How to Achieve Higher Standards in Polyurethane Development?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Development Background and Objectives

Polyurethane (PU) has been a cornerstone in various industries since its discovery in the 1930s. Its versatility and unique properties have led to widespread applications in sectors ranging from construction and automotive to furniture and medical devices. The development of polyurethane has been driven by the need for materials with specific characteristics such as durability, flexibility, and insulation properties.

Over the years, the polyurethane industry has witnessed significant advancements in chemistry, processing techniques, and application methods. However, as global challenges such as environmental sustainability and resource scarcity become more pressing, the focus of PU development has shifted towards achieving higher standards in terms of performance, sustainability, and cost-effectiveness.

The primary objective of modern polyurethane development is to create materials that meet increasingly stringent requirements across various applications while addressing environmental concerns. This includes developing bio-based polyurethanes, improving recycling processes, and enhancing the overall performance of PU products.

One of the key areas of focus is the reduction of volatile organic compounds (VOCs) in polyurethane production and application. This is crucial for improving indoor air quality and reducing the environmental impact of PU-based products. Additionally, there is a growing emphasis on developing polyurethanes with improved fire resistance and thermal insulation properties, particularly for use in construction and automotive industries.

Another significant objective is the development of polyurethanes with enhanced durability and longevity. This not only improves the performance of end products but also contributes to sustainability by reducing the need for frequent replacements. Researchers are exploring novel chemical structures and additives to achieve these goals without compromising other desirable properties of polyurethanes.

The pursuit of higher standards in polyurethane development also involves addressing challenges in processing and manufacturing. This includes improving the efficiency of production processes, reducing energy consumption, and developing more precise control mechanisms for polyurethane reactions. Advanced technologies such as 3D printing and robotics are being integrated into PU manufacturing to achieve higher precision and customization capabilities.

Furthermore, the polyurethane industry is actively seeking alternatives to traditional raw materials, particularly those derived from fossil fuels. The development of bio-based polyols and isocyanates is a key objective, aiming to reduce the carbon footprint of PU products while maintaining or improving their performance characteristics.

In conclusion, the path to achieving higher standards in polyurethane development is multifaceted, involving advancements in chemistry, processing technologies, and application methods. The industry's objectives are aligned with global trends towards sustainability, performance enhancement, and cost-effectiveness, driving innovation in this versatile material for the future.

Over the years, the polyurethane industry has witnessed significant advancements in chemistry, processing techniques, and application methods. However, as global challenges such as environmental sustainability and resource scarcity become more pressing, the focus of PU development has shifted towards achieving higher standards in terms of performance, sustainability, and cost-effectiveness.

The primary objective of modern polyurethane development is to create materials that meet increasingly stringent requirements across various applications while addressing environmental concerns. This includes developing bio-based polyurethanes, improving recycling processes, and enhancing the overall performance of PU products.

One of the key areas of focus is the reduction of volatile organic compounds (VOCs) in polyurethane production and application. This is crucial for improving indoor air quality and reducing the environmental impact of PU-based products. Additionally, there is a growing emphasis on developing polyurethanes with improved fire resistance and thermal insulation properties, particularly for use in construction and automotive industries.

Another significant objective is the development of polyurethanes with enhanced durability and longevity. This not only improves the performance of end products but also contributes to sustainability by reducing the need for frequent replacements. Researchers are exploring novel chemical structures and additives to achieve these goals without compromising other desirable properties of polyurethanes.

The pursuit of higher standards in polyurethane development also involves addressing challenges in processing and manufacturing. This includes improving the efficiency of production processes, reducing energy consumption, and developing more precise control mechanisms for polyurethane reactions. Advanced technologies such as 3D printing and robotics are being integrated into PU manufacturing to achieve higher precision and customization capabilities.

Furthermore, the polyurethane industry is actively seeking alternatives to traditional raw materials, particularly those derived from fossil fuels. The development of bio-based polyols and isocyanates is a key objective, aiming to reduce the carbon footprint of PU products while maintaining or improving their performance characteristics.

In conclusion, the path to achieving higher standards in polyurethane development is multifaceted, involving advancements in chemistry, processing technologies, and application methods. The industry's objectives are aligned with global trends towards sustainability, performance enhancement, and cost-effectiveness, driving innovation in this versatile material for the future.

