How to Minimize Magnetron RF Crosstalk Issues in Circuits

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron RF Crosstalk Background and Objectives

Magnetron RF crosstalk represents a significant challenge in modern electronic circuit design, particularly in high-frequency applications where signal integrity is paramount. The phenomenon emerged as a critical concern in the mid-1980s with the proliferation of compact electronic devices operating at increasingly higher frequencies. As circuit densities have increased and operating frequencies have pushed into the gigahertz range, the problems associated with RF crosstalk have become more pronounced and complex.

Historically, magnetron RF crosstalk issues evolved from simple interference patterns in early radar systems to becoming a fundamental design consideration in contemporary integrated circuits. The progression of wireless technologies, satellite communications, and high-speed computing has accelerated the need for effective crosstalk mitigation strategies. This evolution has been marked by significant technological milestones, including the development of advanced shielding materials, innovative circuit layout techniques, and sophisticated simulation tools.

The primary objective of addressing magnetron RF crosstalk is to maintain signal integrity while maximizing circuit density and performance. This involves developing comprehensive strategies that can effectively isolate RF signals, minimize electromagnetic interference, and prevent unintended coupling between adjacent circuit elements. The goal extends beyond mere interference reduction to enabling the next generation of high-performance, compact electronic systems.

Current technological trends indicate a move toward integrated solutions that combine physical design considerations with active compensation techniques. The industry is witnessing a convergence of traditional RF engineering principles with advanced materials science and computational modeling approaches. This multidisciplinary approach reflects the complexity of the challenge and the sophistication required in modern solutions.

The scope of magnetron RF crosstalk mitigation encompasses various technical domains, including PCB design, component selection, grounding schemes, and system architecture. Each domain contributes unique perspectives and solutions to the overall challenge, necessitating a holistic approach to the problem. The interplay between these domains creates both challenges and opportunities for innovation.

Looking forward, the trajectory of this technology area points toward more sophisticated analytical methods, predictive modeling capabilities, and adaptive mitigation techniques. As electronic devices continue to shrink while operating at higher frequencies, the importance of effective crosstalk management will only increase. The ultimate technical objective remains the development of standardized, scalable approaches that can be applied across diverse electronic systems to ensure optimal performance in increasingly demanding applications.

Historically, magnetron RF crosstalk issues evolved from simple interference patterns in early radar systems to becoming a fundamental design consideration in contemporary integrated circuits. The progression of wireless technologies, satellite communications, and high-speed computing has accelerated the need for effective crosstalk mitigation strategies. This evolution has been marked by significant technological milestones, including the development of advanced shielding materials, innovative circuit layout techniques, and sophisticated simulation tools.

The primary objective of addressing magnetron RF crosstalk is to maintain signal integrity while maximizing circuit density and performance. This involves developing comprehensive strategies that can effectively isolate RF signals, minimize electromagnetic interference, and prevent unintended coupling between adjacent circuit elements. The goal extends beyond mere interference reduction to enabling the next generation of high-performance, compact electronic systems.

Current technological trends indicate a move toward integrated solutions that combine physical design considerations with active compensation techniques. The industry is witnessing a convergence of traditional RF engineering principles with advanced materials science and computational modeling approaches. This multidisciplinary approach reflects the complexity of the challenge and the sophistication required in modern solutions.

The scope of magnetron RF crosstalk mitigation encompasses various technical domains, including PCB design, component selection, grounding schemes, and system architecture. Each domain contributes unique perspectives and solutions to the overall challenge, necessitating a holistic approach to the problem. The interplay between these domains creates both challenges and opportunities for innovation.

Looking forward, the trajectory of this technology area points toward more sophisticated analytical methods, predictive modeling capabilities, and adaptive mitigation techniques. As electronic devices continue to shrink while operating at higher frequencies, the importance of effective crosstalk management will only increase. The ultimate technical objective remains the development of standardized, scalable approaches that can be applied across diverse electronic systems to ensure optimal performance in increasingly demanding applications.

Market Demand for Low-Interference RF Circuit Solutions

The global market for low-interference RF circuit solutions has been experiencing robust growth, driven primarily by the increasing deployment of wireless communication systems across various industries. As devices become more compact and complex, the demand for effective solutions to minimize magnetron RF crosstalk issues has become increasingly critical for maintaining signal integrity and overall system performance.

