How Home-Hybrid Conversion Kits Use LS Engines for Efficiency

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Conversion Background and Objectives

The LS engine conversion for home-hybrid vehicles represents a significant technological advancement in the automotive industry, blending the efficiency of hybrid systems with the power and reliability of General Motors' LS engine series. This conversion trend has emerged as a response to the growing demand for fuel-efficient vehicles that don't compromise on performance.

The LS engine family, introduced by General Motors in 1997, has become renowned for its compact design, lightweight construction, and impressive power-to-weight ratio. These characteristics make it an ideal candidate for hybrid conversions, particularly in home-based or aftermarket applications. The objective of such conversions is to leverage the LS engine's efficiency and power in conjunction with electric propulsion systems, creating a hybrid powertrain that offers the best of both worlds.

The evolution of this technology can be traced back to the early 2000s when hybrid vehicles first gained mainstream attention. As hybrid technology matured and the aftermarket for LS engines expanded, enthusiasts and engineers began exploring ways to combine these two seemingly disparate technologies. The goal was to create vehicles that could deliver improved fuel economy during city driving while maintaining the high-performance capabilities associated with LS engines for highway use or when additional power is needed.

One of the key drivers behind this technological development has been the increasing focus on environmental sustainability in the automotive sector. As regulations around emissions and fuel efficiency have become more stringent, there has been a push to find innovative solutions that can meet these requirements without sacrificing the driving experience that many consumers desire.

The LS engine's adaptability to various vehicle platforms has played a crucial role in its popularity for hybrid conversions. Its compact size and modular design allow for relatively straightforward integration with electric motors and battery systems. This flexibility has opened up possibilities for converting a wide range of vehicles, from classic cars to modern performance vehicles, into efficient hybrids.

As the technology continues to evolve, the objectives for LS engine hybrid conversions have expanded. Beyond just improving fuel efficiency, modern conversions aim to enhance overall vehicle performance, reduce emissions, and provide a more sustainable alternative to traditional engine swaps. Additionally, there is a growing focus on developing plug-in hybrid systems that can offer extended electric-only driving ranges, further improving the environmental credentials of converted vehicles.

The LS engine family, introduced by General Motors in 1997, has become renowned for its compact design, lightweight construction, and impressive power-to-weight ratio. These characteristics make it an ideal candidate for hybrid conversions, particularly in home-based or aftermarket applications. The objective of such conversions is to leverage the LS engine's efficiency and power in conjunction with electric propulsion systems, creating a hybrid powertrain that offers the best of both worlds.

The evolution of this technology can be traced back to the early 2000s when hybrid vehicles first gained mainstream attention. As hybrid technology matured and the aftermarket for LS engines expanded, enthusiasts and engineers began exploring ways to combine these two seemingly disparate technologies. The goal was to create vehicles that could deliver improved fuel economy during city driving while maintaining the high-performance capabilities associated with LS engines for highway use or when additional power is needed.

One of the key drivers behind this technological development has been the increasing focus on environmental sustainability in the automotive sector. As regulations around emissions and fuel efficiency have become more stringent, there has been a push to find innovative solutions that can meet these requirements without sacrificing the driving experience that many consumers desire.

The LS engine's adaptability to various vehicle platforms has played a crucial role in its popularity for hybrid conversions. Its compact size and modular design allow for relatively straightforward integration with electric motors and battery systems. This flexibility has opened up possibilities for converting a wide range of vehicles, from classic cars to modern performance vehicles, into efficient hybrids.

As the technology continues to evolve, the objectives for LS engine hybrid conversions have expanded. Beyond just improving fuel efficiency, modern conversions aim to enhance overall vehicle performance, reduce emissions, and provide a more sustainable alternative to traditional engine swaps. Additionally, there is a growing focus on developing plug-in hybrid systems that can offer extended electric-only driving ranges, further improving the environmental credentials of converted vehicles.

Market Analysis for Home-Hybrid Conversions

The market for home-hybrid conversion kits utilizing LS engines has shown significant growth potential in recent years. This trend is driven by increasing consumer interest in fuel efficiency, environmental consciousness, and the desire to extend the life of older vehicles. The target market primarily consists of automotive enthusiasts, DIY mechanics, and environmentally conscious vehicle owners looking to improve their vehicle's performance and reduce fuel consumption.

