High-Throughput Experimentation in Industrial Lubricants Formulation

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lubricant HTE Background and Objectives

High-throughput experimentation (HTE) represents a paradigm shift in the development of industrial lubricants, evolving from traditional trial-and-error methodologies to systematic, data-driven approaches. The lubricant industry has historically relied on empirical testing and incremental improvements, with formulation development cycles often spanning several years. This conventional approach has become increasingly inadequate in addressing the rapidly evolving demands of modern machinery and stringent environmental regulations.

The evolution of HTE in lubricant formulation can be traced back to the pharmaceutical and materials science sectors, where combinatorial chemistry and parallel synthesis techniques revolutionized research efficiency. Over the past decade, these methodologies have been progressively adapted to meet the specific challenges of lubricant development, enabling the simultaneous evaluation of multiple formulation variables.

Current technological trends in lubricant HTE include miniaturization of testing apparatus, integration of advanced analytics, and implementation of machine learning algorithms for formulation optimization. These developments have collectively reduced experimental volumes from liters to milliliters, while significantly expanding the parameter space that can be explored within a given timeframe.

The primary objective of implementing HTE in industrial lubricant formulation is to accelerate the discovery and optimization of novel lubricant compositions that deliver superior performance characteristics. This includes enhanced thermal stability, reduced friction coefficients, improved wear protection, and extended service intervals across diverse operating conditions.

Additionally, HTE aims to address emerging challenges in the lubricant industry, particularly the transition toward environmentally sustainable formulations with reduced environmental impact. This encompasses the development of bio-based alternatives to conventional mineral oils, reduction of harmful additives, and optimization of biodegradability profiles without compromising performance metrics.

From a strategic perspective, HTE technology seeks to establish predictive models that correlate molecular structures and formulation parameters with macroscopic performance properties. Such models would fundamentally transform the lubricant development process from reactive to proactive, enabling formulators to design products with precisely tailored characteristics for specific applications.

The ultimate goal extends beyond mere efficiency improvements to enable breakthrough innovations that were previously unattainable through conventional methods. By systematically exploring vast chemical spaces and identifying unexpected synergistic effects between components, HTE has the potential to discover entirely new classes of lubricant technologies that redefine industry performance standards.

The evolution of HTE in lubricant formulation can be traced back to the pharmaceutical and materials science sectors, where combinatorial chemistry and parallel synthesis techniques revolutionized research efficiency. Over the past decade, these methodologies have been progressively adapted to meet the specific challenges of lubricant development, enabling the simultaneous evaluation of multiple formulation variables.

Current technological trends in lubricant HTE include miniaturization of testing apparatus, integration of advanced analytics, and implementation of machine learning algorithms for formulation optimization. These developments have collectively reduced experimental volumes from liters to milliliters, while significantly expanding the parameter space that can be explored within a given timeframe.

The primary objective of implementing HTE in industrial lubricant formulation is to accelerate the discovery and optimization of novel lubricant compositions that deliver superior performance characteristics. This includes enhanced thermal stability, reduced friction coefficients, improved wear protection, and extended service intervals across diverse operating conditions.

Additionally, HTE aims to address emerging challenges in the lubricant industry, particularly the transition toward environmentally sustainable formulations with reduced environmental impact. This encompasses the development of bio-based alternatives to conventional mineral oils, reduction of harmful additives, and optimization of biodegradability profiles without compromising performance metrics.

From a strategic perspective, HTE technology seeks to establish predictive models that correlate molecular structures and formulation parameters with macroscopic performance properties. Such models would fundamentally transform the lubricant development process from reactive to proactive, enabling formulators to design products with precisely tailored characteristics for specific applications.

The ultimate goal extends beyond mere efficiency improvements to enable breakthrough innovations that were previously unattainable through conventional methods. By systematically exploring vast chemical spaces and identifying unexpected synergistic effects between components, HTE has the potential to discover entirely new classes of lubricant technologies that redefine industry performance standards.

