How IoT Helps in Live LS Engine Data Transmission

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IoT in LS Engine Data: Background and Objectives

The Internet of Things (IoT) has revolutionized the way we collect, transmit, and analyze data across various industries. In the context of LS (Large Scale) engine data transmission, IoT plays a crucial role in enabling real-time monitoring and analysis of engine performance. This technological advancement has its roots in the broader evolution of industrial automation and the increasing demand for more efficient and reliable engine management systems.

The development of IoT in LS engine data transmission can be traced back to the early 2000s when the concept of machine-to-machine (M2M) communication began to gain traction. As sensor technology improved and wireless connectivity became more widespread, the ability to remotely monitor engine performance in real-time became a reality. This shift from periodic manual inspections to continuous automated monitoring marked a significant milestone in engine maintenance and optimization.

The primary objective of implementing IoT in LS engine data transmission is to enhance operational efficiency, reduce downtime, and improve overall engine performance. By collecting and transmitting live data from various engine components, operators and engineers can gain unprecedented insights into engine behavior, allowing for predictive maintenance, performance optimization, and rapid response to potential issues.

Key technological advancements that have contributed to the evolution of IoT in LS engine data transmission include the development of more robust and miniaturized sensors, improvements in wireless communication protocols, and the emergence of edge computing. These innovations have collectively enabled the creation of comprehensive engine monitoring systems that can operate in challenging industrial environments.

The integration of IoT in LS engine data transmission aligns with broader industry trends towards digitalization and the concept of Industry 4.0. This technological convergence aims to create smart factories and intelligent industrial systems where machines, devices, and systems are interconnected, sharing data and making autonomous decisions to optimize performance and efficiency.

As the technology continues to evolve, the objectives for IoT in LS engine data transmission are expanding. Current goals include achieving near-zero latency in data transmission, enhancing data security to protect sensitive engine information, and developing more sophisticated analytics capabilities to extract actionable insights from the vast amounts of data generated by LS engines.

Looking ahead, the future of IoT in LS engine data transmission is likely to focus on further integration with artificial intelligence and machine learning algorithms. These advanced technologies will enable more accurate predictive maintenance schedules, autonomous optimization of engine parameters, and even self-healing capabilities for minor issues. The ultimate aim is to create a fully connected and intelligent engine ecosystem that can adapt and respond to changing operational conditions in real-time, maximizing efficiency and minimizing environmental impact.

The development of IoT in LS engine data transmission can be traced back to the early 2000s when the concept of machine-to-machine (M2M) communication began to gain traction. As sensor technology improved and wireless connectivity became more widespread, the ability to remotely monitor engine performance in real-time became a reality. This shift from periodic manual inspections to continuous automated monitoring marked a significant milestone in engine maintenance and optimization.

The primary objective of implementing IoT in LS engine data transmission is to enhance operational efficiency, reduce downtime, and improve overall engine performance. By collecting and transmitting live data from various engine components, operators and engineers can gain unprecedented insights into engine behavior, allowing for predictive maintenance, performance optimization, and rapid response to potential issues.

Key technological advancements that have contributed to the evolution of IoT in LS engine data transmission include the development of more robust and miniaturized sensors, improvements in wireless communication protocols, and the emergence of edge computing. These innovations have collectively enabled the creation of comprehensive engine monitoring systems that can operate in challenging industrial environments.

The integration of IoT in LS engine data transmission aligns with broader industry trends towards digitalization and the concept of Industry 4.0. This technological convergence aims to create smart factories and intelligent industrial systems where machines, devices, and systems are interconnected, sharing data and making autonomous decisions to optimize performance and efficiency.

As the technology continues to evolve, the objectives for IoT in LS engine data transmission are expanding. Current goals include achieving near-zero latency in data transmission, enhancing data security to protect sensitive engine information, and developing more sophisticated analytics capabilities to extract actionable insights from the vast amounts of data generated by LS engines.

