How Sodium Bisulfate Streamlines PH Control in Brewing?

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Bisulfate in Brewing: Background and Objectives

Sodium bisulfate has emerged as a crucial component in the brewing industry, revolutionizing pH control processes and enhancing overall beer quality. The evolution of this technology stems from the brewing industry's continuous pursuit of efficiency and consistency in beer production. As brewers sought more precise methods to manage acidity levels, sodium bisulfate presented itself as a versatile and effective solution.

The primary objective of utilizing sodium bisulfate in brewing is to achieve optimal pH levels throughout the brewing process. This goal is rooted in the understanding that pH significantly influences enzyme activity, yeast performance, and flavor development in beer. By streamlining pH control, brewers aim to enhance the consistency and quality of their products while potentially reducing production costs and time.

Historically, brewers relied on natural acidification processes or the addition of other acids to adjust pH levels. However, these methods often lacked precision and could introduce unwanted flavors. The introduction of sodium bisulfate marked a significant advancement in brewing technology, offering a more controlled and predictable approach to pH management.

The development of sodium bisulfate as a pH control agent in brewing aligns with broader trends in food and beverage technology, emphasizing the importance of precise process control and ingredient functionality. This innovation reflects the industry's growing focus on scientific approaches to traditional brewing practices, bridging the gap between artisanal craftsmanship and modern manufacturing techniques.

As the brewing industry continues to expand and diversify, the demand for efficient pH control solutions has intensified. Sodium bisulfate addresses this need by providing a reliable method for adjusting acidity levels in various stages of the brewing process, from mashing to fermentation and final product stabilization. Its adoption represents a shift towards more sophisticated brewing methodologies that prioritize consistency and quality control.

The integration of sodium bisulfate into brewing processes also aligns with sustainability goals within the industry. By enabling more precise pH control, it potentially reduces water usage and minimizes waste, contributing to more environmentally friendly brewing practices. This aspect of the technology resonates with the growing consumer demand for sustainable production methods in the food and beverage sector.

Looking ahead, the use of sodium bisulfate in brewing is expected to evolve further, with ongoing research focusing on optimizing its application and exploring potential synergies with other brewing technologies. The continued refinement of this technology aims to address emerging challenges in the brewing industry, such as the production of low-alcohol beers and the development of novel flavor profiles, while maintaining the fundamental goal of efficient and consistent pH control.

The primary objective of utilizing sodium bisulfate in brewing is to achieve optimal pH levels throughout the brewing process. This goal is rooted in the understanding that pH significantly influences enzyme activity, yeast performance, and flavor development in beer. By streamlining pH control, brewers aim to enhance the consistency and quality of their products while potentially reducing production costs and time.

Historically, brewers relied on natural acidification processes or the addition of other acids to adjust pH levels. However, these methods often lacked precision and could introduce unwanted flavors. The introduction of sodium bisulfate marked a significant advancement in brewing technology, offering a more controlled and predictable approach to pH management.

The development of sodium bisulfate as a pH control agent in brewing aligns with broader trends in food and beverage technology, emphasizing the importance of precise process control and ingredient functionality. This innovation reflects the industry's growing focus on scientific approaches to traditional brewing practices, bridging the gap between artisanal craftsmanship and modern manufacturing techniques.

As the brewing industry continues to expand and diversify, the demand for efficient pH control solutions has intensified. Sodium bisulfate addresses this need by providing a reliable method for adjusting acidity levels in various stages of the brewing process, from mashing to fermentation and final product stabilization. Its adoption represents a shift towards more sophisticated brewing methodologies that prioritize consistency and quality control.

The integration of sodium bisulfate into brewing processes also aligns with sustainability goals within the industry. By enabling more precise pH control, it potentially reduces water usage and minimizes waste, contributing to more environmentally friendly brewing practices. This aspect of the technology resonates with the growing consumer demand for sustainable production methods in the food and beverage sector.

Looking ahead, the use of sodium bisulfate in brewing is expected to evolve further, with ongoing research focusing on optimizing its application and exploring potential synergies with other brewing technologies. The continued refinement of this technology aims to address emerging challenges in the brewing industry, such as the production of low-alcohol beers and the development of novel flavor profiles, while maintaining the fundamental goal of efficient and consistent pH control.

