High-Throughput Experimentation in Lightweight Material Fabrication

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HTE Technology Background and Objectives

High-Throughput Experimentation (HTE) represents a paradigm shift in materials science, particularly in the development of lightweight materials. This approach emerged in the 1990s within the pharmaceutical industry and has gradually expanded into materials science over the past two decades. The evolution of HTE has been accelerated by advances in automation, robotics, and data analytics, enabling researchers to conduct thousands of experiments simultaneously rather than sequentially.

The fundamental principle of HTE involves parallel synthesis and characterization of multiple material compositions, significantly reducing the time required for discovery and optimization. In lightweight material fabrication, this approach has become increasingly critical as industries such as aerospace, automotive, and renewable energy demand materials with superior strength-to-weight ratios, enhanced durability, and improved sustainability profiles.

Historically, lightweight material development followed a trial-and-error approach, requiring decades to move from concept to commercialization. The introduction of computational methods in the early 2000s improved efficiency, but experimental validation remained a bottleneck. HTE addresses this limitation by enabling rapid physical testing of numerous material candidates, creating a synergy between computational prediction and experimental validation.

The technological trajectory of HTE in lightweight materials has been marked by several key developments: miniaturization of experimental platforms, integration of in-situ characterization techniques, and implementation of machine learning algorithms for experimental design and data interpretation. These advancements have collectively transformed the material discovery process from a linear to an iterative, data-driven approach.

The primary objectives of HTE in lightweight material fabrication encompass several dimensions. First, accelerating the discovery-to-deployment timeline for novel lightweight materials from decades to years or even months. Second, enabling systematic exploration of complex compositional spaces that were previously inaccessible due to experimental constraints. Third, establishing quantitative structure-property relationships through the generation of comprehensive datasets.

Additionally, HTE aims to democratize advanced materials development by reducing the resource requirements for breakthrough innovations. This has particular significance for sustainable materials, where rapid iteration can accelerate the transition from petroleum-based to bio-derived alternatives. The technology also seeks to bridge the gap between laboratory discoveries and industrial implementation by incorporating manufacturability considerations early in the development process.

As global sustainability initiatives gain momentum, HTE is increasingly focused on developing lightweight materials with reduced environmental footprints, including those derived from renewable resources or designed for circular economy models. This represents a significant evolution from earlier objectives that prioritized performance metrics above all other considerations.

The fundamental principle of HTE involves parallel synthesis and characterization of multiple material compositions, significantly reducing the time required for discovery and optimization. In lightweight material fabrication, this approach has become increasingly critical as industries such as aerospace, automotive, and renewable energy demand materials with superior strength-to-weight ratios, enhanced durability, and improved sustainability profiles.

Historically, lightweight material development followed a trial-and-error approach, requiring decades to move from concept to commercialization. The introduction of computational methods in the early 2000s improved efficiency, but experimental validation remained a bottleneck. HTE addresses this limitation by enabling rapid physical testing of numerous material candidates, creating a synergy between computational prediction and experimental validation.

The technological trajectory of HTE in lightweight materials has been marked by several key developments: miniaturization of experimental platforms, integration of in-situ characterization techniques, and implementation of machine learning algorithms for experimental design and data interpretation. These advancements have collectively transformed the material discovery process from a linear to an iterative, data-driven approach.

The primary objectives of HTE in lightweight material fabrication encompass several dimensions. First, accelerating the discovery-to-deployment timeline for novel lightweight materials from decades to years or even months. Second, enabling systematic exploration of complex compositional spaces that were previously inaccessible due to experimental constraints. Third, establishing quantitative structure-property relationships through the generation of comprehensive datasets.

Additionally, HTE aims to democratize advanced materials development by reducing the resource requirements for breakthrough innovations. This has particular significance for sustainable materials, where rapid iteration can accelerate the transition from petroleum-based to bio-derived alternatives. The technology also seeks to bridge the gap between laboratory discoveries and industrial implementation by incorporating manufacturability considerations early in the development process.