Looking ahead, the future of IoT in LS engine data transmission is likely to focus on further integration with artificial intelligence and machine learning algorithms. These advanced technologies will enable more accurate predictive maintenance schedules, autonomous optimization of engine parameters, and even self-healing capabilities for minor issues. The ultimate aim is to create a fully connected and intelligent engine ecosystem that can adapt and respond to changing operational conditions in real-time, maximizing efficiency and minimizing environmental impact.

Market Demand for Real-time Engine Monitoring

The market demand for real-time engine monitoring has been steadily increasing across various industries, driven by the need for improved operational efficiency, reduced downtime, and enhanced safety measures. In the automotive sector, both commercial fleet operators and individual vehicle owners are showing growing interest in live engine data transmission systems. These systems provide valuable insights into vehicle performance, fuel consumption, and potential maintenance issues, allowing for proactive maintenance and cost savings.

The industrial sector has also witnessed a surge in demand for real-time engine monitoring solutions. Manufacturing plants, power generation facilities, and heavy machinery operators are increasingly adopting IoT-enabled monitoring systems to optimize their operations. These systems help in predicting equipment failures, scheduling maintenance activities, and improving overall equipment effectiveness (OEE).

In the aviation industry, real-time engine monitoring has become a critical component of aircraft maintenance and safety protocols. Airlines and aircraft manufacturers are investing heavily in IoT-based solutions that provide continuous data on engine performance, enabling predictive maintenance and reducing the risk of in-flight incidents.

The marine industry has also recognized the benefits of live engine data transmission. Shipping companies are implementing IoT solutions to monitor their vessel engines, optimize fuel consumption, and comply with increasingly stringent environmental regulations. This trend is expected to continue as the industry focuses on reducing its carbon footprint and improving operational efficiency.

The agriculture sector is another area where the demand for real-time engine monitoring is growing. Modern farming equipment, such as tractors and harvesters, are being equipped with IoT sensors to provide farmers with real-time data on engine performance, fuel efficiency, and maintenance requirements. This information helps in optimizing farm operations and reducing equipment downtime.

Market research indicates that the global IoT in manufacturing market, which includes real-time engine monitoring solutions, is projected to grow significantly in the coming years. Factors contributing to this growth include the increasing adoption of Industry 4.0 technologies, the need for predictive maintenance, and the push for greater operational efficiency across industries.

As the demand for real-time engine monitoring continues to rise, there is a parallel increase in the need for robust data analytics and artificial intelligence capabilities. These technologies are essential for processing and interpreting the vast amounts of data generated by IoT sensors, enabling more accurate predictions and actionable insights for businesses.

The industrial sector has also witnessed a surge in demand for real-time engine monitoring solutions. Manufacturing plants, power generation facilities, and heavy machinery operators are increasingly adopting IoT-enabled monitoring systems to optimize their operations. These systems help in predicting equipment failures, scheduling maintenance activities, and improving overall equipment effectiveness (OEE).

In the aviation industry, real-time engine monitoring has become a critical component of aircraft maintenance and safety protocols. Airlines and aircraft manufacturers are investing heavily in IoT-based solutions that provide continuous data on engine performance, enabling predictive maintenance and reducing the risk of in-flight incidents.

The marine industry has also recognized the benefits of live engine data transmission. Shipping companies are implementing IoT solutions to monitor their vessel engines, optimize fuel consumption, and comply with increasingly stringent environmental regulations. This trend is expected to continue as the industry focuses on reducing its carbon footprint and improving operational efficiency.

The agriculture sector is another area where the demand for real-time engine monitoring is growing. Modern farming equipment, such as tractors and harvesters, are being equipped with IoT sensors to provide farmers with real-time data on engine performance, fuel efficiency, and maintenance requirements. This information helps in optimizing farm operations and reducing equipment downtime.

Market research indicates that the global IoT in manufacturing market, which includes real-time engine monitoring solutions, is projected to grow significantly in the coming years. Factors contributing to this growth include the increasing adoption of Industry 4.0 technologies, the need for predictive maintenance, and the push for greater operational efficiency across industries.