Market Analysis for Advanced Industrial Lubricants

The global industrial lubricants market is experiencing significant growth, driven by increasing industrialization and the rising demand for high-performance lubricants across various sectors. Currently valued at approximately 62 billion USD, the market is projected to reach 85 billion USD by 2028, representing a compound annual growth rate of 4.5%. This growth trajectory is particularly pronounced in emerging economies where rapid industrialization is creating substantial demand for advanced lubricant solutions.

The industrial lubricants market can be segmented based on application into automotive, manufacturing, power generation, mining, and construction sectors. Among these, manufacturing and automotive industries constitute the largest market share, collectively accounting for over 60% of the total market volume. The power generation sector is emerging as the fastest-growing segment due to increasing energy demands worldwide and the need for efficient lubricants in power plants.

Geographically, Asia-Pacific dominates the industrial lubricants market, holding approximately 45% of the global market share. This dominance is attributed to the robust industrial growth in countries like China, India, and Japan. North America and Europe follow as significant markets, characterized by a strong focus on high-performance and environmentally friendly lubricant formulations.

A notable trend in the market is the increasing demand for bio-based and synthetic lubricants, driven by stringent environmental regulations and sustainability initiatives. These advanced lubricants offer superior performance characteristics such as higher viscosity indices, better thermal stability, and extended service life compared to conventional mineral-based lubricants. The market share of synthetic lubricants has grown from 30% to 38% over the past five years, indicating a clear shift in consumer preferences.

The competitive landscape of the industrial lubricants market is characterized by the presence of both global giants and regional players. Major companies like ExxonMobil, Shell, BP, Chevron, and Total dominate the global market, collectively holding approximately 55% of the market share. These companies are increasingly investing in research and development to develop innovative lubricant formulations that meet the evolving needs of industries.

Customer demands are evolving towards lubricants that offer multifunctional benefits, including extended equipment life, reduced maintenance costs, and improved energy efficiency. This shift is creating opportunities for companies that can leverage high-throughput experimentation to rapidly develop and test new lubricant formulations tailored to specific industrial applications.

The industrial lubricants market can be segmented based on application into automotive, manufacturing, power generation, mining, and construction sectors. Among these, manufacturing and automotive industries constitute the largest market share, collectively accounting for over 60% of the total market volume. The power generation sector is emerging as the fastest-growing segment due to increasing energy demands worldwide and the need for efficient lubricants in power plants.

Geographically, Asia-Pacific dominates the industrial lubricants market, holding approximately 45% of the global market share. This dominance is attributed to the robust industrial growth in countries like China, India, and Japan. North America and Europe follow as significant markets, characterized by a strong focus on high-performance and environmentally friendly lubricant formulations.

A notable trend in the market is the increasing demand for bio-based and synthetic lubricants, driven by stringent environmental regulations and sustainability initiatives. These advanced lubricants offer superior performance characteristics such as higher viscosity indices, better thermal stability, and extended service life compared to conventional mineral-based lubricants. The market share of synthetic lubricants has grown from 30% to 38% over the past five years, indicating a clear shift in consumer preferences.

The competitive landscape of the industrial lubricants market is characterized by the presence of both global giants and regional players. Major companies like ExxonMobil, Shell, BP, Chevron, and Total dominate the global market, collectively holding approximately 55% of the market share. These companies are increasingly investing in research and development to develop innovative lubricant formulations that meet the evolving needs of industries.

Customer demands are evolving towards lubricants that offer multifunctional benefits, including extended equipment life, reduced maintenance costs, and improved energy efficiency. This shift is creating opportunities for companies that can leverage high-throughput experimentation to rapidly develop and test new lubricant formulations tailored to specific industrial applications.

Current HTE Status and Challenges in Lubricant Development

High-throughput experimentation (HTE) has emerged as a transformative approach in industrial lubricant formulation, enabling researchers to conduct multiple experiments simultaneously while minimizing resource consumption. Currently, the implementation of HTE in lubricant development varies significantly across the industry, with major oil companies and additive manufacturers leading adoption while smaller players lag behind due to capital constraints.

