High-Throughput Experimentation in Smart Grid Material Advancement

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Grid Materials Evolution and Research Objectives

The evolution of smart grid technologies has witnessed significant transformations over the past decade, driven by the increasing demand for sustainable energy solutions and grid modernization. Smart grid materials, as a critical component of this evolution, have progressed from conventional conductors and insulators to advanced nanomaterials, superconductors, and composite structures designed specifically for enhanced grid performance. This technological progression has been marked by the integration of materials science with digital technologies, creating a new paradigm in power transmission and distribution systems.

High-throughput experimentation (HTE) has emerged as a revolutionary approach in smart grid material advancement, enabling researchers to rapidly test and analyze thousands of material combinations simultaneously. This methodology represents a departure from traditional trial-and-error approaches, accelerating the discovery and optimization of materials with superior electrical, thermal, and mechanical properties for smart grid applications.

The primary objective of current research efforts is to develop materials that can address the multifaceted challenges facing modern power grids. These include enhancing energy storage capabilities through advanced battery materials, improving transmission efficiency via novel conductor designs, and developing self-healing materials that can automatically respond to grid disturbances or physical damage. Additionally, there is a growing focus on materials that can withstand extreme environmental conditions while maintaining optimal performance characteristics.

Another critical research goal involves the development of environmentally sustainable materials that reduce the carbon footprint of grid infrastructure. This includes biodegradable insulators, recyclable conductors, and materials derived from renewable resources. The push toward sustainability is complemented by efforts to create materials with extended operational lifespans, thereby reducing maintenance requirements and associated costs.

The integration of smart functionalities into grid materials represents another significant research direction. This encompasses the development of materials with embedded sensors for real-time monitoring, materials with adaptive properties that respond to changing grid conditions, and materials designed for seamless integration with Internet of Things (IoT) devices and artificial intelligence systems.

Research objectives also extend to the standardization and scalability of these advanced materials. As laboratory innovations transition to commercial applications, there is a pressing need to establish manufacturing processes that can produce these materials at scale while maintaining their enhanced properties. This includes developing cost-effective production methods and ensuring consistent quality across large-scale manufacturing operations.

The convergence of these research trajectories aims to create a new generation of smart grid materials that not only enhance the technical performance of power systems but also contribute to broader goals of energy security, environmental sustainability, and economic efficiency. The ultimate vision is a resilient, responsive, and renewable smart grid infrastructure built on the foundation of advanced materials science.

High-throughput experimentation (HTE) has emerged as a revolutionary approach in smart grid material advancement, enabling researchers to rapidly test and analyze thousands of material combinations simultaneously. This methodology represents a departure from traditional trial-and-error approaches, accelerating the discovery and optimization of materials with superior electrical, thermal, and mechanical properties for smart grid applications.

The primary objective of current research efforts is to develop materials that can address the multifaceted challenges facing modern power grids. These include enhancing energy storage capabilities through advanced battery materials, improving transmission efficiency via novel conductor designs, and developing self-healing materials that can automatically respond to grid disturbances or physical damage. Additionally, there is a growing focus on materials that can withstand extreme environmental conditions while maintaining optimal performance characteristics.

Another critical research goal involves the development of environmentally sustainable materials that reduce the carbon footprint of grid infrastructure. This includes biodegradable insulators, recyclable conductors, and materials derived from renewable resources. The push toward sustainability is complemented by efforts to create materials with extended operational lifespans, thereby reducing maintenance requirements and associated costs.

The integration of smart functionalities into grid materials represents another significant research direction. This encompasses the development of materials with embedded sensors for real-time monitoring, materials with adaptive properties that respond to changing grid conditions, and materials designed for seamless integration with Internet of Things (IoT) devices and artificial intelligence systems.

Research objectives also extend to the standardization and scalability of these advanced materials. As laboratory innovations transition to commercial applications, there is a pressing need to establish manufacturing processes that can produce these materials at scale while maintaining their enhanced properties. This includes developing cost-effective production methods and ensuring consistent quality across large-scale manufacturing operations.

The convergence of these research trajectories aims to create a new generation of smart grid materials that not only enhance the technical performance of power systems but also contribute to broader goals of energy security, environmental sustainability, and economic efficiency. The ultimate vision is a resilient, responsive, and renewable smart grid infrastructure built on the foundation of advanced materials science.