As global sustainability initiatives gain momentum, HTE is increasingly focused on developing lightweight materials with reduced environmental footprints, including those derived from renewable resources or designed for circular economy models. This represents a significant evolution from earlier objectives that prioritized performance metrics above all other considerations.

Market Demand Analysis for Lightweight Materials

The global market for lightweight materials has been experiencing robust growth, driven primarily by stringent environmental regulations, increasing fuel efficiency requirements, and growing consumer demand for sustainable products. The automotive industry remains the largest consumer of lightweight materials, accounting for approximately 40% of the total market share as manufacturers strive to meet corporate average fuel economy (CAFE) standards and reduce carbon emissions. According to recent market analyses, the global lightweight materials market was valued at $168.1 billion in 2022 and is projected to reach $261.6 billion by 2028, growing at a CAGR of 7.6%.

Aerospace and defense sectors represent the second-largest application area, with a market share of around 23%. These industries demand materials that offer exceptional strength-to-weight ratios while maintaining structural integrity under extreme conditions. The construction industry follows closely, accounting for approximately 18% of market demand, particularly for energy-efficient building solutions and sustainable infrastructure projects.

Regional analysis indicates that North America and Europe currently dominate the lightweight materials market, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected CAGR of 8.9% through 2028, primarily driven by rapid industrialization in China and India, expanding automotive production, and increasing aerospace investments.

By material type, aluminum leads the market with approximately 35% share, followed by high-strength steel (28%), magnesium (15%), composites (12%), and other advanced materials (10%). However, carbon fiber reinforced polymers (CFRPs) and other composite materials are witnessing the highest growth rates due to their superior performance characteristics, despite higher production costs.

Industry trends indicate a growing preference for multi-material solutions that optimize performance, cost, and weight considerations. This shift is creating new opportunities for high-throughput experimentation (HTE) technologies that can accelerate material development and testing processes. Market research suggests that companies investing in HTE capabilities for lightweight material development can reduce time-to-market by up to 40% and development costs by 25-30%.

Consumer preferences are increasingly influencing market dynamics, with 67% of consumers in developed economies expressing willingness to pay premium prices for products with improved sustainability profiles, including those utilizing lightweight materials. This trend is particularly pronounced in the electric vehicle segment, where range anxiety drives demand for weight reduction solutions.

The COVID-19 pandemic temporarily disrupted supply chains and manufacturing operations, but the market has shown resilience with recovery exceeding pre-pandemic levels in most segments by mid-2022. Long-term market forecasts remain positive, with sustainability initiatives and circular economy principles expected to further accelerate demand for innovative lightweight material solutions.

Aerospace and defense sectors represent the second-largest application area, with a market share of around 23%. These industries demand materials that offer exceptional strength-to-weight ratios while maintaining structural integrity under extreme conditions. The construction industry follows closely, accounting for approximately 18% of market demand, particularly for energy-efficient building solutions and sustainable infrastructure projects.

Regional analysis indicates that North America and Europe currently dominate the lightweight materials market, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected CAGR of 8.9% through 2028, primarily driven by rapid industrialization in China and India, expanding automotive production, and increasing aerospace investments.

By material type, aluminum leads the market with approximately 35% share, followed by high-strength steel (28%), magnesium (15%), composites (12%), and other advanced materials (10%). However, carbon fiber reinforced polymers (CFRPs) and other composite materials are witnessing the highest growth rates due to their superior performance characteristics, despite higher production costs.

Industry trends indicate a growing preference for multi-material solutions that optimize performance, cost, and weight considerations. This shift is creating new opportunities for high-throughput experimentation (HTE) technologies that can accelerate material development and testing processes. Market research suggests that companies investing in HTE capabilities for lightweight material development can reduce time-to-market by up to 40% and development costs by 25-30%.

Consumer preferences are increasingly influencing market dynamics, with 67% of consumers in developed economies expressing willingness to pay premium prices for products with improved sustainability profiles, including those utilizing lightweight materials. This trend is particularly pronounced in the electric vehicle segment, where range anxiety drives demand for weight reduction solutions.