As the demand for real-time engine monitoring continues to rise, there is a parallel increase in the need for robust data analytics and artificial intelligence capabilities. These technologies are essential for processing and interpreting the vast amounts of data generated by IoT sensors, enabling more accurate predictions and actionable insights for businesses.

Current IoT Challenges in Engine Data Transmission

The Internet of Things (IoT) has revolutionized the way we collect and transmit data from various sources, including live engine data. However, several challenges persist in the realm of engine data transmission using IoT technologies. These challenges primarily stem from the complex nature of engine systems, the high-speed and high-volume data generation, and the critical importance of real-time analysis for performance optimization and safety.

One of the primary challenges is the sheer volume and velocity of data generated by modern engines. High-performance engines, such as those used in aerospace or racing applications, can produce gigabytes of data per second. This massive data flow puts significant strain on IoT networks and storage systems, often leading to bottlenecks in data transmission and processing.

Data reliability and integrity pose another significant challenge. Engine data is critical for performance analysis, predictive maintenance, and safety monitoring. Any loss or corruption of data during transmission can lead to incorrect insights or missed warning signs. Ensuring end-to-end data integrity in IoT systems, especially in environments with electromagnetic interference or poor connectivity, remains a persistent challenge.

Latency is a crucial factor in live engine data transmission. For real-time monitoring and control applications, even milliseconds of delay can be critical. Reducing latency while maintaining data accuracy and completeness is a complex balancing act that IoT systems must constantly navigate.

Security and privacy concerns also present significant challenges. Engine data often contains proprietary information about performance and design. Protecting this data from unauthorized access or tampering throughout the IoT ecosystem – from sensors to cloud storage – requires robust security measures that can sometimes conflict with the need for rapid data transmission and processing.

Interoperability between different IoT devices, protocols, and platforms is another hurdle. Engine systems often involve components from multiple manufacturers, each with their own data formats and communication protocols. Creating a seamless, integrated IoT ecosystem that can efficiently handle diverse data streams remains a significant challenge.

Power consumption is a critical consideration, especially for mobile or remote applications. IoT sensors and transmission devices need to operate efficiently to avoid draining the engine's power or requiring frequent maintenance. Balancing power efficiency with high-performance data collection and transmission is an ongoing challenge for IoT implementations in engine monitoring.

Finally, the harsh operating environments of many engines present physical challenges to IoT systems. Extreme temperatures, vibrations, and exposure to various elements can affect the reliability and longevity of IoT sensors and transmission equipment. Developing robust hardware that can withstand these conditions while maintaining accurate data collection and transmission is a significant engineering challenge.

One of the primary challenges is the sheer volume and velocity of data generated by modern engines. High-performance engines, such as those used in aerospace or racing applications, can produce gigabytes of data per second. This massive data flow puts significant strain on IoT networks and storage systems, often leading to bottlenecks in data transmission and processing.

Data reliability and integrity pose another significant challenge. Engine data is critical for performance analysis, predictive maintenance, and safety monitoring. Any loss or corruption of data during transmission can lead to incorrect insights or missed warning signs. Ensuring end-to-end data integrity in IoT systems, especially in environments with electromagnetic interference or poor connectivity, remains a persistent challenge.

Latency is a crucial factor in live engine data transmission. For real-time monitoring and control applications, even milliseconds of delay can be critical. Reducing latency while maintaining data accuracy and completeness is a complex balancing act that IoT systems must constantly navigate.

Security and privacy concerns also present significant challenges. Engine data often contains proprietary information about performance and design. Protecting this data from unauthorized access or tampering throughout the IoT ecosystem – from sensors to cloud storage – requires robust security measures that can sometimes conflict with the need for rapid data transmission and processing.

Interoperability between different IoT devices, protocols, and platforms is another hurdle. Engine systems often involve components from multiple manufacturers, each with their own data formats and communication protocols. Creating a seamless, integrated IoT ecosystem that can efficiently handle diverse data streams remains a significant challenge.