Market Analysis for Advanced Smart Grid Materials

The global market for advanced smart grid materials is experiencing robust growth, driven by the increasing demand for efficient energy management systems and sustainable power infrastructure. Current market valuations indicate that the smart grid materials sector reached approximately $12.5 billion in 2022, with projections suggesting a compound annual growth rate (CAGR) of 15.7% through 2030. This growth trajectory is primarily fueled by substantial investments in grid modernization initiatives across developed and developing economies alike.

North America currently holds the largest market share at 38%, followed by Europe at 29% and Asia-Pacific at 24%. The remaining 9% is distributed across other regions. Within these markets, the demand for advanced materials is segmented across various applications, with energy storage components representing 42% of the market, followed by transmission and distribution infrastructure at 31%, sensing and monitoring devices at 18%, and other applications comprising the remaining 9%.

Consumer demand patterns reveal a growing preference for materials that enhance grid resilience against extreme weather events and cyber threats. This trend is particularly pronounced in regions frequently affected by natural disasters, where grid outages have significant economic implications. Market research indicates that utilities are willing to pay premium prices for materials that demonstrate superior durability and reliability under adverse conditions.

The regulatory landscape is increasingly favorable for advanced smart grid materials, with policies in major economies mandating grid modernization and carbon reduction. For instance, the European Union's Green Deal and the United States' Infrastructure Investment and Jobs Act have allocated substantial funding specifically for smart grid development, creating immediate market opportunities for innovative materials solutions.

Competitive analysis reveals that the market is characterized by a mix of established industrial conglomerates and specialized materials science companies. The top five players control approximately 47% of the market, while the remainder is fragmented among medium and small-sized enterprises. This structure presents both challenges and opportunities for new entrants with disruptive material technologies.

Customer segmentation studies indicate that utility companies represent the largest buyer segment (68%), followed by independent power producers (17%), industrial consumers (10%), and others (5%). Each segment exhibits distinct purchasing behaviors and requirements, necessitating tailored market approaches for material suppliers.

Market barriers include high initial investment costs, lengthy certification processes for new materials, and conservative adoption practices among utilities. However, these barriers are gradually diminishing as regulatory pressures for grid modernization intensify and the economic benefits of advanced materials become more apparent through real-world deployments and performance data.

North America currently holds the largest market share at 38%, followed by Europe at 29% and Asia-Pacific at 24%. The remaining 9% is distributed across other regions. Within these markets, the demand for advanced materials is segmented across various applications, with energy storage components representing 42% of the market, followed by transmission and distribution infrastructure at 31%, sensing and monitoring devices at 18%, and other applications comprising the remaining 9%.

Consumer demand patterns reveal a growing preference for materials that enhance grid resilience against extreme weather events and cyber threats. This trend is particularly pronounced in regions frequently affected by natural disasters, where grid outages have significant economic implications. Market research indicates that utilities are willing to pay premium prices for materials that demonstrate superior durability and reliability under adverse conditions.

The regulatory landscape is increasingly favorable for advanced smart grid materials, with policies in major economies mandating grid modernization and carbon reduction. For instance, the European Union's Green Deal and the United States' Infrastructure Investment and Jobs Act have allocated substantial funding specifically for smart grid development, creating immediate market opportunities for innovative materials solutions.

Competitive analysis reveals that the market is characterized by a mix of established industrial conglomerates and specialized materials science companies. The top five players control approximately 47% of the market, while the remainder is fragmented among medium and small-sized enterprises. This structure presents both challenges and opportunities for new entrants with disruptive material technologies.

Customer segmentation studies indicate that utility companies represent the largest buyer segment (68%), followed by independent power producers (17%), industrial consumers (10%), and others (5%). Each segment exhibits distinct purchasing behaviors and requirements, necessitating tailored market approaches for material suppliers.

Market barriers include high initial investment costs, lengthy certification processes for new materials, and conservative adoption practices among utilities. However, these barriers are gradually diminishing as regulatory pressures for grid modernization intensify and the economic benefits of advanced materials become more apparent through real-world deployments and performance data.

