How Blade Battery Improves Safety in Electric Vehicles

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Evolution and Safety Objectives

The evolution of blade batteries represents a significant leap forward in electric vehicle (EV) safety technology. Originating from the need to address safety concerns in lithium-ion batteries, blade batteries have emerged as a promising solution to enhance the overall safety profile of EVs. The development of this technology can be traced back to the early 2010s when researchers began exploring new battery cell designs to mitigate the risks associated with thermal runaway and internal short circuits.

The primary objective of blade battery technology is to dramatically improve the safety of EVs by reducing the likelihood of battery fires and explosions. This goal aligns with the broader industry push towards safer and more reliable electric transportation. Blade batteries achieve this by employing a unique structural design that allows for better heat dissipation and improved stability under extreme conditions.

As the EV market has expanded rapidly over the past decade, the demand for safer battery technologies has intensified. This has driven the evolution of blade batteries from concept to commercial reality. The technology has undergone several iterations, with each generation focusing on enhancing safety features while maintaining or improving energy density and performance characteristics.

One of the key milestones in blade battery evolution was the development of advanced materials that could withstand high pressures and temperatures without compromising structural integrity. This breakthrough enabled the creation of thinner, more densely packed battery cells that could be arranged in a blade-like configuration, giving the technology its name.

The safety objectives of blade batteries extend beyond mere fire prevention. They aim to create a more robust and resilient power source that can withstand various types of physical damage and environmental stresses. This includes improving the battery's ability to maintain stability during collisions, punctures, and extreme temperature fluctuations.

Furthermore, the evolution of blade batteries has been guided by the goal of minimizing the propagation of thermal events within the battery pack. By isolating individual cells more effectively, blade batteries aim to prevent a single cell failure from cascading into a catastrophic battery-wide event, thus significantly enhancing the overall safety of the vehicle.

As the technology continues to mature, researchers and manufacturers are setting increasingly ambitious safety objectives. These include developing blade batteries that can self-diagnose potential issues, implement preemptive safety measures, and even self-extinguish in the unlikely event of a thermal incident. The ongoing evolution of blade batteries reflects the industry's commitment to pushing the boundaries of EV safety, ultimately aiming to make electric vehicles safer than their internal combustion engine counterparts.

The primary objective of blade battery technology is to dramatically improve the safety of EVs by reducing the likelihood of battery fires and explosions. This goal aligns with the broader industry push towards safer and more reliable electric transportation. Blade batteries achieve this by employing a unique structural design that allows for better heat dissipation and improved stability under extreme conditions.

As the EV market has expanded rapidly over the past decade, the demand for safer battery technologies has intensified. This has driven the evolution of blade batteries from concept to commercial reality. The technology has undergone several iterations, with each generation focusing on enhancing safety features while maintaining or improving energy density and performance characteristics.

One of the key milestones in blade battery evolution was the development of advanced materials that could withstand high pressures and temperatures without compromising structural integrity. This breakthrough enabled the creation of thinner, more densely packed battery cells that could be arranged in a blade-like configuration, giving the technology its name.

The safety objectives of blade batteries extend beyond mere fire prevention. They aim to create a more robust and resilient power source that can withstand various types of physical damage and environmental stresses. This includes improving the battery's ability to maintain stability during collisions, punctures, and extreme temperature fluctuations.

Furthermore, the evolution of blade batteries has been guided by the goal of minimizing the propagation of thermal events within the battery pack. By isolating individual cells more effectively, blade batteries aim to prevent a single cell failure from cascading into a catastrophic battery-wide event, thus significantly enhancing the overall safety of the vehicle.

As the technology continues to mature, researchers and manufacturers are setting increasingly ambitious safety objectives. These include developing blade batteries that can self-diagnose potential issues, implement preemptive safety measures, and even self-extinguish in the unlikely event of a thermal incident. The ongoing evolution of blade batteries reflects the industry's commitment to pushing the boundaries of EV safety, ultimately aiming to make electric vehicles safer than their internal combustion engine counterparts.

