How Renewable Energy Impacts Carbon Tetrachloride Production

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Renewable Energy and CCl4 Production Overview

The intersection of renewable energy and carbon tetrachloride (CCl4) production represents a critical area of focus in the ongoing efforts to reduce industrial carbon footprints. Carbon tetrachloride, a compound historically used in various applications including refrigerants and solvents, has been phased out in many countries due to its ozone-depleting properties. However, its production as a byproduct or intermediate in certain chemical processes continues, necessitating innovative approaches to mitigate its environmental impact.

Renewable energy sources, such as solar, wind, and hydroelectric power, offer promising avenues for reducing the carbon intensity of CCl4 production. By integrating these clean energy technologies into the manufacturing process, industries can significantly decrease their reliance on fossil fuels, thereby lowering greenhouse gas emissions associated with CCl4 synthesis. This shift not only addresses environmental concerns but also aligns with global sustainability goals and regulatory requirements.

The production of carbon tetrachloride typically involves energy-intensive processes, including chlorination of methane or other hydrocarbons. By leveraging renewable energy to power these operations, manufacturers can achieve substantial reductions in their carbon footprint. Moreover, the implementation of renewable energy systems can lead to long-term cost savings, enhancing the economic viability of CCl4 production while simultaneously improving its environmental profile.

Advancements in renewable energy technologies have made their integration into industrial processes increasingly feasible. For instance, high-efficiency solar panels and wind turbines can now provide reliable power for chemical manufacturing facilities. Additionally, the development of energy storage solutions, such as advanced batteries and hydrogen fuel cells, enables a more consistent energy supply, addressing the intermittency issues often associated with renewable sources.

The impact of renewable energy on CCl4 production extends beyond direct energy consumption. It also influences the entire supply chain, from raw material extraction to product distribution. By adopting a holistic approach to sustainability, companies can optimize their processes, reduce waste, and minimize the overall environmental impact of CCl4 production. This comprehensive strategy may include the use of renewable energy-powered transportation, energy-efficient equipment, and innovative recycling techniques.

As global efforts to combat climate change intensify, the role of renewable energy in CCl4 production is likely to become increasingly significant. Industry leaders and policymakers are recognizing the potential of clean energy to transform traditional chemical manufacturing processes, paving the way for a more sustainable future. This transition not only addresses environmental concerns but also positions companies at the forefront of innovation, potentially leading to new market opportunities and improved competitiveness in an increasingly eco-conscious global economy.

Renewable energy sources, such as solar, wind, and hydroelectric power, offer promising avenues for reducing the carbon intensity of CCl4 production. By integrating these clean energy technologies into the manufacturing process, industries can significantly decrease their reliance on fossil fuels, thereby lowering greenhouse gas emissions associated with CCl4 synthesis. This shift not only addresses environmental concerns but also aligns with global sustainability goals and regulatory requirements.

The production of carbon tetrachloride typically involves energy-intensive processes, including chlorination of methane or other hydrocarbons. By leveraging renewable energy to power these operations, manufacturers can achieve substantial reductions in their carbon footprint. Moreover, the implementation of renewable energy systems can lead to long-term cost savings, enhancing the economic viability of CCl4 production while simultaneously improving its environmental profile.

Advancements in renewable energy technologies have made their integration into industrial processes increasingly feasible. For instance, high-efficiency solar panels and wind turbines can now provide reliable power for chemical manufacturing facilities. Additionally, the development of energy storage solutions, such as advanced batteries and hydrogen fuel cells, enables a more consistent energy supply, addressing the intermittency issues often associated with renewable sources.

The impact of renewable energy on CCl4 production extends beyond direct energy consumption. It also influences the entire supply chain, from raw material extraction to product distribution. By adopting a holistic approach to sustainability, companies can optimize their processes, reduce waste, and minimize the overall environmental impact of CCl4 production. This comprehensive strategy may include the use of renewable energy-powered transportation, energy-efficient equipment, and innovative recycling techniques.