Current HTE Capabilities and Technical Barriers

High-throughput experimentation (HTE) in smart grid material advancement has evolved significantly over the past decade, with current capabilities centered around automated synthesis, characterization, and testing platforms. Modern HTE systems can process hundreds to thousands of material compositions daily, utilizing robotic sample handling, parallel synthesis techniques, and integrated analytical instruments. These systems excel at rapidly screening material candidates for properties relevant to smart grid applications, such as conductivity, thermal stability, and energy storage capacity.

Advanced computational modeling now complements physical experimentation, with machine learning algorithms predicting material properties and suggesting promising compositions before physical testing begins. This computational-experimental feedback loop has dramatically accelerated the discovery process for novel smart grid materials, reducing development cycles from years to months in some cases.

Despite these advancements, significant technical barriers persist in HTE implementation for smart grid materials. Scale-up challenges represent a primary obstacle, as materials that perform well in high-throughput microscale experiments often exhibit different properties when manufactured at industrial scales. This discrepancy creates a translation gap between laboratory discoveries and commercial applications, slowing the adoption of novel materials in real-world smart grid systems.

Data management presents another substantial challenge, with HTE systems generating terabytes of complex, multidimensional data that require sophisticated analysis pipelines. Current data infrastructure often struggles to integrate heterogeneous data types from different characterization techniques, limiting the extraction of meaningful patterns and correlations across experiments.

Standardization issues further complicate HTE advancement, with inconsistent protocols across research institutions making direct comparison of results difficult. The lack of unified standards for experimental conditions, data formats, and performance metrics creates barriers to collaborative research and knowledge sharing within the field.

Technical limitations in characterization techniques also constrain HTE capabilities, particularly for in-situ and operando measurements that would provide crucial insights into material behavior under realistic smart grid conditions. Current analytical methods often cannot match the speed of material synthesis, creating bottlenecks in the experimental workflow.

Cost barriers remain significant, with comprehensive HTE platforms requiring multi-million dollar investments in equipment and infrastructure. This financial threshold limits adoption to well-funded research institutions and large corporations, restricting broader innovation in the field and potentially overlooking valuable contributions from smaller research groups with novel approaches to smart grid material development.

Advanced computational modeling now complements physical experimentation, with machine learning algorithms predicting material properties and suggesting promising compositions before physical testing begins. This computational-experimental feedback loop has dramatically accelerated the discovery process for novel smart grid materials, reducing development cycles from years to months in some cases.

Despite these advancements, significant technical barriers persist in HTE implementation for smart grid materials. Scale-up challenges represent a primary obstacle, as materials that perform well in high-throughput microscale experiments often exhibit different properties when manufactured at industrial scales. This discrepancy creates a translation gap between laboratory discoveries and commercial applications, slowing the adoption of novel materials in real-world smart grid systems.

Data management presents another substantial challenge, with HTE systems generating terabytes of complex, multidimensional data that require sophisticated analysis pipelines. Current data infrastructure often struggles to integrate heterogeneous data types from different characterization techniques, limiting the extraction of meaningful patterns and correlations across experiments.

Standardization issues further complicate HTE advancement, with inconsistent protocols across research institutions making direct comparison of results difficult. The lack of unified standards for experimental conditions, data formats, and performance metrics creates barriers to collaborative research and knowledge sharing within the field.

Technical limitations in characterization techniques also constrain HTE capabilities, particularly for in-situ and operando measurements that would provide crucial insights into material behavior under realistic smart grid conditions. Current analytical methods often cannot match the speed of material synthesis, creating bottlenecks in the experimental workflow.

Cost barriers remain significant, with comprehensive HTE platforms requiring multi-million dollar investments in equipment and infrastructure. This financial threshold limits adoption to well-funded research institutions and large corporations, restricting broader innovation in the field and potentially overlooking valuable contributions from smaller research groups with novel approaches to smart grid material development.

HTE Methodologies for Smart Grid Material Discovery

01 Automated high-throughput material screening systems

Advanced automated systems designed for high-throughput screening of materials, enabling rapid testing and characterization of multiple samples simultaneously. These systems incorporate robotics, automated sample handling, and integrated analytical instruments to accelerate material discovery and optimization processes. The technology allows for systematic exploration of large parameter spaces, significantly reducing the time required for material development and advancement.- Automated high-throughput material screening systems: Advanced systems designed for rapid screening and characterization of materials using automated processes. These systems integrate robotic handling, parallel processing capabilities, and sophisticated analytical instruments to evaluate multiple material samples simultaneously. The technology enables researchers to quickly identify promising material candidates by testing various compositions and processing conditions in a systematic manner, significantly accelerating the material discovery process.