EV Market Demand for Enhanced Battery Safety

The electric vehicle (EV) market has witnessed a significant surge in demand for enhanced battery safety in recent years. This growing emphasis on safety stems from several factors, including high-profile incidents involving battery fires, increasing consumer awareness, and stringent regulatory requirements. As EVs become more mainstream, potential buyers are placing a premium on vehicles that offer not only performance and range but also superior safety features.

Market research indicates that safety concerns are a major barrier to EV adoption for many consumers. A survey conducted by a leading automotive research firm revealed that over 70% of potential EV buyers consider battery safety as a "very important" factor in their purchasing decision. This sentiment is particularly strong in regions with high population density and in markets where EVs are still in the early adoption phase.

The demand for enhanced battery safety is also driven by the insurance industry. Insurance companies are increasingly factoring in battery safety features when determining premiums for EVs. Vehicles equipped with advanced safety technologies, such as those found in blade batteries, are often eligible for lower insurance rates, creating an additional incentive for consumers to prioritize safety in their EV purchases.

Government regulations and safety standards are playing a crucial role in shaping market demand. Many countries have implemented or are in the process of implementing stricter safety requirements for EV batteries. These regulations are pushing automakers to invest in safer battery technologies, thereby influencing consumer expectations and market trends.

The commercial EV sector, including fleet operators and ride-sharing companies, is another significant driver of demand for enhanced battery safety. These businesses prioritize vehicle uptime and risk mitigation, making them particularly receptive to innovations that improve battery safety and reliability.

Interestingly, the demand for enhanced battery safety is not limited to the automotive sector. The trend is spilling over into adjacent markets such as energy storage systems for residential and commercial applications. Consumers and businesses are increasingly seeking battery technologies that offer improved safety profiles for their home and office energy storage solutions.

As the EV market continues to mature, the demand for enhanced battery safety is expected to intensify. Industry analysts project that by 2025, safety features will be among the top three factors influencing EV purchase decisions, alongside range and price. This shift in consumer priorities is likely to accelerate innovation in battery safety technologies and reshape the competitive landscape of the EV industry.

Market research indicates that safety concerns are a major barrier to EV adoption for many consumers. A survey conducted by a leading automotive research firm revealed that over 70% of potential EV buyers consider battery safety as a "very important" factor in their purchasing decision. This sentiment is particularly strong in regions with high population density and in markets where EVs are still in the early adoption phase.

The demand for enhanced battery safety is also driven by the insurance industry. Insurance companies are increasingly factoring in battery safety features when determining premiums for EVs. Vehicles equipped with advanced safety technologies, such as those found in blade batteries, are often eligible for lower insurance rates, creating an additional incentive for consumers to prioritize safety in their EV purchases.

Government regulations and safety standards are playing a crucial role in shaping market demand. Many countries have implemented or are in the process of implementing stricter safety requirements for EV batteries. These regulations are pushing automakers to invest in safer battery technologies, thereby influencing consumer expectations and market trends.

The commercial EV sector, including fleet operators and ride-sharing companies, is another significant driver of demand for enhanced battery safety. These businesses prioritize vehicle uptime and risk mitigation, making them particularly receptive to innovations that improve battery safety and reliability.

Interestingly, the demand for enhanced battery safety is not limited to the automotive sector. The trend is spilling over into adjacent markets such as energy storage systems for residential and commercial applications. Consumers and businesses are increasingly seeking battery technologies that offer improved safety profiles for their home and office energy storage solutions.

As the EV market continues to mature, the demand for enhanced battery safety is expected to intensify. Industry analysts project that by 2025, safety features will be among the top three factors influencing EV purchase decisions, alongside range and price. This shift in consumer priorities is likely to accelerate innovation in battery safety technologies and reshape the competitive landscape of the EV industry.

