How AI-Driven Models Predict LS Engine Lubrication Needs

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AI-LS Engine Lubrication Prediction Background

The prediction of lubrication needs in LS (Luxury Sport) engines using AI-driven models represents a significant advancement in automotive engineering and maintenance. This technology combines the power of artificial intelligence with the intricate requirements of high-performance engine lubrication systems to optimize engine performance, efficiency, and longevity.

Historically, engine lubrication has relied on predetermined schedules and basic sensor data. However, the complexity of modern LS engines, coupled with varying driving conditions and user behaviors, has necessitated a more sophisticated approach. AI-driven models have emerged as a solution to this challenge, offering real-time, adaptive predictions of lubrication needs.

The development of these AI models has been driven by several key factors. First, the increasing availability of sensor data from modern vehicles has provided a rich dataset for training machine learning algorithms. This includes information on engine temperature, RPM, oil pressure, and various other performance metrics. Second, advancements in computational power and cloud computing have made it possible to process and analyze this data in real-time, enabling more accurate and timely predictions.

The core objective of AI-driven lubrication prediction in LS engines is to maintain optimal engine performance while minimizing wear and maximizing fuel efficiency. This is achieved by precisely determining when and how much lubrication is needed based on current operating conditions and historical data. By doing so, these models can potentially extend engine life, reduce maintenance costs, and improve overall vehicle performance.

Another crucial aspect of this technology is its ability to adapt to individual driving styles and environmental conditions. Traditional lubrication schedules often fail to account for these variables, leading to either over-lubrication, which can result in increased emissions and reduced efficiency, or under-lubrication, which can cause premature wear and potential engine damage.

The evolution of AI-driven lubrication prediction models has also been influenced by broader trends in the automotive industry, such as the push for greater fuel efficiency and reduced emissions. By optimizing lubrication, these models contribute to both goals, making them an attractive technology for manufacturers seeking to meet increasingly stringent environmental regulations.

As this technology continues to develop, it is expected to become an integral part of engine management systems in high-performance vehicles. The potential for integration with other vehicle systems, such as predictive maintenance algorithms and autonomous driving technologies, further underscores the importance of AI-driven lubrication prediction in the future of automotive engineering.

Historically, engine lubrication has relied on predetermined schedules and basic sensor data. However, the complexity of modern LS engines, coupled with varying driving conditions and user behaviors, has necessitated a more sophisticated approach. AI-driven models have emerged as a solution to this challenge, offering real-time, adaptive predictions of lubrication needs.

The development of these AI models has been driven by several key factors. First, the increasing availability of sensor data from modern vehicles has provided a rich dataset for training machine learning algorithms. This includes information on engine temperature, RPM, oil pressure, and various other performance metrics. Second, advancements in computational power and cloud computing have made it possible to process and analyze this data in real-time, enabling more accurate and timely predictions.

The core objective of AI-driven lubrication prediction in LS engines is to maintain optimal engine performance while minimizing wear and maximizing fuel efficiency. This is achieved by precisely determining when and how much lubrication is needed based on current operating conditions and historical data. By doing so, these models can potentially extend engine life, reduce maintenance costs, and improve overall vehicle performance.

Another crucial aspect of this technology is its ability to adapt to individual driving styles and environmental conditions. Traditional lubrication schedules often fail to account for these variables, leading to either over-lubrication, which can result in increased emissions and reduced efficiency, or under-lubrication, which can cause premature wear and potential engine damage.

The evolution of AI-driven lubrication prediction models has also been influenced by broader trends in the automotive industry, such as the push for greater fuel efficiency and reduced emissions. By optimizing lubrication, these models contribute to both goals, making them an attractive technology for manufacturers seeking to meet increasingly stringent environmental regulations.

As this technology continues to develop, it is expected to become an integral part of engine management systems in high-performance vehicles. The potential for integration with other vehicle systems, such as predictive maintenance algorithms and autonomous driving technologies, further underscores the importance of AI-driven lubrication prediction in the future of automotive engineering.

Market Demand Analysis

The market demand for AI-driven models predicting LS engine lubrication needs is experiencing significant growth, driven by the automotive industry's push towards more efficient and reliable engine systems. As vehicle manufacturers strive to meet increasingly stringent emissions regulations and consumer expectations for fuel economy, the optimization of engine lubrication has become a critical focus area.

The global automotive lubricants market, which includes engine oils, is projected to expand substantially in the coming years. This growth is partly attributed to the increasing adoption of advanced lubrication technologies, including those powered by AI predictive models. These models offer the potential to significantly reduce engine wear, extend oil change intervals, and improve overall engine performance.