The telecommunications sector represents the largest market segment, with an estimated demand growth rate outpacing the broader electronics industry. Network infrastructure providers are actively seeking advanced solutions to address RF interference challenges in 5G deployments, where higher frequencies and denser network architectures exacerbate crosstalk problems. This segment's demand is particularly focused on solutions that can be implemented in small cell deployments and massive MIMO systems.

Consumer electronics manufacturers constitute another significant market driver, as smartphones, tablets, and wearable devices continue to integrate multiple wireless technologies within increasingly confined spaces. These manufacturers face mounting pressure to maintain performance standards while reducing device footprints, creating substantial demand for innovative crosstalk mitigation technologies.

The automotive industry has emerged as a rapidly expanding market for low-interference RF solutions, particularly with the advancement of connected and autonomous vehicles. Modern vehicles incorporate numerous wireless systems—from navigation and entertainment to safety-critical driver assistance features—all requiring reliable RF performance in electromagnetically challenging environments.

Defense and aerospace applications represent a premium segment of the market, where performance requirements are exceptionally stringent and reliability is paramount. These sectors are willing to invest in advanced solutions that offer superior crosstalk mitigation, even at higher implementation costs.

Medical device manufacturers have also become significant consumers of RF interference mitigation technologies, as wireless connectivity becomes increasingly integrated into diagnostic and therapeutic equipment. The critical nature of these applications drives demand for solutions with exceptional reliability and performance characteristics.

Market analysis indicates that solutions offering comprehensive approaches—combining innovative circuit design, advanced materials, and intelligent signal processing—command premium pricing and are gaining market share. Industry surveys reveal that engineering teams are increasingly prioritizing RF interference mitigation earlier in the design process rather than addressing it as an aftermarket concern.

Regional market distribution shows North America and Asia-Pacific leading in demand, with Europe following closely. The Asia-Pacific region, particularly China, South Korea, and Taiwan, is expected to show the strongest growth trajectory due to their expanding electronics manufacturing base and telecommunications infrastructure development.

The telecommunications sector represents the largest market segment, with an estimated demand growth rate outpacing the broader electronics industry. Network infrastructure providers are actively seeking advanced solutions to address RF interference challenges in 5G deployments, where higher frequencies and denser network architectures exacerbate crosstalk problems. This segment's demand is particularly focused on solutions that can be implemented in small cell deployments and massive MIMO systems.

Consumer electronics manufacturers constitute another significant market driver, as smartphones, tablets, and wearable devices continue to integrate multiple wireless technologies within increasingly confined spaces. These manufacturers face mounting pressure to maintain performance standards while reducing device footprints, creating substantial demand for innovative crosstalk mitigation technologies.

The automotive industry has emerged as a rapidly expanding market for low-interference RF solutions, particularly with the advancement of connected and autonomous vehicles. Modern vehicles incorporate numerous wireless systems—from navigation and entertainment to safety-critical driver assistance features—all requiring reliable RF performance in electromagnetically challenging environments.

Defense and aerospace applications represent a premium segment of the market, where performance requirements are exceptionally stringent and reliability is paramount. These sectors are willing to invest in advanced solutions that offer superior crosstalk mitigation, even at higher implementation costs.

Medical device manufacturers have also become significant consumers of RF interference mitigation technologies, as wireless connectivity becomes increasingly integrated into diagnostic and therapeutic equipment. The critical nature of these applications drives demand for solutions with exceptional reliability and performance characteristics.

Market analysis indicates that solutions offering comprehensive approaches—combining innovative circuit design, advanced materials, and intelligent signal processing—command premium pricing and are gaining market share. Industry surveys reveal that engineering teams are increasingly prioritizing RF interference mitigation earlier in the design process rather than addressing it as an aftermarket concern.

Regional market distribution shows North America and Asia-Pacific leading in demand, with Europe following closely. The Asia-Pacific region, particularly China, South Korea, and Taiwan, is expected to show the strongest growth trajectory due to their expanding electronics manufacturing base and telecommunications infrastructure development.

Current Challenges in Magnetron RF Isolation

Magnetron RF isolation presents significant challenges in modern circuit design, particularly as electronic devices continue to shrink while operating at higher frequencies. The fundamental issue stems from the inherent nature of magnetrons as powerful RF energy sources, which can generate substantial electromagnetic interference affecting nearby components and circuits. This crosstalk phenomenon becomes increasingly problematic in densely packed electronic assemblies where signal integrity is paramount.