As global efforts to combat climate change intensify, the role of renewable energy in CCl4 production is likely to become increasingly significant. Industry leaders and policymakers are recognizing the potential of clean energy to transform traditional chemical manufacturing processes, paving the way for a more sustainable future. This transition not only addresses environmental concerns but also positions companies at the forefront of innovation, potentially leading to new market opportunities and improved competitiveness in an increasingly eco-conscious global economy.

Market Demand for Green CCl4 Production

The market demand for green carbon tetrachloride (CCl4) production is experiencing a significant upward trend, driven by increasing environmental concerns and stringent regulations on greenhouse gas emissions. As industries worldwide seek to reduce their carbon footprint, there is a growing interest in sustainable production methods for essential chemicals like CCl4.

Carbon tetrachloride, widely used in various industrial applications such as refrigerants, solvents, and raw materials for other chemical compounds, has traditionally been produced through energy-intensive processes that rely heavily on fossil fuels. However, the shift towards renewable energy sources in CCl4 production is creating new market opportunities and reshaping industry dynamics.

The global CCl4 market is projected to expand in the coming years, with a particular emphasis on environmentally friendly production methods. This growth is fueled by the increasing adoption of green technologies across industries and the rising awareness of the environmental impact of traditional chemical manufacturing processes.

Key sectors driving the demand for green CCl4 production include the pharmaceutical industry, where CCl4 is used as a solvent in drug manufacturing, and the electronics sector, where it plays a role in semiconductor production. These industries are under pressure to reduce their environmental impact, making them prime targets for green CCl4 alternatives.

Geographically, developed regions such as North America and Europe are leading the charge in adopting renewable energy for CCl4 production, driven by strict environmental regulations and corporate sustainability goals. However, emerging economies in Asia-Pacific and Latin America are also showing increased interest in green CCl4 production methods as they seek to balance industrial growth with environmental responsibility.

The market demand is further bolstered by consumer preferences for eco-friendly products and the growing trend of corporate social responsibility. Companies that can demonstrate a commitment to sustainable practices, including the use of renewable energy in their production processes, are likely to gain a competitive edge in the market.

Despite the positive outlook, challenges remain in scaling up green CCl4 production to meet global demand. The transition to renewable energy sources requires significant investment in infrastructure and technology, which may initially lead to higher production costs. However, as renewable energy technologies become more efficient and widespread, the long-term economic benefits are expected to outweigh the initial investments.

In conclusion, the market demand for green CCl4 production using renewable energy is poised for substantial growth. This trend reflects a broader shift towards sustainability in the chemical industry and presents opportunities for innovation and market differentiation for companies willing to invest in environmentally friendly production methods.

Carbon tetrachloride, widely used in various industrial applications such as refrigerants, solvents, and raw materials for other chemical compounds, has traditionally been produced through energy-intensive processes that rely heavily on fossil fuels. However, the shift towards renewable energy sources in CCl4 production is creating new market opportunities and reshaping industry dynamics.

The global CCl4 market is projected to expand in the coming years, with a particular emphasis on environmentally friendly production methods. This growth is fueled by the increasing adoption of green technologies across industries and the rising awareness of the environmental impact of traditional chemical manufacturing processes.

Key sectors driving the demand for green CCl4 production include the pharmaceutical industry, where CCl4 is used as a solvent in drug manufacturing, and the electronics sector, where it plays a role in semiconductor production. These industries are under pressure to reduce their environmental impact, making them prime targets for green CCl4 alternatives.

Geographically, developed regions such as North America and Europe are leading the charge in adopting renewable energy for CCl4 production, driven by strict environmental regulations and corporate sustainability goals. However, emerging economies in Asia-Pacific and Latin America are also showing increased interest in green CCl4 production methods as they seek to balance industrial growth with environmental responsibility.