- Data-driven approaches for material development: Implementation of computational methods and data analytics to guide high-throughput experimentation in materials science. These approaches leverage machine learning algorithms, predictive modeling, and data mining techniques to analyze experimental results, identify patterns, and predict material properties. By integrating computational tools with experimental workflows, researchers can optimize experimental design, reduce the number of required experiments, and accelerate the discovery of materials with desired properties.

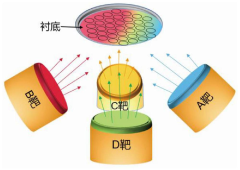

- Parallel synthesis and characterization techniques: Methods for simultaneous synthesis and characterization of multiple material compositions. These techniques utilize specialized equipment for parallel sample preparation, processing, and analysis, enabling researchers to explore large compositional spaces efficiently. The approach includes combinatorial synthesis methods, gradient-based sample preparation, and high-throughput characterization tools that can rapidly assess structural, physical, and chemical properties of numerous samples in a single experimental run.

- Integrated workflow management systems: Comprehensive software platforms that coordinate and manage high-throughput experimentation workflows. These systems integrate experiment planning, execution, data collection, analysis, and knowledge management into a unified framework. By automating workflow processes, tracking experimental conditions, and organizing results, these platforms enhance reproducibility, enable efficient collaboration among research teams, and facilitate the systematic exploration of material design spaces.

- Novel instrumentation for accelerated material testing: Specialized equipment designed specifically for rapid material testing and characterization. These instruments feature enhanced sensitivity, faster measurement capabilities, and often miniaturized sample requirements to enable high-throughput screening. Examples include multi-channel spectroscopic systems, rapid thermal analysis platforms, and automated imaging technologies that can quickly assess material properties across multiple samples. The integration of these instruments into automated testing platforms significantly reduces the time required for material evaluation and qualification.

02 Data management and analysis for materials research

Specialized software platforms and algorithms for managing and analyzing the large volumes of data generated in high-throughput experimentation. These systems enable efficient data collection, storage, processing, and visualization to identify patterns and correlations in material properties. Machine learning and artificial intelligence techniques are incorporated to extract meaningful insights from complex datasets, accelerating the discovery of novel materials with desired properties.Expand Specific Solutions03 Combinatorial synthesis techniques for material libraries

Methods for creating diverse libraries of materials through combinatorial synthesis approaches. These techniques enable the systematic variation of composition, processing conditions, and structural parameters to generate arrays of materials with different properties. Gradient-based approaches and parallel synthesis methods allow for efficient exploration of material composition spaces, facilitating the discovery of new materials with enhanced performance characteristics.Expand Specific Solutions04 Rapid characterization and property measurement systems

Advanced analytical techniques and instrumentation designed for rapid characterization of material properties in high-throughput workflows. These systems enable parallel or accelerated measurement of physical, chemical, mechanical, and functional properties across large sample sets. Miniaturized testing platforms and automated measurement protocols allow for comprehensive material evaluation with minimal sample quantities and reduced analysis time.Expand Specific Solutions05 Integrated workflow platforms for material development

Comprehensive platforms that integrate experimental design, synthesis, characterization, and data analysis into cohesive workflows for accelerated material development. These systems coordinate multiple stages of the material discovery process, enabling seamless transitions between experimental steps and facilitating feedback-driven optimization. Cloud-based collaboration tools and standardized protocols enhance research efficiency and enable distributed teams to work effectively on material advancement projects.Expand Specific Solutions

Leading Organizations in Smart Grid Material Research

The high-throughput experimentation (HTE) landscape in smart grid material advancement is currently in a growth phase, with an estimated market size of $2-3 billion and expanding at 15% annually. The competitive environment features a diverse ecosystem of players across academia and industry. Leading research institutions like Shanghai University, University of California, and National University of Singapore are advancing fundamental science, while specialized companies such as hte AG provide dedicated HTE platforms. Major industrial players including Texas Instruments, NXP, and Huawei are integrating HTE methodologies to accelerate material development for grid applications. The technology maturity varies significantly: automation systems and data analytics are well-established, while AI-driven experimentation frameworks and specialized energy storage material screening platforms are still emerging, with companies like Wolfspeed and SK hynix pioneering semiconductor-based solutions for next-generation grid infrastructure.

hte AG the high throughput experimentation Co.