Power consumption is a critical consideration, especially for mobile or remote applications. IoT sensors and transmission devices need to operate efficiently to avoid draining the engine's power or requiring frequent maintenance. Balancing power efficiency with high-performance data collection and transmission is an ongoing challenge for IoT implementations in engine monitoring.

Finally, the harsh operating environments of many engines present physical challenges to IoT systems. Extreme temperatures, vibrations, and exposure to various elements can affect the reliability and longevity of IoT sensors and transmission equipment. Developing robust hardware that can withstand these conditions while maintaining accurate data collection and transmission is a significant engineering challenge.

Existing IoT Solutions for LS Engine Data Transmission

01 Secure data transmission protocols

IoT devices utilize secure protocols for data transmission, ensuring confidentiality and integrity of information. These protocols may include encryption methods, authentication mechanisms, and secure key exchange algorithms to protect data during transmission between devices and cloud platforms.- Secure data transmission protocols: IoT devices utilize secure protocols for data transmission, ensuring the confidentiality and integrity of information. These protocols may include encryption methods, authentication mechanisms, and secure key exchange algorithms to protect data during transmission between devices and cloud platforms.

- Edge computing for IoT data processing: Edge computing techniques are employed to process IoT data closer to the source, reducing latency and bandwidth usage. This approach involves distributing computation and storage resources across the network, enabling real-time analysis and decision-making at the edge of the IoT infrastructure.

- Low-power communication protocols: IoT devices often utilize low-power communication protocols to extend battery life and optimize energy consumption. These protocols are designed to transmit data efficiently over short distances while minimizing power usage, making them suitable for resource-constrained IoT devices.

- Data compression and optimization techniques: Various data compression and optimization techniques are implemented to reduce the volume of data transmitted by IoT devices. These methods help conserve bandwidth, improve transmission speed, and enhance overall network efficiency in IoT ecosystems.

- Mesh networking for IoT connectivity: Mesh networking architectures are employed to enhance IoT device connectivity and data transmission. This approach allows devices to form self-organizing networks, improving coverage, reliability, and scalability of IoT deployments, particularly in challenging environments or large-scale installations.

02 Edge computing for IoT data processing

Edge computing techniques are employed to process IoT data closer to the source, reducing latency and bandwidth usage. This approach involves distributed data processing, local storage, and intelligent decision-making at the edge of the network, improving overall system efficiency and response times.Expand Specific Solutions03 Low-power communication protocols

IoT devices utilize low-power communication protocols to extend battery life and optimize energy consumption during data transmission. These protocols are designed to minimize power usage while maintaining reliable connectivity, enabling long-term deployment of IoT sensors and devices in various environments.Expand Specific Solutions04 Data compression and optimization techniques

IoT systems employ data compression and optimization techniques to reduce the volume of transmitted data. These methods include efficient encoding algorithms, data aggregation, and selective transmission of relevant information, minimizing bandwidth requirements and improving overall system performance.Expand Specific Solutions05 Adaptive transmission protocols

IoT devices implement adaptive transmission protocols that dynamically adjust data transmission parameters based on network conditions and device status. These protocols optimize transmission rates, power consumption, and reliability by adapting to changing environmental factors and network congestion.Expand Specific Solutions

Key Players in IoT-Enabled Engine Monitoring

The IoT live LS engine data transmission market is in a growth phase, driven by increasing demand for real-time monitoring and optimization of engine performance. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing quickly, with major players like Huawei, Samsung, and LG Electronics leading innovation. These companies are developing sophisticated IoT platforms and sensors for enhanced data collection and transmission. Emerging players such as Soracom and E-Surfing IoT Tech are also contributing to technological advancements, particularly in cloud-based IoT solutions and network connectivity. The competitive landscape is dynamic, with both established tech giants and specialized IoT firms vying for market share.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a comprehensive IoT solution for live LS engine data transmission. Their approach utilizes NB-IoT (Narrowband Internet of Things) technology, which provides wide coverage, low power consumption, and massive connectivity[1]. The solution incorporates edge computing capabilities, allowing for real-time data processing and analysis at the source. Huawei's OceanConnect IoT platform serves as the central hub for data aggregation and management, enabling seamless integration with various LS engine systems[2]. The platform supports multi-protocol access and provides robust security features, including end-to-end encryption and device authentication[3]. Additionally, Huawei has implemented AI algorithms for predictive maintenance, optimizing engine performance and reducing downtime[4].