The market demand is further bolstered by consumer preferences for eco-friendly products and the growing trend of corporate social responsibility. Companies that can demonstrate a commitment to sustainable practices, including the use of renewable energy in their production processes, are likely to gain a competitive edge in the market.

Despite the positive outlook, challenges remain in scaling up green CCl4 production to meet global demand. The transition to renewable energy sources requires significant investment in infrastructure and technology, which may initially lead to higher production costs. However, as renewable energy technologies become more efficient and widespread, the long-term economic benefits are expected to outweigh the initial investments.

In conclusion, the market demand for green CCl4 production using renewable energy is poised for substantial growth. This trend reflects a broader shift towards sustainability in the chemical industry and presents opportunities for innovation and market differentiation for companies willing to invest in environmentally friendly production methods.

Challenges in Integrating Renewables in CCl4 Manufacturing

The integration of renewable energy into carbon tetrachloride (CCl4) manufacturing processes presents several significant challenges. One of the primary obstacles is the intermittent nature of renewable energy sources, such as solar and wind power. CCl4 production requires a consistent and reliable energy supply to maintain optimal operating conditions and ensure product quality. The variability of renewable energy output can disrupt the delicate balance of chemical reactions and potentially compromise the integrity of the final product.

Another challenge lies in the high energy intensity of CCl4 manufacturing. The process typically involves chlorination of methane or other hydrocarbons, which demands substantial thermal energy. While renewable sources can provide electricity, the heat requirements for CCl4 production often necessitate the use of fossil fuels or specialized electric heating systems. Transitioning to renewable-powered heating solutions may require significant modifications to existing infrastructure and equipment, leading to considerable capital investments.

The geographical limitations of renewable energy sources also pose a challenge for CCl4 manufacturers. Many chemical plants are located in areas with limited access to abundant renewable resources, making it difficult to rely solely on clean energy. This mismatch between energy production and consumption locations may necessitate the development of advanced energy storage and transmission systems to ensure a stable power supply for CCl4 production facilities.

Furthermore, the integration of renewable energy into CCl4 manufacturing processes requires sophisticated control systems and energy management strategies. Balancing the fluctuating energy input with the precise requirements of chemical reactions demands advanced monitoring and adjustment capabilities. This may involve the implementation of smart grid technologies, energy storage solutions, and adaptive process control systems, all of which add complexity and cost to the manufacturing process.

The regulatory landscape surrounding both renewable energy adoption and CCl4 production presents additional challenges. Stringent environmental regulations on CCl4, due to its ozone-depleting properties, coupled with evolving policies on renewable energy integration, create a complex compliance environment for manufacturers. Navigating these regulatory requirements while maintaining operational efficiency and cost-effectiveness can be a significant hurdle for companies in the sector.

Lastly, the economic viability of integrating renewable energy into CCl4 production remains a concern. While the long-term benefits of reduced carbon emissions and potential energy cost savings are evident, the initial capital expenditure for renewable energy infrastructure can be substantial. Manufacturers must carefully evaluate the return on investment and consider the potential impact on product pricing and competitiveness in the global market.

Another challenge lies in the high energy intensity of CCl4 manufacturing. The process typically involves chlorination of methane or other hydrocarbons, which demands substantial thermal energy. While renewable sources can provide electricity, the heat requirements for CCl4 production often necessitate the use of fossil fuels or specialized electric heating systems. Transitioning to renewable-powered heating solutions may require significant modifications to existing infrastructure and equipment, leading to considerable capital investments.

The geographical limitations of renewable energy sources also pose a challenge for CCl4 manufacturers. Many chemical plants are located in areas with limited access to abundant renewable resources, making it difficult to rely solely on clean energy. This mismatch between energy production and consumption locations may necessitate the development of advanced energy storage and transmission systems to ensure a stable power supply for CCl4 production facilities.