In the commercial vehicle sector, where LS (Low-Speed) engines are commonly used, the demand for predictive lubrication models is particularly strong. Fleet operators are increasingly recognizing the value of AI-driven solutions in reducing maintenance costs and minimizing vehicle downtime. The ability to accurately predict lubrication needs based on real-time engine data can lead to substantial savings in operational expenses.

The passenger vehicle market is also showing growing interest in AI-driven lubrication prediction technologies. As consumers become more aware of the importance of proper engine maintenance, there is an increasing demand for vehicles equipped with advanced diagnostic and predictive maintenance features. This trend is expected to drive further adoption of AI-based lubrication models in mainstream automotive applications.

Moreover, the rise of connected and autonomous vehicles is creating new opportunities for AI-driven lubrication prediction systems. These vehicles generate vast amounts of data, which can be leveraged to improve the accuracy and effectiveness of lubrication models. As the automotive industry continues its transition towards more intelligent and connected vehicles, the demand for sophisticated AI-driven engine management systems, including lubrication prediction, is expected to surge.

Environmental concerns and sustainability initiatives are also contributing to the market demand for AI-driven lubrication prediction models. By optimizing engine lubrication, these systems can help reduce oil consumption and minimize the environmental impact of vehicle operations. This aligns with the broader industry trend towards more sustainable and eco-friendly transportation solutions.

In conclusion, the market demand for AI-driven models predicting LS engine lubrication needs is robust and multifaceted. It is driven by factors such as cost reduction, performance optimization, environmental considerations, and the broader trend towards intelligent and connected vehicles. As the technology continues to mature and demonstrate its value, it is expected to become an increasingly integral part of engine management systems across various vehicle segments.

The global automotive lubricants market, which includes engine oils, is projected to expand substantially in the coming years. This growth is partly attributed to the increasing adoption of advanced lubrication technologies, including those powered by AI predictive models. These models offer the potential to significantly reduce engine wear, extend oil change intervals, and improve overall engine performance.

In the commercial vehicle sector, where LS (Low-Speed) engines are commonly used, the demand for predictive lubrication models is particularly strong. Fleet operators are increasingly recognizing the value of AI-driven solutions in reducing maintenance costs and minimizing vehicle downtime. The ability to accurately predict lubrication needs based on real-time engine data can lead to substantial savings in operational expenses.

The passenger vehicle market is also showing growing interest in AI-driven lubrication prediction technologies. As consumers become more aware of the importance of proper engine maintenance, there is an increasing demand for vehicles equipped with advanced diagnostic and predictive maintenance features. This trend is expected to drive further adoption of AI-based lubrication models in mainstream automotive applications.

Moreover, the rise of connected and autonomous vehicles is creating new opportunities for AI-driven lubrication prediction systems. These vehicles generate vast amounts of data, which can be leveraged to improve the accuracy and effectiveness of lubrication models. As the automotive industry continues its transition towards more intelligent and connected vehicles, the demand for sophisticated AI-driven engine management systems, including lubrication prediction, is expected to surge.

Environmental concerns and sustainability initiatives are also contributing to the market demand for AI-driven lubrication prediction models. By optimizing engine lubrication, these systems can help reduce oil consumption and minimize the environmental impact of vehicle operations. This aligns with the broader industry trend towards more sustainable and eco-friendly transportation solutions.

In conclusion, the market demand for AI-driven models predicting LS engine lubrication needs is robust and multifaceted. It is driven by factors such as cost reduction, performance optimization, environmental considerations, and the broader trend towards intelligent and connected vehicles. As the technology continues to mature and demonstrate its value, it is expected to become an increasingly integral part of engine management systems across various vehicle segments.

Current Challenges in AI-Driven Lubrication Prediction

The field of AI-driven lubrication prediction for LS engines faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the complexity of engine systems and the multitude of variables that affect lubrication needs. LS engines, with their intricate designs and varying operational conditions, present a formidable task for AI models to accurately predict lubrication requirements.

Data quality and quantity remain persistent issues in developing robust AI models for lubrication prediction. While modern engines are equipped with numerous sensors, the data collected may not always be comprehensive or consistent enough to train highly accurate predictive models. Furthermore, the dynamic nature of engine operation means that historical data may not always be representative of future conditions, particularly when considering factors like engine wear over time.

Another challenge lies in the integration of AI-driven models with existing engine management systems. Many current LS engines utilize traditional control systems that may not be readily compatible with advanced AI algorithms. This incompatibility can lead to difficulties in implementing real-time lubrication predictions and adjustments, potentially limiting the practical benefits of AI-driven solutions.

The interpretability of AI models poses a significant hurdle in the automotive industry, where safety and reliability are paramount. Complex machine learning algorithms, particularly deep learning models, often operate as "black boxes," making it challenging for engineers and regulators to understand and validate their decision-making processes. This lack of transparency can impede regulatory approval and user trust in AI-driven lubrication systems.