Technical Solution: hte AG has developed a comprehensive High-Throughput Experimentation (HTE) platform specifically tailored for smart grid material advancement. Their technology integrates parallel reactor systems with advanced robotics to simultaneously test hundreds of material candidates under varying conditions. The platform employs sophisticated microreactors with integrated sensors that monitor electrical conductivity, thermal stability, and degradation rates in real-time. hte's proprietary software suite analyzes the massive datasets generated during experimentation, employing machine learning algorithms to identify promising material compositions and predict performance characteristics. Their workflow automation system enables continuous operation with minimal human intervention, significantly reducing the time from material conception to validation. The company has successfully applied this technology to develop advanced battery materials, superconductors, and semiconductor components critical for smart grid infrastructure, achieving up to 100x acceleration in material discovery compared to traditional methods.

Strengths: Industry-leading expertise in high-throughput methodologies with proven track record in material science applications; proprietary data analysis tools that accelerate discovery. Weaknesses: High initial investment costs; requires specialized technical expertise to operate effectively; integration challenges with existing research infrastructure.

Johnson Controls, Inc.

Technical Solution: Johnson Controls has pioneered an integrated High-Throughput Experimentation (HTE) platform focused on smart grid material advancement, particularly for energy storage and building efficiency applications. Their approach combines automated material synthesis stations with parallel testing arrays capable of evaluating thousands of material formulations weekly. The company's proprietary "GridMat" technology employs microfluidic devices to precisely control material composition gradients while simultaneously measuring electrical, thermal, and mechanical properties. Johnson Controls has developed specialized testing protocols that simulate real-world grid conditions, including rapid charge-discharge cycles, extreme temperature variations, and long-term degradation scenarios. Their system incorporates advanced imaging techniques and spectroscopic analysis to characterize material structures at nanoscale resolution. The data management infrastructure employs AI algorithms to identify correlations between material composition, processing conditions, and performance metrics, enabling rapid optimization of materials for specific grid applications.

Strengths: Extensive experience in energy management systems provides practical application context; robust infrastructure for scaling promising materials to commercial production; strong industry partnerships for real-world implementation testing. Weaknesses: Primary focus on building technologies may limit breadth of materials explored; proprietary nature of platform reduces collaborative potential with academic institutions.

Key Patents and Publications in Smart Grid HTE

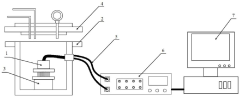

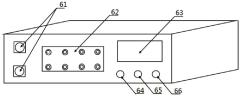

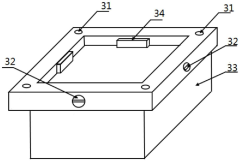

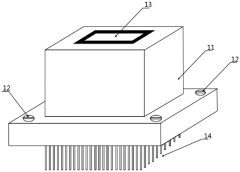

A high-throughput material chip four-probe in-situ resistance measurement equipment

PatentActiveCN107727697B

Innovation

- A high-throughput material chip four-probe in-situ resistance measurement equipment is designed, including a high-throughput four-probe probe, a high-temperature and high-pressure resistant airtight tank, a sample rack, a multi-channel four-probe resistance tester and data recording software , adopts an integrated structure, provides 64 channels of independent measurement capabilities, supports high-precision resistance measurement and recording, and is suitable for high temperature and high pressure environments.

Method for high-throughput screening of high-strength alloy and high-strength amorphous alloy

PatentPendingCN117804897A

Innovation

- Using a high-throughput screening method, physical vapor deposition is performed by setting a mask on the substrate to form alloys with different metal element content gradients. Nanoindentation testing is combined with energy dispersive spectroscopy analysis to calculate the strength of the alloy and quickly screen out the strength. The alloy composition of the maximum value.