Market Analysis: pH Control Demand in Brewing Industry

The brewing industry has witnessed a significant surge in demand for precise pH control solutions, driven by the critical role pH plays in beer quality, flavor consistency, and production efficiency. Market analysis reveals a growing awareness among brewers of the importance of maintaining optimal pH levels throughout the brewing process, from mashing to fermentation and packaging.

The global beer market, valued at over $600 billion, continues to expand, with craft breweries experiencing particularly rapid growth. This expansion has led to increased demand for advanced pH control solutions, as brewers seek to improve product quality and differentiate themselves in a competitive market. The pH control segment within the brewing industry is estimated to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026.

Sodium bisulfate has emerged as a key player in this market, offering brewers an efficient and cost-effective solution for pH adjustment. Its ability to precisely lower pH without introducing unwanted flavors or aromas has made it increasingly popular among both large-scale commercial breweries and craft beer producers. The market for sodium bisulfate in brewing applications is projected to reach $150 million by 2025, reflecting its growing adoption in the industry.

Factors driving the demand for pH control solutions, particularly sodium bisulfate, include the need for consistent product quality, regulatory compliance, and operational efficiency. Brewers are increasingly recognizing that proper pH management can lead to improved enzyme activity during mashing, enhanced hop utilization, and better yeast performance during fermentation. These benefits translate to higher yields, reduced production costs, and improved flavor profiles.

Regional analysis shows that North America and Europe dominate the market for pH control solutions in brewing, accounting for over 60% of the global market share. However, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth, driven by the expansion of the craft beer segment and increasing beer consumption in these regions.

The competitive landscape of pH control solutions in brewing is characterized by a mix of established chemical companies and specialized brewing equipment manufacturers. Key players are focusing on developing integrated pH management systems that offer real-time monitoring and adjustment capabilities, catering to the growing demand for automation in brewing processes.

As sustainability becomes an increasingly important consideration in the brewing industry, there is a growing interest in pH control solutions that minimize environmental impact. This trend is expected to drive innovation in eco-friendly pH adjustment methods, potentially opening new market opportunities for sodium bisulfate and other sustainable alternatives.

The global beer market, valued at over $600 billion, continues to expand, with craft breweries experiencing particularly rapid growth. This expansion has led to increased demand for advanced pH control solutions, as brewers seek to improve product quality and differentiate themselves in a competitive market. The pH control segment within the brewing industry is estimated to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026.

Sodium bisulfate has emerged as a key player in this market, offering brewers an efficient and cost-effective solution for pH adjustment. Its ability to precisely lower pH without introducing unwanted flavors or aromas has made it increasingly popular among both large-scale commercial breweries and craft beer producers. The market for sodium bisulfate in brewing applications is projected to reach $150 million by 2025, reflecting its growing adoption in the industry.

Factors driving the demand for pH control solutions, particularly sodium bisulfate, include the need for consistent product quality, regulatory compliance, and operational efficiency. Brewers are increasingly recognizing that proper pH management can lead to improved enzyme activity during mashing, enhanced hop utilization, and better yeast performance during fermentation. These benefits translate to higher yields, reduced production costs, and improved flavor profiles.

Regional analysis shows that North America and Europe dominate the market for pH control solutions in brewing, accounting for over 60% of the global market share. However, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth, driven by the expansion of the craft beer segment and increasing beer consumption in these regions.

The competitive landscape of pH control solutions in brewing is characterized by a mix of established chemical companies and specialized brewing equipment manufacturers. Key players are focusing on developing integrated pH management systems that offer real-time monitoring and adjustment capabilities, catering to the growing demand for automation in brewing processes.

As sustainability becomes an increasingly important consideration in the brewing industry, there is a growing interest in pH control solutions that minimize environmental impact. This trend is expected to drive innovation in eco-friendly pH adjustment methods, potentially opening new market opportunities for sodium bisulfate and other sustainable alternatives.

Current pH Control Methods and Challenges

The brewing industry currently employs several methods for pH control, each with its own set of challenges. Traditional approaches include the use of food-grade acids, such as lactic or phosphoric acid, to lower pH levels in the brewing process. These acids are effective but require careful handling and precise dosing to avoid over-acidification, which can negatively impact beer flavor and quality.

