How LM7 engine ignition systems have evolved over time

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Background

The LM7 engine, also known as the Vortec 5300, is a V8 engine produced by General Motors (GM) as part of its Gen III small-block engine family. Introduced in 1999, the LM7 was designed to replace the older 5.7L Vortec 5700 engine and became a popular choice for GM's full-size trucks and SUVs. This engine featured a displacement of 5.3 liters (325 cubic inches) and was known for its balance of power, efficiency, and reliability.

The LM7 engine was built on GM's LS engine architecture, which represented a significant leap forward in engine design compared to its predecessors. It incorporated advanced features such as aluminum cylinder heads, a deep-skirt cylinder block design, and a coil-near-plug ignition system. These innovations contributed to improved performance, reduced weight, and enhanced durability.

One of the key aspects of the LM7 engine was its ignition system, which played a crucial role in its overall performance and efficiency. The evolution of the LM7 ignition system reflects broader trends in automotive technology during the late 1990s and early 2000s. Initially, the LM7 utilized a distributor-less ignition system with individual coils for each cylinder, a significant advancement over traditional distributor-based systems.

Throughout its production run, the LM7 engine saw several updates and refinements, particularly in its ignition system. These improvements were aimed at enhancing reliability, increasing fuel efficiency, and reducing emissions. The evolution of the ignition system was closely tied to advancements in engine control modules (ECMs) and sensor technology, allowing for more precise control over ignition timing and fuel delivery.

The LM7 engine's background is also notable for its widespread adoption across GM's vehicle lineup. It was used in a variety of popular models, including the Chevrolet Silverado, GMC Sierra, Chevrolet Tahoe, and GMC Yukon. This widespread use contributed to the engine's reputation and allowed for continuous refinement based on real-world performance data and customer feedback.

Understanding the background of the LM7 engine provides essential context for examining how its ignition system evolved over time. The engine's design philosophy, which emphasized a balance of power, efficiency, and reliability, directly influenced the development of its ignition system. This background sets the stage for exploring the specific technological advancements and engineering solutions that shaped the LM7's ignition system throughout its production lifecycle.

The LM7 engine was built on GM's LS engine architecture, which represented a significant leap forward in engine design compared to its predecessors. It incorporated advanced features such as aluminum cylinder heads, a deep-skirt cylinder block design, and a coil-near-plug ignition system. These innovations contributed to improved performance, reduced weight, and enhanced durability.

One of the key aspects of the LM7 engine was its ignition system, which played a crucial role in its overall performance and efficiency. The evolution of the LM7 ignition system reflects broader trends in automotive technology during the late 1990s and early 2000s. Initially, the LM7 utilized a distributor-less ignition system with individual coils for each cylinder, a significant advancement over traditional distributor-based systems.

Throughout its production run, the LM7 engine saw several updates and refinements, particularly in its ignition system. These improvements were aimed at enhancing reliability, increasing fuel efficiency, and reducing emissions. The evolution of the ignition system was closely tied to advancements in engine control modules (ECMs) and sensor technology, allowing for more precise control over ignition timing and fuel delivery.

The LM7 engine's background is also notable for its widespread adoption across GM's vehicle lineup. It was used in a variety of popular models, including the Chevrolet Silverado, GMC Sierra, Chevrolet Tahoe, and GMC Yukon. This widespread use contributed to the engine's reputation and allowed for continuous refinement based on real-world performance data and customer feedback.

Understanding the background of the LM7 engine provides essential context for examining how its ignition system evolved over time. The engine's design philosophy, which emphasized a balance of power, efficiency, and reliability, directly influenced the development of its ignition system. This background sets the stage for exploring the specific technological advancements and engineering solutions that shaped the LM7's ignition system throughout its production lifecycle.

Market Demand Analysis

The market demand for LM7 engine ignition systems has experienced significant growth and evolution over the years, driven by the automotive industry's pursuit of improved performance, fuel efficiency, and emissions reduction. As vehicle manufacturers strive to meet increasingly stringent environmental regulations and consumer expectations, the demand for advanced ignition systems has surged.

Initially, the market for LM7 engine ignition systems was primarily focused on traditional distributor-based systems. However, as technology progressed, there was a shift towards more sophisticated electronic ignition systems. This transition was fueled by the need for better engine control, increased reliability, and improved fuel economy.