Furthermore, the integration of renewable energy into CCl4 manufacturing processes requires sophisticated control systems and energy management strategies. Balancing the fluctuating energy input with the precise requirements of chemical reactions demands advanced monitoring and adjustment capabilities. This may involve the implementation of smart grid technologies, energy storage solutions, and adaptive process control systems, all of which add complexity and cost to the manufacturing process.

The regulatory landscape surrounding both renewable energy adoption and CCl4 production presents additional challenges. Stringent environmental regulations on CCl4, due to its ozone-depleting properties, coupled with evolving policies on renewable energy integration, create a complex compliance environment for manufacturers. Navigating these regulatory requirements while maintaining operational efficiency and cost-effectiveness can be a significant hurdle for companies in the sector.

Lastly, the economic viability of integrating renewable energy into CCl4 production remains a concern. While the long-term benefits of reduced carbon emissions and potential energy cost savings are evident, the initial capital expenditure for renewable energy infrastructure can be substantial. Manufacturers must carefully evaluate the return on investment and consider the potential impact on product pricing and competitiveness in the global market.

Current Renewable Energy Solutions for CCl4 Production

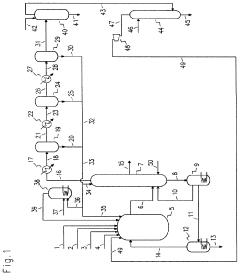

01 Chlorination of methane or other hydrocarbons

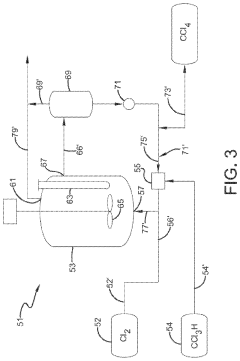

Carbon tetrachloride can be produced through the chlorination of methane or other hydrocarbons. This process involves the reaction of the hydrocarbon with chlorine gas, often in the presence of a catalyst or under specific reaction conditions to promote the formation of carbon tetrachloride.- Chlorination of methane or other hydrocarbons: Carbon tetrachloride can be produced through the chlorination of methane or other hydrocarbons. This process involves the reaction of the hydrocarbon with chlorine gas, often in the presence of a catalyst or under specific reaction conditions to promote the formation of carbon tetrachloride.

- Thermal decomposition of chlorinated hydrocarbons: Another method for producing carbon tetrachloride involves the thermal decomposition of chlorinated hydrocarbons. This process typically requires high temperatures and may use catalysts to facilitate the breakdown of the starting materials into carbon tetrachloride and other products.

- Catalytic processes for carbon tetrachloride production: Various catalytic processes have been developed to enhance the production of carbon tetrachloride. These may involve the use of specific catalysts, reaction conditions, or process configurations to improve yield, selectivity, or efficiency in the production of carbon tetrachloride from different starting materials.

- Purification and separation techniques: The production of carbon tetrachloride often requires purification and separation steps to isolate the desired product from by-products or unreacted starting materials. This may involve distillation, extraction, or other separation techniques to obtain high-purity carbon tetrachloride.

- Continuous production methods: Continuous production methods have been developed for the large-scale manufacture of carbon tetrachloride. These processes aim to improve efficiency, reduce costs, and maintain consistent product quality through the use of specialized equipment and process control systems.

02 Thermal decomposition of chlorinated hydrocarbons

Another method for producing carbon tetrachloride involves the thermal decomposition of chlorinated hydrocarbons. This process typically requires high temperatures and may use catalysts to facilitate the breakdown of the starting materials into carbon tetrachloride and other products.Expand Specific Solutions03 Catalytic processes for carbon tetrachloride production

Various catalytic processes have been developed for the production of carbon tetrachloride. These may involve the use of specific catalysts, such as metal chlorides or supported metal catalysts, to promote the formation of carbon tetrachloride from different starting materials or to improve the selectivity of the reaction.Expand Specific Solutions04 Purification and separation techniques