Current Challenges in EV Battery Safety

Electric vehicle (EV) battery safety remains a critical concern in the automotive industry, with several challenges persisting despite significant advancements in battery technology. One of the primary issues is thermal runaway, a chain reaction that can lead to rapid temperature increase, gas generation, and potential fire or explosion. This phenomenon can be triggered by various factors, including mechanical damage, overcharging, or internal short circuits.

Another significant challenge is the vulnerability of lithium-ion batteries to physical damage. In the event of a collision, battery packs can be punctured or deformed, potentially causing internal short circuits and subsequent thermal events. This risk is particularly pronounced in severe accidents, where the structural integrity of the battery pack may be compromised.

The issue of battery degradation over time also poses safety concerns. As batteries age, their capacity diminishes, and internal resistance increases. This can lead to reduced performance and, in some cases, increased susceptibility to thermal events. Managing this degradation process and ensuring safe operation throughout the battery's lifecycle remains a challenge for EV manufacturers.

Extreme temperature conditions present another hurdle for EV battery safety. High temperatures can accelerate chemical reactions within the battery, potentially leading to thermal runaway, while extremely low temperatures can affect battery performance and charging capabilities. Developing battery systems that maintain safety and efficiency across a wide range of environmental conditions is an ongoing challenge.

The complexity of battery management systems (BMS) adds another layer to safety concerns. These systems are responsible for monitoring and controlling various aspects of battery operation, including temperature, state of charge, and cell balancing. Ensuring the reliability and accuracy of BMS in detecting and mitigating potential safety issues is crucial but technically challenging.

Lastly, the scale of EV battery packs presents unique safety challenges. With capacities often exceeding 60 kWh, the energy density in these large battery packs is substantial. In the event of a thermal incident, the sheer amount of energy stored can lead to more severe consequences compared to smaller battery systems. Developing effective containment and suppression strategies for large-scale battery fires remains an area of active research and development in the EV industry.

Another significant challenge is the vulnerability of lithium-ion batteries to physical damage. In the event of a collision, battery packs can be punctured or deformed, potentially causing internal short circuits and subsequent thermal events. This risk is particularly pronounced in severe accidents, where the structural integrity of the battery pack may be compromised.

The issue of battery degradation over time also poses safety concerns. As batteries age, their capacity diminishes, and internal resistance increases. This can lead to reduced performance and, in some cases, increased susceptibility to thermal events. Managing this degradation process and ensuring safe operation throughout the battery's lifecycle remains a challenge for EV manufacturers.

Extreme temperature conditions present another hurdle for EV battery safety. High temperatures can accelerate chemical reactions within the battery, potentially leading to thermal runaway, while extremely low temperatures can affect battery performance and charging capabilities. Developing battery systems that maintain safety and efficiency across a wide range of environmental conditions is an ongoing challenge.

The complexity of battery management systems (BMS) adds another layer to safety concerns. These systems are responsible for monitoring and controlling various aspects of battery operation, including temperature, state of charge, and cell balancing. Ensuring the reliability and accuracy of BMS in detecting and mitigating potential safety issues is crucial but technically challenging.

Lastly, the scale of EV battery packs presents unique safety challenges. With capacities often exceeding 60 kWh, the energy density in these large battery packs is substantial. In the event of a thermal incident, the sheer amount of energy stored can lead to more severe consequences compared to smaller battery systems. Developing effective containment and suppression strategies for large-scale battery fires remains an area of active research and development in the EV industry.