Computational resources and processing speed present additional challenges, especially for real-time applications. AI models capable of accurate lubrication prediction may require substantial computing power, which can be difficult to integrate into existing engine control units without significant hardware upgrades. This limitation can affect the model's ability to provide timely predictions and adjustments during engine operation.

Lastly, the development of AI models for lubrication prediction faces the challenge of generalization across different engine types and operating conditions. Creating a model that performs consistently across various LS engine designs, environmental conditions, and usage patterns requires extensive testing and validation, which can be both time-consuming and costly for manufacturers.

Data quality and quantity remain persistent issues in developing robust AI models for lubrication prediction. While modern engines are equipped with numerous sensors, the data collected may not always be comprehensive or consistent enough to train highly accurate predictive models. Furthermore, the dynamic nature of engine operation means that historical data may not always be representative of future conditions, particularly when considering factors like engine wear over time.

Another challenge lies in the integration of AI-driven models with existing engine management systems. Many current LS engines utilize traditional control systems that may not be readily compatible with advanced AI algorithms. This incompatibility can lead to difficulties in implementing real-time lubrication predictions and adjustments, potentially limiting the practical benefits of AI-driven solutions.

The interpretability of AI models poses a significant hurdle in the automotive industry, where safety and reliability are paramount. Complex machine learning algorithms, particularly deep learning models, often operate as "black boxes," making it challenging for engineers and regulators to understand and validate their decision-making processes. This lack of transparency can impede regulatory approval and user trust in AI-driven lubrication systems.

Computational resources and processing speed present additional challenges, especially for real-time applications. AI models capable of accurate lubrication prediction may require substantial computing power, which can be difficult to integrate into existing engine control units without significant hardware upgrades. This limitation can affect the model's ability to provide timely predictions and adjustments during engine operation.

Lastly, the development of AI models for lubrication prediction faces the challenge of generalization across different engine types and operating conditions. Creating a model that performs consistently across various LS engine designs, environmental conditions, and usage patterns requires extensive testing and validation, which can be both time-consuming and costly for manufacturers.

Existing AI Models for LS Engine Lubrication Prediction

01 AI-driven lubrication optimization

AI models are used to optimize lubrication processes in various industrial applications. These models analyze data from sensors and historical performance to predict optimal lubrication schedules, amounts, and types of lubricants needed for specific machinery or components. This approach can significantly improve equipment efficiency and longevity while reducing maintenance costs.- AI-driven lubrication optimization: AI models are used to optimize lubrication processes in various industrial applications. These models analyze data from sensors and historical performance to predict optimal lubrication schedules, amounts, and types of lubricants needed for different machinery and operating conditions. This approach can significantly improve equipment efficiency and reduce maintenance costs.

- Machine learning for predictive maintenance: Machine learning algorithms are employed to predict when lubrication is needed based on equipment performance data. These models can detect patterns and anomalies that indicate potential lubrication issues before they lead to equipment failure. This proactive approach helps in scheduling maintenance activities more effectively and extends the lifespan of machinery.

- Smart lubricant delivery systems: AI-driven smart lubricant delivery systems use real-time data and predictive models to automatically adjust lubrication parameters. These systems can control the timing, quantity, and type of lubricant applied to different parts of machinery based on current operating conditions and predicted future needs. This results in more precise and efficient lubrication management.

- AI-enhanced lubricant formulation: Artificial intelligence is used in the development of advanced lubricant formulations. AI models analyze vast amounts of data on chemical properties, performance characteristics, and environmental factors to design lubricants with improved properties such as better viscosity index, higher thermal stability, and reduced friction. This leads to more effective and environmentally friendly lubricants.

- Integration of IoT and AI for lubrication management: The combination of Internet of Things (IoT) sensors and AI analytics creates a comprehensive lubrication management system. IoT devices collect real-time data on equipment performance, environmental conditions, and lubricant properties. AI models then process this data to provide insights for optimal lubrication strategies, enabling a more holistic and responsive approach to machinery maintenance.