The state-of-the-art HTE platforms in lubricant development typically incorporate automated liquid handling systems, miniaturized testing apparatus, and advanced data management software. These systems can process hundreds of formulations daily, representing a paradigm shift from traditional methods that might evaluate only 5-10 formulations in the same timeframe. Notable implementations include ExxonMobil's Parallel Formulation Evaluation technology and Shell's Rapid Formulation Development platform, both demonstrating significant reductions in development cycles.

Despite progress, several technical challenges persist in HTE application to lubricant development. Miniaturization of tribological tests presents particular difficulty, as wear and friction behaviors often don't scale linearly with sample size. This creates reliability concerns when translating results from micro-scale tests to real-world applications. Additionally, the high viscosity and complex rheological properties of many lubricant components create handling challenges for automated dispensing systems, frequently resulting in dosing inaccuracies.

Data management represents another significant hurdle. The volume of data generated through HTE approaches can overwhelm traditional laboratory information management systems, while ensuring data quality and consistency across multiple parallel experiments requires sophisticated validation protocols. Furthermore, developing predictive models that can effectively interpret HTE results remains challenging due to the complex, non-linear relationships between formulation variables and performance characteristics.

Standardization issues also impede broader adoption, with limited consensus on protocols for miniaturized testing methods. This creates difficulties in comparing results across different HTE platforms and translating findings to standard industry tests. The lack of established correlation factors between high-throughput screening results and conventional bench tests further complicates validation efforts.

Geographically, HTE technology development for lubricants shows concentration in North America and Western Europe, with emerging capabilities in East Asia, particularly Japan and China. This distribution largely follows the locations of major lubricant research centers and specialized equipment manufacturers, creating potential barriers to global adoption.

The state-of-the-art HTE platforms in lubricant development typically incorporate automated liquid handling systems, miniaturized testing apparatus, and advanced data management software. These systems can process hundreds of formulations daily, representing a paradigm shift from traditional methods that might evaluate only 5-10 formulations in the same timeframe. Notable implementations include ExxonMobil's Parallel Formulation Evaluation technology and Shell's Rapid Formulation Development platform, both demonstrating significant reductions in development cycles.

Despite progress, several technical challenges persist in HTE application to lubricant development. Miniaturization of tribological tests presents particular difficulty, as wear and friction behaviors often don't scale linearly with sample size. This creates reliability concerns when translating results from micro-scale tests to real-world applications. Additionally, the high viscosity and complex rheological properties of many lubricant components create handling challenges for automated dispensing systems, frequently resulting in dosing inaccuracies.

Data management represents another significant hurdle. The volume of data generated through HTE approaches can overwhelm traditional laboratory information management systems, while ensuring data quality and consistency across multiple parallel experiments requires sophisticated validation protocols. Furthermore, developing predictive models that can effectively interpret HTE results remains challenging due to the complex, non-linear relationships between formulation variables and performance characteristics.

Standardization issues also impede broader adoption, with limited consensus on protocols for miniaturized testing methods. This creates difficulties in comparing results across different HTE platforms and translating findings to standard industry tests. The lack of established correlation factors between high-throughput screening results and conventional bench tests further complicates validation efforts.

Geographically, HTE technology development for lubricants shows concentration in North America and Western Europe, with emerging capabilities in East Asia, particularly Japan and China. This distribution largely follows the locations of major lubricant research centers and specialized equipment manufacturers, creating potential barriers to global adoption.