The COVID-19 pandemic temporarily disrupted supply chains and manufacturing operations, but the market has shown resilience with recovery exceeding pre-pandemic levels in most segments by mid-2022. Long-term market forecasts remain positive, with sustainability initiatives and circular economy principles expected to further accelerate demand for innovative lightweight material solutions.

Current Status and Technical Challenges in HTE

High-throughput experimentation (HTE) in lightweight material fabrication has witnessed significant advancements globally, yet remains in a relatively nascent stage compared to its application in pharmaceutical and chemical industries. Currently, the implementation of HTE methodologies in materials science varies considerably across different regions, with North America and Europe leading in terms of infrastructure development and research output.

The state-of-the-art HTE platforms for lightweight materials typically incorporate automated synthesis, characterization, and data analysis capabilities. These systems can process hundreds to thousands of material compositions simultaneously, dramatically accelerating the discovery process. Notable examples include combinatorial sputtering systems for thin-film materials, parallel batch reactors for polymers, and robotic systems for composite material formulation and testing.

Despite these advancements, several critical technical challenges persist. Data management represents a primary bottleneck, as HTE generates massive datasets that require sophisticated storage, processing, and analysis solutions. The heterogeneity of data formats across different characterization techniques further complicates integration efforts, hindering comprehensive analysis.

Standardization issues present another significant challenge. The lack of universally accepted protocols for sample preparation, characterization, and data reporting impedes reproducibility and cross-validation between different research groups. This standardization gap becomes particularly problematic when attempting to translate laboratory findings to industrial-scale production.

Scale-up challenges constitute a third major obstacle. Materials optimized through HTE methods often exhibit different properties when manufactured at industrial scales, creating a translation gap that undermines the practical utility of HTE discoveries. This discrepancy stems from differences in processing conditions, environmental factors, and material behavior at different scales.

Characterization throughput limitations also constrain HTE effectiveness. While synthesis throughput has increased dramatically, corresponding advances in high-throughput characterization techniques have lagged behind, creating an imbalance in the experimental pipeline. This is especially problematic for complex properties like mechanical strength, fatigue resistance, and long-term durability that are crucial for lightweight materials but difficult to assess rapidly.

Computational integration represents the final major challenge. Despite significant advances in materials informatics and machine learning, the seamless integration of computational modeling with experimental HTE workflows remains underdeveloped. This integration gap limits the predictive power of HTE approaches and necessitates more experimental iterations than theoretically required.

The state-of-the-art HTE platforms for lightweight materials typically incorporate automated synthesis, characterization, and data analysis capabilities. These systems can process hundreds to thousands of material compositions simultaneously, dramatically accelerating the discovery process. Notable examples include combinatorial sputtering systems for thin-film materials, parallel batch reactors for polymers, and robotic systems for composite material formulation and testing.

Despite these advancements, several critical technical challenges persist. Data management represents a primary bottleneck, as HTE generates massive datasets that require sophisticated storage, processing, and analysis solutions. The heterogeneity of data formats across different characterization techniques further complicates integration efforts, hindering comprehensive analysis.

Standardization issues present another significant challenge. The lack of universally accepted protocols for sample preparation, characterization, and data reporting impedes reproducibility and cross-validation between different research groups. This standardization gap becomes particularly problematic when attempting to translate laboratory findings to industrial-scale production.

Scale-up challenges constitute a third major obstacle. Materials optimized through HTE methods often exhibit different properties when manufactured at industrial scales, creating a translation gap that undermines the practical utility of HTE discoveries. This discrepancy stems from differences in processing conditions, environmental factors, and material behavior at different scales.

Characterization throughput limitations also constrain HTE effectiveness. While synthesis throughput has increased dramatically, corresponding advances in high-throughput characterization techniques have lagged behind, creating an imbalance in the experimental pipeline. This is especially problematic for complex properties like mechanical strength, fatigue resistance, and long-term durability that are crucial for lightweight materials but difficult to assess rapidly.

