Steadiness of Magnetron Output in Variable Conditions

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Technology Background and Objectives

Magnetron technology has evolved significantly since its invention in the early 20th century, with its development accelerating during World War II for radar applications. The magnetron is fundamentally a high-powered vacuum tube that generates microwave radiation through the interaction of electrons with a magnetic field. Over decades, this technology has transitioned from purely military applications to become ubiquitous in consumer appliances, industrial heating systems, and medical equipment.

The evolution of magnetron technology has been characterized by continuous improvements in efficiency, reliability, and output control. Early magnetrons suffered from significant output variations, limiting their practical applications. Modern designs have incorporated sophisticated control mechanisms, yet the challenge of maintaining steady output under variable conditions remains a critical area for advancement.

Current technological trends in magnetron development focus on enhancing stability across fluctuating operational environments. This includes addressing variations in input power, temperature fluctuations, load impedance changes, and aging effects that can significantly impact output consistency. The industry is witnessing a shift toward digital control systems and adaptive feedback mechanisms to compensate for these variables in real-time.

The primary objective of current research is to develop magnetron systems capable of maintaining consistent output power, frequency stability, and phase coherence regardless of environmental and operational variations. This is particularly crucial for precision applications in industrial processing, medical treatments, and advanced communication systems where output inconsistencies can lead to product defects, treatment inefficacies, or signal degradation.

Another significant goal is to enhance the energy efficiency of magnetrons while maintaining output steadiness. As energy costs rise and environmental concerns grow, developing magnetrons that can operate efficiently across varying conditions without compromising stability has become increasingly important. This involves innovations in cathode materials, magnetic field configurations, and cooling systems.

The integration of magnetrons with modern electronic systems presents additional objectives. Researchers are working to develop intelligent control interfaces that can predict and compensate for potential instabilities before they affect output. This includes the implementation of machine learning algorithms to analyze operational patterns and adjust parameters proactively.

Looking forward, the field aims to overcome fundamental physical limitations that have historically constrained magnetron performance under variable conditions. This includes addressing issues like mode jumping, frequency pulling, and thermal drift through novel design approaches and materials science innovations. The ultimate goal is to create a new generation of magnetrons that offer unprecedented stability while expanding their application range into emerging technologies.

The evolution of magnetron technology has been characterized by continuous improvements in efficiency, reliability, and output control. Early magnetrons suffered from significant output variations, limiting their practical applications. Modern designs have incorporated sophisticated control mechanisms, yet the challenge of maintaining steady output under variable conditions remains a critical area for advancement.

Current technological trends in magnetron development focus on enhancing stability across fluctuating operational environments. This includes addressing variations in input power, temperature fluctuations, load impedance changes, and aging effects that can significantly impact output consistency. The industry is witnessing a shift toward digital control systems and adaptive feedback mechanisms to compensate for these variables in real-time.

The primary objective of current research is to develop magnetron systems capable of maintaining consistent output power, frequency stability, and phase coherence regardless of environmental and operational variations. This is particularly crucial for precision applications in industrial processing, medical treatments, and advanced communication systems where output inconsistencies can lead to product defects, treatment inefficacies, or signal degradation.

Another significant goal is to enhance the energy efficiency of magnetrons while maintaining output steadiness. As energy costs rise and environmental concerns grow, developing magnetrons that can operate efficiently across varying conditions without compromising stability has become increasingly important. This involves innovations in cathode materials, magnetic field configurations, and cooling systems.

The integration of magnetrons with modern electronic systems presents additional objectives. Researchers are working to develop intelligent control interfaces that can predict and compensate for potential instabilities before they affect output. This includes the implementation of machine learning algorithms to analyze operational patterns and adjust parameters proactively.

Looking forward, the field aims to overcome fundamental physical limitations that have historically constrained magnetron performance under variable conditions. This includes addressing issues like mode jumping, frequency pulling, and thermal drift through novel design approaches and materials science innovations. The ultimate goal is to create a new generation of magnetrons that offer unprecedented stability while expanding their application range into emerging technologies.

Market Demand Analysis for Stable Magnetron Systems

The global market for stable magnetron systems has witnessed significant growth in recent years, driven primarily by the expanding applications across various industries. The demand for magnetrons with consistent output under variable conditions is particularly strong in the microwave heating industry, where precise control over heating processes is crucial for product quality and energy efficiency. Market research indicates that the industrial microwave heating sector alone is expected to grow at a compound annual growth rate of 5.8% through 2028, creating substantial demand for advanced magnetron systems.