The advent of computerized engine management systems further accelerated the demand for advanced ignition technologies. Manufacturers and consumers alike sought systems that could provide precise timing control, adapt to varying driving conditions, and optimize engine performance across a wide range of operating parameters.

In recent years, the market has seen a growing interest in coil-on-plug ignition systems for LM7 engines. These systems offer several advantages, including improved spark energy delivery, reduced electromagnetic interference, and enhanced durability. The elimination of high-tension spark plug wires also contributes to a cleaner engine bay and easier maintenance.

The aftermarket sector has also played a crucial role in shaping the demand for LM7 ignition systems. Performance enthusiasts and tuners have driven the development of high-output ignition components, seeking systems that can support increased horsepower and higher engine speeds.

Environmental concerns and fuel efficiency requirements have further influenced market demand. Ignition systems that enable more complete combustion and reduce emissions have become increasingly sought after, aligning with global efforts to minimize the environmental impact of internal combustion engines.

The integration of ignition systems with other engine management components has become a key market trend. Manufacturers are developing comprehensive solutions that seamlessly combine ignition control with fuel injection, variable valve timing, and other advanced engine technologies.

As the automotive industry gradually shifts towards electrification, there is a growing demand for ignition systems that can support hybrid powertrains. These systems must be capable of seamlessly transitioning between combustion and electric modes while maintaining optimal performance and efficiency.

In conclusion, the market demand for LM7 engine ignition systems has been characterized by a continuous push for technological advancement, driven by the need for improved performance, efficiency, and environmental compatibility. This evolution reflects the broader trends in the automotive industry and highlights the critical role that ignition systems play in modern engine design and operation.

Initially, the market for LM7 engine ignition systems was primarily focused on traditional distributor-based systems. However, as technology progressed, there was a shift towards more sophisticated electronic ignition systems. This transition was fueled by the need for better engine control, increased reliability, and improved fuel economy.

The advent of computerized engine management systems further accelerated the demand for advanced ignition technologies. Manufacturers and consumers alike sought systems that could provide precise timing control, adapt to varying driving conditions, and optimize engine performance across a wide range of operating parameters.

In recent years, the market has seen a growing interest in coil-on-plug ignition systems for LM7 engines. These systems offer several advantages, including improved spark energy delivery, reduced electromagnetic interference, and enhanced durability. The elimination of high-tension spark plug wires also contributes to a cleaner engine bay and easier maintenance.

The aftermarket sector has also played a crucial role in shaping the demand for LM7 ignition systems. Performance enthusiasts and tuners have driven the development of high-output ignition components, seeking systems that can support increased horsepower and higher engine speeds.

Environmental concerns and fuel efficiency requirements have further influenced market demand. Ignition systems that enable more complete combustion and reduce emissions have become increasingly sought after, aligning with global efforts to minimize the environmental impact of internal combustion engines.

The integration of ignition systems with other engine management components has become a key market trend. Manufacturers are developing comprehensive solutions that seamlessly combine ignition control with fuel injection, variable valve timing, and other advanced engine technologies.

As the automotive industry gradually shifts towards electrification, there is a growing demand for ignition systems that can support hybrid powertrains. These systems must be capable of seamlessly transitioning between combustion and electric modes while maintaining optimal performance and efficiency.

In conclusion, the market demand for LM7 engine ignition systems has been characterized by a continuous push for technological advancement, driven by the need for improved performance, efficiency, and environmental compatibility. This evolution reflects the broader trends in the automotive industry and highlights the critical role that ignition systems play in modern engine design and operation.

Ignition Tech Challenges

The evolution of LM7 engine ignition systems has faced several significant challenges over time. One of the primary obstacles has been the need for improved fuel efficiency and reduced emissions. As environmental regulations became more stringent, engineers had to develop ignition systems that could provide more precise control over the combustion process.

Another major challenge has been the demand for increased power output and performance. This required ignition systems to deliver higher energy sparks and more accurate timing across a wider range of engine operating conditions. The transition from traditional distributor-based systems to more advanced electronic ignition systems was driven by these requirements.

Durability and reliability have also been ongoing concerns. Early ignition systems were prone to wear and degradation, particularly in the harsh environment of an engine compartment. Engineers had to develop more robust components and designs to ensure consistent performance over the life of the engine.