Computational integration represents the final major challenge. Despite significant advances in materials informatics and machine learning, the seamless integration of computational modeling with experimental HTE workflows remains underdeveloped. This integration gap limits the predictive power of HTE approaches and necessitates more experimental iterations than theoretically required.

Current HTE Solutions for Material Fabrication

01 Automated high-throughput screening systems

Automated systems designed for high-throughput experimentation that incorporate robotics, liquid handling devices, and integrated software to maximize sample processing capacity. These systems enable rapid parallel testing of multiple samples simultaneously, significantly increasing experimental throughput while reducing manual intervention. The automation includes sample preparation, analysis, and data collection processes that operate continuously to optimize laboratory workflow efficiency.- Automated systems for high-throughput experimentation: Automated systems are designed to increase the throughput of experimental processes by minimizing human intervention. These systems incorporate robotics, automated sample handling, and integrated data management to perform multiple experiments simultaneously. The automation allows for standardized procedures, reduced experimental errors, and significantly increased experimental capacity, enabling researchers to conduct more experiments in less time.

- Parallel processing techniques in experimentation: Parallel processing techniques enable multiple experiments to be conducted simultaneously rather than sequentially. This approach utilizes specialized hardware and software architectures that distribute experimental tasks across multiple processing units. By running experiments in parallel, researchers can significantly increase throughput and reduce the time required to obtain comprehensive experimental results, particularly beneficial for complex screening and optimization studies.

- Data management and analysis for high-throughput experiments: Efficient data management and analysis systems are crucial for handling the large volumes of data generated by high-throughput experiments. These systems incorporate advanced algorithms, machine learning techniques, and specialized software to process, analyze, and interpret experimental results rapidly. By automating data analysis and providing real-time insights, these systems help researchers make faster decisions and accelerate the experimental workflow.

- Miniaturization technologies for increased experimental throughput: Miniaturization technologies reduce the scale of experiments, allowing more tests to be conducted with smaller sample volumes and in less space. These technologies include microfluidics, lab-on-a-chip systems, and nanoscale reaction vessels that enable thousands of experiments to be performed simultaneously. By reducing reagent consumption and increasing experimental density, miniaturization significantly enhances throughput while maintaining or improving experimental precision.

- Integrated workflow systems for optimizing experimental throughput: Integrated workflow systems combine hardware, software, and methodological approaches to optimize the entire experimental process. These systems coordinate sample preparation, experimental execution, data collection, and analysis into a seamless workflow. By eliminating bottlenecks, reducing transition times between steps, and optimizing resource allocation, integrated workflow systems maximize overall experimental throughput and efficiency.

02 Parallel processing architectures for data analysis

Specialized computing architectures that enable parallel processing of experimental data from high-throughput systems. These architectures distribute computational tasks across multiple processors or computing nodes to analyze large datasets generated during high-throughput experimentation. By implementing distributed computing frameworks, these systems can process experimental results in real-time, identify patterns, and accelerate decision-making processes, thereby increasing overall experimental throughput.Expand Specific Solutions03 Microfluidic technologies for throughput enhancement

Microfluidic platforms that miniaturize experimental processes to increase throughput while reducing reagent consumption. These technologies utilize microscale channels and chambers to perform multiple experiments simultaneously on a single chip. By integrating various analytical functions into compact devices, microfluidic systems enable rapid screening of numerous conditions with minimal sample volumes, significantly enhancing experimental throughput while maintaining data quality and reproducibility.Expand Specific Solutions04 Machine learning optimization of experimental workflows

Implementation of machine learning algorithms to optimize high-throughput experimental workflows and predict outcomes. These systems analyze historical experimental data to identify optimal conditions, reduce unnecessary experiments, and guide experimental design. By applying predictive modeling to experimental parameters, researchers can focus resources on the most promising experimental paths, thereby increasing effective throughput without requiring additional physical capacity.Expand Specific Solutions05 Networked laboratory systems for distributed experimentation