The demand for these conversion kits is closely tied to fluctuations in fuel prices and environmental regulations. As fuel costs rise, more vehicle owners seek cost-effective solutions to improve fuel economy. Additionally, stricter emissions standards in many regions have prompted consumers to explore alternative options for their existing vehicles.

Market research indicates that the home-hybrid conversion kit sector is still in its early stages but shows promising growth prospects. The market size is expected to expand as awareness of these solutions increases and technology becomes more accessible. Key factors driving market growth include the rising cost of new hybrid vehicles, the desire to reduce carbon footprints, and the growing popularity of vehicle customization.

Consumer demographics for home-hybrid conversion kits skew towards middle-aged and older individuals who own older vehicles and possess some mechanical knowledge. However, there is also a growing interest among younger generations who are attracted to the eco-friendly aspects and the potential for cost savings over time.

The market landscape is characterized by a mix of established automotive aftermarket companies and innovative startups. These players are competing to develop more efficient, user-friendly, and cost-effective conversion solutions. The availability of LS engines, known for their reliability and performance, has been a significant factor in the market's development.

Geographically, the market for home-hybrid conversion kits is most developed in North America and Europe, where there is a large base of older vehicles and a strong culture of DIY automotive modification. However, emerging markets in Asia and South America are showing increasing interest as environmental concerns grow and disposable incomes rise.

Challenges in the market include regulatory hurdles, as many regions have strict laws regarding vehicle modifications. Additionally, the complexity of installation and the need for specialized knowledge can limit the market's reach to a broader consumer base. However, advancements in kit design and increasing support from professional installers are helping to address these barriers.

Overall, the market analysis suggests a positive outlook for home-hybrid conversion kits using LS engines. As technology improves and awareness grows, this sector is poised for continued expansion, offering a unique solution at the intersection of sustainability, performance, and automotive customization.

The demand for these conversion kits is closely tied to fluctuations in fuel prices and environmental regulations. As fuel costs rise, more vehicle owners seek cost-effective solutions to improve fuel economy. Additionally, stricter emissions standards in many regions have prompted consumers to explore alternative options for their existing vehicles.

Market research indicates that the home-hybrid conversion kit sector is still in its early stages but shows promising growth prospects. The market size is expected to expand as awareness of these solutions increases and technology becomes more accessible. Key factors driving market growth include the rising cost of new hybrid vehicles, the desire to reduce carbon footprints, and the growing popularity of vehicle customization.

Consumer demographics for home-hybrid conversion kits skew towards middle-aged and older individuals who own older vehicles and possess some mechanical knowledge. However, there is also a growing interest among younger generations who are attracted to the eco-friendly aspects and the potential for cost savings over time.

The market landscape is characterized by a mix of established automotive aftermarket companies and innovative startups. These players are competing to develop more efficient, user-friendly, and cost-effective conversion solutions. The availability of LS engines, known for their reliability and performance, has been a significant factor in the market's development.

Geographically, the market for home-hybrid conversion kits is most developed in North America and Europe, where there is a large base of older vehicles and a strong culture of DIY automotive modification. However, emerging markets in Asia and South America are showing increasing interest as environmental concerns grow and disposable incomes rise.

Challenges in the market include regulatory hurdles, as many regions have strict laws regarding vehicle modifications. Additionally, the complexity of installation and the need for specialized knowledge can limit the market's reach to a broader consumer base. However, advancements in kit design and increasing support from professional installers are helping to address these barriers.

Overall, the market analysis suggests a positive outlook for home-hybrid conversion kits using LS engines. As technology improves and awareness grows, this sector is poised for continued expansion, offering a unique solution at the intersection of sustainability, performance, and automotive customization.

Technical Challenges in LS Engine Adaptations

Adapting LS engines for home-hybrid conversion kits presents several technical challenges that require innovative solutions. One of the primary obstacles is the integration of the LS engine with existing hybrid systems. The LS engine, designed primarily for conventional combustion vehicles, must be modified to work seamlessly with electric motors and battery systems. This integration demands sophisticated control systems to manage power distribution between the combustion engine and electric components.