The integration of ignition systems with other engine management components presented another significant challenge. As engine control became more sophisticated, ignition systems needed to communicate and work seamlessly with fuel injection, emissions control, and other systems. This required the development of more complex electronic control units and sensors.

Heat management has been a persistent issue in ignition system design. The high temperatures generated by the engine can affect the performance and longevity of ignition components. Engineers have had to develop innovative cooling solutions and heat-resistant materials to address this challenge.

The push for greater fuel efficiency led to the development of technologies like variable valve timing and direct injection, which in turn created new challenges for ignition systems. These advancements required ignition systems to adapt to changing combustion chamber conditions and provide more flexible spark timing.

Electromagnetic interference (EMI) has been another hurdle in ignition system evolution. As vehicles incorporated more electronic systems, the potential for interference with the ignition system increased. This necessitated improved shielding and signal processing techniques to ensure reliable operation.

Cost considerations have also played a significant role in shaping ignition system development. While more advanced technologies offered improved performance, they often came with higher production costs. Engineers have had to balance the implementation of new features with the need to maintain affordability for mass-market vehicles.

The transition to alternative fuels and hybrid powertrains has presented new challenges for ignition system design. These systems often require different ignition characteristics and must be able to operate efficiently under varying conditions, such as during engine start-stop cycles in hybrid vehicles.

Another major challenge has been the demand for increased power output and performance. This required ignition systems to deliver higher energy sparks and more accurate timing across a wider range of engine operating conditions. The transition from traditional distributor-based systems to more advanced electronic ignition systems was driven by these requirements.

Durability and reliability have also been ongoing concerns. Early ignition systems were prone to wear and degradation, particularly in the harsh environment of an engine compartment. Engineers had to develop more robust components and designs to ensure consistent performance over the life of the engine.

The integration of ignition systems with other engine management components presented another significant challenge. As engine control became more sophisticated, ignition systems needed to communicate and work seamlessly with fuel injection, emissions control, and other systems. This required the development of more complex electronic control units and sensors.

Heat management has been a persistent issue in ignition system design. The high temperatures generated by the engine can affect the performance and longevity of ignition components. Engineers have had to develop innovative cooling solutions and heat-resistant materials to address this challenge.

The push for greater fuel efficiency led to the development of technologies like variable valve timing and direct injection, which in turn created new challenges for ignition systems. These advancements required ignition systems to adapt to changing combustion chamber conditions and provide more flexible spark timing.

Electromagnetic interference (EMI) has been another hurdle in ignition system evolution. As vehicles incorporated more electronic systems, the potential for interference with the ignition system increased. This necessitated improved shielding and signal processing techniques to ensure reliable operation.

Cost considerations have also played a significant role in shaping ignition system development. While more advanced technologies offered improved performance, they often came with higher production costs. Engineers have had to balance the implementation of new features with the need to maintain affordability for mass-market vehicles.

The transition to alternative fuels and hybrid powertrains has presented new challenges for ignition system design. These systems often require different ignition characteristics and must be able to operate efficiently under varying conditions, such as during engine start-stop cycles in hybrid vehicles.

Current Ignition Solutions

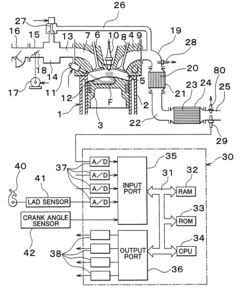

01 Electronic ignition control systems

Modern LM7 engines often utilize electronic ignition control systems. These systems use sensors and computerized modules to precisely control ignition timing and spark delivery, improving engine performance and efficiency. They can adjust timing based on various engine parameters and operating conditions.- Electronic ignition control systems: Advanced electronic control systems are used in LM7 engines to manage ignition timing and spark distribution. These systems utilize sensors and microprocessors to optimize engine performance, fuel efficiency, and emissions control across various operating conditions.

- Distributor-less ignition systems: LM7 engines often employ distributor-less ignition systems, which use individual coils for each cylinder or pair of cylinders. This design improves reliability, reduces maintenance, and allows for more precise ignition timing control compared to traditional distributor-based systems.

- Spark plug technology: Specialized spark plugs are utilized in LM7 engines to ensure efficient combustion and optimal performance. These plugs are designed to withstand high temperatures and pressures while providing consistent spark delivery throughout the engine's operating range.