The primary technical challenge involves containing the electromagnetic field generated by magnetrons within designated boundaries. Traditional shielding methods often prove inadequate at the frequencies typically employed by magnetrons (commonly in the GHz range), as electromagnetic waves can penetrate or bypass conventional barriers through various coupling mechanisms. Engineers face difficulties in designing effective isolation structures that don't compromise the magnetron's performance while maintaining compact form factors.

Material limitations represent another significant obstacle. Many conventional RF-blocking materials exhibit diminished effectiveness at higher frequencies or may introduce unacceptable losses into the system. The search for advanced materials with superior electromagnetic absorption or reflection properties at specific frequency bands continues to be an active area of research, with current solutions often requiring compromise between effectiveness, cost, and manufacturability.

Thermal management further complicates isolation efforts. Magnetrons generate substantial heat during operation, and many isolation materials have temperature-dependent electromagnetic properties. This creates a complex interdependency where thermal solutions may interfere with RF isolation strategies and vice versa, requiring sophisticated multi-physics modeling approaches to resolve.

Ground plane integrity and power distribution network (PDN) design present additional challenges. Improper grounding can create unintended return paths for RF energy, effectively bypassing isolation measures. Similarly, power and signal lines can act as antennas, coupling magnetron energy into sensitive circuits despite physical separation or shielding.

Testing and validation methodologies for magnetron isolation solutions remain problematic. The complex near-field behavior of magnetrons makes accurate measurement difficult, while simulation tools often struggle to model all relevant coupling mechanisms simultaneously. This creates uncertainty in design validation, potentially leading to unexpected field failures or performance issues.

Regulatory compliance adds another layer of complexity, with increasingly stringent EMC/EMI standards limiting allowable emissions across broader frequency ranges. Meeting these requirements while maintaining device functionality and cost targets represents a significant engineering challenge, particularly for consumer electronics and medical devices where magnetrons may be employed.

The primary technical challenge involves containing the electromagnetic field generated by magnetrons within designated boundaries. Traditional shielding methods often prove inadequate at the frequencies typically employed by magnetrons (commonly in the GHz range), as electromagnetic waves can penetrate or bypass conventional barriers through various coupling mechanisms. Engineers face difficulties in designing effective isolation structures that don't compromise the magnetron's performance while maintaining compact form factors.

Material limitations represent another significant obstacle. Many conventional RF-blocking materials exhibit diminished effectiveness at higher frequencies or may introduce unacceptable losses into the system. The search for advanced materials with superior electromagnetic absorption or reflection properties at specific frequency bands continues to be an active area of research, with current solutions often requiring compromise between effectiveness, cost, and manufacturability.

Thermal management further complicates isolation efforts. Magnetrons generate substantial heat during operation, and many isolation materials have temperature-dependent electromagnetic properties. This creates a complex interdependency where thermal solutions may interfere with RF isolation strategies and vice versa, requiring sophisticated multi-physics modeling approaches to resolve.

Ground plane integrity and power distribution network (PDN) design present additional challenges. Improper grounding can create unintended return paths for RF energy, effectively bypassing isolation measures. Similarly, power and signal lines can act as antennas, coupling magnetron energy into sensitive circuits despite physical separation or shielding.

Testing and validation methodologies for magnetron isolation solutions remain problematic. The complex near-field behavior of magnetrons makes accurate measurement difficult, while simulation tools often struggle to model all relevant coupling mechanisms simultaneously. This creates uncertainty in design validation, potentially leading to unexpected field failures or performance issues.

Regulatory compliance adds another layer of complexity, with increasingly stringent EMC/EMI standards limiting allowable emissions across broader frequency ranges. Meeting these requirements while maintaining device functionality and cost targets represents a significant engineering challenge, particularly for consumer electronics and medical devices where magnetrons may be employed.

Existing Magnetron RF Crosstalk Suppression Methods

01 Shielding techniques for magnetron RF circuits

Various shielding techniques are employed in magnetron RF circuits to minimize crosstalk between components. These include electromagnetic shields, metal enclosures, and specialized barrier structures that isolate RF signals. Proper shielding design prevents unwanted coupling between circuit elements and reduces interference that can degrade system performance. Advanced shielding configurations can be tailored to specific frequency ranges and power levels used in magnetron applications.- Shielding techniques for RF circuit isolation: Various shielding techniques are employed in magnetron RF circuits to minimize crosstalk between components. These include metallic enclosures, compartmentalization, and specialized shielding materials that block electromagnetic interference. Proper shielding design prevents unwanted signal coupling between adjacent circuits, improving overall system performance and reducing noise in sensitive RF applications.