Blade Battery Design and Safety Features

01 Battery cell structure and design

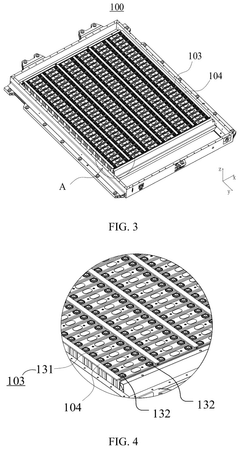

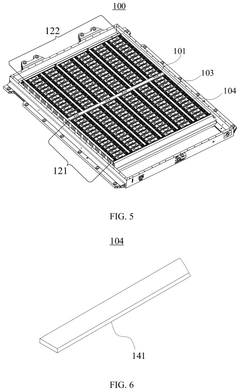

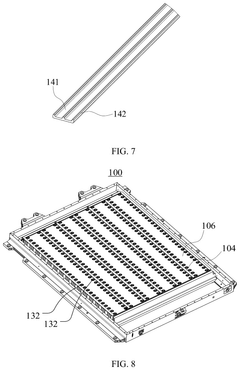

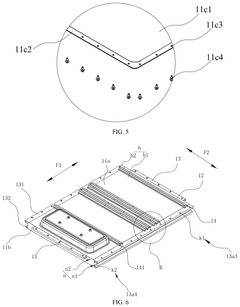

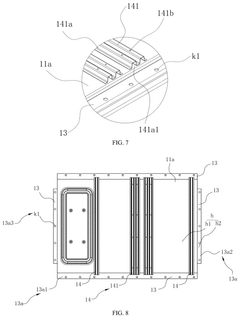

Blade batteries employ a unique structural design to enhance safety. This includes optimized cell arrangement, improved heat dissipation mechanisms, and reinforced casing materials. The design aims to prevent thermal runaway and minimize the risk of fire or explosion in case of damage or malfunction.- Battery cell structure and design: Blade batteries incorporate innovative structural designs to enhance safety. This includes optimized cell arrangements, improved casing materials, and reinforced internal components. These design elements help prevent short circuits, manage thermal runaway, and increase overall structural integrity.

- Thermal management systems: Advanced thermal management systems are implemented in blade batteries to regulate temperature and prevent overheating. These systems may include heat dissipation mechanisms, cooling channels, and temperature sensors to monitor and control battery temperature during operation and charging.

- Safety mechanisms and fail-safes: Blade batteries incorporate various safety mechanisms and fail-safes to prevent accidents and mitigate risks. These may include pressure relief valves, current interrupt devices, and intelligent battery management systems that can detect and respond to potential safety issues in real-time.

- Manufacturing processes and quality control: Improved manufacturing processes and stringent quality control measures are employed in the production of blade batteries. This includes advanced electrode coating techniques, precise assembly methods, and comprehensive testing procedures to ensure consistent performance and safety standards.

- Battery management and monitoring systems: Sophisticated battery management and monitoring systems are integrated into blade batteries to enhance safety. These systems continuously monitor various parameters such as voltage, current, and temperature, and can implement protective measures or shut down the battery if abnormal conditions are detected.

02 Safety monitoring and control systems

Advanced monitoring and control systems are integrated into blade batteries to ensure safe operation. These systems include temperature sensors, voltage monitors, and intelligent management algorithms that can detect abnormalities and trigger protective measures such as power cut-off or cooling activation.Expand Specific Solutions03 Thermal management solutions

Effective thermal management is crucial for blade battery safety. This involves innovative cooling systems, heat-resistant materials, and thermal insulation techniques to prevent overheating and maintain optimal operating temperatures, even under high-stress conditions or in extreme environments.Expand Specific Solutions04 Manufacturing processes and quality control

Specialized manufacturing processes and stringent quality control measures are implemented to enhance blade battery safety. This includes precision assembly techniques, advanced testing procedures, and the use of high-quality materials to minimize defects and ensure consistent performance and safety standards.Expand Specific Solutions05 Safety certification and testing protocols

Rigorous safety certification and testing protocols are developed specifically for blade batteries. These include comprehensive abuse tests, simulated crash scenarios, and long-term reliability assessments to verify the battery's ability to withstand various hazardous conditions and maintain safety throughout its lifecycle.Expand Specific Solutions