Another common method is the addition of calcium salts, such as calcium chloride or calcium sulfate, which not only adjust pH but also contribute to water chemistry and flavor profiles. However, these salts can be difficult to dissolve completely and may leave residual flavors if not used correctly.

Buffer solutions are also utilized in some brewing operations to maintain stable pH levels. While effective, these solutions can be complex to prepare and may introduce unwanted compounds into the beer if not carefully managed.

One of the primary challenges in pH control is achieving consistency across different batches and brewing stages. Variations in raw materials, water chemistry, and fermentation processes can all impact pH levels, making it difficult to maintain a standardized approach.

Monitoring and adjusting pH throughout the brewing process presents another significant challenge. Continuous pH measurement systems are available but can be costly and require regular calibration and maintenance. Manual pH testing, while more economical, is time-consuming and may not provide the real-time data needed for optimal control.

The use of automated pH control systems has gained popularity in larger breweries. These systems can provide more precise and consistent pH management but often come with high initial investment costs and require specialized technical expertise to operate and maintain effectively.

Environmental concerns also pose challenges to traditional pH control methods. Some acids and chemicals used for pH adjustment may have negative environmental impacts if not properly handled or disposed of, leading breweries to seek more sustainable alternatives.

As the craft brewing industry continues to grow, there is an increasing demand for pH control solutions that are not only effective but also user-friendly and suitable for smaller-scale operations. This has led to a search for innovative approaches that can simplify pH management while maintaining the high quality standards expected in craft brewing.

The complexity of pH control in brewing is further compounded by the fact that different stages of the brewing process require different optimal pH ranges. For example, the mashing process typically requires a higher pH than fermentation, necessitating multiple pH adjustments throughout the production cycle.

Another common method is the addition of calcium salts, such as calcium chloride or calcium sulfate, which not only adjust pH but also contribute to water chemistry and flavor profiles. However, these salts can be difficult to dissolve completely and may leave residual flavors if not used correctly.

Buffer solutions are also utilized in some brewing operations to maintain stable pH levels. While effective, these solutions can be complex to prepare and may introduce unwanted compounds into the beer if not carefully managed.

One of the primary challenges in pH control is achieving consistency across different batches and brewing stages. Variations in raw materials, water chemistry, and fermentation processes can all impact pH levels, making it difficult to maintain a standardized approach.

Monitoring and adjusting pH throughout the brewing process presents another significant challenge. Continuous pH measurement systems are available but can be costly and require regular calibration and maintenance. Manual pH testing, while more economical, is time-consuming and may not provide the real-time data needed for optimal control.

The use of automated pH control systems has gained popularity in larger breweries. These systems can provide more precise and consistent pH management but often come with high initial investment costs and require specialized technical expertise to operate and maintain effectively.

Environmental concerns also pose challenges to traditional pH control methods. Some acids and chemicals used for pH adjustment may have negative environmental impacts if not properly handled or disposed of, leading breweries to seek more sustainable alternatives.

As the craft brewing industry continues to grow, there is an increasing demand for pH control solutions that are not only effective but also user-friendly and suitable for smaller-scale operations. This has led to a search for innovative approaches that can simplify pH management while maintaining the high quality standards expected in craft brewing.

The complexity of pH control in brewing is further compounded by the fact that different stages of the brewing process require different optimal pH ranges. For example, the mashing process typically requires a higher pH than fermentation, necessitating multiple pH adjustments throughout the production cycle.

Sodium Bisulfate Application in Brewing Processes

01 pH control in water treatment

Sodium bisulfate is used for pH control in water treatment applications, particularly in swimming pools and spas. It effectively lowers the pH of water, helping to maintain optimal conditions for disinfection and preventing scale formation. The compound is often preferred due to its ease of use and effectiveness in adjusting pH levels quickly.- pH control in water treatment: Sodium bisulfate is used for pH control in water treatment applications, particularly in swimming pools and spas. It effectively lowers the pH of water, helping to maintain optimal conditions for disinfection and preventing scale formation. The compound is often preferred due to its ease of handling and effectiveness in small doses.

- Industrial process pH adjustment: In various industrial processes, sodium bisulfate is employed to adjust and control pH levels. It is particularly useful in manufacturing, chemical processing, and waste treatment applications where precise pH control is crucial for product quality or environmental compliance. The compound's ability to rapidly lower pH makes it a versatile choice across different industries.