- Circuit layout optimization to reduce crosstalk: Optimizing the physical layout of magnetron RF circuits is crucial for minimizing crosstalk. This includes strategic component placement, proper trace routing, maintaining adequate separation between signal paths, and implementing ground planes. Advanced layout techniques consider the electromagnetic field patterns to ensure minimal interference between circuit elements, particularly in high-frequency applications.

- Filtering and signal processing solutions: Implementing filtering mechanisms and signal processing techniques helps mitigate crosstalk in magnetron RF circuits. These include bandpass filters, notch filters, and digital signal processing algorithms that can identify and remove interference. Advanced filtering approaches can dynamically adapt to changing operating conditions, ensuring consistent performance even in electromagnetically noisy environments.

- Grounding and power distribution strategies: Effective grounding and power distribution are essential for reducing crosstalk in magnetron RF circuits. Techniques include implementing star grounding, using dedicated ground planes, isolating digital and analog grounds, and careful power rail design. Proper grounding prevents common impedance coupling and provides low-impedance return paths for RF signals, significantly reducing unwanted signal coupling between circuit sections.

- Advanced materials and component isolation: Using specialized materials and component isolation techniques helps minimize crosstalk in magnetron RF circuits. This includes employing high-frequency laminates with controlled dielectric properties, absorptive materials that dampen electromagnetic waves, and physical isolation structures. Component selection also plays a role, with certain designs offering inherently better isolation characteristics for high-frequency applications.

02 Circuit layout optimization to reduce crosstalk

Optimizing the physical layout of magnetron RF circuits is critical for minimizing crosstalk. This includes careful component placement, strategic routing of transmission lines, and maintaining appropriate separation between signal paths. Circuit layout techniques such as orthogonal routing, ground plane optimization, and differential signaling can significantly reduce unwanted coupling between adjacent circuits. Advanced layout methodologies may incorporate computational modeling to predict and mitigate potential crosstalk issues before fabrication.Expand Specific Solutions03 Filtering and isolation components for crosstalk reduction

Specialized filtering and isolation components are integrated into magnetron RF circuits to minimize crosstalk. These include band-pass filters, isolators, circulators, and attenuators strategically placed to prevent signal leakage between circuit sections. Ferrite components and resonant structures can be employed to absorb or redirect unwanted RF energy. Advanced filtering techniques may incorporate tunable elements to adapt to changing operating conditions and maintain isolation across different frequency bands.Expand Specific Solutions04 Grounding and power distribution strategies

Effective grounding and power distribution are essential for controlling crosstalk in magnetron RF circuits. This includes implementing star grounding configurations, segregating analog and digital grounds, and using dedicated power planes. Proper decoupling capacitor placement and sizing help isolate RF energy and prevent it from propagating through power distribution networks. Advanced techniques may incorporate impedance-controlled power delivery networks and specialized RF ground structures to maintain signal integrity at high frequencies.Expand Specific Solutions05 Active cancellation and compensation techniques

Active cancellation and compensation techniques are implemented to counteract crosstalk effects in magnetron RF circuits. These include adaptive filtering, phase compensation, and digital signal processing methods that detect and neutralize interference patterns. Feedback systems can dynamically adjust circuit parameters to maintain isolation between channels as operating conditions change. Advanced implementations may incorporate machine learning algorithms to predict and preemptively mitigate crosstalk based on historical performance data.Expand Specific Solutions

Leading Companies in RF Shielding and Circuit Design

The RF magnetron crosstalk minimization market is in a growth phase, with increasing demand driven by the proliferation of high-frequency applications in telecommunications and consumer electronics. Key players including Samsung Electronics, Apple, and LG Electronics are investing heavily in advanced circuit isolation techniques, while specialized semiconductor manufacturers like NXP USA, Texas Instruments, and Renesas Electronics are developing innovative solutions for RF interference reduction. The technology maturity varies across applications, with companies like CommScope and Amphenol focusing on connector-level isolation, while research institutions such as Industrial Technology Research Institute and University of California are exploring next-generation materials and designs. The market is expected to reach $3.5 billion by 2025, with significant growth in 5G infrastructure and IoT applications.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced electromagnetic interference (EMI) shielding techniques specifically targeting magnetron RF crosstalk in high-density circuits. Their approach combines multi-layered shielding structures with specialized grounding schemes to isolate RF components. Samsung's solution incorporates conformal shielding technology that applies metallic coating directly onto package surfaces, creating a Faraday cage effect around sensitive components[1]. They've also implemented strategic component placement methodologies that maintain critical distances between RF elements based on wavelength calculations. Their latest designs feature embedded ground planes within PCB stackups and specialized vias patterns that create effective RF isolation barriers[3]. Samsung has further enhanced this with proprietary EMI absorbing materials that can be selectively applied to high-risk crosstalk areas.