Market Demand Analysis for Advanced PU

The global polyurethane (PU) market has been experiencing significant growth, driven by increasing demand across various industries. Advanced PU materials are particularly sought after due to their superior properties and versatility. The automotive sector remains a key driver, with a growing emphasis on lightweight materials for improved fuel efficiency and reduced emissions. Advanced PU foams and composites are increasingly used in vehicle interiors, seating, and structural components.

The construction industry also shows strong demand for high-performance PU materials, especially in insulation applications. As energy efficiency regulations become more stringent worldwide, there is a growing need for advanced PU insulation products that offer superior thermal performance and durability. The trend towards green building practices further amplifies this demand, with manufacturers focusing on developing eco-friendly PU formulations.

In the furniture and bedding sector, there is a rising demand for advanced PU foams that offer enhanced comfort, durability, and sustainability. Consumers are increasingly seeking products with improved ergonomics and longevity, driving innovation in PU foam technologies. The medical industry also presents significant opportunities for advanced PU materials, particularly in wound care, orthopedic devices, and medical equipment.

The electronics industry is another area of growth for advanced PU materials. With the increasing miniaturization and complexity of electronic devices, there is a growing need for PU-based encapsulants, adhesives, and coatings that offer excellent protection and thermal management properties.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for advanced PU materials, driven by rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe continue to be significant markets, with a focus on high-value, specialized applications.

The demand for sustainable and bio-based PU materials is a notable trend across all sectors. Manufacturers are investing in research and development to create PU products with reduced environmental impact, including those derived from renewable resources and those designed for easier recycling or biodegradability.

Overall, the market demand for advanced PU materials is robust and diverse, with opportunities for innovation across multiple industries. To achieve higher standards in PU development, manufacturers must focus on addressing specific industry needs while also considering broader trends such as sustainability, performance enhancement, and cost-effectiveness.

The construction industry also shows strong demand for high-performance PU materials, especially in insulation applications. As energy efficiency regulations become more stringent worldwide, there is a growing need for advanced PU insulation products that offer superior thermal performance and durability. The trend towards green building practices further amplifies this demand, with manufacturers focusing on developing eco-friendly PU formulations.

In the furniture and bedding sector, there is a rising demand for advanced PU foams that offer enhanced comfort, durability, and sustainability. Consumers are increasingly seeking products with improved ergonomics and longevity, driving innovation in PU foam technologies. The medical industry also presents significant opportunities for advanced PU materials, particularly in wound care, orthopedic devices, and medical equipment.

The electronics industry is another area of growth for advanced PU materials. With the increasing miniaturization and complexity of electronic devices, there is a growing need for PU-based encapsulants, adhesives, and coatings that offer excellent protection and thermal management properties.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for advanced PU materials, driven by rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe continue to be significant markets, with a focus on high-value, specialized applications.

The demand for sustainable and bio-based PU materials is a notable trend across all sectors. Manufacturers are investing in research and development to create PU products with reduced environmental impact, including those derived from renewable resources and those designed for easier recycling or biodegradability.

Overall, the market demand for advanced PU materials is robust and diverse, with opportunities for innovation across multiple industries. To achieve higher standards in PU development, manufacturers must focus on addressing specific industry needs while also considering broader trends such as sustainability, performance enhancement, and cost-effectiveness.

Current PU Technology Challenges

Polyurethane (PU) technology has made significant strides in recent years, yet several challenges persist in achieving higher standards of development. One of the primary obstacles is the environmental impact of traditional PU production processes. The use of isocyanates, a key component in PU synthesis, raises concerns due to their toxicity and potential health hazards. This has led to increased pressure on manufacturers to develop safer, more sustainable alternatives.

Another significant challenge lies in enhancing the performance characteristics of PU materials. While PU already offers a wide range of properties, there is a constant demand for materials with improved durability, thermal stability, and chemical resistance. Achieving these enhancements without compromising other desirable properties, such as flexibility or processability, remains a complex task for researchers and developers.

The recyclability of PU products presents another hurdle in the industry. Many PU materials, especially those used in composite structures or with complex formulations, are difficult to recycle effectively. This challenge is particularly pressing given the growing emphasis on circular economy principles and the need to reduce waste in industrial processes.