Another significant challenge lies in the thermal management of the hybrid system. LS engines, known for their high performance, generate considerable heat. In a hybrid setup, this heat must be efficiently dissipated to prevent overheating of both the engine and the electrical components. Developing an effective cooling system that can handle the combined thermal load of the LS engine and the hybrid components is crucial for maintaining optimal performance and longevity.

Weight distribution and packaging pose additional challenges. LS engines are relatively heavy, and their incorporation into a hybrid system adds further weight from batteries and electric motors. Balancing this weight to maintain proper vehicle dynamics while ensuring all components fit within the limited space of a passenger vehicle requires careful engineering and design considerations.

The adaptation of the LS engine's fuel system to work efficiently in a hybrid environment is another technical hurdle. The engine must be capable of rapid start-stop cycles, common in hybrid operations, without compromising fuel efficiency or emissions. This necessitates modifications to the fuel injection system and engine management software to optimize fuel delivery and combustion under varying load conditions.

Emissions control presents a unique challenge in LS engine hybrid adaptations. While hybrid systems generally aim to reduce emissions, integrating a high-performance LS engine requires advanced catalytic converter systems and precise engine tuning to meet stringent environmental regulations. Achieving the right balance between performance and emissions compliance is a complex task that demands extensive testing and refinement.

Durability and reliability concerns also arise when adapting LS engines for hybrid use. The frequent transitions between combustion and electric power can subject engine components to increased stress. Ensuring that all parts, from the crankshaft to valve train components, can withstand these dynamic operating conditions is essential for long-term reliability.

Lastly, the challenge of maintaining the LS engine's renowned performance characteristics while optimizing it for hybrid efficiency cannot be overlooked. Engineers must find ways to preserve the engine's power output and responsiveness while adapting it to work in harmony with electric drive systems. This often involves fine-tuning engine parameters and developing sophisticated control algorithms to manage power delivery across different driving modes.

Another significant challenge lies in the thermal management of the hybrid system. LS engines, known for their high performance, generate considerable heat. In a hybrid setup, this heat must be efficiently dissipated to prevent overheating of both the engine and the electrical components. Developing an effective cooling system that can handle the combined thermal load of the LS engine and the hybrid components is crucial for maintaining optimal performance and longevity.

Weight distribution and packaging pose additional challenges. LS engines are relatively heavy, and their incorporation into a hybrid system adds further weight from batteries and electric motors. Balancing this weight to maintain proper vehicle dynamics while ensuring all components fit within the limited space of a passenger vehicle requires careful engineering and design considerations.

The adaptation of the LS engine's fuel system to work efficiently in a hybrid environment is another technical hurdle. The engine must be capable of rapid start-stop cycles, common in hybrid operations, without compromising fuel efficiency or emissions. This necessitates modifications to the fuel injection system and engine management software to optimize fuel delivery and combustion under varying load conditions.

Emissions control presents a unique challenge in LS engine hybrid adaptations. While hybrid systems generally aim to reduce emissions, integrating a high-performance LS engine requires advanced catalytic converter systems and precise engine tuning to meet stringent environmental regulations. Achieving the right balance between performance and emissions compliance is a complex task that demands extensive testing and refinement.

Durability and reliability concerns also arise when adapting LS engines for hybrid use. The frequent transitions between combustion and electric power can subject engine components to increased stress. Ensuring that all parts, from the crankshaft to valve train components, can withstand these dynamic operating conditions is essential for long-term reliability.

Lastly, the challenge of maintaining the LS engine's renowned performance characteristics while optimizing it for hybrid efficiency cannot be overlooked. Engineers must find ways to preserve the engine's power output and responsiveness while adapting it to work in harmony with electric drive systems. This often involves fine-tuning engine parameters and developing sophisticated control algorithms to manage power delivery across different driving modes.