The production of carbon tetrachloride often requires purification and separation steps to isolate the desired product from byproducts and unreacted starting materials. These techniques may include distillation, extraction, or other separation methods to obtain high-purity carbon tetrachloride.Expand Specific Solutions05 Continuous production processes

Continuous production processes have been developed for the large-scale manufacture of carbon tetrachloride. These processes aim to improve efficiency, reduce costs, and maintain consistent product quality through the use of specialized equipment and optimized reaction conditions.Expand Specific Solutions

Key Players in Renewable Energy and CCl4 Production

The renewable energy sector's impact on carbon tetrachloride production is in a transitional phase, with the market showing moderate growth and technological advancements. The industry is moving towards more sustainable practices, driven by environmental concerns and regulatory pressures. Companies like Shell, Toshiba, and BYD are investing in research and development to improve energy efficiency and reduce carbon emissions in production processes. While the market size is expanding, it remains relatively niche compared to traditional energy sectors. The technology is progressing, with firms like Bayer and BASF leading innovations in green chemistry and sustainable manufacturing techniques. However, full maturity and widespread adoption are still ongoing challenges for the industry.

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has been focusing on integrating renewable energy into industrial processes, which could indirectly impact carbon tetrachloride production. They have developed advanced solar thermal energy storage systems that could provide consistent power for chemical manufacturing processes[10]. Their research into smart grid technologies and energy management systems could enable more efficient use of renewable energy in chemical production facilities[11]. While not directly working on carbon tetrachloride, their innovations in clean energy integration could lead to more sustainable production methods for chlorinated compounds and potentially influence the overall demand for carbon tetrachloride.

Strengths: Specialized focus on clean energy integration, strong research capabilities. Weaknesses: Limited direct experience in chemical production processes.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been investing in renewable energy and green chemical production, which could impact carbon tetrachloride manufacturing. They have developed a "Green Hydrogen" project that uses solar power to produce hydrogen through water electrolysis[8]. This technology could potentially be applied to the production of chlorinated compounds. Sinopec has also been exploring the use of biomass as a renewable feedstock for chemical production, which could offer alternative pathways for producing carbon tetrachloride or its substitutes[9]. Their large-scale implementation of solar power in their operations could significantly reduce the carbon footprint of chemical production processes.

Strengths: Massive production capacity, strong government support for green initiatives. Weaknesses: Balancing traditional petrochemical operations with renewable energy transition may be challenging.

Innovative Technologies for Green CCl4 Synthesis

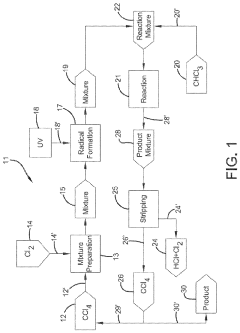

Photochlorination of partially-chlorinated chloromethanes to carbon tetrachloride

PatentActiveUS20240025823A1

Innovation

- A method involving the photochlorination of a chloromethanes stream containing chloroform, methyl chloride, and methylene chloride, combined with chlorine and additional carbon tetrachloride, and subjected to electromagnetic radiation to form carbon tetrachloride, achieving high conversion rates with reduced levels of unwanted chlorinated hydrocarbons.

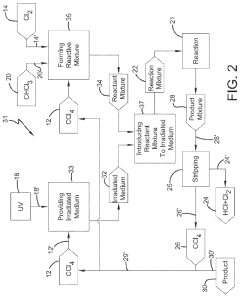

Chlorinolysis process for producing carbon tetrachloride

PatentActiveUS20210130266A1

Innovation

- A process involving a chlorination zone with chlorine, a C1 chlorinated compound, and a carbon/second chlorine source to produce a reaction mixture that favors the formation of carbon tetrachloride over perchloroethylene, using waste products as the carbon/second chlorine source to enhance efficiency and reduce impurity formation.