Energy efficiency in PU production is an additional area requiring improvement. Current manufacturing processes often involve high energy consumption, contributing to increased production costs and environmental impact. Developing more energy-efficient production methods without sacrificing product quality or production speed is a key challenge facing the industry.

Furthermore, the customization and tailoring of PU properties for specific applications remain complex. While PU's versatility is one of its strengths, precisely controlling and predicting material properties for diverse applications, from automotive parts to medical devices, continues to be challenging. This requires advanced formulation techniques and a deeper understanding of structure-property relationships in PU systems.

Lastly, the integration of smart and responsive functionalities into PU materials represents a frontier in PU development. Creating PU materials that can adapt to environmental stimuli or possess self-healing properties is an area of intense research. However, incorporating these advanced functionalities while maintaining the core benefits of PU materials poses significant technical challenges.

Addressing these challenges requires a multifaceted approach, combining innovations in chemistry, process engineering, and material science. It also necessitates collaboration between industry, academia, and regulatory bodies to drive sustainable and high-performance PU development forward.

Another significant challenge lies in enhancing the performance characteristics of PU materials. While PU already offers a wide range of properties, there is a constant demand for materials with improved durability, thermal stability, and chemical resistance. Achieving these enhancements without compromising other desirable properties, such as flexibility or processability, remains a complex task for researchers and developers.

The recyclability of PU products presents another hurdle in the industry. Many PU materials, especially those used in composite structures or with complex formulations, are difficult to recycle effectively. This challenge is particularly pressing given the growing emphasis on circular economy principles and the need to reduce waste in industrial processes.

Energy efficiency in PU production is an additional area requiring improvement. Current manufacturing processes often involve high energy consumption, contributing to increased production costs and environmental impact. Developing more energy-efficient production methods without sacrificing product quality or production speed is a key challenge facing the industry.

Furthermore, the customization and tailoring of PU properties for specific applications remain complex. While PU's versatility is one of its strengths, precisely controlling and predicting material properties for diverse applications, from automotive parts to medical devices, continues to be challenging. This requires advanced formulation techniques and a deeper understanding of structure-property relationships in PU systems.

Lastly, the integration of smart and responsive functionalities into PU materials represents a frontier in PU development. Creating PU materials that can adapt to environmental stimuli or possess self-healing properties is an area of intense research. However, incorporating these advanced functionalities while maintaining the core benefits of PU materials poses significant technical challenges.

Addressing these challenges requires a multifaceted approach, combining innovations in chemistry, process engineering, and material science. It also necessitates collaboration between industry, academia, and regulatory bodies to drive sustainable and high-performance PU development forward.

Current PU Development Solutions

01 Polyurethane testing and quality control standards

Standards for testing and quality control of polyurethane materials, including methods for evaluating physical properties, chemical composition, and performance characteristics. These standards ensure consistency and reliability in polyurethane products across various industries.- Polyurethane testing and quality control standards: Standards for testing and quality control of polyurethane materials are essential for ensuring consistent product performance. These standards may include methods for measuring physical properties, chemical composition, and durability of polyurethane products. They help manufacturers maintain quality and meet industry requirements.

- Polyurethane formulation and processing standards: Standards for polyurethane formulation and processing provide guidelines for the proper mixing, curing, and application of polyurethane materials. These standards ensure consistency in production processes and help achieve desired material properties. They may cover aspects such as raw material specifications, mixing ratios, and curing conditions.

- Environmental and safety standards for polyurethane: Environmental and safety standards for polyurethane address concerns related to emissions, toxicity, and disposal of polyurethane materials. These standards aim to minimize environmental impact and ensure worker safety during production and use of polyurethane products. They may include guidelines for handling, storage, and disposal of raw materials and finished products.

- Performance standards for polyurethane applications: Performance standards for polyurethane applications define the required characteristics and properties for specific uses of polyurethane materials. These standards may cover areas such as automotive parts, construction materials, or medical devices. They ensure that polyurethane products meet the necessary performance criteria for their intended applications.