Current LS Engine Conversion Solutions

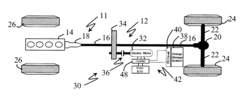

01 Electric motor integration for hybrid conversion

Home hybrid conversion kits often involve integrating electric motors into existing vehicles. These kits typically include components for mounting the electric motor, connecting it to the drivetrain, and interfacing with the vehicle's existing systems. The efficiency of these conversions depends on factors such as motor placement, power output, and integration with the original engine.- Electric motor integration for hybrid conversion: Home hybrid conversion kits often involve integrating electric motors into existing combustion engine vehicles. These kits typically include components for mounting the electric motor, power controllers, and battery systems. The efficiency of the conversion depends on the seamless integration of these components with the existing drivetrain, optimizing power distribution between the electric and combustion systems.

- Battery management and energy storage solutions: Efficient home hybrid conversion kits incorporate advanced battery management systems and energy storage solutions. These systems optimize the use of electrical energy, manage charging and discharging cycles, and enhance overall vehicle performance. The efficiency of the conversion is greatly influenced by the capacity, weight, and placement of the battery pack within the vehicle.

- Regenerative braking and energy recovery: Home hybrid conversion kits often include regenerative braking systems to improve overall efficiency. These systems capture kinetic energy during deceleration and convert it into electrical energy, which is then stored in the battery. The effectiveness of the regenerative braking system significantly contributes to the overall efficiency of the hybrid conversion.

- Control systems and power management: Efficient hybrid conversion kits incorporate sophisticated control systems and power management algorithms. These systems optimize the interplay between the electric motor and the combustion engine, ensuring smooth transitions and maximizing fuel efficiency. Advanced control units can adapt to driving conditions and user preferences, further enhancing the overall efficiency of the converted vehicle.

- Aerodynamic modifications and weight reduction: To maximize the efficiency of home hybrid conversions, kits may include components for aerodynamic improvements and weight reduction. These modifications can include lightweight body panels, streamlined exterior components, and the removal of unnecessary weight from the vehicle. By reducing drag and overall vehicle weight, the efficiency of the hybrid powertrain is further enhanced.

02 Battery and energy management systems

Efficient home hybrid conversion kits incorporate advanced battery technologies and energy management systems. These components are crucial for storing and distributing electrical energy effectively. The systems often include regenerative braking capabilities, intelligent power distribution, and battery monitoring to optimize overall efficiency and range.Expand Specific Solutions03 Control systems and software integration

The efficiency of home hybrid conversion kits is greatly influenced by the control systems and software integration. Advanced control algorithms manage the interplay between the electric motor and the internal combustion engine, optimizing power delivery and fuel efficiency. These systems often include user interfaces for monitoring performance and adjusting driving modes.Expand Specific Solutions04 Lightweight materials and aerodynamic modifications

To enhance efficiency, some home hybrid conversion kits incorporate lightweight materials and aerodynamic modifications. These can include replacing heavy components with lighter alternatives, adding aerodynamic body panels, or modifying the vehicle's suspension. Such changes can significantly improve the overall efficiency of the converted hybrid vehicle.Expand Specific Solutions05 Plug-in charging capabilities

Many home hybrid conversion kits now include plug-in charging capabilities to further improve efficiency. These systems allow the vehicle to be charged from external power sources, reducing reliance on the internal combustion engine and increasing the overall electric range. The integration of charging systems often requires additional components and safety features.Expand Specific Solutions

Key Players in Aftermarket Conversion Industry

The competition landscape for home-hybrid conversion kits using LS engines for efficiency is in a nascent stage, with the market still developing. The automotive industry is transitioning towards more sustainable solutions, creating opportunities for innovative aftermarket products. Major players like GM, Ford, and Honda are exploring this space, leveraging their expertise in engine technology. However, the market size remains relatively small, with niche companies and startups also entering the field. The technology's maturity is evolving, with established automotive giants like GM Global Technology Operations LLC having an advantage in LS engine expertise, while companies like Turntide Technologies bring fresh perspectives on efficiency improvements. As the market grows, we can expect increased competition and technological advancements from both traditional automakers and new entrants.