02 Machine learning for predictive maintenance

Machine learning algorithms are employed to predict when lubrication is needed based on real-time data and historical patterns. These models can detect anomalies in equipment performance, anticipate potential failures, and recommend proactive lubrication interventions. This predictive approach helps minimize downtime and extends the life of machinery.Expand Specific Solutions03 Smart lubricant formulation using AI

AI-driven models are utilized in the development of advanced lubricant formulations. These models analyze the chemical properties of various ingredients and predict their performance under different conditions. This enables the creation of tailored lubricants for specific applications, optimizing their effectiveness and environmental impact.Expand Specific Solutions04 AI-enhanced lubrication systems

Intelligent lubrication systems incorporate AI to dynamically adjust lubrication parameters based on real-time operating conditions. These systems use sensors and AI algorithms to monitor factors such as temperature, pressure, and vibration, automatically modifying lubrication delivery to maintain optimal performance and reduce waste.Expand Specific Solutions05 AI-driven tribology research

AI models are employed in advanced tribology research to study and simulate the complex interactions between surfaces in relative motion. These models help in understanding wear mechanisms, friction dynamics, and lubrication behavior at the molecular level. This research contributes to the development of more efficient lubrication strategies and materials.Expand Specific Solutions

Key Players in AI-Driven Engine Lubrication

The AI-driven prediction of LS engine lubrication needs is an emerging field within the automotive industry, currently in its early development stage. The market size is growing, driven by increasing demand for advanced engine management systems and fuel efficiency. While the technology is still evolving, several key players are making significant strides. Companies like BASF SE, Robert Bosch GmbH, and Mercedes-Benz Group AG are leveraging their extensive automotive expertise to develop sophisticated AI models. Academic institutions such as Tongji University and Beihang University are contributing valuable research. The technology's maturity varies, with established automotive suppliers like Continental Automotive GmbH and emerging players like TotalEnergies OneTech SAS at different stages of development and implementation.

Robert Bosch GmbH

Technical Solution: Bosch has implemented an AI-driven predictive maintenance system for LS engine lubrication. Their approach combines sensor data from various engine components with machine learning algorithms to forecast lubrication needs. The system uses a neural network trained on vast amounts of historical engine data to identify patterns and anomalies in oil degradation[2]. Bosch's technology also incorporates real-time oil quality sensors that feed data into the AI model, allowing for dynamic adjustments to lubrication schedules. The system can predict potential engine issues related to inadequate lubrication, enabling proactive maintenance[4].

Strengths: Comprehensive sensor integration, real-time monitoring capabilities. Weaknesses: High initial implementation cost, complexity in retrofitting older vehicles.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed an advanced AI-driven lubrication prediction system for their LS engines. Their approach utilizes a combination of onboard sensors and cloud-based machine learning algorithms to analyze engine performance and predict lubrication needs. The system takes into account factors such as engine temperature, oil viscosity, and driving conditions to optimize oil change intervals. Mercedes' AI model also incorporates data from their fleet of vehicles to improve prediction accuracy across different models and driving scenarios[5]. The system can adapt to individual driving styles and environmental conditions, providing personalized maintenance recommendations[6].

Strengths: Integration with vehicle telematics, ability to leverage fleet-wide data for improved predictions. Weaknesses: Potential over-reliance on connectivity for optimal performance.

Core Innovations in AI-Driven Lubrication Modeling

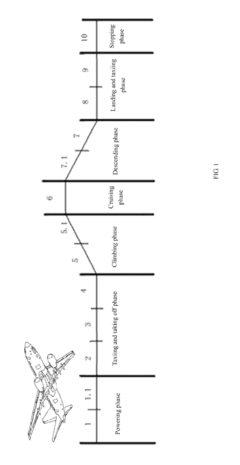

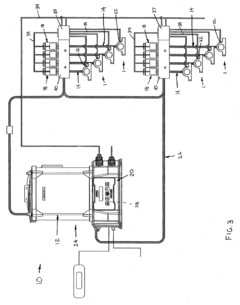

System and method for monitoring lubricant of an engine

PatentActiveUS20150068289A1

Innovation

- A system comprising a lubricant sensor, data acquisition unit, and message generation unit that continuously monitors lubricant quantity and sends alerts for abnormalities, using a ground-air data link to transmit data to airline companies, enabling real-time monitoring and reducing human error.