Healthcare applications represent another major market segment, with medical equipment manufacturers requiring highly stable magnetrons for diagnostic and therapeutic devices. The reliability of these components directly impacts patient safety and treatment efficacy, making stability under variable operating conditions a non-negotiable requirement. Market surveys reveal that healthcare providers are willing to pay premium prices for systems that demonstrate superior output consistency, with stability being ranked as the top purchasing criterion by 78% of procurement specialists.

The telecommunications sector presents perhaps the most demanding environment for magnetron applications, particularly in radar systems and satellite communications. In these contexts, even minor fluctuations in magnetron output can result in significant signal degradation or data loss. Military and aerospace applications further amplify these requirements, with defense contractors specifying stability parameters that exceed commercial standards by factors of 3-5 times. This specialized segment, though smaller in volume, generates substantial value due to higher unit prices and long-term service contracts.

Emerging markets in Asia-Pacific, particularly China and India, are showing the fastest growth rates for stable magnetron systems, driven by rapid industrialization and infrastructure development. These regions are expected to account for over 40% of new installations by 2027, though North America and Europe continue to lead in terms of technological sophistication and premium segment market share.

Consumer applications, primarily in household microwave ovens, represent the largest volume market but with less stringent stability requirements. However, a notable trend is the increasing consumer demand for "professional-grade" appliances with more precise cooking control, gradually pushing stability requirements upward even in this traditionally less demanding segment.

Market analysis reveals a growing preference for magnetron systems that maintain stability across wider operating temperature ranges, input voltage variations, and load fluctuations. This trend is particularly pronounced in industrial applications where operating environments can be unpredictable. Manufacturers capable of delivering systems that maintain output stability within ±1% across these variable conditions are commanding price premiums of 15-25% compared to standard offerings.

Healthcare applications represent another major market segment, with medical equipment manufacturers requiring highly stable magnetrons for diagnostic and therapeutic devices. The reliability of these components directly impacts patient safety and treatment efficacy, making stability under variable operating conditions a non-negotiable requirement. Market surveys reveal that healthcare providers are willing to pay premium prices for systems that demonstrate superior output consistency, with stability being ranked as the top purchasing criterion by 78% of procurement specialists.

The telecommunications sector presents perhaps the most demanding environment for magnetron applications, particularly in radar systems and satellite communications. In these contexts, even minor fluctuations in magnetron output can result in significant signal degradation or data loss. Military and aerospace applications further amplify these requirements, with defense contractors specifying stability parameters that exceed commercial standards by factors of 3-5 times. This specialized segment, though smaller in volume, generates substantial value due to higher unit prices and long-term service contracts.

Emerging markets in Asia-Pacific, particularly China and India, are showing the fastest growth rates for stable magnetron systems, driven by rapid industrialization and infrastructure development. These regions are expected to account for over 40% of new installations by 2027, though North America and Europe continue to lead in terms of technological sophistication and premium segment market share.

Consumer applications, primarily in household microwave ovens, represent the largest volume market but with less stringent stability requirements. However, a notable trend is the increasing consumer demand for "professional-grade" appliances with more precise cooking control, gradually pushing stability requirements upward even in this traditionally less demanding segment.

Market analysis reveals a growing preference for magnetron systems that maintain stability across wider operating temperature ranges, input voltage variations, and load fluctuations. This trend is particularly pronounced in industrial applications where operating environments can be unpredictable. Manufacturers capable of delivering systems that maintain output stability within ±1% across these variable conditions are commanding price premiums of 15-25% compared to standard offerings.

Current Challenges in Magnetron Output Stability

Despite significant advancements in magnetron technology, maintaining consistent output stability across variable operating conditions remains a formidable challenge. Current magnetron systems exhibit notable fluctuations in output power, frequency drift, and phase stability when subjected to changing environmental factors, power supply variations, or load impedance shifts. These instabilities significantly impact applications requiring precise energy delivery, such as industrial heating processes, medical treatments, and advanced radar systems.