GM Global Technology Operations LLC

Technical Solution: GM's home-hybrid conversion kit utilizing LS engines focuses on integrating their proven LS engine technology with advanced hybrid systems. The LS engine, known for its reliability and power, is modified to work in tandem with electric motors. This system employs a sophisticated engine management system that optimizes the use of gasoline and electric power based on driving conditions. The conversion kit includes a high-capacity battery pack, power inverter, and regenerative braking system to maximize energy efficiency[1]. GM's approach also incorporates cylinder deactivation technology, allowing the engine to run on fewer cylinders during light load conditions, further improving fuel economy[2]. The kit is designed for easy installation, with plug-and-play components that can be fitted to various vehicle models, making it a versatile solution for aftermarket hybridization[3].

Strengths: Leverages GM's extensive experience with LS engines and hybrid technology. Offers significant fuel economy improvements. Adaptable to multiple vehicle platforms. Weaknesses: May be more expensive than some competitors due to advanced technology integration. Potential complexity in installation for non-professional mechanics.

Ford Motor Co.

Technical Solution: Ford's home-hybrid conversion kit for LS engines focuses on a modular approach, allowing for easy integration with existing Ford vehicle platforms. The system utilizes a split-power architecture, where the LS engine is coupled with an electric motor through a power-split device. This allows for seamless transitions between electric-only, hybrid, and engine-only modes[1]. Ford's kit includes a lithium-ion battery pack, power electronics, and a regenerative braking system. The company has developed a proprietary control algorithm that optimizes power distribution between the LS engine and electric motor, maximizing efficiency across various driving conditions[2]. Additionally, Ford has incorporated its EcoBoost technology principles into the LS engine modifications, including direct injection and turbocharging, to further enhance fuel efficiency and power output[3]. The kit also features an advanced thermal management system to ensure optimal performance of both the engine and electric components.

Strengths: Modular design allows for easier installation and compatibility with various Ford models. Integration of EcoBoost technology enhances overall efficiency. Weaknesses: May require more extensive modifications to non-Ford vehicles. Potential for higher costs due to advanced technology integration.

Core Innovations in Hybrid-LS Integration

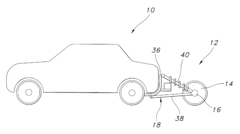

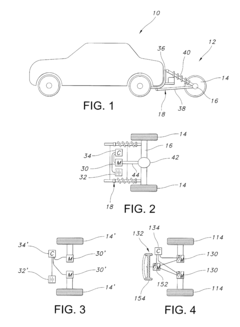

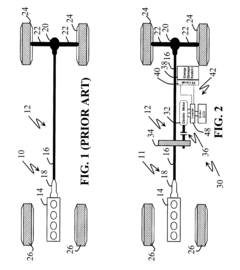

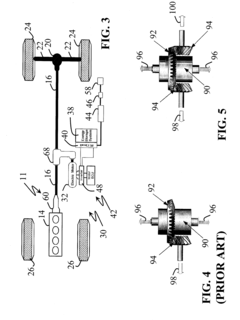

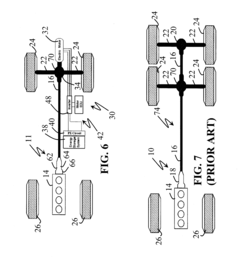

Hybrid Conversion Kits And Methods

PatentInactiveUS20090127008A1

Innovation

- A hybrid conversion kit comprising a frame assembly, an auxiliary wheel, a generator/motor, and an energy storage device, along with a controller, which allows for the attachment to a pre-existing vehicle to capture kinetic energy during deceleration and store it for later use, enhancing fuel efficiency and reducing environmental impact.

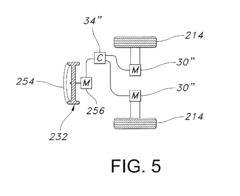

Hybrid electric conversion kit for rear-wheel drive, all wheel drive, and four wheel drive vehicles

PatentInactiveUS20090223725A1

Innovation

- A parallel hybrid electric vehicle conversion kit that includes a motor-generator, torque coupler, battery, power electronics module, and controller, allowing for the retrofitting of conventional vehicles to enhance performance, fuel economy, and reduce emissions by integrating an electric drive system with the existing internal combustion engine.