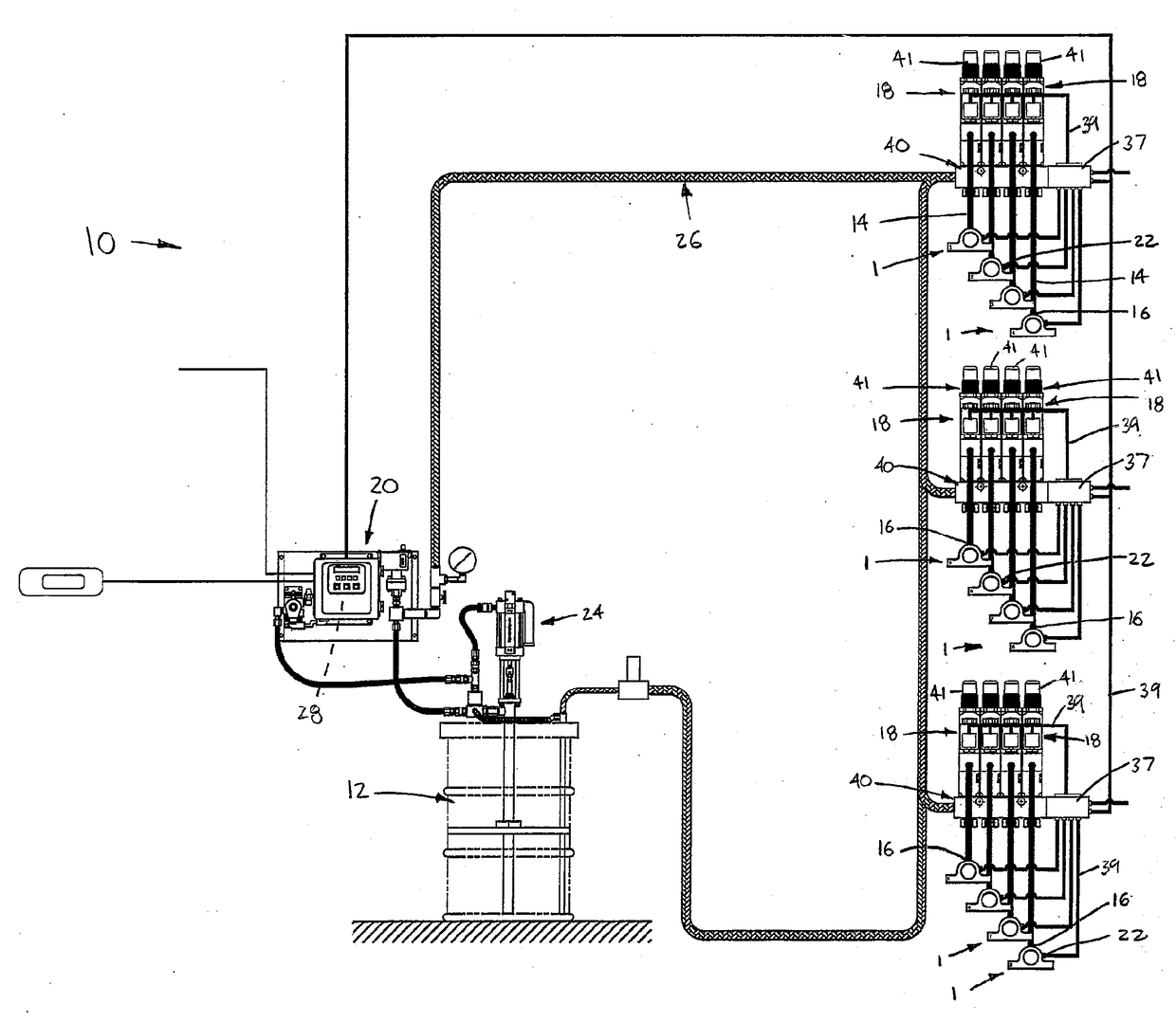

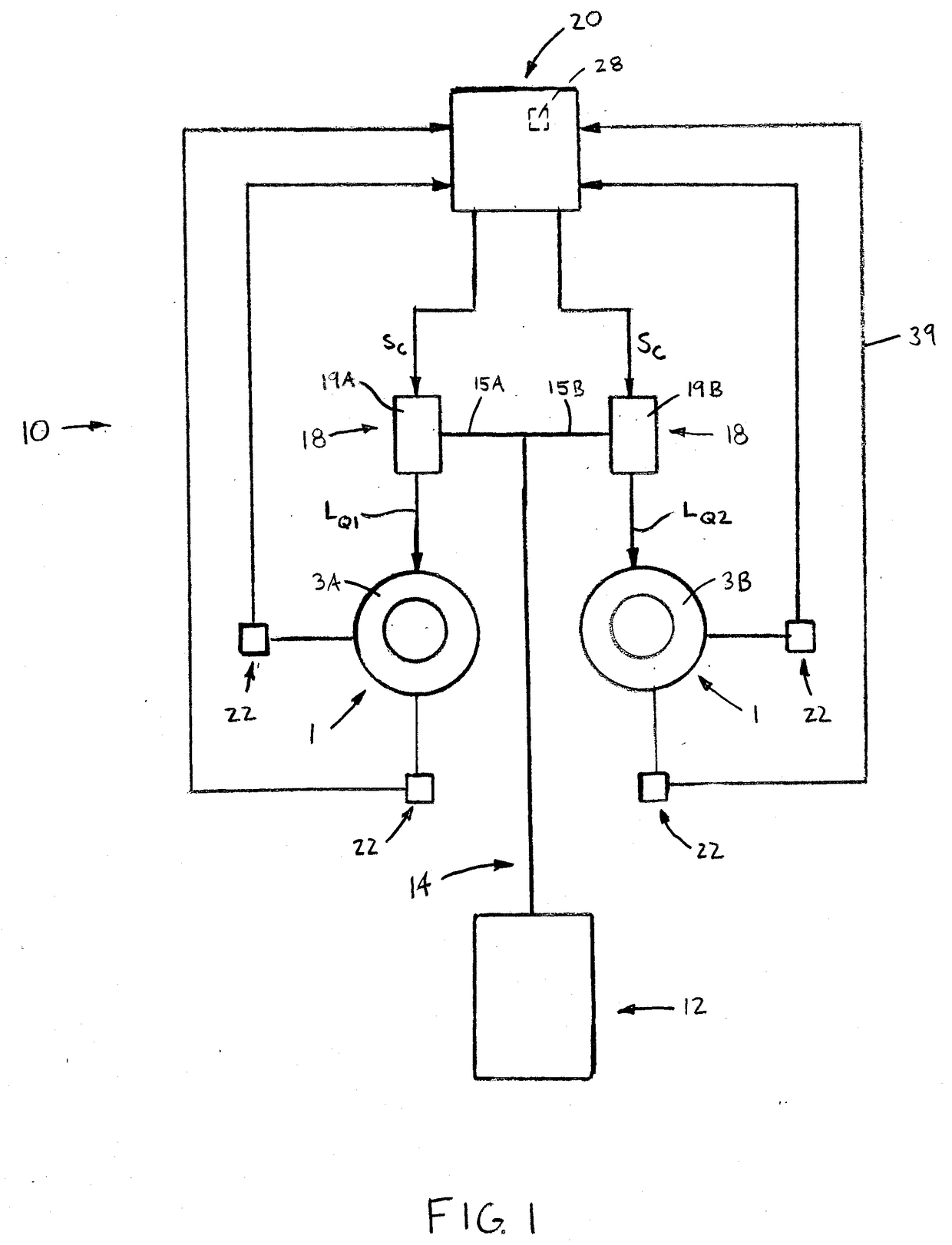

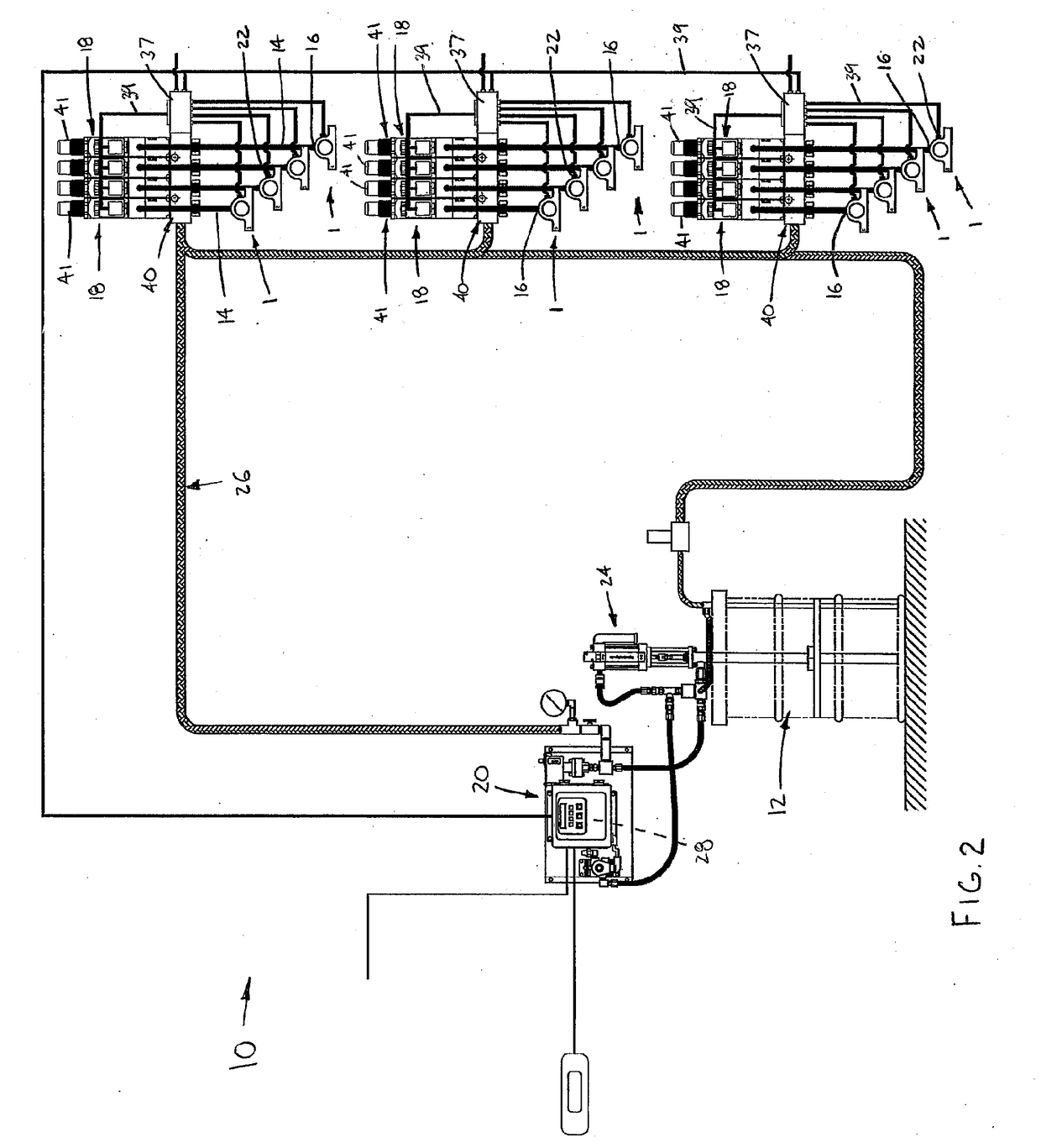

Lubrication system with lubricant condition monitoring

PatentInactiveUS20170114957A1

Innovation

- A lubrication system with a sensor-controlled valve that determines the estimated effectiveness period of the lubricant and automatically dispenses fresh lubricant before it degrades, ensuring continuous lubrication and preventing metal-to-metal contact.

Environmental Impact of AI-Optimized Lubrication

The implementation of AI-driven models for predicting LS engine lubrication needs has significant environmental implications. By optimizing lubrication processes, these models contribute to reduced oil consumption and waste, leading to a decrease in the overall environmental footprint of engine operations.

One of the primary environmental benefits is the reduction in oil usage. AI models can accurately predict when lubrication is needed, preventing both over-lubrication and under-lubrication. This precision results in less oil being consumed over the engine's lifetime, which in turn reduces the demand for oil production and its associated environmental impacts, such as drilling, refining, and transportation.

Moreover, optimized lubrication leads to improved engine efficiency and longevity. When engines are properly lubricated, they experience less wear and tear, resulting in extended lifespans. This reduction in the frequency of engine replacements translates to fewer resources being used for manufacturing new engines and less waste from discarded ones.