- Standardization of polyurethane terminology and classification: Standards for polyurethane terminology and classification provide a common language and system for describing and categorizing polyurethane materials. These standards help improve communication within the industry and ensure consistency in product descriptions and specifications. They may include definitions of terms, classification systems based on chemical composition or physical properties, and standardized naming conventions.

02 Polyurethane formulation and processing standards

Guidelines and specifications for the formulation and processing of polyurethane materials, including raw material selection, mixing ratios, curing conditions, and manufacturing processes. These standards help optimize product performance and ensure reproducibility in production.Expand Specific Solutions03 Environmental and safety standards for polyurethane

Regulations and guidelines addressing environmental impact and safety considerations in polyurethane production and use. These standards cover aspects such as emissions control, waste management, and occupational health and safety measures in polyurethane-related industries.Expand Specific Solutions04 Polyurethane application-specific standards

Specialized standards for polyurethane applications in various industries, such as automotive, construction, and medical devices. These standards define performance requirements, durability criteria, and compatibility specifications for polyurethane materials used in specific end-use applications.Expand Specific Solutions05 Polyurethane recycling and sustainability standards

Guidelines and best practices for recycling polyurethane materials and promoting sustainability in the polyurethane industry. These standards address issues such as material recovery, circular economy principles, and life cycle assessment of polyurethane products.Expand Specific Solutions

Key Players in PU Industry

The polyurethane development landscape is characterized by a mature market with steady growth, driven by increasing demand across various industries. The global market size is substantial, with projections indicating continued expansion. Technologically, the field is in a phase of incremental innovation, with major players like BASF, Covestro, and Dow Global Technologies leading research efforts. These companies, along with others such as DuPont and Asahi Kasei, are focusing on developing more sustainable and high-performance polyurethane materials. The competitive landscape is intense, with established multinationals competing alongside emerging regional players, particularly from Asia. Key areas of technological advancement include bio-based polyurethanes, improved thermal and mechanical properties, and enhanced recyclability.

BASF Corp.

Technical Solution: BASF has developed a novel polyurethane system called Elastollan® HPM (High Performance Material). This system incorporates advanced chemical structures and processing techniques to enhance the material's mechanical properties, thermal stability, and chemical resistance. The technology involves the use of specially designed isocyanates and polyols, along with optimized chain extenders and additives. This combination results in polyurethane materials with superior tensile strength, elongation, and abrasion resistance compared to conventional polyurethanes. Additionally, BASF has implemented a proprietary mixing and curing process that ensures uniform molecular weight distribution and crosslinking, further improving the material's performance.

Strengths: Exceptional mechanical properties, improved thermal and chemical resistance, versatility in applications. Weaknesses: Potentially higher production costs, may require specialized equipment for processing.

Covestro Deutschland AG

Technical Solution: Covestro has introduced a groundbreaking technology called INSQIN® for sustainable polyurethane coating of textiles. This waterborne polyurethane technology eliminates the need for solvents in the production process, significantly reducing environmental impact. The INSQIN® system uses a unique combination of aliphatic polyurethane dispersions and crosslinkers that form a durable, flexible coating when applied to textiles. The process involves a controlled application of the waterborne polyurethane, followed by a carefully optimized curing step that ensures excellent adhesion and performance properties. This technology not only improves sustainability but also allows for more intricate designs and better quality in the final product.

Strengths: Environmentally friendly, reduced VOC emissions, improved worker safety, enables complex designs. Weaknesses: May require adaptation of existing production lines, potential limitations in certain high-performance applications.

Core PU Research Breakthroughs

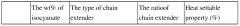

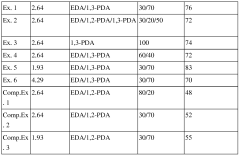

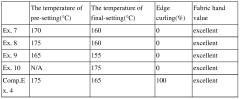

A polyurethane elastic fiber with high heat settable property

PatentWO2008016255A1

Innovation

- A process involving the reaction of polyols with excessive diisocyanate to form a prepolymer, dissolved in an organic solvent, and then reacting with a chain extender containing 1,3-diaminopropane at 40 mol% or more, along with specific additives, to produce polyurethane elastic yarns that can be heat-set at lower temperatures, preventing fiber degradation and edge curling.