Environmental Impact Assessment

The environmental impact of home-hybrid conversion kits using LS engines for efficiency is a complex issue that requires careful consideration. These conversion kits, which allow for the retrofitting of existing vehicles with more efficient LS engines, have both positive and negative environmental implications.

On the positive side, these conversion kits can significantly improve the fuel efficiency of older vehicles. LS engines, known for their advanced design and technology, can provide better fuel economy compared to many older engine models. This increased efficiency translates to reduced fuel consumption, which in turn leads to lower greenhouse gas emissions per mile driven. By extending the life of existing vehicles while improving their environmental performance, these kits can potentially reduce the need for new vehicle production, thus conserving resources and energy associated with manufacturing.

However, the environmental benefits are not without caveats. The production and installation of these conversion kits require additional resources and energy, which must be factored into the overall environmental assessment. The manufacturing process of the LS engines and associated components may involve the use of raw materials and energy-intensive processes, potentially offsetting some of the gains in operational efficiency.

Another consideration is the disposal of the original engines and components that are replaced during the conversion process. Proper recycling and disposal methods must be implemented to minimize the environmental impact of discarded parts. Additionally, the long-term durability and reliability of these conversions may affect their overall environmental footprint. If the converted vehicles require more frequent maintenance or have a shorter lifespan than expected, it could negate some of the intended environmental benefits.

The impact on local air quality is another important factor to consider. While LS engines generally produce fewer emissions than older engine models, the specific emission profile may vary depending on the conversion quality and the vehicle's overall condition. In some cases, these conversions might lead to improved local air quality, particularly in urban areas with high concentrations of older, less efficient vehicles.

The broader implications for energy consumption and resource allocation should also be examined. If these conversion kits become widely adopted, it could potentially slow the transition to fully electric vehicles, which may have more significant long-term environmental benefits. However, in regions where the electricity grid is still heavily reliant on fossil fuels, hybrid conversions might offer a more immediate environmental advantage.

In conclusion, while home-hybrid conversion kits using LS engines for efficiency can offer notable environmental benefits, particularly in terms of improved fuel efficiency and reduced emissions, their overall environmental impact is nuanced. A comprehensive life-cycle assessment, considering factors such as production, installation, operation, maintenance, and end-of-life disposal, is necessary to fully understand the environmental implications of this technology.

On the positive side, these conversion kits can significantly improve the fuel efficiency of older vehicles. LS engines, known for their advanced design and technology, can provide better fuel economy compared to many older engine models. This increased efficiency translates to reduced fuel consumption, which in turn leads to lower greenhouse gas emissions per mile driven. By extending the life of existing vehicles while improving their environmental performance, these kits can potentially reduce the need for new vehicle production, thus conserving resources and energy associated with manufacturing.

However, the environmental benefits are not without caveats. The production and installation of these conversion kits require additional resources and energy, which must be factored into the overall environmental assessment. The manufacturing process of the LS engines and associated components may involve the use of raw materials and energy-intensive processes, potentially offsetting some of the gains in operational efficiency.

Another consideration is the disposal of the original engines and components that are replaced during the conversion process. Proper recycling and disposal methods must be implemented to minimize the environmental impact of discarded parts. Additionally, the long-term durability and reliability of these conversions may affect their overall environmental footprint. If the converted vehicles require more frequent maintenance or have a shorter lifespan than expected, it could negate some of the intended environmental benefits.

The impact on local air quality is another important factor to consider. While LS engines generally produce fewer emissions than older engine models, the specific emission profile may vary depending on the conversion quality and the vehicle's overall condition. In some cases, these conversions might lead to improved local air quality, particularly in urban areas with high concentrations of older, less efficient vehicles.

The broader implications for energy consumption and resource allocation should also be examined. If these conversion kits become widely adopted, it could potentially slow the transition to fully electric vehicles, which may have more significant long-term environmental benefits. However, in regions where the electricity grid is still heavily reliant on fossil fuels, hybrid conversions might offer a more immediate environmental advantage.