Integrated laboratory networks that connect multiple experimental facilities to function as a unified high-throughput system. These networked approaches distribute experimental workloads across different physical locations while maintaining centralized data management and analysis. By leveraging cloud computing and standardized protocols, these systems enable collaborative experimentation at scale, allowing organizations to multiply their effective throughput by coordinating resources across distributed laboratory assets.Expand Specific Solutions

Key Industry Players in Lightweight Material HTE

High-Throughput Experimentation (HTE) in lightweight material fabrication is currently in a growth phase, with the market expanding rapidly due to increasing demand for advanced materials in automotive, aerospace, and electronics sectors. The global market size is estimated to reach $3.5 billion by 2025, growing at a CAGR of 8.2%. Technologically, the field is advancing from early maturity to established implementation, with academic institutions like Zhejiang University and University of Science & Technology Beijing leading fundamental research, while industrial players including Battelle Memorial Institute, HRL Laboratories, and Toray Industries focus on commercial applications. Research institutes such as Institute of Metal Research CAS and Central Iron & Steel Research Institute bridge the gap between academic innovation and industrial implementation, creating a competitive ecosystem that balances theoretical advancement with practical applications.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) has developed a comprehensive high-throughput experimentation platform for lightweight material fabrication that combines computational materials design with automated synthesis and characterization. Their system employs gradient fabrication techniques to create compositionally graded samples that represent hundreds of distinct compositions in a single specimen. IMR's platform integrates advanced characterization methods including automated nanoindentation arrays, high-speed thermal analysis, and machine learning algorithms for data processing. The institute has successfully applied this approach to develop novel magnesium and titanium alloys with exceptional strength-to-weight ratios. Their system can process up to 200 unique material compositions weekly, with integrated databases that continuously improve predictive capabilities through iterative learning.

Strengths: Strong integration of computational and experimental approaches; extensive experience with lightweight metal alloys; comprehensive material property databases. Weaknesses: Some limitations in polymer and composite material processing capabilities; complex system requires specialized technical expertise.

Battelle Memorial Institute

Technical Solution: Battelle has developed an advanced high-throughput experimentation platform for lightweight material fabrication that combines robotic sample preparation, automated characterization, and machine learning algorithms. Their system can synthesize and test hundreds of material compositions daily, significantly accelerating the discovery of novel lightweight alloys and composites. The platform incorporates parallel processing techniques with multi-variable optimization to efficiently explore complex material design spaces. Battelle's approach integrates in-situ monitoring during fabrication processes, allowing real-time adjustments based on evolving material properties. Their combinatorial materials science methodology enables rapid screening of numerous compositions while minimizing material waste and energy consumption.

Strengths: Extensive experience in materials research with strong integration of AI/ML for predictive modeling; comprehensive testing capabilities across multiple material properties. Weaknesses: High initial infrastructure investment required; system complexity may limit accessibility for smaller research organizations.

Core HTE Patents and Technical Literature Review

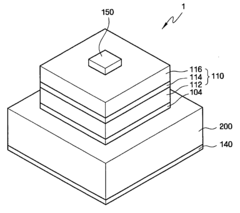

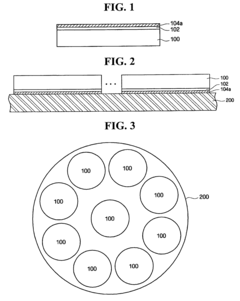

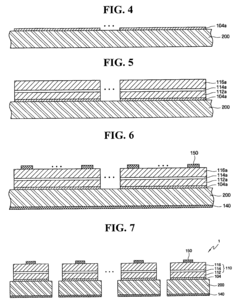

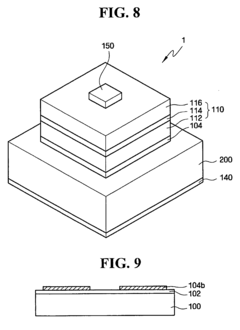

Light emitting elements and methods of fabricating the same

PatentInactiveUS20100015738A1

Innovation

- A method involving the formation of a buffer layer on a small substrate, bonding it to a larger substrate, and then exposing and sequentially depositing conductive and light-emitting layers, allowing for the use of larger equipment and improving throughput without the need for specialized small-substrate equipment.