Current HTE Methodologies for Lubricant Screening

01 Automated systems for high-throughput experimentation

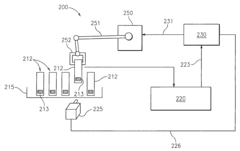

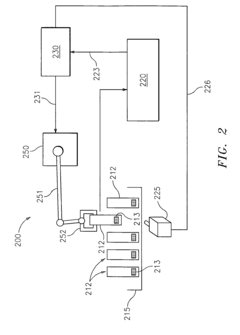

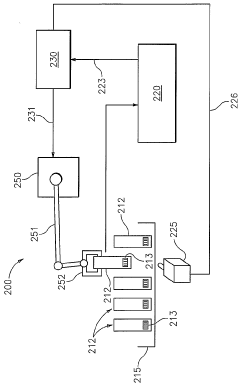

Automated systems are designed to increase experimental throughput by minimizing human intervention. These systems incorporate robotics, automated sample handling, and integrated analytical instruments to perform multiple experiments simultaneously. The automation allows for standardized protocols, reduced experimental errors, and significantly increased experimental capacity, enabling researchers to conduct hundreds or thousands of experiments in parallel.- Automated laboratory systems for high-throughput experimentation: Automated laboratory systems enable high-throughput experimentation by integrating robotics, liquid handling, and sample processing technologies. These systems can perform multiple experiments simultaneously, significantly increasing experimental throughput compared to manual methods. They typically include automated sample preparation, reaction monitoring, and data collection components that work together to accelerate the research and development process.

- Parallel processing technologies for experimental data: Parallel processing technologies enhance high-throughput experimentation by enabling simultaneous analysis of multiple data streams. These systems distribute computational tasks across multiple processors or computing nodes, allowing for faster data processing and analysis. The implementation of parallel computing architectures significantly reduces the time required for complex calculations and data interpretation in high-throughput screening applications.

- Microfluidic platforms for increased experimental throughput: Microfluidic platforms facilitate high-throughput experimentation by miniaturizing reaction volumes and enabling multiple reactions to occur simultaneously in confined spaces. These systems use small channels and chambers to control fluid flow at the microscale, allowing for precise manipulation of small sample volumes. The reduced scale leads to faster reaction times, lower reagent consumption, and higher experimental throughput compared to conventional methods.

- Machine learning and AI for optimizing experimental throughput: Machine learning and artificial intelligence technologies optimize high-throughput experimentation by predicting experimental outcomes, identifying patterns in complex datasets, and automating decision-making processes. These computational approaches can analyze historical experimental data to suggest optimal experimental conditions, reducing the number of experiments needed while maximizing information gain. The integration of AI with laboratory automation creates self-optimizing systems that continuously improve experimental efficiency.

- Networked laboratory infrastructure for distributed experimentation: Networked laboratory infrastructure enables distributed high-throughput experimentation across multiple physical locations. These systems connect instruments, data storage, and analysis tools through secure networks, allowing researchers to collaborate remotely and share resources. Cloud-based platforms facilitate real-time data sharing, remote instrument control, and collaborative analysis, effectively multiplying experimental throughput by leveraging distributed resources and expertise.

02 Data processing and analysis for high-throughput experiments

Advanced data processing techniques are essential for managing the large volumes of data generated in high-throughput experimentation. These include specialized algorithms, machine learning approaches, and statistical methods that can rapidly analyze experimental results, identify patterns, and extract meaningful insights. Such systems enable real-time data processing, automated decision-making, and optimization of experimental parameters to further enhance throughput.Expand Specific Solutions03 Parallel processing technologies for increased throughput

Parallel processing technologies enable simultaneous execution of multiple experimental workflows. These technologies include multicore processors, distributed computing systems, and specialized hardware architectures designed for parallel operations. By dividing experimental tasks across multiple processing units, these systems can dramatically reduce the time required for complex calculations, simulations, and data analysis, thereby increasing overall experimental throughput.Expand Specific Solutions04 Miniaturization and microfluidic technologies

Miniaturization technologies, particularly microfluidic systems, allow for the reduction in sample volumes and reaction times while increasing experimental density. These technologies enable the integration of multiple experimental steps on a single chip or plate, with automated fluid handling and precise control of reaction conditions. The reduced scale leads to faster reaction kinetics, lower reagent consumption, and higher experimental throughput.Expand Specific Solutions05 Network-based collaborative experimentation platforms