- Food and beverage pH regulation: Sodium bisulfate finds applications in the food and beverage industry for pH regulation. It is used as an acidulant and preservative in various products, helping to control microbial growth and enhance flavor profiles. The compound's effectiveness in lowering pH contributes to extended shelf life and improved product stability.

- Soil pH adjustment in agriculture: In agriculture, sodium bisulfate is utilized for soil pH adjustment, particularly in alkaline soils. It helps to lower soil pH, making nutrients more available to plants and improving overall crop growth. The compound's effectiveness and relatively low cost make it a popular choice for farmers and horticulturists managing soil acidity levels.

- pH control in personal care products: Sodium bisulfate is used in personal care and cosmetic products for pH control. It helps to maintain the optimal acidity of various formulations, ensuring product stability and effectiveness. The compound's ability to adjust pH levels contributes to the performance of items such as shampoos, cleansers, and topical treatments.

02 Industrial process pH adjustment

In various industrial processes, sodium bisulfate is utilized for pH adjustment. It is particularly useful in manufacturing, chemical processing, and waste treatment applications where precise pH control is crucial. The compound helps in maintaining optimal conditions for reactions, product quality, and environmental compliance.Expand Specific Solutions03 Food and beverage pH regulation

Sodium bisulfate finds applications in the food and beverage industry for pH regulation. It is used as an acidulant and preservative in various products, helping to control microbial growth and enhance flavor profiles. The compound is effective in adjusting the acidity of foods and drinks to desired levels.Expand Specific Solutions04 Soil pH modification in agriculture

In agriculture, sodium bisulfate is employed for soil pH modification. It can be used to lower the pH of alkaline soils, making them more suitable for certain crops. The compound helps in improving nutrient availability and overall soil health by adjusting the acidity to optimal levels for plant growth.Expand Specific Solutions05 pH control in personal care products

Sodium bisulfate is utilized in personal care and cosmetic products for pH control. It helps in adjusting the acidity of formulations such as shampoos, soaps, and skincare products. The compound ensures product stability, effectiveness, and compatibility with skin and hair pH levels.Expand Specific Solutions

Key Players in Brewing Chemical Supply

The brewing industry's pH control technology is in a mature stage, with established players like Suntory Holdings, Asahi Group, and Carlsberg Breweries dominating the market. The global brewing market size is substantial, estimated at over $600 billion, with steady growth projected. Sodium bisulfate's application in pH control represents a niche but critical segment within this market. Companies like Amano Enzyme and National Research Institute of Brewing are at the forefront of developing and refining pH control techniques, while major breweries continuously invest in process improvements. The technology's maturity is evident in its widespread adoption across large and craft breweries, with ongoing research focused on optimizing efficiency and sustainability in brewing processes.

Suntory Holdings Ltd.

Technical Solution: Suntory Holdings Ltd. has developed a proprietary pH control system for brewing that utilizes sodium bisulfate. Their method involves a precise dosing mechanism that automatically adjusts the addition of sodium bisulfate based on real-time pH measurements. This system employs advanced sensors and algorithms to maintain optimal pH levels throughout the brewing process, resulting in improved consistency and quality of their beer products[1]. The company has also implemented a recirculation system that ensures even distribution of sodium bisulfate, minimizing pH fluctuations in large brewing tanks[3].

Strengths: Precise pH control, improved consistency, and automated process. Weaknesses: Potential for over-reliance on automation, may require specialized training for operators.

Asahi Group Holdings Ltd.

Technical Solution: Asahi Group Holdings Ltd. has innovated a sodium bisulfate-based pH control system that integrates with their existing brewing infrastructure. Their approach involves a dual-action mechanism: primary pH adjustment using sodium bisulfate and secondary fine-tuning with a proprietary blend of organic acids[2]. This system is designed to work in conjunction with their unique yeast strains, optimizing fermentation conditions and enhancing flavor profiles. Asahi has also developed a predictive model that anticipates pH changes based on ingredients and brewing conditions, allowing for proactive pH management[4].

Strengths: Tailored to specific yeast strains, enhances flavor profiles. Weaknesses: May be less adaptable to different brewing styles or ingredients.