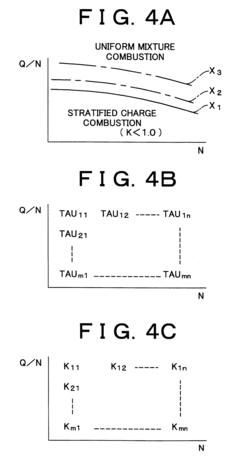

- Ignition timing control strategies: LM7 engines implement sophisticated ignition timing control strategies to optimize performance and efficiency. These strategies may include variable timing based on engine load, speed, and environmental factors, as well as knock detection and prevention mechanisms.

- Integration with engine management systems: The ignition system in LM7 engines is closely integrated with the overall engine management system. This integration allows for coordinated control of fuel injection, valve timing, and other engine parameters to achieve optimal performance, fuel economy, and emissions control.

02 Distributor-based ignition systems

Some LM7 engines may use distributor-based ignition systems. These systems employ a central distributor that routes high-voltage electricity to each spark plug in the correct firing order. While less common in modern engines, distributor systems can still be found in some older or modified LM7 setups.Expand Specific Solutions03 Coil-on-plug ignition systems

Coil-on-plug ignition systems are frequently used in LM7 engines. This design places an individual ignition coil directly on top of each spark plug, eliminating the need for long spark plug wires. This arrangement can provide more consistent spark energy and reduce electromagnetic interference.Expand Specific Solutions04 Ignition timing control and optimization

LM7 engine ignition systems often incorporate advanced timing control and optimization features. These can include variable timing mechanisms, knock sensors, and adaptive learning algorithms to fine-tune ignition timing for optimal performance, fuel efficiency, and emissions control across various operating conditions.Expand Specific Solutions05 Integration with engine management systems

The ignition system in LM7 engines is typically integrated with the overall engine management system. This integration allows for coordinated control of ignition timing, fuel injection, and other engine parameters. It enables features like cylinder deactivation, improved cold-start performance, and better emissions control.Expand Specific Solutions

Key Industry Players

The LM7 engine ignition system market has evolved significantly over time, reflecting the broader automotive industry's transition from mature to advanced technologies. The market has grown substantially, driven by increasing vehicle production and demand for more efficient, reliable ignition systems. Technologically, the industry has progressed from traditional distributor-based systems to more sophisticated electronic ignition systems. Key players like Toyota, Honda, Bosch, and Denso have been at the forefront of this evolution, investing heavily in R&D to develop advanced ignition technologies. These companies have moved towards integrated engine management systems, incorporating ignition control with fuel injection and other powertrain functions, significantly improving engine performance and emissions.

Toyota Motor Corp.

Technical Solution: Toyota has made significant advancements in LM7 engine ignition system technology. They have developed a Direct Ignition System (DIS) that eliminates the distributor, providing individual ignition coils for each cylinder[16]. Toyota's systems now incorporate intelligent spark timing control, adjusting ignition based on engine load, speed, and environmental conditions[17]. They have also introduced long-reach spark plugs with iridium tips, improving ignitability and reducing electrode wear[18]. Toyota's latest innovation includes integrating the ignition system with their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology, allowing for precise control of both port and direct fuel injection in conjunction with optimized ignition timing[19].

Strengths: Improved fuel efficiency, reduced emissions, and enhanced durability. Weaknesses: Increased system complexity and potentially higher replacement costs for specialized components.

Robert Bosch GmbH

Technical Solution: Bosch has been at the forefront of LM7 engine ignition system evolution. They have developed advanced electronic control units (ECUs) that precisely manage ignition timing and fuel injection. Their latest systems incorporate direct injection technology, allowing for multiple injection events per cycle[1]. Bosch has also introduced smart ignition coils with integrated electronics, improving energy transfer efficiency and reducing electromagnetic interference[2]. Their systems now feature advanced knock control algorithms and cylinder pressure-based combustion control, optimizing performance and emissions across various operating conditions[3].

Strengths: Cutting-edge technology, high precision control, and improved fuel efficiency. Weaknesses: Higher cost compared to traditional systems and increased complexity in diagnostics and repairs.