Key Players in Blade Battery Manufacturing

The blade battery technology for electric vehicles is currently in a growth phase, with increasing market adoption and technological advancements. The global market for EV batteries is expanding rapidly, driven by the rising demand for electric vehicles. Companies like Contemporary Amperex Technology Co., Ltd. (CATL), BYD Co., Ltd., and LG Energy Solution Ltd. are at the forefront of blade battery development, demonstrating varying levels of technological maturity. CATL and BYD have made significant progress in commercializing blade batteries, while other major automakers such as Mercedes-Benz Group AG and Toyota Motor Corp. are actively exploring and integrating this technology into their electric vehicle lineups. The blade battery's improved safety features and energy density are attracting attention from both established manufacturers and emerging players in the EV industry.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed its own Cell-to-Pack (CTP) technology, which integrates cells directly into the battery pack, similar to BYD's approach. Their third-generation CTP technology, known as Qilin, achieves a volume utilization efficiency of 72% and an energy density of up to 255 Wh/kg[5]. CATL's batteries incorporate advanced thermal management systems, using liquid cooling and smart temperature control algorithms to maintain optimal operating conditions[6]. The company has also introduced its LFP-based "M3P" battery, which offers improved energy density over traditional LFP cells while maintaining high safety standards[7].

Strengths: High energy density, advanced thermal management, and innovative cell integration techniques. Weaknesses: The complexity of CTP design may increase manufacturing costs and potentially complicate battery repairs or replacements.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced nickel-rich cathode materials for high-energy-density batteries, focusing on NCM (Nickel, Cobalt, Manganese) chemistry. Their latest batteries achieve energy densities of up to 300 Wh/kg[8]. The company employs a multi-layer safety system, including a ceramic-coated separator that prevents internal short circuits and thermal runaway[9]. LG has also introduced its "Stack and Folding" technology, which allows for more efficient use of space within the battery pack, improving energy density and thermal management[10].

Strengths: High energy density, advanced safety features, and efficient space utilization. Weaknesses: Nickel-rich chemistries can be more prone to thermal issues than LFP, requiring more complex safety systems.

Core Innovations in Blade Battery Technology

Battery and electric apparatus

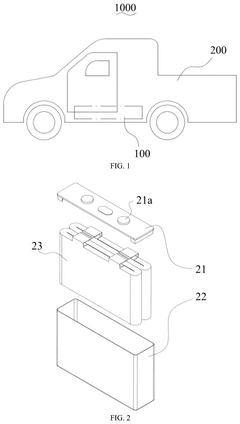

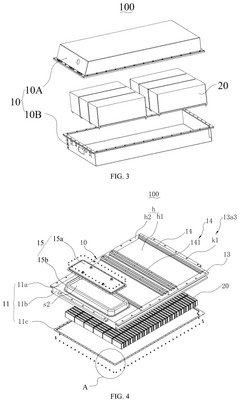

PatentPendingUS20250233293A1

Innovation

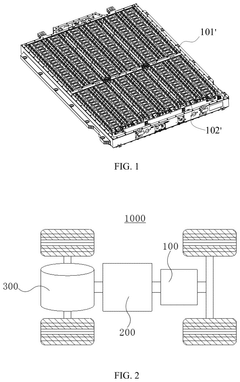

- A battery design that uses connecting pieces to bond battery cells, with cross beams to divide the cells into regions, limiting swelling and deformation, and employs insulating pieces to simplify the structure and improve energy density.

Box body, battery, and electric device

PatentPendingUS20240416765A1

Innovation

- A box body design for batteries that includes a main body with a side impact reinforcing beam extending from the middle of the top to the outer edges, enhancing anti-side collision capabilities and integrating a high-voltage bin at the top to prevent external damage, while also allowing for weight reduction and improved structural strength through protrusions and hidden channels.

Regulatory Framework for EV Battery Safety

The regulatory framework for electric vehicle (EV) battery safety is a critical aspect of ensuring the widespread adoption and safe operation of EVs. Governments and regulatory bodies worldwide have established stringent standards and guidelines to address the unique safety challenges posed by high-capacity lithium-ion batteries used in electric vehicles.