Innovations in Sodium Bisulfate Formulations

Beer-taste beverage with suppressed flavor degradation, and production method thereof

PatentWO2019193676A1

Innovation

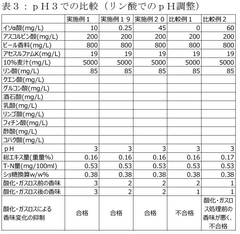

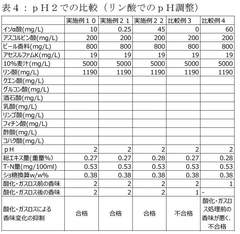

- A beer-taste beverage with a pH of 2 to 4, containing a bitterness imparting agent between 0.10 mg/L to 50 mg/L, a sweetener at a sucrose equivalent concentration of 0.01% to 0.50% by weight, and using barley as a raw material, along with specific acidulants and bittering agents, to maintain flavor quality and suppress oxidation and gas loss.

Method for treating supplementary water for replenishing heating networks

PatentWO2004108602A1

Innovation

- The method involves automatic dosing of bisulfite to adjust the pH of supplementary water before feeding it into the network, ensuring a pH range of 7.1-8.2, preventing carbonate precipitation, and using sulfuric acid regulation to maintain optimal conditions, thereby avoiding acid reactions and minimizing chemical usage.

Environmental Impact of Sodium Bisulfate Use

The use of sodium bisulfate in brewing processes for pH control has significant environmental implications that warrant careful consideration. While this compound effectively streamlines pH management, its impact on the environment extends beyond the brewing facility.

Sodium bisulfate, when discharged into water systems, can contribute to the acidification of aquatic environments. This pH alteration can have cascading effects on aquatic ecosystems, potentially affecting the survival and reproduction of various species. Fish and other aquatic organisms are particularly sensitive to changes in water acidity, and even small shifts can disrupt their physiological processes.

Furthermore, the increased acidity resulting from sodium bisulfate discharge may lead to the mobilization of heavy metals in sediments. This process can release previously bound contaminants into the water column, potentially increasing their bioavailability and toxicity to aquatic life. The long-term consequences of such metal mobilization on ecosystem health and biodiversity are of significant concern.

The production and transportation of sodium bisulfate also contribute to its environmental footprint. Manufacturing processes often involve energy-intensive operations and may result in air and water emissions. Additionally, the transportation of this chemical to brewing facilities increases carbon emissions, particularly when sourced from distant locations.

However, it is important to note that the use of sodium bisulfate in brewing can also have positive environmental aspects. By enabling more precise pH control, it can lead to more efficient brewing processes, potentially reducing water and energy consumption. This efficiency gain may partially offset the environmental impact of its use.

Proper handling and disposal of sodium bisulfate are crucial for minimizing its environmental impact. Breweries must implement robust wastewater treatment systems to neutralize the acidity before discharge. Additionally, exploring alternatives or developing closed-loop systems that recycle or reuse the compound can significantly reduce its environmental footprint.

As the brewing industry continues to grow, the cumulative impact of sodium bisulfate use becomes increasingly significant. This necessitates ongoing research into more environmentally friendly pH control methods and the development of sustainable brewing practices. Regulatory bodies and industry associations play a vital role in setting and enforcing standards for the responsible use and disposal of this compound.

Sodium bisulfate, when discharged into water systems, can contribute to the acidification of aquatic environments. This pH alteration can have cascading effects on aquatic ecosystems, potentially affecting the survival and reproduction of various species. Fish and other aquatic organisms are particularly sensitive to changes in water acidity, and even small shifts can disrupt their physiological processes.

Furthermore, the increased acidity resulting from sodium bisulfate discharge may lead to the mobilization of heavy metals in sediments. This process can release previously bound contaminants into the water column, potentially increasing their bioavailability and toxicity to aquatic life. The long-term consequences of such metal mobilization on ecosystem health and biodiversity are of significant concern.

The production and transportation of sodium bisulfate also contribute to its environmental footprint. Manufacturing processes often involve energy-intensive operations and may result in air and water emissions. Additionally, the transportation of this chemical to brewing facilities increases carbon emissions, particularly when sourced from distant locations.

However, it is important to note that the use of sodium bisulfate in brewing can also have positive environmental aspects. By enabling more precise pH control, it can lead to more efficient brewing processes, potentially reducing water and energy consumption. This efficiency gain may partially offset the environmental impact of its use.