Core Ignition Innovations

Emission control apparatus of internal combustion engine

PatentInactiveUS6698188B2

Innovation

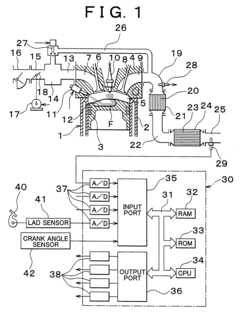

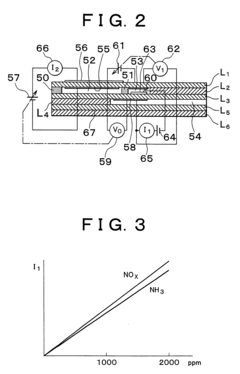

- Incorporating a sensor to detect ammonia concentration downstream of the NOx occluding member, allowing for the determination of the surplus reducing agent amount, which enables precise control of the air-fuel ratio and NOx release by adjusting the amount and duration of fuel-richness, thereby assessing the NOx occluding member's state and performance.

Emissions Regulations

The evolution of LM7 engine ignition systems has been significantly influenced by increasingly stringent emissions regulations over the years. These regulations have driven continuous improvements in ignition technology to reduce harmful emissions and improve fuel efficiency.

In the early stages of LM7 engine development, emissions standards were relatively lenient. However, as environmental concerns grew, regulatory bodies worldwide began implementing stricter emissions limits. This shift prompted engine manufacturers to focus on enhancing ignition systems to achieve cleaner combustion.

One of the key advancements in LM7 ignition systems was the transition from distributor-based ignition to coil-on-plug (COP) technology. This change was largely driven by the need to meet tighter emissions standards. COP systems provide more precise ignition timing and higher spark energy, resulting in more complete combustion and reduced emissions.

The introduction of electronic control units (ECUs) in LM7 engines also played a crucial role in meeting emissions regulations. ECUs allowed for real-time adjustment of ignition timing based on various engine parameters, optimizing combustion efficiency and minimizing emissions across different operating conditions.

As emissions standards continued to tighten, LM7 ignition systems incorporated more advanced features. These included multi-spark ignition, which helps ensure complete fuel combustion, particularly during cold starts when emissions are typically higher. Additionally, ionization current sensing technology was introduced to provide feedback on combustion quality, allowing for further refinement of ignition timing to reduce emissions.

The implementation of variable valve timing (VVT) in LM7 engines, while not directly part of the ignition system, worked in conjunction with improved ignition control to meet stricter emissions targets. VVT allowed for optimized air-fuel mixture and combustion timing, complementing the advancements in ignition technology.

More recent emissions regulations have pushed for even cleaner engine operation, leading to the integration of ignition systems with other engine management components. This holistic approach has resulted in more sophisticated control strategies that balance performance, fuel efficiency, and emissions reduction.

In response to the latest emissions standards, LM7 ignition systems have begun incorporating predictive algorithms and machine learning techniques. These advanced technologies enable the ignition system to anticipate and adapt to changing engine conditions, further optimizing combustion and minimizing emissions across a wide range of operating scenarios.

In the early stages of LM7 engine development, emissions standards were relatively lenient. However, as environmental concerns grew, regulatory bodies worldwide began implementing stricter emissions limits. This shift prompted engine manufacturers to focus on enhancing ignition systems to achieve cleaner combustion.

One of the key advancements in LM7 ignition systems was the transition from distributor-based ignition to coil-on-plug (COP) technology. This change was largely driven by the need to meet tighter emissions standards. COP systems provide more precise ignition timing and higher spark energy, resulting in more complete combustion and reduced emissions.

The introduction of electronic control units (ECUs) in LM7 engines also played a crucial role in meeting emissions regulations. ECUs allowed for real-time adjustment of ignition timing based on various engine parameters, optimizing combustion efficiency and minimizing emissions across different operating conditions.

As emissions standards continued to tighten, LM7 ignition systems incorporated more advanced features. These included multi-spark ignition, which helps ensure complete fuel combustion, particularly during cold starts when emissions are typically higher. Additionally, ionization current sensing technology was introduced to provide feedback on combustion quality, allowing for further refinement of ignition timing to reduce emissions.

The implementation of variable valve timing (VVT) in LM7 engines, while not directly part of the ignition system, worked in conjunction with improved ignition control to meet stricter emissions targets. VVT allowed for optimized air-fuel mixture and combustion timing, complementing the advancements in ignition technology.