The AI-driven models also contribute to a decrease in harmful emissions. Proper lubrication ensures that engines run more smoothly and efficiently, leading to reduced fuel consumption and, consequently, lower greenhouse gas emissions. This aspect is particularly crucial in the context of global efforts to combat climate change and reduce carbon footprints across industries.

Additionally, these models can help prevent oil leaks and spills by identifying potential issues before they occur. This proactive approach minimizes the risk of oil contamination in soil and water bodies, protecting ecosystems and biodiversity. The reduction in oil-related accidents also means fewer resources are needed for cleanup operations, further decreasing the environmental impact.

The implementation of AI-optimized lubrication systems can also lead to a reduction in the production and disposal of oil filters. With more precise lubrication schedules, filters may need to be changed less frequently, reducing the amount of waste generated and the resources required for filter production.

Furthermore, the data collected by these AI systems can be used to improve engine designs, potentially leading to the development of more environmentally friendly engines in the future. This long-term impact on engine technology could result in significant environmental benefits across various industries that rely on LS engines.

One of the primary environmental benefits is the reduction in oil usage. AI models can accurately predict when lubrication is needed, preventing both over-lubrication and under-lubrication. This precision results in less oil being consumed over the engine's lifetime, which in turn reduces the demand for oil production and its associated environmental impacts, such as drilling, refining, and transportation.

Moreover, optimized lubrication leads to improved engine efficiency and longevity. When engines are properly lubricated, they experience less wear and tear, resulting in extended lifespans. This reduction in the frequency of engine replacements translates to fewer resources being used for manufacturing new engines and less waste from discarded ones.

The AI-driven models also contribute to a decrease in harmful emissions. Proper lubrication ensures that engines run more smoothly and efficiently, leading to reduced fuel consumption and, consequently, lower greenhouse gas emissions. This aspect is particularly crucial in the context of global efforts to combat climate change and reduce carbon footprints across industries.

Additionally, these models can help prevent oil leaks and spills by identifying potential issues before they occur. This proactive approach minimizes the risk of oil contamination in soil and water bodies, protecting ecosystems and biodiversity. The reduction in oil-related accidents also means fewer resources are needed for cleanup operations, further decreasing the environmental impact.