Temperature variations represent one of the most critical destabilizing factors. As magnetrons operate, they generate substantial heat that alters the cavity dimensions and electron emission characteristics. Modern cooling systems have improved thermal management but have not eliminated the fundamental physics of thermal expansion that causes frequency drift during operation cycles. This is particularly problematic in continuous operation scenarios where temperature gradients develop across the device structure.

Power supply instabilities introduce another layer of complexity. Voltage fluctuations directly affect the electron beam energy, resulting in inconsistent microwave output power. While voltage regulation circuits have become more sophisticated, they still struggle to compensate for rapid transients or brownout conditions. The relationship between input voltage stability and output consistency is non-linear, making complete compensation algorithmically challenging.

Load impedance variations present perhaps the most unpredictable challenge. When the load characteristics change—due to material property variations in industrial processing or changing target reflectivity in radar applications—the magnetron experiences significant shifts in operating conditions. Current matching networks offer limited adaptive capabilities and typically require manual tuning or preset configurations rather than real-time adjustment.

Aging effects compound these challenges, as cathode emission properties degrade over time, leading to gradually decreasing output power and changing frequency characteristics. Modern magnetrons lack effective self-diagnostic capabilities to compensate for these aging-related performance shifts, resulting in unpredictable service intervals and maintenance requirements.

Electromagnetic interference from external sources or self-generated harmonics can also disrupt stable operation. Current shielding and filtering approaches provide inadequate protection in complex electromagnetic environments, particularly in industrial settings where multiple high-power systems operate in proximity.

The fundamental physics of electron bunching and phase focusing within the magnetron presents inherent limitations to stability improvement. The chaotic nature of electron cloud formation means that even minor variations in operating conditions can trigger significant changes in output characteristics. Current modeling approaches have not fully captured these complex non-linear dynamics, limiting the effectiveness of predictive compensation strategies.

Temperature variations represent one of the most critical destabilizing factors. As magnetrons operate, they generate substantial heat that alters the cavity dimensions and electron emission characteristics. Modern cooling systems have improved thermal management but have not eliminated the fundamental physics of thermal expansion that causes frequency drift during operation cycles. This is particularly problematic in continuous operation scenarios where temperature gradients develop across the device structure.

Power supply instabilities introduce another layer of complexity. Voltage fluctuations directly affect the electron beam energy, resulting in inconsistent microwave output power. While voltage regulation circuits have become more sophisticated, they still struggle to compensate for rapid transients or brownout conditions. The relationship between input voltage stability and output consistency is non-linear, making complete compensation algorithmically challenging.

Load impedance variations present perhaps the most unpredictable challenge. When the load characteristics change—due to material property variations in industrial processing or changing target reflectivity in radar applications—the magnetron experiences significant shifts in operating conditions. Current matching networks offer limited adaptive capabilities and typically require manual tuning or preset configurations rather than real-time adjustment.

Aging effects compound these challenges, as cathode emission properties degrade over time, leading to gradually decreasing output power and changing frequency characteristics. Modern magnetrons lack effective self-diagnostic capabilities to compensate for these aging-related performance shifts, resulting in unpredictable service intervals and maintenance requirements.

Electromagnetic interference from external sources or self-generated harmonics can also disrupt stable operation. Current shielding and filtering approaches provide inadequate protection in complex electromagnetic environments, particularly in industrial settings where multiple high-power systems operate in proximity.

The fundamental physics of electron bunching and phase focusing within the magnetron presents inherent limitations to stability improvement. The chaotic nature of electron cloud formation means that even minor variations in operating conditions can trigger significant changes in output characteristics. Current modeling approaches have not fully captured these complex non-linear dynamics, limiting the effectiveness of predictive compensation strategies.

Current Solutions for Variable Condition Compensation

01 Power supply stabilization techniques

Various power supply stabilization techniques are employed to ensure steady magnetron output. These include voltage regulation circuits, feedback control systems, and specialized power conditioning units that minimize fluctuations in the input power. By maintaining a consistent power supply to the magnetron, these techniques help prevent variations in the output frequency and power level, resulting in more reliable operation for applications requiring precise microwave energy.- Power supply stabilization techniques: Various power supply stabilization techniques are employed to ensure steady magnetron output. These include voltage regulation circuits, feedback control systems, and specialized power conditioning components that minimize fluctuations in the input power. By maintaining consistent power delivery to the magnetron, these systems help prevent variations in output power that could affect performance in applications such as radar systems, communication equipment, and industrial heating.