More recent emissions regulations have pushed for even cleaner engine operation, leading to the integration of ignition systems with other engine management components. This holistic approach has resulted in more sophisticated control strategies that balance performance, fuel efficiency, and emissions reduction.

In response to the latest emissions standards, LM7 ignition systems have begun incorporating predictive algorithms and machine learning techniques. These advanced technologies enable the ignition system to anticipate and adapt to changing engine conditions, further optimizing combustion and minimizing emissions across a wide range of operating scenarios.

Performance Benchmarks

The performance benchmarks of LM7 engine ignition systems have shown significant improvements over time, reflecting the evolution of technology and the increasing demands for efficiency and reliability in automotive engines. Early LM7 engines utilized traditional distributor-based ignition systems, which were adequate for their time but limited in terms of precision timing and adaptability to varying engine conditions.

As electronic control units (ECUs) became more sophisticated, the LM7 transitioned to distributorless ignition systems (DIS). This change marked a substantial leap in performance, allowing for more precise spark timing and improved fuel efficiency. DIS systems eliminated the need for mechanical distributors, reducing maintenance requirements and increasing overall system reliability.

The introduction of coil-on-plug (COP) ignition systems in later LM7 engines further enhanced performance benchmarks. COP systems provide dedicated ignition coils for each cylinder, resulting in higher voltage delivery and more consistent spark energy. This configuration has demonstrated improved combustion efficiency, reduced emissions, and enhanced cold-start performance compared to earlier ignition systems.

Advancements in ignition control algorithms have also contributed to performance gains. Modern LM7 engines utilize sophisticated ECU programming that can adjust ignition timing based on a multitude of factors, including engine load, temperature, and fuel quality. This adaptive capability has led to optimized performance across a wide range of operating conditions, resulting in improved power output and fuel economy.

Durability tests have shown that newer ignition systems in LM7 engines have significantly longer service intervals and improved resistance to environmental factors such as heat and vibration. This increased reliability translates to reduced maintenance costs and improved long-term engine performance.

Emissions testing has revealed that the evolution of LM7 ignition systems has played a crucial role in meeting increasingly stringent environmental regulations. The precise control offered by modern systems has allowed for more complete combustion, reducing unburned hydrocarbons and other pollutants in exhaust gases.

Comparative dyno testing between early and current LM7 engines has demonstrated measurable improvements in horsepower and torque output, attributable in part to the advancements in ignition technology. These gains are particularly noticeable in mid-range power delivery, enhancing real-world drivability and performance.

As electronic control units (ECUs) became more sophisticated, the LM7 transitioned to distributorless ignition systems (DIS). This change marked a substantial leap in performance, allowing for more precise spark timing and improved fuel efficiency. DIS systems eliminated the need for mechanical distributors, reducing maintenance requirements and increasing overall system reliability.

The introduction of coil-on-plug (COP) ignition systems in later LM7 engines further enhanced performance benchmarks. COP systems provide dedicated ignition coils for each cylinder, resulting in higher voltage delivery and more consistent spark energy. This configuration has demonstrated improved combustion efficiency, reduced emissions, and enhanced cold-start performance compared to earlier ignition systems.

Advancements in ignition control algorithms have also contributed to performance gains. Modern LM7 engines utilize sophisticated ECU programming that can adjust ignition timing based on a multitude of factors, including engine load, temperature, and fuel quality. This adaptive capability has led to optimized performance across a wide range of operating conditions, resulting in improved power output and fuel economy.

Durability tests have shown that newer ignition systems in LM7 engines have significantly longer service intervals and improved resistance to environmental factors such as heat and vibration. This increased reliability translates to reduced maintenance costs and improved long-term engine performance.

Emissions testing has revealed that the evolution of LM7 ignition systems has played a crucial role in meeting increasingly stringent environmental regulations. The precise control offered by modern systems has allowed for more complete combustion, reducing unburned hydrocarbons and other pollutants in exhaust gases.

Comparative dyno testing between early and current LM7 engines has demonstrated measurable improvements in horsepower and torque output, attributable in part to the advancements in ignition technology. These gains are particularly noticeable in mid-range power delivery, enhancing real-world drivability and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!