Strengths: Wide coverage and low power consumption of NB-IoT, robust security features, and AI-driven predictive maintenance. Weaknesses: Potential vendor lock-in and reliance on Huawei's ecosystem.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung's approach to IoT-enabled live LS engine data transmission leverages their ARTIK IoT platform. The solution incorporates advanced sensors and connectivity modules designed specifically for industrial applications[1]. Samsung's SmartThings cloud platform serves as the backbone for data collection, processing, and analysis. The system utilizes edge computing capabilities to reduce latency and enable real-time decision-making[2]. Samsung has also integrated blockchain technology to enhance data security and ensure the integrity of transmitted engine data[3]. Their solution supports multiple communication protocols, including LTE-M and NB-IoT, providing flexibility in deployment across various environments[4]. Additionally, Samsung has developed machine learning algorithms that analyze engine data to predict maintenance needs and optimize performance[5].

Strengths: Robust ecosystem integration, advanced security features with blockchain, and flexible connectivity options. Weaknesses: Potential complexity in implementation and integration with existing systems.

Core IoT Technologies for Live Engine Data

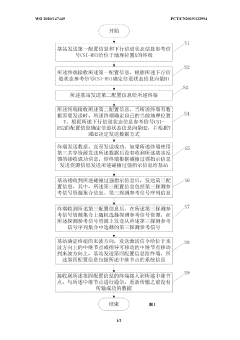

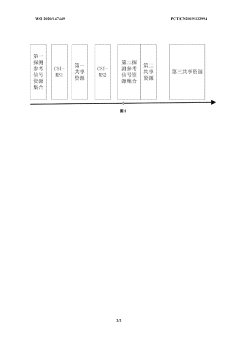

Heterogeneous network-based multi-level data transmission method in narrow-band internet of things

PatentWO2020147449A1

Innovation

- 采用基于异构网络的多级数据传输方法,通过基站发送配置信息和信道状态参考信号,终端根据信道状态信息决定数据发送方式,并利用多共享资源和中继节点提高数据传输的可靠性和效率。

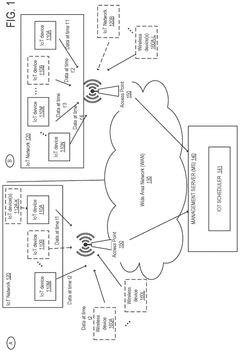

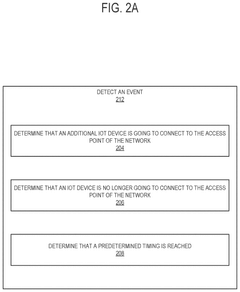

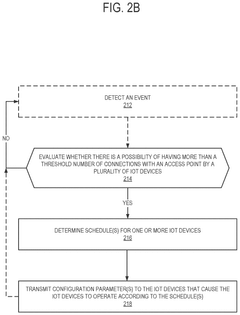

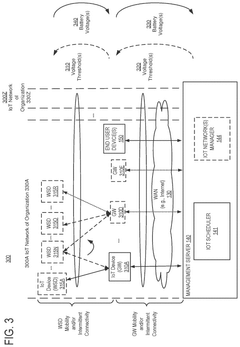

Dynamic scheduling of data transmission from internet of things (IOT) devices based on density of IOT devices

PatentActiveUS12177101B2

Innovation

- A dynamic scheduling system managed by a server that evaluates the number of IoT devices connected to an access point and adjusts their transmission schedules to prevent exceeding a threshold, thereby reducing the likelihood of network overload by staggering data transmission times.

Cybersecurity in IoT Engine Data Transmission

As the Internet of Things (IoT) continues to revolutionize various industries, its application in live LS engine data transmission has raised significant cybersecurity concerns. The interconnected nature of IoT devices and the sensitive nature of engine data make this ecosystem particularly vulnerable to cyber threats. To address these challenges, a multi-layered approach to cybersecurity is essential.

