporate up to 30% recycled content without compromising performance specifications, creating circular economy opportunities within the ceramic industry.

Life cycle assessment (LCA) integration with HTE represents an emerging frontier in sustainable ceramic manufacturing. By incorporating environmental impact metrics into experimental design and analysis protocols, researchers can simultaneously optimize for technical performance and sustainability outcomes. This holistic approach ensures that improvements in one environmental dimension do not create unintended consequences in others, supporting truly sustainable innovation in ceramic device manufacturing.

Energy consumption represents one of the most significant sustainability challenges in ceramic manufacturing, with traditional firing processes requiring temperatures exceeding 1000°C for extended periods. HTE enables rapid screening of alternative formulations and processing conditions that can lower firing temperatures while maintaining product integrity. Recent experiments have demonstrated that certain dopants and composite structures identified through HTE can reduce sintering temperatures by 100-200°C, potentially decreasing energy consumption by 15-30%.

Raw material efficiency constitutes another critical sustainability dimension where HTE provides substantial benefits. By systematically exploring diverse material combinations and proportions, manufacturers can identify formulations that minimize the use of rare or environmentally problematic elements. For instance, HTE has facilitated the development of lead-free piezoelectric ceramics that maintain performance comparable to traditional lead-containing variants, addressing both environmental and regulatory concerns.

Water usage optimization in ceramic processing has been revolutionized through HTE approaches. Parallel testing of various dispersants, binders, and processing aids has identified combinations that maintain rheological properties while reducing water requirements by up to 40% in some slurry formulations. These improvements directly translate to reduced energy needs for drying stages and decreased wastewater treatment demands.

Waste reduction strategies have similarly benefited from HTE methodologies. Rapid screening of recycled material incorporation has established viable pathways for utilizing manufacturing scrap and end-of-life ceramic products as raw material inputs. Some HTE-optimized formulations can now incorporate up to 30% recycled content without compromising performance specifications, creating circular economy opportunities within the ceramic industry.

Life cycle assessment (LCA) integration with HTE represents an emerging frontier in sustainable ceramic manufacturing. By incorporating environmental impact metrics into experimental design and analysis protocols, researchers can simultaneously optimize for technical performance and sustainability outcomes. This holistic approach ensures that improvements in one environmental dimension do not create unintended consequences in others, supporting truly sustainable innovation in ceramic device manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!