Environmental Regulations on CCl4 Production

Environmental regulations on carbon tetrachloride (CCl4) production have become increasingly stringent in recent years, reflecting growing concerns about its impact on the ozone layer and climate change. These regulations have significantly influenced the production processes and market dynamics of CCl4, particularly in the context of renewable energy adoption.

The Montreal Protocol, an international treaty designed to protect the ozone layer, has played a crucial role in phasing out the production and consumption of ozone-depleting substances, including CCl4. As a result, many countries have implemented strict controls on CCl4 production, limiting its use to specific essential applications and requiring permits for production and import.

In the United States, the Environmental Protection Agency (EPA) has established regulations under the Clean Air Act to control CCl4 emissions. These regulations mandate the use of maximum achievable control technology (MACT) for CCl4 production facilities, requiring them to implement stringent emission reduction measures.

The European Union has also implemented strict regulations on CCl4 production through its Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) program. Under REACH, CCl4 is classified as a substance of very high concern (SVHC), subjecting it to authorization requirements and potential restrictions.

As renewable energy sources become more prevalent, their impact on CCl4 production regulations is twofold. Firstly, the shift towards cleaner energy sources has led to increased pressure on industries to reduce their carbon footprint, including those involved in CCl4 production. This has resulted in more stringent emission standards and energy efficiency requirements for production facilities.

Secondly, the growth of renewable energy technologies has opened up new possibilities for reducing the environmental impact of CCl4 production. For instance, the use of renewable energy in powering production facilities can help reduce greenhouse gas emissions associated with CCl4 manufacturing processes.

Some countries have introduced incentives for CCl4 producers to adopt renewable energy sources in their operations. These incentives may include tax breaks, grants, or preferential treatment in regulatory compliance for facilities that incorporate renewable energy into their production processes.

The integration of renewable energy into CCl4 production has also led to the development of new regulatory frameworks. These frameworks aim to balance the need for continued CCl4 production for essential uses with the imperative to minimize its environmental impact. For example, some jurisdictions have introduced regulations that require CCl4 producers to source a certain percentage of their energy from renewable sources.

As global efforts to combat climate change intensify, it is likely that environmental regulations on CCl4 production will continue to evolve, with an increasing emphasis on the role of renewable energy in mitigating the industry's environmental impact.

The Montreal Protocol, an international treaty designed to protect the ozone layer, has played a crucial role in phasing out the production and consumption of ozone-depleting substances, including CCl4. As a result, many countries have implemented strict controls on CCl4 production, limiting its use to specific essential applications and requiring permits for production and import.

In the United States, the Environmental Protection Agency (EPA) has established regulations under the Clean Air Act to control CCl4 emissions. These regulations mandate the use of maximum achievable control technology (MACT) for CCl4 production facilities, requiring them to implement stringent emission reduction measures.

The European Union has also implemented strict regulations on CCl4 production through its Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) program. Under REACH, CCl4 is classified as a substance of very high concern (SVHC), subjecting it to authorization requirements and potential restrictions.

As renewable energy sources become more prevalent, their impact on CCl4 production regulations is twofold. Firstly, the shift towards cleaner energy sources has led to increased pressure on industries to reduce their carbon footprint, including those involved in CCl4 production. This has resulted in more stringent emission standards and energy efficiency requirements for production facilities.

Secondly, the growth of renewable energy technologies has opened up new possibilities for reducing the environmental impact of CCl4 production. For instance, the use of renewable energy in powering production facilities can help reduce greenhouse gas emissions associated with CCl4 manufacturing processes.

Some countries have introduced incentives for CCl4 producers to adopt renewable energy sources in their operations. These incentives may include tax breaks, grants, or preferential treatment in regulatory compliance for facilities that incorporate renewable energy into their production processes.

The integration of renewable energy into CCl4 production has also led to the development of new regulatory frameworks. These frameworks aim to balance the need for continued CCl4 production for essential uses with the imperative to minimize its environmental impact. For example, some jurisdictions have introduced regulations that require CCl4 producers to source a certain percentage of their energy from renewable sources.