At the device level, robust authentication mechanisms must be implemented to ensure that only authorized devices can access and transmit engine data. This includes the use of unique device identifiers, digital certificates, and secure boot processes to prevent unauthorized access or tampering. Additionally, encryption of data at rest and in transit is crucial to protect against interception and manipulation of sensitive engine information.

Network security plays a vital role in safeguarding IoT engine data transmission. Implementing secure communication protocols, such as TLS/SSL, helps establish encrypted channels between devices and data centers. Network segmentation and firewalls can isolate IoT devices from other parts of the network, reducing the attack surface and limiting the potential impact of a breach.

Cloud security measures are equally important, as much of the data processing and analysis occurs in cloud environments. Robust access controls, regular security audits, and compliance with industry standards like ISO 27001 or NIST Cybersecurity Framework are essential for maintaining the integrity and confidentiality of engine data in the cloud.

Continuous monitoring and threat detection systems are crucial for identifying and responding to potential security incidents in real-time. Advanced analytics and machine learning algorithms can be employed to detect anomalies in data patterns, potentially indicating a security breach or malfunction in the engine data transmission process.

Regular software updates and patch management are critical to address known vulnerabilities and protect against emerging threats. Over-the-air (OTA) update capabilities should be built into IoT devices to ensure that security patches can be deployed quickly and efficiently across the entire fleet of connected engines.

Human factors also play a significant role in cybersecurity. Training and awareness programs for personnel involved in the operation and maintenance of IoT-enabled engines are essential to prevent social engineering attacks and ensure adherence to security protocols.

As the threat landscape evolves, it is crucial to adopt a proactive approach to cybersecurity in IoT engine data transmission. This includes regular security assessments, penetration testing, and staying informed about the latest threats and best practices in IoT security. By implementing a comprehensive cybersecurity strategy, organizations can harness the benefits of IoT in live LS engine data transmission while mitigating the associated risks.

At the device level, robust authentication mechanisms must be implemented to ensure that only authorized devices can access and transmit engine data. This includes the use of unique device identifiers, digital certificates, and secure boot processes to prevent unauthorized access or tampering. Additionally, encryption of data at rest and in transit is crucial to protect against interception and manipulation of sensitive engine information.

Network security plays a vital role in safeguarding IoT engine data transmission. Implementing secure communication protocols, such as TLS/SSL, helps establish encrypted channels between devices and data centers. Network segmentation and firewalls can isolate IoT devices from other parts of the network, reducing the attack surface and limiting the potential impact of a breach.

Cloud security measures are equally important, as much of the data processing and analysis occurs in cloud environments. Robust access controls, regular security audits, and compliance with industry standards like ISO 27001 or NIST Cybersecurity Framework are essential for maintaining the integrity and confidentiality of engine data in the cloud.

Continuous monitoring and threat detection systems are crucial for identifying and responding to potential security incidents in real-time. Advanced analytics and machine learning algorithms can be employed to detect anomalies in data patterns, potentially indicating a security breach or malfunction in the engine data transmission process.

Regular software updates and patch management are critical to address known vulnerabilities and protect against emerging threats. Over-the-air (OTA) update capabilities should be built into IoT devices to ensure that security patches can be deployed quickly and efficiently across the entire fleet of connected engines.

Human factors also play a significant role in cybersecurity. Training and awareness programs for personnel involved in the operation and maintenance of IoT-enabled engines are essential to prevent social engineering attacks and ensure adherence to security protocols.

As the threat landscape evolves, it is crucial to adopt a proactive approach to cybersecurity in IoT engine data transmission. This includes regular security assessments, penetration testing, and staying informed about the latest threats and best practices in IoT security. By implementing a comprehensive cybersecurity strategy, organizations can harness the benefits of IoT in live LS engine data transmission while mitigating the associated risks.