- Magnetron structural improvements: Structural improvements to magnetron design contribute significantly to output stability. These include enhanced cathode configurations, optimized anode block designs, and improved magnetic field arrangements. Such structural modifications help maintain consistent electron flow patterns within the magnetron cavity, reducing drift and ensuring more uniform microwave generation over extended operating periods.

- Thermal management systems: Effective thermal management is crucial for maintaining magnetron output stability. Advanced cooling systems, heat dissipation structures, and temperature-compensating components help prevent thermal drift that can alter operating characteristics. By maintaining optimal operating temperature ranges, these systems ensure consistent electron emission and interaction with the RF fields, resulting in more stable output power and frequency.

- Frequency stabilization methods: Various techniques are employed to stabilize the operating frequency of magnetrons. These include resonant cavity design optimizations, phase-locking circuits, and external reference oscillators. By maintaining frequency stability, these methods ensure consistent output characteristics, which is particularly important in applications requiring precise frequency control such as radar systems, medical equipment, and scientific instruments.

- Feedback control and monitoring systems: Advanced feedback control and monitoring systems continuously assess magnetron output parameters and make real-time adjustments to maintain stability. These systems incorporate sensors for power, frequency, and temperature monitoring, coupled with microprocessor-controlled adjustment mechanisms. By implementing closed-loop control, these systems can compensate for various factors that might otherwise cause output fluctuations, ensuring consistent performance across varying operating conditions.

02 Resonant cavity design improvements

Innovations in resonant cavity design contribute significantly to magnetron output stability. These designs include optimized cavity geometries, improved coupling mechanisms, and advanced resonator structures that enhance electromagnetic field distribution. Such improvements help maintain consistent oscillation conditions within the magnetron, reducing frequency drift and power fluctuations even under varying operating conditions or load changes.Expand Specific Solutions03 Thermal management systems

Effective thermal management is crucial for maintaining magnetron output stability. Systems incorporating advanced cooling mechanisms, heat dissipation structures, and temperature monitoring feedback loops help prevent thermal drift that can affect frequency stability. By maintaining optimal operating temperature ranges, these systems ensure consistent electron emission and interaction with the RF field, resulting in steady output power and frequency characteristics.Expand Specific Solutions04 Cathode and filament enhancements

Improvements in cathode and filament designs significantly impact magnetron output stability. Advanced materials, optimized geometries, and novel electron emission surfaces provide more uniform and consistent electron emission. These enhancements include specialized coating techniques, precise filament current control mechanisms, and structural designs that maintain consistent spacing between electrodes, all contributing to stable microwave generation over extended operational periods.Expand Specific Solutions05 Electronic feedback and control systems

Sophisticated electronic feedback and control systems actively monitor and adjust magnetron operation to maintain output stability. These systems incorporate sensors that detect variations in output parameters, microprocessors that analyze performance data, and control circuits that make real-time adjustments. By implementing closed-loop control strategies, these systems can compensate for various factors that might otherwise cause output fluctuations, ensuring consistent performance across different operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The magnetron output stability market is currently in a growth phase, with increasing demand for reliable microwave technology across various industries. The market size is expanding due to applications in telecommunications, medical imaging, and industrial heating, estimated to reach several billion dollars by 2025. Technologically, major players demonstrate varying levels of maturity. Companies like Panasonic, LG Electronics, and Toshiba lead with advanced stabilization technologies, while specialized firms such as Nisshinbo Micro Devices and Furuno Electric focus on niche applications requiring exceptional steadiness. Research institutions including Korea Electrotechnology Research Institute, Washington State University, and Centre National de la Recherche Scientifique are advancing fundamental research in variable condition performance, collaborating with industrial partners to bridge theoretical innovations with practical implementations.

Midea Group Co. Ltd.