Polyurethane molded body having improved tear propagation resistance and improved bending fatigue behavior

PatentActiveEP2408841A1

Innovation

- A method for producing polyurethane moldings using polyisocyanates, polyether polyols containing propylene oxide and ethylene oxide with controlled ethylene oxide content and primary OH groups, combined with chain extenders, catalysts, and optional blowing agents, to form a reaction mixture that is cured in a mold, resulting in improved mechanical properties.

Environmental Impact of PU Production

The environmental impact of polyurethane (PU) production has become a critical concern in the pursuit of higher standards in polyurethane development. As the demand for PU products continues to grow, the industry faces increasing pressure to address sustainability issues and reduce its ecological footprint.

One of the primary environmental challenges in PU production is the use of fossil fuel-based raw materials. Traditional PU manufacturing relies heavily on petroleum-derived polyols and isocyanates, contributing to resource depletion and greenhouse gas emissions. To mitigate this impact, researchers are exploring bio-based alternatives, such as plant-derived polyols from vegetable oils or recycled PET. These renewable sources not only reduce dependency on fossil fuels but also offer potential carbon sequestration benefits.

The production process itself poses significant environmental risks, particularly due to the use of volatile organic compounds (VOCs) and hazardous chemicals. Emissions from PU manufacturing can contribute to air pollution and pose health risks to workers and surrounding communities. To address this, advanced emission control technologies and closed-loop production systems are being implemented to minimize the release of harmful substances into the environment.

Water pollution is another concern in PU production, primarily from the discharge of process water containing chemical residues. Innovative wastewater treatment technologies and water recycling systems are being developed to reduce water consumption and minimize the release of pollutants into aquatic ecosystems.

The end-of-life management of PU products presents a significant environmental challenge due to their durability and resistance to degradation. Landfilling and incineration of PU waste contribute to soil and air pollution. To tackle this issue, researchers are focusing on developing more recyclable PU formulations and improving recycling technologies. Chemical recycling methods, such as glycolysis and acidolysis, show promise in breaking down PU waste into reusable raw materials.

Energy consumption during PU production is another area of environmental concern. The industry is exploring energy-efficient manufacturing processes and equipment to reduce its carbon footprint. This includes the adoption of renewable energy sources and the implementation of heat recovery systems to optimize energy use throughout the production cycle.

As the industry strives for higher standards, life cycle assessment (LCA) has become an essential tool in evaluating the environmental impact of PU products from cradle to grave. LCA studies help identify hotspots in the production chain and guide the development of more sustainable PU formulations and manufacturing processes.

One of the primary environmental challenges in PU production is the use of fossil fuel-based raw materials. Traditional PU manufacturing relies heavily on petroleum-derived polyols and isocyanates, contributing to resource depletion and greenhouse gas emissions. To mitigate this impact, researchers are exploring bio-based alternatives, such as plant-derived polyols from vegetable oils or recycled PET. These renewable sources not only reduce dependency on fossil fuels but also offer potential carbon sequestration benefits.

The production process itself poses significant environmental risks, particularly due to the use of volatile organic compounds (VOCs) and hazardous chemicals. Emissions from PU manufacturing can contribute to air pollution and pose health risks to workers and surrounding communities. To address this, advanced emission control technologies and closed-loop production systems are being implemented to minimize the release of harmful substances into the environment.

Water pollution is another concern in PU production, primarily from the discharge of process water containing chemical residues. Innovative wastewater treatment technologies and water recycling systems are being developed to reduce water consumption and minimize the release of pollutants into aquatic ecosystems.

The end-of-life management of PU products presents a significant environmental challenge due to their durability and resistance to degradation. Landfilling and incineration of PU waste contribute to soil and air pollution. To tackle this issue, researchers are focusing on developing more recyclable PU formulations and improving recycling technologies. Chemical recycling methods, such as glycolysis and acidolysis, show promise in breaking down PU waste into reusable raw materials.

Energy consumption during PU production is another area of environmental concern. The industry is exploring energy-efficient manufacturing processes and equipment to reduce its carbon footprint. This includes the adoption of renewable energy sources and the implementation of heat recovery systems to optimize energy use throughout the production cycle.

