How to Advance Magnetron Transient Response Measurements

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Transient Response Measurement Background and Objectives

Magnetron technology has evolved significantly since its invention in the early 20th century, becoming a cornerstone of microwave generation systems in various applications ranging from radar systems to industrial heating and medical equipment. The transient response characteristics of magnetrons—how they behave during power-up, power-down, and rapid load changes—have become increasingly critical as applications demand greater precision and reliability. Understanding these transient behaviors is essential for optimizing performance, extending device lifespan, and ensuring operational safety across diverse operational environments.

Historically, magnetron transient response measurements have been limited by instrumentation capabilities, often relying on simplified models that fail to capture the complex electromagnetic interactions during transitional states. The evolution of measurement techniques has progressed from basic oscilloscope readings to more sophisticated spectrum analysis, yet significant gaps remain in real-time high-resolution monitoring of transient phenomena.

The primary objective of advancing magnetron transient response measurements is to develop comprehensive methodologies that can accurately characterize the dynamic behavior of magnetrons across their operational spectrum. This includes capturing microsecond-level variations in frequency, phase, and amplitude during state transitions, which are crucial for applications requiring precise energy delivery or signal integrity.

Recent technological advancements in high-speed data acquisition systems, coupled with machine learning algorithms for signal processing, have opened new possibilities for enhancing measurement precision. These developments coincide with increasing industry demands for magnetrons with more predictable behavior in variable load conditions, particularly in medical applications where precise energy delivery is paramount.

Current research trends indicate a shift toward integrated measurement systems that combine traditional RF measurement techniques with advanced computational models to predict and analyze transient behaviors. This integration represents a significant departure from conventional approaches that treated steady-state and transient behaviors as separate domains of analysis.

The global research landscape shows concentrated efforts in regions with strong electronics manufacturing bases, particularly in East Asia, North America, and Europe. Academic institutions and industrial R&D centers are increasingly collaborating on standardizing measurement protocols to facilitate cross-platform comparisons and accelerate technological improvements.

Achieving breakthrough advancements in this field requires addressing fundamental challenges in sensor technology, data processing algorithms, and theoretical modeling of non-linear electromagnetic interactions. Success in these endeavors would significantly impact the design and application of next-generation microwave systems across multiple industries.

Historically, magnetron transient response measurements have been limited by instrumentation capabilities, often relying on simplified models that fail to capture the complex electromagnetic interactions during transitional states. The evolution of measurement techniques has progressed from basic oscilloscope readings to more sophisticated spectrum analysis, yet significant gaps remain in real-time high-resolution monitoring of transient phenomena.

The primary objective of advancing magnetron transient response measurements is to develop comprehensive methodologies that can accurately characterize the dynamic behavior of magnetrons across their operational spectrum. This includes capturing microsecond-level variations in frequency, phase, and amplitude during state transitions, which are crucial for applications requiring precise energy delivery or signal integrity.

Recent technological advancements in high-speed data acquisition systems, coupled with machine learning algorithms for signal processing, have opened new possibilities for enhancing measurement precision. These developments coincide with increasing industry demands for magnetrons with more predictable behavior in variable load conditions, particularly in medical applications where precise energy delivery is paramount.

Current research trends indicate a shift toward integrated measurement systems that combine traditional RF measurement techniques with advanced computational models to predict and analyze transient behaviors. This integration represents a significant departure from conventional approaches that treated steady-state and transient behaviors as separate domains of analysis.

The global research landscape shows concentrated efforts in regions with strong electronics manufacturing bases, particularly in East Asia, North America, and Europe. Academic institutions and industrial R&D centers are increasingly collaborating on standardizing measurement protocols to facilitate cross-platform comparisons and accelerate technological improvements.

Achieving breakthrough advancements in this field requires addressing fundamental challenges in sensor technology, data processing algorithms, and theoretical modeling of non-linear electromagnetic interactions. Success in these endeavors would significantly impact the design and application of next-generation microwave systems across multiple industries.