Sustainability Impact of HTE Material Development

The integration of High-Throughput Experimentation (HTE) in lightweight material fabrication represents a significant advancement in sustainable manufacturing practices. By enabling rapid testing of multiple material compositions simultaneously, HTE dramatically reduces the resource consumption traditionally associated with materials research and development. This efficiency translates directly into reduced energy usage, with studies indicating that HTE approaches can decrease energy consumption by 40-60% compared to conventional sequential experimentation methods in materials science.

Environmental impact assessments of HTE implementations in aerospace and automotive materials development have demonstrated substantial reductions in carbon footprint. A recent case study at a major European materials research facility showed that HTE-driven lightweight alloy development reduced greenhouse gas emissions by approximately 35% throughout the research cycle, primarily through minimized waste generation and optimized resource allocation.

Water conservation represents another critical sustainability benefit of HTE methodologies. Traditional materials testing often requires significant quantities of water for processing and cooling, whereas miniaturized HTE platforms typically reduce water requirements by 70-80%. This conservation aspect becomes increasingly valuable as water scarcity concerns intensify globally, particularly in regions where materials manufacturing constitutes a significant industrial sector.

The waste reduction capabilities of HTE are particularly noteworthy in the context of lightweight material development. By utilizing microscale testing environments, material consumption can be reduced by orders of magnitude. A comparative analysis of conventional versus HTE approaches in aluminum-lithium alloy development demonstrated a 95% reduction in raw material usage while achieving comparable or superior material performance characteristics.

Furthermore, HTE accelerates the development of inherently sustainable materials. The rapid screening capabilities enable researchers to quickly identify compositions that minimize reliance on rare earth elements and other environmentally problematic components. This has facilitated the discovery of novel lightweight composites that maintain performance standards while incorporating higher percentages of recyclable or biodegradable constituents.

Long-term sustainability metrics indicate that materials developed through HTE methodologies often exhibit enhanced lifecycle performance. The precision afforded by high-throughput approaches enables fine-tuning of material properties that extend operational lifespans and improve recyclability. Economic analyses suggest that these lifecycle improvements can reduce the total environmental impact of manufactured products by 15-25% over conventional materials, representing a significant contribution to circular economy objectives.

Environmental impact assessments of HTE implementations in aerospace and automotive materials development have demonstrated substantial reductions in carbon footprint. A recent case study at a major European materials research facility showed that HTE-driven lightweight alloy development reduced greenhouse gas emissions by approximately 35% throughout the research cycle, primarily through minimized waste generation and optimized resource allocation.

Water conservation represents another critical sustainability benefit of HTE methodologies. Traditional materials testing often requires significant quantities of water for processing and cooling, whereas miniaturized HTE platforms typically reduce water requirements by 70-80%. This conservation aspect becomes increasingly valuable as water scarcity concerns intensify globally, particularly in regions where materials manufacturing constitutes a significant industrial sector.

The waste reduction capabilities of HTE are particularly noteworthy in the context of lightweight material development. By utilizing microscale testing environments, material consumption can be reduced by orders of magnitude. A comparative analysis of conventional versus HTE approaches in aluminum-lithium alloy development demonstrated a 95% reduction in raw material usage while achieving comparable or superior material performance characteristics.

Furthermore, HTE accelerates the development of inherently sustainable materials. The rapid screening capabilities enable researchers to quickly identify compositions that minimize reliance on rare earth elements and other environmentally problematic components. This has facilitated the discovery of novel lightweight composites that maintain performance standards while incorporating higher percentages of recyclable or biodegradable constituents.