In conclusion, while home-hybrid conversion kits using LS engines for efficiency can offer notable environmental benefits, particularly in terms of improved fuel efficiency and reduced emissions, their overall environmental impact is nuanced. A comprehensive life-cycle assessment, considering factors such as production, installation, operation, maintenance, and end-of-life disposal, is necessary to fully understand the environmental implications of this technology.

Legal and Safety Considerations

The implementation of home-hybrid conversion kits using LS engines for efficiency raises several important legal and safety considerations that must be carefully addressed. From a legal standpoint, vehicle modifications must comply with local, state, and federal regulations. Many jurisdictions have specific laws governing vehicle alterations, particularly those affecting emissions and safety systems. Installers and vehicle owners need to ensure that the conversion meets all applicable standards, including emissions requirements and safety certifications.

Safety is paramount in any vehicle modification, especially one as significant as a hybrid conversion. The integration of high-voltage electrical systems with traditional combustion engines presents unique safety challenges. Proper insulation and shielding of electrical components are critical to prevent short circuits and potential fire hazards. The battery pack, in particular, requires careful placement and protection to maintain structural integrity in the event of a collision.

Braking systems may need to be upgraded to handle the additional weight and regenerative braking capabilities of the hybrid system. The vehicle's suspension and weight distribution must also be carefully considered to maintain handling characteristics and stability. Installers should be certified and trained in high-voltage safety protocols to minimize the risk of electrical shock during installation and maintenance.

Electromagnetic compatibility (EMC) is another crucial safety aspect. The hybrid system must not interfere with the vehicle's existing electronic systems, including critical safety features like airbags and anti-lock braking systems. Comprehensive testing is necessary to ensure all vehicle systems function correctly after the conversion.

Consumer education is essential for safe operation of converted vehicles. Owners must be thoroughly briefed on the unique characteristics of their hybrid-converted vehicle, including proper charging procedures, maintenance requirements, and emergency protocols. Clear documentation and labeling of high-voltage components are necessary to alert first responders in case of accidents.

Liability considerations are also significant. Installers may need specialized insurance coverage to protect against potential claims arising from conversion-related issues. Vehicle owners should consult with their insurance providers to ensure their policies cover modified vehicles.

Lastly, end-of-life considerations must be addressed. Proper disposal or recycling of hybrid components, particularly batteries, is crucial to comply with environmental regulations and minimize ecological impact. Conversion kit manufacturers and installers should provide guidance on the appropriate handling of these materials when the vehicle is eventually decommissioned.

Safety is paramount in any vehicle modification, especially one as significant as a hybrid conversion. The integration of high-voltage electrical systems with traditional combustion engines presents unique safety challenges. Proper insulation and shielding of electrical components are critical to prevent short circuits and potential fire hazards. The battery pack, in particular, requires careful placement and protection to maintain structural integrity in the event of a collision.

Braking systems may need to be upgraded to handle the additional weight and regenerative braking capabilities of the hybrid system. The vehicle's suspension and weight distribution must also be carefully considered to maintain handling characteristics and stability. Installers should be certified and trained in high-voltage safety protocols to minimize the risk of electrical shock during installation and maintenance.

Electromagnetic compatibility (EMC) is another crucial safety aspect. The hybrid system must not interfere with the vehicle's existing electronic systems, including critical safety features like airbags and anti-lock braking systems. Comprehensive testing is necessary to ensure all vehicle systems function correctly after the conversion.

Consumer education is essential for safe operation of converted vehicles. Owners must be thoroughly briefed on the unique characteristics of their hybrid-converted vehicle, including proper charging procedures, maintenance requirements, and emergency protocols. Clear documentation and labeling of high-voltage components are necessary to alert first responders in case of accidents.

Liability considerations are also significant. Installers may need specialized insurance coverage to protect against potential claims arising from conversion-related issues. Vehicle owners should consult with their insurance providers to ensure their policies cover modified vehicles.

Lastly, end-of-life considerations must be addressed. Proper disposal or recycling of hybrid components, particularly batteries, is crucial to comply with environmental regulations and minimize ecological impact. Conversion kit manufacturers and installers should provide guidance on the appropriate handling of these materials when the vehicle is eventually decommissioned.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!