Market Applications and Demand Analysis for Advanced Magnetron Measurements

The global magnetron market is experiencing significant growth, driven by increasing applications in various industries beyond traditional microwave ovens. The market was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2028, with a compound annual growth rate of 6.7%. This growth underscores the expanding demand for advanced magnetron measurement technologies, particularly those focused on transient response characteristics.

The defense and aerospace sectors represent the largest market segment for advanced magnetron measurements, accounting for nearly 35% of the total demand. In these applications, precise characterization of magnetron transient behavior is critical for radar systems, electronic warfare equipment, and satellite communications. Military-grade systems require magnetrons with highly predictable and stable performance under varying operational conditions, driving the need for sophisticated measurement solutions.

Medical equipment manufacturers constitute another significant market segment, particularly for radiation therapy and medical imaging devices. These applications demand magnetrons with extremely precise power output and frequency stability, where even minor transient anomalies can impact treatment efficacy or diagnostic accuracy. The healthcare magnetron market segment is growing at 8.2% annually, faster than the overall market.

Industrial processing applications, including material processing, plasma generation, and industrial heating, represent approximately 25% of the market demand for advanced magnetron measurements. In these contexts, understanding transient responses is essential for process optimization, energy efficiency, and equipment longevity. Manufacturers in this segment are increasingly seeking measurement solutions that can operate in harsh industrial environments while providing real-time data.

Research institutions and semiconductor fabrication facilities form a smaller but rapidly growing market segment, with particular interest in magnetron sputtering applications. This segment demands the highest precision in transient response measurements for developing next-generation thin-film deposition processes and materials research.

Geographically, North America leads the market for advanced magnetron measurement technologies (38%), followed by Asia-Pacific (32%) and Europe (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.3% annually, driven by expanding manufacturing capabilities and increasing R&D investments in China, Japan, and South Korea.

Customer requirements across these segments consistently emphasize several key factors: measurement accuracy in the nanosecond range, real-time monitoring capabilities, integration with existing systems, and comprehensive data analysis tools. Additionally, there is growing demand for portable measurement solutions that can be deployed in field conditions, particularly from defense contractors and maintenance service providers.

The defense and aerospace sectors represent the largest market segment for advanced magnetron measurements, accounting for nearly 35% of the total demand. In these applications, precise characterization of magnetron transient behavior is critical for radar systems, electronic warfare equipment, and satellite communications. Military-grade systems require magnetrons with highly predictable and stable performance under varying operational conditions, driving the need for sophisticated measurement solutions.

Medical equipment manufacturers constitute another significant market segment, particularly for radiation therapy and medical imaging devices. These applications demand magnetrons with extremely precise power output and frequency stability, where even minor transient anomalies can impact treatment efficacy or diagnostic accuracy. The healthcare magnetron market segment is growing at 8.2% annually, faster than the overall market.

Industrial processing applications, including material processing, plasma generation, and industrial heating, represent approximately 25% of the market demand for advanced magnetron measurements. In these contexts, understanding transient responses is essential for process optimization, energy efficiency, and equipment longevity. Manufacturers in this segment are increasingly seeking measurement solutions that can operate in harsh industrial environments while providing real-time data.

Research institutions and semiconductor fabrication facilities form a smaller but rapidly growing market segment, with particular interest in magnetron sputtering applications. This segment demands the highest precision in transient response measurements for developing next-generation thin-film deposition processes and materials research.

Geographically, North America leads the market for advanced magnetron measurement technologies (38%), followed by Asia-Pacific (32%) and Europe (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.3% annually, driven by expanding manufacturing capabilities and increasing R&D investments in China, Japan, and South Korea.

Customer requirements across these segments consistently emphasize several key factors: measurement accuracy in the nanosecond range, real-time monitoring capabilities, integration with existing systems, and comprehensive data analysis tools. Additionally, there is growing demand for portable measurement solutions that can be deployed in field conditions, particularly from defense contractors and maintenance service providers.