Collaborative platforms enable multiple researchers or laboratories to coordinate high-throughput experimentation efforts across different locations. These systems incorporate cloud computing, secure data sharing, and standardized experimental protocols to facilitate collaboration. By distributing experimental workloads across multiple sites and leveraging collective expertise, these platforms can significantly increase overall experimental throughput while maintaining data integrity and consistency.Expand Specific Solutions

Leading Companies in Industrial Lubricant HTE

High-Throughput Experimentation (HTE) in industrial lubricants formulation is currently in a growth phase, with the global lubricants market expected to reach $166.59 billion by 2027. The competitive landscape features established petroleum giants like ExxonMobil, Shell, and Chevron alongside specialized additive manufacturers such as Lubrizol, Infineum, and Afton Chemical. These companies are investing heavily in HTE technologies to accelerate product development cycles and reduce costs. The technology maturity varies significantly across players, with research institutions like Southwest Research Institute and China University of Mining & Technology providing academic support, while industry leaders like Chevron Oronite and BASF have developed proprietary high-throughput screening platforms. Asian companies, particularly from China and Japan, are rapidly closing the technology gap with Western counterparts.

The Lubrizol Corp.

Technical Solution: Lubrizol has developed an advanced High-Throughput Experimentation (HTE) platform specifically for industrial lubricant formulation that combines robotic sample preparation, automated testing, and machine learning algorithms. Their system can simultaneously evaluate hundreds of formulations with varying additive packages, base oils, and concentration levels. The platform incorporates miniaturized testing equipment that requires only milliliter quantities of sample material, significantly reducing material costs and environmental impact. Lubrizol's approach integrates multiple performance parameters including oxidation stability, wear protection, viscosity modifiers, and friction characteristics into a unified screening protocol. Their data management system captures and analyzes results in real-time, enabling rapid identification of promising formulation candidates and structure-property relationships. The company has reported up to 50x increase in experimental throughput compared to traditional methods, with successful application in developing next-generation engine oils and industrial lubricants.

Strengths: Comprehensive integration of robotics, analytics and machine learning provides superior throughput and data quality. Their established position in the lubricant additives market enables immediate commercial application of discoveries. Weaknesses: Proprietary nature of their system limits collaboration potential with external partners, and the high capital investment required for their HTE infrastructure creates significant barriers to entry for smaller competitors.

Infineum International Ltd.

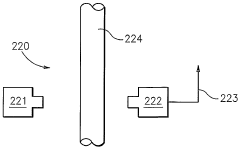

Technical Solution: Infineum has pioneered a modular High-Throughput Experimentation system for lubricant formulation that focuses on parallel synthesis and evaluation of additive packages. Their technology employs a combination of automated liquid handling robots capable of precise dispensing across 96-well plates, integrated with specialized thermal and mechanical stress testing equipment. The company has developed proprietary algorithms that design experimental matrices to efficiently explore complex formulation spaces with minimal experimental runs. Infineum's approach particularly excels in studying additive-additive interactions and base oil compatibility, with capabilities to rapidly screen for deposit control, oxidation resistance, and wear protection properties. Their system incorporates in-line analytical techniques including FTIR spectroscopy and rheological measurements to provide real-time feedback on formulation performance. The platform has been successfully deployed to accelerate development of low-viscosity lubricants for fuel economy while maintaining protection performance, reducing typical development cycles from years to months.

Strengths: Exceptional capability to identify and optimize synergistic additive combinations through sophisticated experimental design algorithms. Their specialized focus on additive chemistry provides deeper insights into molecular mechanisms. Weaknesses: Their system is more specialized toward additive package development rather than comprehensive lubricant formulation, potentially limiting application scope in base oil optimization or entirely novel lubricant technologies.

Key Technical Innovations in Lubricant HTE

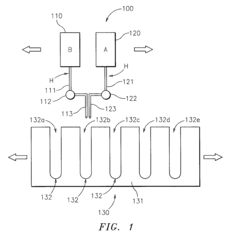

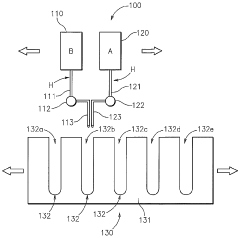

High throughput screening methods for lubricating oil compositions

PatentInactiveUS7137289B2

Innovation

- A high throughput screening method and system for lubricating oil compositions that automatically prepare and test multiple samples under program control, using a combination of base oils and additives with a base oil-insoluble material to measure dispersancy performance, allowing for efficient determination of optimal composition characteristics.