The implementation of AI-optimized lubrication systems can also lead to a reduction in the production and disposal of oil filters. With more precise lubrication schedules, filters may need to be changed less frequently, reducing the amount of waste generated and the resources required for filter production.

Furthermore, the data collected by these AI systems can be used to improve engine designs, potentially leading to the development of more environmentally friendly engines in the future. This long-term impact on engine technology could result in significant environmental benefits across various industries that rely on LS engines.

Data Privacy in AI-Driven Engine Diagnostics

As AI-driven models become increasingly prevalent in engine diagnostics, the protection of sensitive data has emerged as a critical concern. The integration of artificial intelligence in predicting LS engine lubrication needs involves processing vast amounts of proprietary and potentially personal information, necessitating robust data privacy measures.

Engine diagnostic systems collect and analyze a wide range of data points, including engine performance metrics, maintenance histories, and operational patterns. This data, when aggregated and processed by AI models, can reveal sensitive information about vehicle usage, driver behavior, and even business operations in the case of commercial fleets. Consequently, safeguarding this data against unauthorized access, breaches, and misuse is paramount.

One of the primary challenges in maintaining data privacy in AI-driven engine diagnostics is the need for data sharing across different stakeholders. Manufacturers, service providers, and vehicle owners all have legitimate interests in accessing diagnostic data, yet each party's access must be carefully controlled to prevent privacy violations. Implementing granular access controls and data anonymization techniques can help balance the need for data utilization with privacy protection.

Another critical aspect of data privacy in this context is the secure transmission and storage of diagnostic information. As engine data is often collected in real-time and transmitted to cloud-based AI systems for analysis, robust encryption protocols must be employed to protect data in transit. Similarly, secure storage solutions with stringent access controls are essential to safeguard data at rest.

The use of federated learning techniques presents a promising approach to enhancing data privacy in AI-driven engine diagnostics. This method allows AI models to be trained on distributed datasets without centralizing sensitive information, thereby reducing the risk of large-scale data breaches. By keeping individual vehicle data localized and only sharing model updates, federated learning can significantly enhance privacy while still enabling the development of sophisticated predictive models.

Compliance with data protection regulations, such as GDPR in Europe or CCPA in California, is another crucial consideration. These regulations impose strict requirements on the collection, processing, and storage of personal data, including information that could be derived from engine diagnostics. AI systems must be designed with privacy-by-design principles to ensure compliance and protect user rights.

As AI-driven engine diagnostic systems continue to evolve, ongoing research and development in privacy-preserving AI techniques will be essential. This includes advancements in differential privacy, homomorphic encryption, and secure multi-party computation, which can enable more sophisticated analysis while maintaining strong privacy guarantees.

Engine diagnostic systems collect and analyze a wide range of data points, including engine performance metrics, maintenance histories, and operational patterns. This data, when aggregated and processed by AI models, can reveal sensitive information about vehicle usage, driver behavior, and even business operations in the case of commercial fleets. Consequently, safeguarding this data against unauthorized access, breaches, and misuse is paramount.

One of the primary challenges in maintaining data privacy in AI-driven engine diagnostics is the need for data sharing across different stakeholders. Manufacturers, service providers, and vehicle owners all have legitimate interests in accessing diagnostic data, yet each party's access must be carefully controlled to prevent privacy violations. Implementing granular access controls and data anonymization techniques can help balance the need for data utilization with privacy protection.

Another critical aspect of data privacy in this context is the secure transmission and storage of diagnostic information. As engine data is often collected in real-time and transmitted to cloud-based AI systems for analysis, robust encryption protocols must be employed to protect data in transit. Similarly, secure storage solutions with stringent access controls are essential to safeguard data at rest.

The use of federated learning techniques presents a promising approach to enhancing data privacy in AI-driven engine diagnostics. This method allows AI models to be trained on distributed datasets without centralizing sensitive information, thereby reducing the risk of large-scale data breaches. By keeping individual vehicle data localized and only sharing model updates, federated learning can significantly enhance privacy while still enabling the development of sophisticated predictive models.

Compliance with data protection regulations, such as GDPR in Europe or CCPA in California, is another crucial consideration. These regulations impose strict requirements on the collection, processing, and storage of personal data, including information that could be derived from engine diagnostics. AI systems must be designed with privacy-by-design principles to ensure compliance and protect user rights.

As AI-driven engine diagnostic systems continue to evolve, ongoing research and development in privacy-preserving AI techniques will be essential. This includes advancements in differential privacy, homomorphic encryption, and secure multi-party computation, which can enable more sophisticated analysis while maintaining strong privacy guarantees.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!