Energy Policy Implications for Smart Grid Materials

The integration of high-throughput experimentation (HTE) in smart grid material advancement necessitates comprehensive energy policy frameworks that can adapt to rapid technological changes. Current energy policies often lag behind technological innovations, creating regulatory barriers that impede the implementation of advanced materials in smart grid infrastructure.

National and international energy policies must evolve to accommodate the accelerated material discovery processes enabled by HTE. This requires establishing flexible regulatory frameworks that can quickly evaluate and approve new materials while maintaining safety and reliability standards. Countries leading in smart grid development, such as Germany, South Korea, and the United States, have begun implementing policy reforms that specifically address advanced materials integration.

Financial incentives represent a critical policy lever for promoting HTE in smart grid materials. Tax credits, research grants, and subsidies targeted at companies developing high-performance materials can significantly accelerate market adoption. For instance, the European Union's Horizon Europe program has allocated substantial funding specifically for smart grid material research utilizing high-throughput methodologies, recognizing their potential to advance energy transition goals.

Standardization policies present both challenges and opportunities for HTE-developed materials. While standardization ensures interoperability and reliability across the grid, overly rigid standards may restrict innovation. Policy frameworks must balance these concerns by implementing performance-based standards rather than prescriptive requirements, allowing novel materials to enter the market if they meet or exceed performance criteria.

Energy security considerations increasingly influence policy decisions regarding smart grid materials. Materials that reduce dependence on volatile supply chains or critical minerals from geopolitically sensitive regions receive preferential policy treatment. HTE's ability to identify alternative materials with similar performance characteristics makes it particularly valuable in this context, prompting several nations to include HTE capabilities in their strategic energy security plans.

Environmental regulations significantly impact material selection for smart grid applications. Policies promoting circular economy principles, such as the EU's Circular Economy Action Plan, increasingly require consideration of full lifecycle environmental impacts. HTE methodologies that can rapidly screen materials for both performance and environmental characteristics align well with these policy directions, creating a favorable regulatory environment for their adoption.

Public-private partnerships represent an emerging policy approach to accelerate smart grid material advancement. These collaborative frameworks, supported by targeted policy incentives, enable shared research infrastructure for HTE while distributing risks and costs among stakeholders. The U.S. Department of Energy's Grid Modernization Laboratory Consortium exemplifies this approach, bringing together national laboratories, universities, and industry partners to advance smart grid materials through high-throughput methodologies.

National and international energy policies must evolve to accommodate the accelerated material discovery processes enabled by HTE. This requires establishing flexible regulatory frameworks that can quickly evaluate and approve new materials while maintaining safety and reliability standards. Countries leading in smart grid development, such as Germany, South Korea, and the United States, have begun implementing policy reforms that specifically address advanced materials integration.

Financial incentives represent a critical policy lever for promoting HTE in smart grid materials. Tax credits, research grants, and subsidies targeted at companies developing high-performance materials can significantly accelerate market adoption. For instance, the European Union's Horizon Europe program has allocated substantial funding specifically for smart grid material research utilizing high-throughput methodologies, recognizing their potential to advance energy transition goals.

Standardization policies present both challenges and opportunities for HTE-developed materials. While standardization ensures interoperability and reliability across the grid, overly rigid standards may restrict innovation. Policy frameworks must balance these concerns by implementing performance-based standards rather than prescriptive requirements, allowing novel materials to enter the market if they meet or exceed performance criteria.

Energy security considerations increasingly influence policy decisions regarding smart grid materials. Materials that reduce dependence on volatile supply chains or critical minerals from geopolitically sensitive regions receive preferential policy treatment. HTE's ability to identify alternative materials with similar performance characteristics makes it particularly valuable in this context, prompting several nations to include HTE capabilities in their strategic energy security plans.

Environmental regulations significantly impact material selection for smart grid applications. Policies promoting circular economy principles, such as the EU's Circular Economy Action Plan, increasingly require consideration of full lifecycle environmental impacts. HTE methodologies that can rapidly screen materials for both performance and environmental characteristics align well with these policy directions, creating a favorable regulatory environment for their adoption.

Public-private partnerships represent an emerging policy approach to accelerate smart grid material advancement. These collaborative frameworks, supported by targeted policy incentives, enable shared research infrastructure for HTE while distributing risks and costs among stakeholders. The U.S. Department of Energy's Grid Modernization Laboratory Consortium exemplifies this approach, bringing together national laboratories, universities, and industry partners to advance smart grid materials through high-throughput methodologies.