High throughput screening methods for lubricating oil compositions

PatentWO2005044961A2

Innovation

- A high throughput screening method that automatically measures the oxidation stability of multiple lubricating oil compositions under program control, using a combination of base oils and additives in test receptacles, allowing for efficient identification of leading compositions based on adjustable selection criteria.

Sustainability Factors in Modern Lubricant Development

Sustainability has emerged as a critical factor in modern lubricant development, particularly within the context of high-throughput experimentation (HTE) methodologies. The lubricant industry faces increasing pressure to reduce environmental footprints while maintaining or improving product performance. This dual challenge necessitates innovative approaches to formulation that consider the entire lifecycle of lubricant products.

Environmental regulations worldwide are becoming more stringent, driving lubricant manufacturers to develop products with reduced toxicity, improved biodegradability, and lower emissions profiles. High-throughput experimentation enables rapid screening of bio-based alternatives to traditional petroleum-derived base oils and additives, accelerating the transition toward more sustainable formulations without compromising technical performance.

Resource efficiency represents another key sustainability dimension in modern lubricant development. HTE platforms significantly reduce material consumption during the research and development phase by utilizing miniaturized testing protocols. This approach not only conserves valuable raw materials but also minimizes waste generation associated with traditional trial-and-error formulation methods.

Energy considerations throughout the lubricant lifecycle are increasingly important sustainability factors. Advanced lubricants developed through HTE can contribute to energy efficiency in end applications by reducing friction and wear more effectively. The experimental platforms themselves are being optimized for lower energy consumption, with automated systems designed to maximize testing throughput while minimizing power requirements.

Circular economy principles are being integrated into lubricant development strategies, with HTE facilitating the evaluation of recycled base stocks and re-refined oils. These technologies enable rapid assessment of multiple recycled material sources and processing conditions to identify formulations that meet performance specifications while incorporating sustainable materials.

Water conservation has become another critical sustainability factor addressed through high-throughput methodologies. Water-based lubricant formulations are being developed as alternatives to oil-based products for certain applications, while testing protocols are being redesigned to minimize water usage during experimentation and manufacturing processes.

Carbon footprint reduction remains a central sustainability objective, with HTE accelerating the development of lubricants that contribute to lower greenhouse gas emissions. This includes formulations that enable more efficient machinery operation and products manufactured through less carbon-intensive processes, all identified and optimized through rapid parallel experimentation techniques.

Environmental regulations worldwide are becoming more stringent, driving lubricant manufacturers to develop products with reduced toxicity, improved biodegradability, and lower emissions profiles. High-throughput experimentation enables rapid screening of bio-based alternatives to traditional petroleum-derived base oils and additives, accelerating the transition toward more sustainable formulations without compromising technical performance.

Resource efficiency represents another key sustainability dimension in modern lubricant development. HTE platforms significantly reduce material consumption during the research and development phase by utilizing miniaturized testing protocols. This approach not only conserves valuable raw materials but also minimizes waste generation associated with traditional trial-and-error formulation methods.

Energy considerations throughout the lubricant lifecycle are increasingly important sustainability factors. Advanced lubricants developed through HTE can contribute to energy efficiency in end applications by reducing friction and wear more effectively. The experimental platforms themselves are being optimized for lower energy consumption, with automated systems designed to maximize testing throughput while minimizing power requirements.

Circular economy principles are being integrated into lubricant development strategies, with HTE facilitating the evaluation of recycled base stocks and re-refined oils. These technologies enable rapid assessment of multiple recycled material sources and processing conditions to identify formulations that meet performance specifications while incorporating sustainable materials.