As the industry strives for higher standards, life cycle assessment (LCA) has become an essential tool in evaluating the environmental impact of PU products from cradle to grave. LCA studies help identify hotspots in the production chain and guide the development of more sustainable PU formulations and manufacturing processes.

PU Quality Control Standards

Quality control standards play a crucial role in achieving higher standards in polyurethane development. These standards ensure consistency, reliability, and performance of polyurethane products across various applications. The implementation of robust quality control measures begins with raw material selection and extends throughout the manufacturing process to the final product evaluation.

One of the primary aspects of PU quality control is the careful selection and testing of raw materials. This includes rigorous checks on the purity and composition of polyols, isocyanates, and additives. Advanced analytical techniques such as HPLC, GC-MS, and FTIR spectroscopy are employed to verify the chemical properties and detect any contaminants that could compromise the final product quality.

Process control is another critical element in maintaining high standards. This involves continuous monitoring and adjustment of reaction parameters such as temperature, pressure, and mixing ratios. Real-time data acquisition systems and statistical process control (SPC) methods are utilized to ensure that the production process remains within specified tolerances. Additionally, in-line viscosity measurements and rheological analysis help maintain consistent flow properties throughout the manufacturing process.

Physical and mechanical testing of the final polyurethane products is essential to verify compliance with industry standards and customer specifications. These tests may include tensile strength, elongation, hardness, compression set, and tear resistance. Environmental testing, such as accelerated aging and weathering simulations, is also conducted to assess long-term performance and durability.

To achieve higher standards, many manufacturers are adopting advanced quality management systems like Six Sigma and Lean Manufacturing principles. These methodologies focus on reducing variability, eliminating defects, and continuously improving processes. Implementation of these systems often involves extensive employee training, establishment of quality circles, and regular audits to ensure adherence to best practices.

Traceability is becoming increasingly important in polyurethane quality control. Advanced lot tracking systems and digital record-keeping allow manufacturers to trace any quality issues back to specific batches or even individual components. This capability not only aids in problem-solving but also supports compliance with regulatory requirements in industries such as automotive and medical device manufacturing.

As sustainability becomes a greater concern, quality control standards are expanding to include environmental and health considerations. This includes monitoring and reducing volatile organic compound (VOC) emissions, ensuring compliance with REACH regulations, and developing safer alternatives to potentially harmful additives. These evolving standards are driving innovation in green chemistry and eco-friendly polyurethane formulations.

One of the primary aspects of PU quality control is the careful selection and testing of raw materials. This includes rigorous checks on the purity and composition of polyols, isocyanates, and additives. Advanced analytical techniques such as HPLC, GC-MS, and FTIR spectroscopy are employed to verify the chemical properties and detect any contaminants that could compromise the final product quality.

Process control is another critical element in maintaining high standards. This involves continuous monitoring and adjustment of reaction parameters such as temperature, pressure, and mixing ratios. Real-time data acquisition systems and statistical process control (SPC) methods are utilized to ensure that the production process remains within specified tolerances. Additionally, in-line viscosity measurements and rheological analysis help maintain consistent flow properties throughout the manufacturing process.

Physical and mechanical testing of the final polyurethane products is essential to verify compliance with industry standards and customer specifications. These tests may include tensile strength, elongation, hardness, compression set, and tear resistance. Environmental testing, such as accelerated aging and weathering simulations, is also conducted to assess long-term performance and durability.

To achieve higher standards, many manufacturers are adopting advanced quality management systems like Six Sigma and Lean Manufacturing principles. These methodologies focus on reducing variability, eliminating defects, and continuously improving processes. Implementation of these systems often involves extensive employee training, establishment of quality circles, and regular audits to ensure adherence to best practices.

Traceability is becoming increasingly important in polyurethane quality control. Advanced lot tracking systems and digital record-keeping allow manufacturers to trace any quality issues back to specific batches or even individual components. This capability not only aids in problem-solving but also supports compliance with regulatory requirements in industries such as automotive and medical device manufacturing.

As sustainability becomes a greater concern, quality control standards are expanding to include environmental and health considerations. This includes monitoring and reducing volatile organic compound (VOC) emissions, ensuring compliance with REACH regulations, and developing safer alternatives to potentially harmful additives. These evolving standards are driving innovation in green chemistry and eco-friendly polyurethane formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!