Current Challenges in Magnetron Transient Response Measurement

Despite significant advancements in magnetron technology, the measurement of transient response characteristics continues to present substantial challenges for researchers and engineers. Current measurement systems struggle with capturing the rapid changes in magnetron behavior during startup, shutdown, and power modulation phases. The primary limitation lies in the insufficient temporal resolution of conventional measurement equipment, which fails to accurately record phenomena occurring in the nanosecond to microsecond range.

Traditional oscilloscope-based measurements often introduce signal distortion due to impedance mismatching between the measurement system and the magnetron's output circuit. This impedance mismatch creates reflections and standing waves that contaminate the measurement data, making it difficult to distinguish between actual magnetron behavior and measurement artifacts.

Another significant challenge is the electromagnetic interference (EMI) generated by the magnetron itself. The high-power microwave radiation can couple into measurement cables and equipment, introducing noise and further degrading measurement accuracy. Current shielding techniques provide inadequate protection, particularly when attempting to measure subtle transient effects.

The harsh operating environment of magnetrons presents additional complications. High voltage, strong magnetic fields, and elevated temperatures can affect the performance and reliability of measurement sensors placed in proximity to the device. Existing temperature-compensated sensors often lack the necessary bandwidth to capture rapid transient events while maintaining calibration accuracy.

Data acquisition systems face bandwidth limitations when attempting to capture the full spectrum of transient behaviors. Most commercial systems sacrifice either sampling rate or bit depth, resulting in either temporal resolution loss or amplitude quantization errors that mask important transient features. The trade-off between sampling rate and dynamic range remains a significant bottleneck.

Calibration procedures for transient measurements lack standardization across the industry. Different laboratories employ varying methodologies, making it difficult to compare results between research groups. The absence of traceable calibration standards specifically designed for magnetron transient measurements further complicates the establishment of reliable measurement protocols.

Software analysis tools for processing transient response data remain underdeveloped. Current algorithms struggle to separate signal from noise and often fail to identify subtle but important features in the transient response. The lack of sophisticated signal processing techniques specifically optimized for magnetron transient analysis limits the extraction of meaningful insights from measurement data.

Traditional oscilloscope-based measurements often introduce signal distortion due to impedance mismatching between the measurement system and the magnetron's output circuit. This impedance mismatch creates reflections and standing waves that contaminate the measurement data, making it difficult to distinguish between actual magnetron behavior and measurement artifacts.

Another significant challenge is the electromagnetic interference (EMI) generated by the magnetron itself. The high-power microwave radiation can couple into measurement cables and equipment, introducing noise and further degrading measurement accuracy. Current shielding techniques provide inadequate protection, particularly when attempting to measure subtle transient effects.

The harsh operating environment of magnetrons presents additional complications. High voltage, strong magnetic fields, and elevated temperatures can affect the performance and reliability of measurement sensors placed in proximity to the device. Existing temperature-compensated sensors often lack the necessary bandwidth to capture rapid transient events while maintaining calibration accuracy.

Data acquisition systems face bandwidth limitations when attempting to capture the full spectrum of transient behaviors. Most commercial systems sacrifice either sampling rate or bit depth, resulting in either temporal resolution loss or amplitude quantization errors that mask important transient features. The trade-off between sampling rate and dynamic range remains a significant bottleneck.

Calibration procedures for transient measurements lack standardization across the industry. Different laboratories employ varying methodologies, making it difficult to compare results between research groups. The absence of traceable calibration standards specifically designed for magnetron transient measurements further complicates the establishment of reliable measurement protocols.

Software analysis tools for processing transient response data remain underdeveloped. Current algorithms struggle to separate signal from noise and often fail to identify subtle but important features in the transient response. The lack of sophisticated signal processing techniques specifically optimized for magnetron transient analysis limits the extraction of meaningful insights from measurement data.