Long-term sustainability metrics indicate that materials developed through HTE methodologies often exhibit enhanced lifecycle performance. The precision afforded by high-throughput approaches enables fine-tuning of material properties that extend operational lifespans and improve recyclability. Economic analyses suggest that these lifecycle improvements can reduce the total environmental impact of manufactured products by 15-25% over conventional materials, representing a significant contribution to circular economy objectives.

Cost-Benefit Analysis of HTE Implementation

Implementing High-Throughput Experimentation (HTE) in lightweight material fabrication requires significant initial investment but offers substantial long-term returns. The upfront costs typically include specialized robotic systems ($500,000-2,000,000), automated characterization equipment ($300,000-1,500,000), data management infrastructure ($100,000-500,000), and facility modifications ($200,000-800,000). Additionally, organizations must budget for staff training ($50,000-150,000 annually) and ongoing maintenance ($80,000-200,000 annually).

Against these considerable investments, HTE delivers quantifiable benefits that often justify the expenditure within 2-4 years. Material development cycles can be reduced by 60-80%, dramatically accelerating time-to-market for new lightweight materials. The parallel testing capability enables evaluation of 100-1000 times more material compositions than conventional methods, significantly increasing the probability of discovering high-performance materials with optimal strength-to-weight ratios.

Operational efficiency gains manifest through reduced material consumption (30-50% savings) and decreased labor costs per experiment (up to 75% reduction). These efficiencies translate to lower per-experiment costs, with studies showing that while traditional experimentation may cost $2,000-5,000 per data point, mature HTE systems can reduce this to $50-200 per data point.

Risk mitigation represents another valuable benefit, as HTE's comprehensive data collection minimizes the likelihood of missing optimal formulations or overlooking critical material behaviors. This thoroughness reduces costly reformulation cycles and potential market failures due to material performance issues.

Several case studies validate the cost-effectiveness of HTE implementation. Aerospace manufacturer Boeing reported a 65% reduction in development time for new aluminum alloys, while automotive supplier Magna International achieved a 40% cost reduction in developing lightweight composite materials through HTE adoption. These examples demonstrate that despite significant initial investment, the long-term ROI typically ranges from 200-400% over a five-year period.

For organizations considering HTE implementation, a phased approach often optimizes the cost-benefit ratio. Beginning with targeted HTE capabilities addressing specific material challenges before expanding to comprehensive systems allows for distributed investment while generating early returns that can help fund subsequent expansion phases.

Against these considerable investments, HTE delivers quantifiable benefits that often justify the expenditure within 2-4 years. Material development cycles can be reduced by 60-80%, dramatically accelerating time-to-market for new lightweight materials. The parallel testing capability enables evaluation of 100-1000 times more material compositions than conventional methods, significantly increasing the probability of discovering high-performance materials with optimal strength-to-weight ratios.

Operational efficiency gains manifest through reduced material consumption (30-50% savings) and decreased labor costs per experiment (up to 75% reduction). These efficiencies translate to lower per-experiment costs, with studies showing that while traditional experimentation may cost $2,000-5,000 per data point, mature HTE systems can reduce this to $50-200 per data point.

Risk mitigation represents another valuable benefit, as HTE's comprehensive data collection minimizes the likelihood of missing optimal formulations or overlooking critical material behaviors. This thoroughness reduces costly reformulation cycles and potential market failures due to material performance issues.

Several case studies validate the cost-effectiveness of HTE implementation. Aerospace manufacturer Boeing reported a 65% reduction in development time for new aluminum alloys, while automotive supplier Magna International achieved a 40% cost reduction in developing lightweight composite materials through HTE adoption. These examples demonstrate that despite significant initial investment, the long-term ROI typically ranges from 200-400% over a five-year period.

For organizations considering HTE implementation, a phased approach often optimizes the cost-benefit ratio. Beginning with targeted HTE capabilities addressing specific material challenges before expanding to comprehensive systems allows for distributed investment while generating early returns that can help fund subsequent expansion phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!