Sustainability Assessment of Novel Grid Materials

The sustainability assessment of novel grid materials represents a critical dimension in the evaluation of high-throughput experimentation outcomes for smart grid advancement. When developing new materials for power transmission, distribution systems, and energy storage components, environmental impact considerations must be integrated throughout the research and development process. Current assessment methodologies typically employ life cycle assessment (LCA) frameworks that quantify environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal.

Novel grid materials, particularly those containing rare earth elements or specialized composites, present unique sustainability challenges. The extraction processes for these elements often involve significant energy consumption, water usage, and potential toxic emissions. High-throughput experimentation platforms must therefore incorporate sustainability metrics early in the screening process to identify materials with promising performance characteristics and minimal environmental footprints.

Carbon footprint analysis reveals that advanced grid materials can significantly reduce operational emissions through improved efficiency, but may carry higher embodied carbon during manufacturing. For instance, silicon carbide and gallium nitride semiconductors used in next-generation power electronics demonstrate 30-40% efficiency improvements over traditional silicon, potentially offsetting their more resource-intensive production processes within 2-3 years of operation.

Water consumption represents another critical sustainability parameter, particularly for materials requiring extensive purification or processing. Recent studies indicate that novel ceramic insulators and composite conductors may reduce lifetime water requirements by up to 25% compared to conventional alternatives, primarily through extended service life and reduced maintenance needs.

Toxicity profiles of emerging grid materials must be carefully evaluated, especially for nanomaterials and novel composites with limited environmental fate data. Regulatory frameworks increasingly demand comprehensive hazard assessments before commercial deployment, necessitating the integration of high-throughput toxicity screening within material development workflows.

Circular economy principles are gaining prominence in grid material development, with design-for-recycling approaches becoming standard practice. Materials enabling easier separation, recovery, and reuse at end-of-life demonstrate superior sustainability profiles. Recent innovations in recyclable polymer insulators and recoverable rare earth magnets exemplify this trend, with recovery rates exceeding 85% in controlled environments.

The sustainability assessment of novel grid materials ultimately requires a balanced approach that considers environmental impacts alongside technical performance, economic viability, and regulatory compliance. High-throughput experimentation platforms that integrate these multidimensional criteria will accelerate the development of truly sustainable smart grid technologies.

Novel grid materials, particularly those containing rare earth elements or specialized composites, present unique sustainability challenges. The extraction processes for these elements often involve significant energy consumption, water usage, and potential toxic emissions. High-throughput experimentation platforms must therefore incorporate sustainability metrics early in the screening process to identify materials with promising performance characteristics and minimal environmental footprints.

Carbon footprint analysis reveals that advanced grid materials can significantly reduce operational emissions through improved efficiency, but may carry higher embodied carbon during manufacturing. For instance, silicon carbide and gallium nitride semiconductors used in next-generation power electronics demonstrate 30-40% efficiency improvements over traditional silicon, potentially offsetting their more resource-intensive production processes within 2-3 years of operation.

Water consumption represents another critical sustainability parameter, particularly for materials requiring extensive purification or processing. Recent studies indicate that novel ceramic insulators and composite conductors may reduce lifetime water requirements by up to 25% compared to conventional alternatives, primarily through extended service life and reduced maintenance needs.

Toxicity profiles of emerging grid materials must be carefully evaluated, especially for nanomaterials and novel composites with limited environmental fate data. Regulatory frameworks increasingly demand comprehensive hazard assessments before commercial deployment, necessitating the integration of high-throughput toxicity screening within material development workflows.

Circular economy principles are gaining prominence in grid material development, with design-for-recycling approaches becoming standard practice. Materials enabling easier separation, recovery, and reuse at end-of-life demonstrate superior sustainability profiles. Recent innovations in recyclable polymer insulators and recoverable rare earth magnets exemplify this trend, with recovery rates exceeding 85% in controlled environments.

The sustainability assessment of novel grid materials ultimately requires a balanced approach that considers environmental impacts alongside technical performance, economic viability, and regulatory compliance. High-throughput experimentation platforms that integrate these multidimensional criteria will accelerate the development of truly sustainable smart grid technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!