State-of-the-Art Measurement Methodologies and Instrumentation

01 Magnetron power control and stabilization

Various techniques are employed to control and stabilize magnetron power output during transient conditions. These include feedback control systems that monitor output parameters and adjust power accordingly, specialized circuits for maintaining stable operation during startup and load changes, and methods to prevent oscillations or instability in the magnetron's response to rapid changes in operating conditions.- Magnetron power control and stabilization: Various techniques for controlling and stabilizing magnetron power output during transient conditions. These include feedback control systems that monitor and adjust power levels to maintain stability during startup, load changes, and other transient events. Advanced control algorithms compensate for variations in input voltage, temperature, and load impedance to ensure consistent magnetron performance and prevent damage from power fluctuations.

- Transient response measurement and analysis: Methods and systems for measuring and analyzing the transient response characteristics of magnetrons. These include specialized test equipment and procedures to evaluate how magnetrons respond to sudden changes in operating conditions. The measurement techniques capture key parameters such as rise time, settling time, overshoot, and frequency stability during transient events, providing essential data for optimizing magnetron design and operation.

- Protection circuits for magnetron transients: Protective circuitry designed to shield magnetrons from harmful transient events. These circuits detect abnormal conditions such as voltage spikes, current surges, or impedance mismatches and take corrective action to prevent damage. Protection mechanisms include crowbar circuits, soft-start capabilities, and intelligent shutdown systems that respond to potentially damaging transient conditions before they can harm the magnetron or associated components.

- Digital control systems for transient management: Advanced digital control architectures that manage magnetron transient response through computational methods. These systems employ digital signal processors, microcontrollers, or FPGAs to implement sophisticated control algorithms that predict and compensate for transient behavior. The digital approach allows for adaptive control strategies that can be optimized for different operating conditions and can implement complex responses to various transient scenarios.

- Magnetron circuit design for improved transient response: Innovative circuit designs specifically engineered to enhance magnetron transient response characteristics. These include specialized power supply configurations, novel filtering techniques, and impedance matching networks that minimize the impact of transient events. The circuit designs focus on maintaining stable operation during rapid changes in operating conditions, reducing settling time after disturbances, and ensuring consistent output during dynamic load conditions.

02 Transient response measurement and analysis

Systems and methods for measuring and analyzing the transient response characteristics of magnetrons are essential for understanding their behavior under dynamic conditions. These include specialized test equipment, signal processing techniques for capturing fast transient events, and analytical models that can predict magnetron performance during state transitions. Such measurements help in optimizing magnetron design and operation.Expand Specific Solutions03 Protection circuits for magnetron transients

Protection circuits are implemented to safeguard magnetrons and associated components from harmful transient events. These include surge protection devices, current limiting circuits, and rapid shutdown mechanisms that activate when abnormal transient conditions are detected. Such protection is critical for preventing damage to the magnetron and extending its operational lifespan during power fluctuations or load changes.Expand Specific Solutions04 Magnetron startup and shutdown optimization

Specialized techniques are developed to optimize the startup and shutdown sequences of magnetrons to manage transient responses during these critical phases. These include controlled ramp-up procedures, soft-start circuits, and sequential power application methods that minimize stress on components. Proper management of these transitions helps prevent damage and ensures consistent performance over the magnetron's lifetime.Expand Specific Solutions05 Digital control systems for magnetron transient management

Advanced digital control systems are implemented to manage magnetron transient responses with greater precision. These include microprocessor-based controllers, digital signal processing algorithms, and adaptive control systems that can respond to changing conditions in real-time. Such systems enable more sophisticated transient management strategies compared to traditional analog approaches, resulting in improved stability and performance.Expand Specific Solutions