Strengths: Excellent integration with their existing manufacturing processes, allowing for cost-effective implementation at scale. Their solutions maintain signal integrity while minimizing space requirements. Weaknesses: Some of their more advanced shielding techniques require specialized manufacturing equipment and can increase overall device thickness, potentially limiting application in ultra-thin consumer electronics.

CommScope Technologies LLC

Technical Solution: CommScope has developed specialized RF isolation technologies specifically targeting magnetron crosstalk in high-frequency communication circuits. Their approach centers on advanced material science combined with innovative structural designs. CommScope's solution incorporates metamaterial-based isolation barriers that create electromagnetic bandgaps precisely tuned to problematic frequencies[7]. They've pioneered specialized connector designs with integrated filtering elements that prevent RF leakage at circuit interfaces. Their technology includes precision-engineered cavity resonators that trap and dissipate unwanted RF energy before it can couple to adjacent circuits. CommScope has also developed composite shielding materials that combine multiple layers of different materials to create broadband isolation properties. Their designs feature specialized transmission line geometries that inherently resist crosstalk through modal isolation techniques[8]. Additionally, they implement strategic ground plane segmentation that prevents common-mode currents from propagating between circuit sections.

Strengths: Particularly effective in high-power RF applications where traditional isolation techniques may break down. Their solutions maintain excellent performance across wide temperature ranges and environmental conditions. Weaknesses: Some of their more advanced materials and structures can be costly to implement and may require specialized manufacturing processes not widely available.

Key Technologies for Electromagnetic Interference Reduction

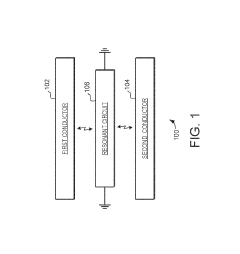

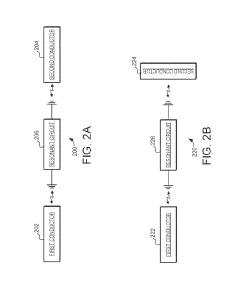

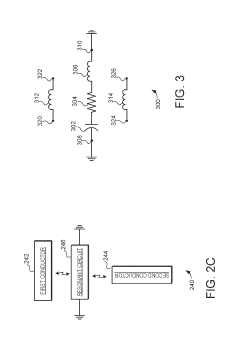

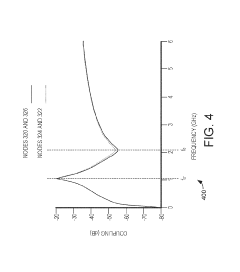

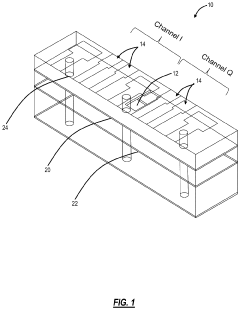

Radio frequency (RF) devices with resonant circuits to reduce coupling

PatentActiveUS10249582B2

Innovation

- The implementation of resonant circuits configured to resonate with conductors at a selected frequency, providing a path to ground for crosstalk energy and reducing electromagnetic coupling between conductors such as circuit traces, bond wires, and package leads.

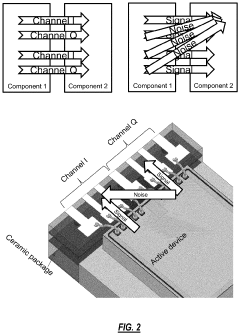

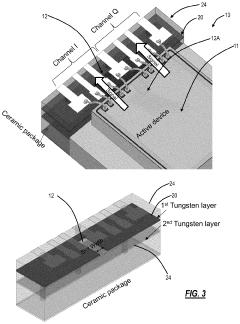

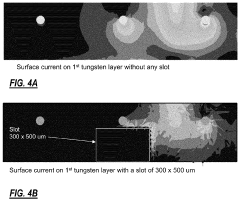

Low RF crosstalk devices via a slot for isolation

PatentActiveUS20240071897A1

Innovation

- Introducing a slot in the ground plane, such as in a ceramic package or Transimpedance Amplifier, to reduce undesired signal propagation and mitigate crosstalk, allowing for improved inter-channel isolation without requiring additional space.