In the United States, the National Highway Traffic Safety Administration (NHTSA) plays a pivotal role in setting safety standards for EVs and their batteries. The Federal Motor Vehicle Safety Standards (FMVSS) include specific requirements for electric vehicle safety, such as FMVSS No. 305, which addresses electric powertrain safety. This standard outlines requirements for battery isolation, electrical shock protection, and post-crash electrical safety.

The European Union has implemented the UN Regulation No. 100, which covers battery electric vehicle safety. This regulation specifies requirements for the construction, functional safety, and hydrogen emissions of rechargeable energy storage systems. It also mandates rigorous testing procedures to ensure battery safety under various conditions, including mechanical stress, thermal abuse, and overcharging.

China, as a major player in the EV market, has developed its own set of regulations. The GB/T 31485 standard focuses on safety requirements and test methods for traction battery packs and systems of electric vehicles. This standard covers aspects such as mechanical integrity, thermal management, and electrical safety.

International organizations like the Society of Automotive Engineers (SAE) and the International Electrotechnical Commission (IEC) have also contributed to the development of safety standards for EV batteries. The SAE J2464 standard, for instance, provides guidelines for electric and hybrid vehicle battery systems, while IEC 62660 addresses performance and life testing of lithium-ion cells for EV applications.

Regulatory bodies are continuously updating these frameworks to keep pace with technological advancements. Recent focus areas include thermal runaway prevention, battery management systems, and fire suppression technologies. The implementation of these regulations has led to significant improvements in EV battery safety, fostering consumer confidence and accelerating the transition to electric mobility.

As the EV industry evolves, regulators are also addressing emerging concerns such as battery recycling, second-life applications, and the environmental impact of battery production. These aspects are becoming integral parts of the overall regulatory framework, ensuring a holistic approach to EV battery safety and sustainability.

In the United States, the National Highway Traffic Safety Administration (NHTSA) plays a pivotal role in setting safety standards for EVs and their batteries. The Federal Motor Vehicle Safety Standards (FMVSS) include specific requirements for electric vehicle safety, such as FMVSS No. 305, which addresses electric powertrain safety. This standard outlines requirements for battery isolation, electrical shock protection, and post-crash electrical safety.

The European Union has implemented the UN Regulation No. 100, which covers battery electric vehicle safety. This regulation specifies requirements for the construction, functional safety, and hydrogen emissions of rechargeable energy storage systems. It also mandates rigorous testing procedures to ensure battery safety under various conditions, including mechanical stress, thermal abuse, and overcharging.

China, as a major player in the EV market, has developed its own set of regulations. The GB/T 31485 standard focuses on safety requirements and test methods for traction battery packs and systems of electric vehicles. This standard covers aspects such as mechanical integrity, thermal management, and electrical safety.

International organizations like the Society of Automotive Engineers (SAE) and the International Electrotechnical Commission (IEC) have also contributed to the development of safety standards for EV batteries. The SAE J2464 standard, for instance, provides guidelines for electric and hybrid vehicle battery systems, while IEC 62660 addresses performance and life testing of lithium-ion cells for EV applications.

Regulatory bodies are continuously updating these frameworks to keep pace with technological advancements. Recent focus areas include thermal runaway prevention, battery management systems, and fire suppression technologies. The implementation of these regulations has led to significant improvements in EV battery safety, fostering consumer confidence and accelerating the transition to electric mobility.

As the EV industry evolves, regulators are also addressing emerging concerns such as battery recycling, second-life applications, and the environmental impact of battery production. These aspects are becoming integral parts of the overall regulatory framework, ensuring a holistic approach to EV battery safety and sustainability.

Environmental Impact of Blade Batteries

The environmental impact of Blade Batteries in electric vehicles is a crucial aspect to consider when evaluating their overall sustainability. These innovative batteries, developed by BYD, offer significant improvements in safety and performance, but their environmental footprint throughout their lifecycle is equally important.