As global efforts to combat climate change intensify, it is likely that environmental regulations on CCl4 production will continue to evolve, with an increasing emphasis on the role of renewable energy in mitigating the industry's environmental impact.

Life Cycle Assessment of Renewable-Powered CCl4 Production

Life Cycle Assessment (LCA) of renewable-powered carbon tetrachloride (CCl4) production provides a comprehensive evaluation of the environmental impacts associated with this manufacturing process. This assessment encompasses the entire lifecycle of CCl4 production, from raw material extraction to final disposal, with a specific focus on the integration of renewable energy sources.

The study begins by examining the traditional CCl4 production process, which typically relies on fossil fuel-based energy sources. This serves as a baseline for comparison with the renewable-powered alternative. The assessment then delves into the various renewable energy options that can be integrated into the production process, such as solar, wind, hydroelectric, or biomass power.

A key aspect of the LCA is the quantification of greenhouse gas emissions throughout the production chain. This includes not only the direct emissions from the manufacturing process but also the indirect emissions associated with energy generation and transportation. The analysis reveals significant reductions in carbon dioxide emissions when renewable energy sources are employed, contributing to the overall goal of mitigating climate change.

The assessment also considers other environmental impact categories, such as water consumption, land use, and resource depletion. These factors are crucial in providing a holistic view of the sustainability of renewable-powered CCl4 production. For instance, while solar energy may reduce carbon emissions, it requires substantial land area for panel installation, which is factored into the overall environmental impact.

Energy efficiency improvements in the production process are also evaluated as part of the LCA. The integration of renewable energy often necessitates modifications to existing manufacturing equipment and processes, which can lead to enhanced energy efficiency. These improvements are quantified and incorporated into the overall assessment of environmental impact.

The LCA extends to the end-of-life phase of CCl4, considering disposal methods and potential recycling opportunities. This cradle-to-grave approach ensures a comprehensive understanding of the environmental implications of renewable-powered CCl4 production throughout its entire lifecycle.

Finally, the assessment includes a sensitivity analysis to account for variabilities in renewable energy availability and production scales. This analysis helps identify the most critical factors influencing the environmental performance of renewable-powered CCl4 production and guides future optimization efforts.

The study begins by examining the traditional CCl4 production process, which typically relies on fossil fuel-based energy sources. This serves as a baseline for comparison with the renewable-powered alternative. The assessment then delves into the various renewable energy options that can be integrated into the production process, such as solar, wind, hydroelectric, or biomass power.

A key aspect of the LCA is the quantification of greenhouse gas emissions throughout the production chain. This includes not only the direct emissions from the manufacturing process but also the indirect emissions associated with energy generation and transportation. The analysis reveals significant reductions in carbon dioxide emissions when renewable energy sources are employed, contributing to the overall goal of mitigating climate change.

The assessment also considers other environmental impact categories, such as water consumption, land use, and resource depletion. These factors are crucial in providing a holistic view of the sustainability of renewable-powered CCl4 production. For instance, while solar energy may reduce carbon emissions, it requires substantial land area for panel installation, which is factored into the overall environmental impact.

Energy efficiency improvements in the production process are also evaluated as part of the LCA. The integration of renewable energy often necessitates modifications to existing manufacturing equipment and processes, which can lead to enhanced energy efficiency. These improvements are quantified and incorporated into the overall assessment of environmental impact.

The LCA extends to the end-of-life phase of CCl4, considering disposal methods and potential recycling opportunities. This cradle-to-grave approach ensures a comprehensive understanding of the environmental implications of renewable-powered CCl4 production throughout its entire lifecycle.

Finally, the assessment includes a sensitivity analysis to account for variabilities in renewable energy availability and production scales. This analysis helps identify the most critical factors influencing the environmental performance of renewable-powered CCl4 production and guides future optimization efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!