EMC Standards and Compliance Requirements

Compliance with electromagnetic compatibility (EMC) standards is crucial when addressing magnetron RF crosstalk issues in circuits. The International Electrotechnical Commission (IEC) has established the IEC 61000 series, which provides comprehensive guidelines for electromagnetic compatibility. Specifically, IEC 61000-4-3 addresses immunity to radiated RF electromagnetic fields, while IEC 61000-4-6 focuses on immunity to conducted disturbances induced by RF fields. These standards define test methods, measurement techniques, and acceptable limits that circuits must meet to ensure proper operation in electromagnetic environments.

For circuits containing magnetrons, additional standards such as CISPR 11 (for industrial, scientific, and medical equipment) become particularly relevant. This standard specifies emission limits and measurement methods for RF disturbances, categorizing equipment into Groups 1 and 2, with magnetron-based systems typically falling under Group 2 due to their intentional generation of RF energy.

Regional compliance requirements add another layer of complexity. In the United States, the Federal Communications Commission (FCC) Part 18 regulations govern industrial, scientific, and medical equipment, including specific provisions for magnetron devices. The European Union enforces the EMC Directive (2014/30/EU), requiring CE marking for products sold within its borders. Asian markets have their own variants, with Japan's VCCI standards and China's CCC certification imposing region-specific requirements.

Military and aerospace applications face even more stringent standards, such as MIL-STD-461G, which provides detailed requirements for the control of electromagnetic interference characteristics of subsystems and equipment. This standard includes specific limits for conducted and radiated emissions (CE and RE) as well as conducted and radiated susceptibility (CS and RS).

Testing methodologies prescribed by these standards typically involve specialized equipment such as anechoic chambers, EMI receivers, and spectrum analyzers. For magnetron circuits, particular attention must be paid to RE102 (radiated emissions) and RS103 (radiated susceptibility) test procedures, as these directly address the RF interference issues common in such systems.

Compliance strategies should be integrated early in the design process rather than treated as an afterthought. Pre-compliance testing during development can identify potential issues before formal certification, saving considerable time and resources. Documentation requirements for EMC compliance include detailed test reports, technical construction files, and declarations of conformity that must be maintained and updated throughout the product lifecycle.

For circuits containing magnetrons, additional standards such as CISPR 11 (for industrial, scientific, and medical equipment) become particularly relevant. This standard specifies emission limits and measurement methods for RF disturbances, categorizing equipment into Groups 1 and 2, with magnetron-based systems typically falling under Group 2 due to their intentional generation of RF energy.

Regional compliance requirements add another layer of complexity. In the United States, the Federal Communications Commission (FCC) Part 18 regulations govern industrial, scientific, and medical equipment, including specific provisions for magnetron devices. The European Union enforces the EMC Directive (2014/30/EU), requiring CE marking for products sold within its borders. Asian markets have their own variants, with Japan's VCCI standards and China's CCC certification imposing region-specific requirements.

Military and aerospace applications face even more stringent standards, such as MIL-STD-461G, which provides detailed requirements for the control of electromagnetic interference characteristics of subsystems and equipment. This standard includes specific limits for conducted and radiated emissions (CE and RE) as well as conducted and radiated susceptibility (CS and RS).

Testing methodologies prescribed by these standards typically involve specialized equipment such as anechoic chambers, EMI receivers, and spectrum analyzers. For magnetron circuits, particular attention must be paid to RE102 (radiated emissions) and RS103 (radiated susceptibility) test procedures, as these directly address the RF interference issues common in such systems.

Compliance strategies should be integrated early in the design process rather than treated as an afterthought. Pre-compliance testing during development can identify potential issues before formal certification, saving considerable time and resources. Documentation requirements for EMC compliance include detailed test reports, technical construction files, and declarations of conformity that must be maintained and updated throughout the product lifecycle.