Blade Batteries utilize lithium iron phosphate (LFP) chemistry, which presents several environmental advantages. Compared to traditional lithium-ion batteries, LFP batteries require less cobalt, a metal associated with ethical and environmental concerns in its mining process. This reduction in cobalt usage contributes to a more sustainable supply chain and minimizes the ecological impact of battery production.

The manufacturing process of Blade Batteries also demonstrates improved energy efficiency. BYD's innovative design and production techniques result in a more streamlined manufacturing process, potentially reducing energy consumption and associated carbon emissions during production. This efficiency extends to the battery's performance in electric vehicles, where its high energy density and long lifespan contribute to reduced resource consumption over time.

In terms of longevity, Blade Batteries exhibit exceptional durability and cycle life. This extended lifespan means fewer battery replacements are needed over the lifetime of an electric vehicle, reducing waste and the demand for new battery production. Additionally, the improved safety features of Blade Batteries, such as their resistance to thermal runaway, contribute to a lower risk of environmental contamination due to accidents or improper disposal.

The end-of-life considerations for Blade Batteries also present potential environmental benefits. Their composition makes them more amenable to recycling processes, with a higher percentage of materials that can be recovered and reused. This recyclability helps close the loop in the battery lifecycle, reducing the need for virgin materials and minimizing waste.

However, it's important to note that the large-scale production of any battery technology comes with environmental challenges. The extraction of raw materials, energy-intensive manufacturing processes, and the need for proper recycling infrastructure all contribute to the overall environmental impact. As Blade Battery technology continues to evolve, ongoing research and development efforts are likely to focus on further reducing its ecological footprint.

In conclusion, while Blade Batteries offer promising environmental advantages in terms of resource use, energy efficiency, and recyclability, a comprehensive lifecycle assessment is necessary to fully quantify their environmental impact compared to other battery technologies. As the electric vehicle market expands, the continued improvement of battery technologies like Blade Batteries will play a crucial role in minimizing the environmental impact of transportation.

Blade Batteries utilize lithium iron phosphate (LFP) chemistry, which presents several environmental advantages. Compared to traditional lithium-ion batteries, LFP batteries require less cobalt, a metal associated with ethical and environmental concerns in its mining process. This reduction in cobalt usage contributes to a more sustainable supply chain and minimizes the ecological impact of battery production.

The manufacturing process of Blade Batteries also demonstrates improved energy efficiency. BYD's innovative design and production techniques result in a more streamlined manufacturing process, potentially reducing energy consumption and associated carbon emissions during production. This efficiency extends to the battery's performance in electric vehicles, where its high energy density and long lifespan contribute to reduced resource consumption over time.

In terms of longevity, Blade Batteries exhibit exceptional durability and cycle life. This extended lifespan means fewer battery replacements are needed over the lifetime of an electric vehicle, reducing waste and the demand for new battery production. Additionally, the improved safety features of Blade Batteries, such as their resistance to thermal runaway, contribute to a lower risk of environmental contamination due to accidents or improper disposal.

The end-of-life considerations for Blade Batteries also present potential environmental benefits. Their composition makes them more amenable to recycling processes, with a higher percentage of materials that can be recovered and reused. This recyclability helps close the loop in the battery lifecycle, reducing the need for virgin materials and minimizing waste.

However, it's important to note that the large-scale production of any battery technology comes with environmental challenges. The extraction of raw materials, energy-intensive manufacturing processes, and the need for proper recycling infrastructure all contribute to the overall environmental impact. As Blade Battery technology continues to evolve, ongoing research and development efforts are likely to focus on further reducing its ecological footprint.

In conclusion, while Blade Batteries offer promising environmental advantages in terms of resource use, energy efficiency, and recyclability, a comprehensive lifecycle assessment is necessary to fully quantify their environmental impact compared to other battery technologies. As the electric vehicle market expands, the continued improvement of battery technologies like Blade Batteries will play a crucial role in minimizing the environmental impact of transportation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!