Environmental Impact of IoT in Engine Monitoring

The integration of IoT in live LS engine data transmission has significant environmental implications, both positive and negative. One of the primary benefits is the potential for improved fuel efficiency and reduced emissions. By continuously monitoring engine performance in real-time, IoT systems can detect inefficiencies and anomalies promptly, allowing for immediate adjustments and optimizations. This proactive approach can lead to substantial reductions in fuel consumption and, consequently, lower greenhouse gas emissions.

Furthermore, IoT-enabled engine monitoring systems contribute to extended engine life and reduced maintenance needs. By providing early warnings of potential issues, these systems help prevent catastrophic failures and minimize the need for premature engine replacements. This not only conserves resources but also reduces the environmental impact associated with manufacturing and disposing of engine components.

However, the widespread adoption of IoT in engine monitoring also raises concerns about electronic waste. As older engines are retrofitted with IoT devices and sensors, and newer engines come equipped with increasingly sophisticated monitoring systems, there is a potential increase in electronic waste generation. This issue is particularly pertinent given the rapid pace of technological advancement, which may lead to frequent upgrades and replacements of IoT components.

Energy consumption is another environmental consideration. While IoT systems can lead to overall energy savings through improved engine efficiency, the devices themselves require power to operate. In some cases, this additional energy consumption may offset a portion of the environmental benefits gained from improved engine performance.

Data centers and network infrastructure supporting IoT systems also have an environmental footprint. The massive amount of data generated by IoT-enabled engine monitoring requires significant computational resources for processing and storage. As the adoption of these systems grows, so does the demand for data center capacity, potentially leading to increased energy consumption and associated emissions.

On a broader scale, the environmental impact of IoT in engine monitoring extends to urban planning and transportation systems. By providing detailed insights into engine performance and usage patterns, IoT can inform more efficient traffic management strategies and contribute to the development of smarter, more sustainable cities. This could lead to reduced congestion, improved air quality, and more effective use of transportation resources.

In conclusion, while IoT in engine monitoring offers substantial environmental benefits through improved efficiency and reduced emissions, it also presents challenges related to electronic waste and energy consumption. Balancing these factors and implementing sustainable practices in the development and deployment of IoT systems will be crucial in maximizing the positive environmental impact of this technology in the context of LS engine data transmission.

Furthermore, IoT-enabled engine monitoring systems contribute to extended engine life and reduced maintenance needs. By providing early warnings of potential issues, these systems help prevent catastrophic failures and minimize the need for premature engine replacements. This not only conserves resources but also reduces the environmental impact associated with manufacturing and disposing of engine components.

However, the widespread adoption of IoT in engine monitoring also raises concerns about electronic waste. As older engines are retrofitted with IoT devices and sensors, and newer engines come equipped with increasingly sophisticated monitoring systems, there is a potential increase in electronic waste generation. This issue is particularly pertinent given the rapid pace of technological advancement, which may lead to frequent upgrades and replacements of IoT components.

Energy consumption is another environmental consideration. While IoT systems can lead to overall energy savings through improved engine efficiency, the devices themselves require power to operate. In some cases, this additional energy consumption may offset a portion of the environmental benefits gained from improved engine performance.

Data centers and network infrastructure supporting IoT systems also have an environmental footprint. The massive amount of data generated by IoT-enabled engine monitoring requires significant computational resources for processing and storage. As the adoption of these systems grows, so does the demand for data center capacity, potentially leading to increased energy consumption and associated emissions.

On a broader scale, the environmental impact of IoT in engine monitoring extends to urban planning and transportation systems. By providing detailed insights into engine performance and usage patterns, IoT can inform more efficient traffic management strategies and contribute to the development of smarter, more sustainable cities. This could lead to reduced congestion, improved air quality, and more effective use of transportation resources.

In conclusion, while IoT in engine monitoring offers substantial environmental benefits through improved efficiency and reduced emissions, it also presents challenges related to electronic waste and energy consumption. Balancing these factors and implementing sustainable practices in the development and deployment of IoT systems will be crucial in maximizing the positive environmental impact of this technology in the context of LS engine data transmission.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!