Leading Organizations and Research Institutions in Magnetron Technology

The magnetron transient response measurement technology landscape is currently in a growth phase, with increasing market demand driven by applications in radar, communications, and medical imaging. The market is expected to reach significant scale as industries adopt more sophisticated measurement techniques. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include research institutions like Helmholtz-Zentrum Berlin and Tsinghua University advancing fundamental research, while companies such as Honeywell International, Robert Bosch, and Huawei Technologies focus on practical applications. MediaTek and TDK are developing specialized measurement solutions, while Rosatom and United Imaging Healthcare are exploring applications in energy and medical sectors respectively. The competitive landscape features collaboration between academic institutions and industrial players to overcome technical challenges in high-frequency transient measurements.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a comprehensive magnetron transient response measurement system that integrates high-speed data acquisition with advanced signal processing capabilities. Their technology employs specialized RF sensors with minimal loading effect on the magnetron circuit, ensuring measurements accurately represent actual operating conditions. The system features simultaneous multi-parameter acquisition, capturing voltage, current, RF power, and frequency data with precise time synchronization. Honeywell's approach includes proprietary algorithms for transient analysis that can identify subtle anomalies in startup behavior that might indicate potential reliability issues. Their measurement platform incorporates automated calibration procedures that ensure measurement accuracy is maintained over time and across different test setups. The system also features an intuitive user interface that simplifies complex measurement tasks, making advanced magnetron characterization accessible to a broader range of engineers and technicians. Additionally, Honeywell has implemented cloud connectivity options that enable remote monitoring and collaborative analysis of magnetron performance data.

Strengths: Excellent measurement accuracy with minimal circuit loading; comprehensive automated calibration capabilities; user-friendly interface reducing training requirements. Weakness: Less customizable than some competing systems; higher recurring costs due to software licensing model; limited compatibility with legacy magnetron test fixtures.

Bruker BioSpin MRI GmbH

Technical Solution: Bruker BioSpin MRI GmbH has developed advanced magnetron transient response measurement systems that integrate high-precision digital sampling oscilloscopes with specialized RF probes. Their technology employs time-domain reflectometry (TDR) techniques to capture magnetron startup characteristics with nanosecond resolution. The system features real-time monitoring capabilities that allow for continuous assessment of magnetron performance during operation, particularly focusing on the critical startup phase where transient behaviors are most pronounced. Bruker's solution incorporates proprietary signal processing algorithms that filter noise while preserving important transient features, enabling researchers to identify subtle changes in magnetron behavior that might indicate degradation or performance issues. Their measurement platform also includes temperature-controlled test environments to ensure consistent and reproducible measurements across different operating conditions.

Strengths: Superior temporal resolution allowing capture of ultra-fast transient phenomena; integrated environmental control systems for highly reproducible measurements; advanced signal processing capabilities for noise reduction. Weakness: High system complexity requiring specialized training; significant cost compared to conventional measurement approaches; limited portability for field measurements.

Critical Patents and Research in Transient Response Measurement

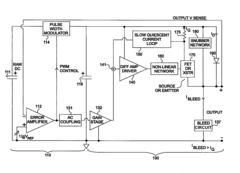

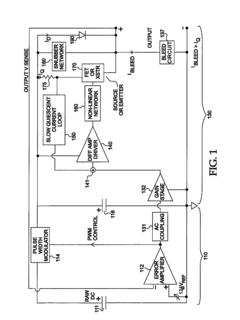

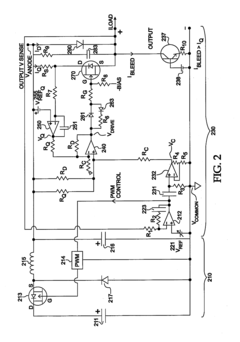

Transient response device, having parallel connected diode and transistor, for improving transient response of power supply

PatentActiveUS8461818B1

Innovation

- A transient response circuit is connected in series with the output stage of the power supply, comprising a diode and a source follower transistor that selectively bypasses the diode's voltage drop during transient periods, allowing the power supply to quickly increase output voltage by removing the diode's forward voltage drop.

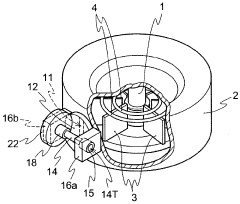

Method for varying oscillation frequency of high-frequency oscillator

PatentWO2012176293A1

Innovation

- A method involving a switch element with a metal plate that reflects high frequencies, coupled electromagnetically to the cavity resonator, allowing for a wide range of oscillation frequency changes by applying a bias voltage without mechanical parts, reducing the influence of switch element characteristics and mounting accuracy.