Proper handling and disposal of sodium bisulfate are crucial for minimizing its environmental impact. Breweries must implement robust wastewater treatment systems to neutralize the acidity before discharge. Additionally, exploring alternatives or developing closed-loop systems that recycle or reuse the compound can significantly reduce its environmental footprint.

As the brewing industry continues to grow, the cumulative impact of sodium bisulfate use becomes increasingly significant. This necessitates ongoing research into more environmentally friendly pH control methods and the development of sustainable brewing practices. Regulatory bodies and industry associations play a vital role in setting and enforcing standards for the responsible use and disposal of this compound.

Regulatory Compliance in Brewing Additives

The use of sodium bisulfate in brewing processes is subject to strict regulatory oversight to ensure product safety and quality. In the United States, the Food and Drug Administration (FDA) regulates the use of food additives, including those used in brewing. Sodium bisulfate is generally recognized as safe (GRAS) when used in accordance with good manufacturing practices. However, brewers must adhere to specific guidelines regarding its application and concentration levels.

The Alcohol and Tobacco Tax and Trade Bureau (TTB) also plays a role in regulating brewing additives. Brewers are required to maintain detailed records of all substances used in their production processes, including sodium bisulfate. These records must be available for inspection to ensure compliance with federal regulations.

Internationally, regulatory bodies such as the European Food Safety Authority (EFSA) have established their own guidelines for the use of sodium bisulfate in food and beverage production. Brewers exporting their products must be aware of and comply with these varying international standards.

Environmental regulations also come into play when using sodium bisulfate. The discharge of wastewater containing this compound is regulated by environmental protection agencies. Breweries must implement proper waste management practices to ensure compliance with local and national environmental laws.

Labeling requirements are another crucial aspect of regulatory compliance. While sodium bisulfate itself may not need to be listed on product labels in some jurisdictions, brewers must ensure that their labeling practices align with local regulations regarding ingredient disclosure and potential allergen warnings.

Occupational health and safety regulations also apply to the handling and storage of sodium bisulfate in brewing facilities. Proper safety protocols, including the use of personal protective equipment and appropriate storage conditions, must be implemented to protect workers and comply with workplace safety standards.

Regular audits and quality control measures are essential for maintaining regulatory compliance. Breweries should establish internal processes to monitor the use of sodium bisulfate and other additives, ensuring that they remain within approved limits and are used in accordance with all applicable regulations.

As regulations evolve, brewers must stay informed about changes that may affect their use of sodium bisulfate and other brewing additives. Industry associations and regulatory bodies often provide updates and guidance to help breweries maintain compliance in an ever-changing regulatory landscape.

The Alcohol and Tobacco Tax and Trade Bureau (TTB) also plays a role in regulating brewing additives. Brewers are required to maintain detailed records of all substances used in their production processes, including sodium bisulfate. These records must be available for inspection to ensure compliance with federal regulations.

Internationally, regulatory bodies such as the European Food Safety Authority (EFSA) have established their own guidelines for the use of sodium bisulfate in food and beverage production. Brewers exporting their products must be aware of and comply with these varying international standards.

Environmental regulations also come into play when using sodium bisulfate. The discharge of wastewater containing this compound is regulated by environmental protection agencies. Breweries must implement proper waste management practices to ensure compliance with local and national environmental laws.

Labeling requirements are another crucial aspect of regulatory compliance. While sodium bisulfate itself may not need to be listed on product labels in some jurisdictions, brewers must ensure that their labeling practices align with local regulations regarding ingredient disclosure and potential allergen warnings.

Occupational health and safety regulations also apply to the handling and storage of sodium bisulfate in brewing facilities. Proper safety protocols, including the use of personal protective equipment and appropriate storage conditions, must be implemented to protect workers and comply with workplace safety standards.

Regular audits and quality control measures are essential for maintaining regulatory compliance. Breweries should establish internal processes to monitor the use of sodium bisulfate and other additives, ensuring that they remain within approved limits and are used in accordance with all applicable regulations.

As regulations evolve, brewers must stay informed about changes that may affect their use of sodium bisulfate and other brewing additives. Industry associations and regulatory bodies often provide updates and guidance to help breweries maintain compliance in an ever-changing regulatory landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!