Thermal Management Considerations in RF Shielding Solutions

Thermal management represents a critical consideration in the design and implementation of RF shielding solutions aimed at minimizing magnetron RF crosstalk in circuits. The interaction between RF shielding materials and thermal dissipation creates a complex engineering challenge that must be carefully balanced to maintain optimal circuit performance.

RF shielding materials, particularly metals like copper and aluminum, often exhibit high thermal conductivity. This characteristic can be advantageous when properly integrated into thermal management strategies. Effective heat dissipation through shielding components can prevent temperature-related degradation of circuit performance, especially in high-power magnetron applications where thermal buildup can significantly alter the electromagnetic properties of components.

The thermal expansion coefficients of shielding materials must be considered when designing solutions for environments with variable operating temperatures. Mismatched expansion rates between shielding components and circuit elements can create mechanical stress, potentially compromising shield integrity and increasing crosstalk vulnerability. Advanced composite materials with controlled thermal expansion properties offer promising alternatives to traditional metal shields in thermally challenging environments.

Heat sinks and thermal vias can be strategically incorporated into RF shielding designs to channel heat away from sensitive components. This approach is particularly valuable in densely packed circuits where magnetron-generated heat may concentrate in confined spaces. The placement of thermal management features must be carefully calculated to avoid creating unintended RF pathways that could exacerbate crosstalk issues rather than mitigate them.

Computational fluid dynamics (CFD) modeling has emerged as an essential tool for predicting the thermal behavior of shielded RF circuits. These simulations allow engineers to identify potential hotspots and optimize both shielding effectiveness and thermal dissipation before physical prototyping. The integration of electromagnetic and thermal simulation platforms enables comprehensive analysis of the interdependencies between RF performance and thermal characteristics.

Passive cooling techniques, including specialized thermal interface materials (TIMs), can enhance heat transfer between shielding components and heat dissipation structures. These materials must be selected not only for their thermal properties but also for their RF characteristics to ensure they don't compromise shielding effectiveness. Silicone-based TIMs with embedded metallic particles offer an effective balance between thermal conductivity and RF shielding capability.

Active cooling solutions, such as miniaturized fans or liquid cooling systems, may be necessary for high-power magnetron applications where passive thermal management proves insufficient. The introduction of these systems requires careful electromagnetic compatibility analysis to ensure cooling components themselves don't introduce new sources of RF interference or crosstalk pathways.

RF shielding materials, particularly metals like copper and aluminum, often exhibit high thermal conductivity. This characteristic can be advantageous when properly integrated into thermal management strategies. Effective heat dissipation through shielding components can prevent temperature-related degradation of circuit performance, especially in high-power magnetron applications where thermal buildup can significantly alter the electromagnetic properties of components.

The thermal expansion coefficients of shielding materials must be considered when designing solutions for environments with variable operating temperatures. Mismatched expansion rates between shielding components and circuit elements can create mechanical stress, potentially compromising shield integrity and increasing crosstalk vulnerability. Advanced composite materials with controlled thermal expansion properties offer promising alternatives to traditional metal shields in thermally challenging environments.

Heat sinks and thermal vias can be strategically incorporated into RF shielding designs to channel heat away from sensitive components. This approach is particularly valuable in densely packed circuits where magnetron-generated heat may concentrate in confined spaces. The placement of thermal management features must be carefully calculated to avoid creating unintended RF pathways that could exacerbate crosstalk issues rather than mitigate them.

Computational fluid dynamics (CFD) modeling has emerged as an essential tool for predicting the thermal behavior of shielded RF circuits. These simulations allow engineers to identify potential hotspots and optimize both shielding effectiveness and thermal dissipation before physical prototyping. The integration of electromagnetic and thermal simulation platforms enables comprehensive analysis of the interdependencies between RF performance and thermal characteristics.

Passive cooling techniques, including specialized thermal interface materials (TIMs), can enhance heat transfer between shielding components and heat dissipation structures. These materials must be selected not only for their thermal properties but also for their RF characteristics to ensure they don't compromise shielding effectiveness. Silicone-based TIMs with embedded metallic particles offer an effective balance between thermal conductivity and RF shielding capability.

Active cooling solutions, such as miniaturized fans or liquid cooling systems, may be necessary for high-power magnetron applications where passive thermal management proves insufficient. The introduction of these systems requires careful electromagnetic compatibility analysis to ensure cooling components themselves don't introduce new sources of RF interference or crosstalk pathways.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!