Standardization and Calibration Protocols for Measurement Accuracy

To establish reliable and reproducible magnetron transient response measurements, standardized protocols and calibration methodologies are essential. Current measurement practices often vary significantly between laboratories, resulting in inconsistent data that hinders technological advancement and cross-validation of research findings. A comprehensive standardization framework must address multiple aspects of the measurement process.

Calibration of measurement equipment represents the foundation of accurate transient response analysis. This includes regular calibration of oscilloscopes, spectrum analyzers, and network analyzers against traceable standards. For high-frequency measurements typical in magnetron applications, calibration should account for cable losses, connector mismatches, and impedance variations that can significantly distort transient signals.

Reference standards specifically designed for magnetron transient response validation are currently lacking in the industry. Development of standardized reference magnetrons with well-characterized transient behaviors would provide a common benchmark for measurement system verification. These reference devices should exhibit reproducible turn-on characteristics, frequency-pulling behaviors, and mode-switching transients across a range of operating conditions.

Environmental factors significantly impact measurement accuracy and must be controlled within standardized protocols. Temperature variations can alter magnetron performance characteristics, while electromagnetic interference can corrupt sensitive transient measurements. Standardized protocols should specify acceptable environmental parameters including temperature range (typically 22±2°C), humidity limits, and minimum electromagnetic shielding requirements.

Measurement sequence and timing considerations require explicit standardization. The precise timing of voltage application, current measurement, and RF output monitoring must follow consistent procedures. Protocols should define warm-up periods, sampling rates, trigger thresholds, and measurement durations to ensure comparable results across different research facilities.

Data processing methodologies represent another critical area requiring standardization. Raw transient response data typically requires filtering, normalization, and statistical analysis. Standardized algorithms for noise reduction, feature extraction, and uncertainty quantification would significantly improve measurement reproducibility and facilitate meaningful comparison between different research groups.

Interlaboratory comparison programs would validate the effectiveness of standardization efforts. Regular round-robin testing using identical magnetron samples would identify systematic measurement biases and refine calibration protocols. Such collaborative efforts would accelerate the development of industry-wide measurement standards and improve overall measurement accuracy in magnetron transient response characterization.

Calibration of measurement equipment represents the foundation of accurate transient response analysis. This includes regular calibration of oscilloscopes, spectrum analyzers, and network analyzers against traceable standards. For high-frequency measurements typical in magnetron applications, calibration should account for cable losses, connector mismatches, and impedance variations that can significantly distort transient signals.

Reference standards specifically designed for magnetron transient response validation are currently lacking in the industry. Development of standardized reference magnetrons with well-characterized transient behaviors would provide a common benchmark for measurement system verification. These reference devices should exhibit reproducible turn-on characteristics, frequency-pulling behaviors, and mode-switching transients across a range of operating conditions.

Environmental factors significantly impact measurement accuracy and must be controlled within standardized protocols. Temperature variations can alter magnetron performance characteristics, while electromagnetic interference can corrupt sensitive transient measurements. Standardized protocols should specify acceptable environmental parameters including temperature range (typically 22±2°C), humidity limits, and minimum electromagnetic shielding requirements.

Measurement sequence and timing considerations require explicit standardization. The precise timing of voltage application, current measurement, and RF output monitoring must follow consistent procedures. Protocols should define warm-up periods, sampling rates, trigger thresholds, and measurement durations to ensure comparable results across different research facilities.

Data processing methodologies represent another critical area requiring standardization. Raw transient response data typically requires filtering, normalization, and statistical analysis. Standardized algorithms for noise reduction, feature extraction, and uncertainty quantification would significantly improve measurement reproducibility and facilitate meaningful comparison between different research groups.

Interlaboratory comparison programs would validate the effectiveness of standardization efforts. Regular round-robin testing using identical magnetron samples would identify systematic measurement biases and refine calibration protocols. Such collaborative efforts would accelerate the development of industry-wide measurement standards and improve overall measurement accuracy in magnetron transient response characterization.