Water conservation has become another critical sustainability factor addressed through high-throughput methodologies. Water-based lubricant formulations are being developed as alternatives to oil-based products for certain applications, while testing protocols are being redesigned to minimize water usage during experimentation and manufacturing processes.

Carbon footprint reduction remains a central sustainability objective, with HTE accelerating the development of lubricants that contribute to lower greenhouse gas emissions. This includes formulations that enable more efficient machinery operation and products manufactured through less carbon-intensive processes, all identified and optimized through rapid parallel experimentation techniques.

Data Management Systems for HTE Lubricant Research

The effective management of data generated through High-Throughput Experimentation (HTE) in lubricant formulation represents a critical challenge for industrial researchers. As the volume of experimental data continues to grow exponentially, traditional spreadsheet-based approaches have proven inadequate for handling the complexity and scale of modern lubricant development programs.

Current data management systems for HTE lubricant research typically incorporate relational database architectures with specialized modules for chemical structure representation, property prediction, and formulation tracking. Leading solutions such as LabVantage LIMS, Dotmatics, and ACD/Labs offer varying degrees of integration with laboratory automation equipment, though significant customization is often required for lubricant-specific applications.

A key advancement in recent years has been the implementation of cloud-based platforms that enable collaborative research across multiple sites and organizations. These systems facilitate real-time data sharing and analysis, accelerating the pace of lubricant development while maintaining robust security protocols to protect proprietary formulations and test results.

Machine learning integration represents the cutting edge of data management for lubricant HTE. Advanced systems now incorporate predictive analytics capabilities that can identify patterns in formulation-performance relationships that might otherwise remain hidden. This functionality is particularly valuable for complex lubricant systems where multiple additives interact in ways that are difficult to model using traditional approaches.

Standardization of data formats remains a significant challenge in the field. While efforts such as the FAIR (Findable, Accessible, Interoperable, Reusable) data principles have gained traction in academic settings, industrial adoption has been slower due to concerns about intellectual property protection and legacy system compatibility.

Visualization tools have become increasingly sophisticated, with modern systems offering interactive dashboards that allow researchers to explore multidimensional property spaces. These interfaces enable formulators to rapidly identify promising regions for further investigation, significantly reducing development timelines compared to traditional sequential approaches.

Integration with regulatory compliance systems represents another critical aspect of data management for industrial lubricant development. Modern platforms incorporate features for tracking environmental impact assessments, safety data, and regional regulatory requirements, streamlining the path from laboratory to market.

Current data management systems for HTE lubricant research typically incorporate relational database architectures with specialized modules for chemical structure representation, property prediction, and formulation tracking. Leading solutions such as LabVantage LIMS, Dotmatics, and ACD/Labs offer varying degrees of integration with laboratory automation equipment, though significant customization is often required for lubricant-specific applications.

A key advancement in recent years has been the implementation of cloud-based platforms that enable collaborative research across multiple sites and organizations. These systems facilitate real-time data sharing and analysis, accelerating the pace of lubricant development while maintaining robust security protocols to protect proprietary formulations and test results.

Machine learning integration represents the cutting edge of data management for lubricant HTE. Advanced systems now incorporate predictive analytics capabilities that can identify patterns in formulation-performance relationships that might otherwise remain hidden. This functionality is particularly valuable for complex lubricant systems where multiple additives interact in ways that are difficult to model using traditional approaches.

Standardization of data formats remains a significant challenge in the field. While efforts such as the FAIR (Findable, Accessible, Interoperable, Reusable) data principles have gained traction in academic settings, industrial adoption has been slower due to concerns about intellectual property protection and legacy system compatibility.

Visualization tools have become increasingly sophisticated, with modern systems offering interactive dashboards that allow researchers to explore multidimensional property spaces. These interfaces enable formulators to rapidly identify promising regions for further investigation, significantly reducing development timelines compared to traditional sequential approaches.

Integration with regulatory compliance systems represents another critical aspect of data management for industrial lubricant development. Modern platforms incorporate features for tracking environmental impact assessments, safety data, and regional regulatory requirements, streamlining the path from laboratory to market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!