Environmental and Safety Considerations in Magnetron Testing

Magnetron testing environments present unique safety challenges due to the combination of high voltage, microwave radiation, and thermal considerations. Laboratory settings must maintain strict electromagnetic compatibility (EMC) standards to prevent interference with measurement equipment and ensure accurate transient response data. Testing facilities require specialized shielding with attenuation capabilities exceeding 80dB across operational frequency ranges, particularly important when measuring rapid state transitions in magnetrons.

Temperature control represents a critical environmental factor, as magnetron performance characteristics vary significantly with thermal conditions. Advanced testing protocols now incorporate temperature-controlled chambers maintaining ±0.5°C stability to ensure reproducible transient response measurements. This precision becomes particularly important when characterizing magnetron startup behavior and frequency pulling effects under varying thermal loads.

Radiation safety protocols must address both ionizing and non-ionizing radiation risks. Modern magnetron testing facilities implement multi-layered safety systems including physical barriers, interlocks, and real-time monitoring equipment. Personnel exposure monitoring has evolved from basic dosimetry to comprehensive systems tracking cumulative exposure across multiple parameters, with automated shutdown mechanisms when predetermined thresholds are approached.

High-voltage safety considerations remain paramount, with testing environments now implementing isolated ground systems, redundant emergency shutdown capabilities, and specialized insulation monitoring. The transient nature of magnetron operation creates additional safety challenges during measurement, as voltage spikes during state transitions can exceed steady-state levels by significant margins, necessitating robust protection systems with response times under 10 microseconds.

Environmental sustainability has emerged as an additional consideration in magnetron testing facilities. Water cooling systems, often essential for high-power magnetron testing, now incorporate closed-loop designs with minimal environmental impact. Energy recovery systems capture and repurpose waste heat, reducing the overall environmental footprint of extended testing operations.

Acoustic considerations have gained increased attention, particularly for high-power industrial magnetrons where operational noise can exceed 85dB. Testing environments now incorporate acoustic dampening materials and monitoring systems to protect personnel during extended measurement sessions, especially important when characterizing long-duration transient responses.

The integration of these environmental and safety considerations into magnetron testing protocols has significantly advanced measurement capabilities, allowing researchers to characterize transient responses under increasingly realistic operational conditions while maintaining stringent safety standards.

Temperature control represents a critical environmental factor, as magnetron performance characteristics vary significantly with thermal conditions. Advanced testing protocols now incorporate temperature-controlled chambers maintaining ±0.5°C stability to ensure reproducible transient response measurements. This precision becomes particularly important when characterizing magnetron startup behavior and frequency pulling effects under varying thermal loads.

Radiation safety protocols must address both ionizing and non-ionizing radiation risks. Modern magnetron testing facilities implement multi-layered safety systems including physical barriers, interlocks, and real-time monitoring equipment. Personnel exposure monitoring has evolved from basic dosimetry to comprehensive systems tracking cumulative exposure across multiple parameters, with automated shutdown mechanisms when predetermined thresholds are approached.

High-voltage safety considerations remain paramount, with testing environments now implementing isolated ground systems, redundant emergency shutdown capabilities, and specialized insulation monitoring. The transient nature of magnetron operation creates additional safety challenges during measurement, as voltage spikes during state transitions can exceed steady-state levels by significant margins, necessitating robust protection systems with response times under 10 microseconds.

Environmental sustainability has emerged as an additional consideration in magnetron testing facilities. Water cooling systems, often essential for high-power magnetron testing, now incorporate closed-loop designs with minimal environmental impact. Energy recovery systems capture and repurpose waste heat, reducing the overall environmental footprint of extended testing operations.

Acoustic considerations have gained increased attention, particularly for high-power industrial magnetrons where operational noise can exceed 85dB. Testing environments now incorporate acoustic dampening materials and monitoring systems to protect personnel during extended measurement sessions, especially important when characterizing long-duration transient responses.

The integration of these environmental and safety considerations into magnetron testing protocols has significantly advanced measurement capabilities, allowing researchers to characterize transient responses under increasingly realistic operational conditions while maintaining stringent safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!