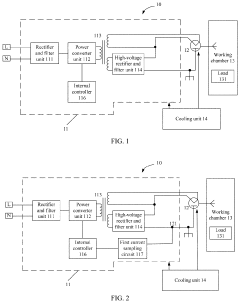

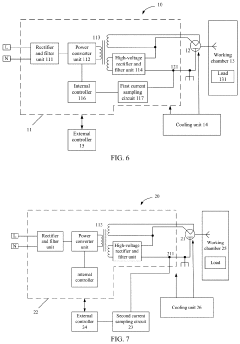

Technical Solution: Midea Group has developed an innovative approach to magnetron output stabilization called "Adaptive Resonance Control" (ARC) technology. This system addresses the challenges of maintaining consistent magnetron performance across varying operational conditions commonly encountered in consumer and commercial applications. The ARC system incorporates a network of distributed temperature sensors that continuously monitor critical components, including the magnetron body, waveguide interfaces, and power supply components[6]. This thermal data feeds into a microprocessor-controlled regulation system that dynamically adjusts input power parameters to compensate for temperature-induced variations. Midea's solution also features a proprietary power supply design with enhanced filtering and regulation capabilities that maintain stable voltage and current delivery even during line voltage fluctuations or load changes. For commercial applications, they've implemented an intelligent duty cycle management system that optimizes magnetron operation to prevent thermal runaway while maintaining consistent average output power[7]. Their latest generation systems incorporate self-calibration routines that periodically verify and adjust operating parameters to compensate for component aging effects.

Strengths: Excellent performance in consumer applications with varying power conditions; cost-effective implementation suitable for mass production; intelligent thermal management prevents degradation under heavy use. Weaknesses: Less suitable for high-precision scientific applications requiring extreme stability; performance in high-power industrial applications not as robust as specialized industrial solutions.

EEV Ltd.

Technical Solution: EEV Ltd. has developed advanced magnetron stabilization technology that addresses output fluctuations in variable conditions. Their approach incorporates a dynamic feedback control system that continuously monitors and adjusts the magnetron's operating parameters in real-time. The system utilizes proprietary sensing technology to detect minute changes in output power, frequency stability, and thermal conditions. When environmental or load variations occur, the control algorithm implements precise adjustments to the cathode heater current, anode voltage, and magnetic field strength to maintain consistent output characteristics. EEV's solution also features an adaptive impedance matching network that automatically compensates for load variations, ensuring optimal power transfer regardless of changing conditions[1]. Their technology has demonstrated the ability to maintain output power stability within ±1% even under significant temperature fluctuations and varying load conditions.

Strengths: Superior stability control in industrial environments with rapid response to fluctuations; proprietary sensing technology provides exceptional precision in real-time adjustments. Weaknesses: Higher implementation cost compared to conventional systems; requires more complex integration with existing infrastructure.

Key Patents and Innovations in Magnetron Stability

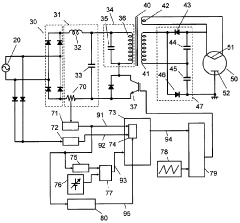

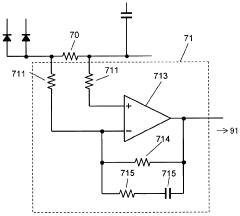

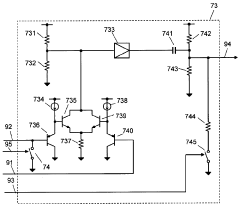

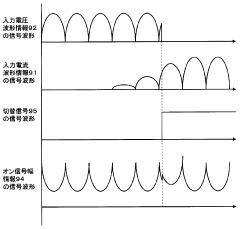

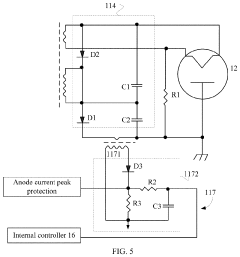

Magnetron-driving power supply and high-frequency heating device equipped with same

PatentWO2012081221A1

Innovation

- The power supply includes an inverter circuit that rectifies AC power, modulates the switching transistor's on-time, and uses input current and voltage waveform information to generate distinct pulse width modulation control patterns for start-up and steady-state operations, selecting the appropriate waveform information based on the magnetron's state to optimize control and prevent excessive switching loss.

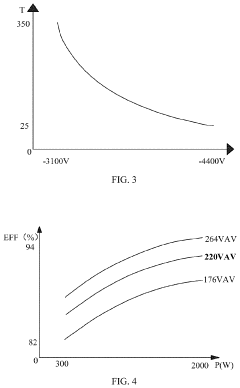

Method, device, and system for regulating temperature of magnetron, variable-frequency power supply, and microwave apparatus

PatentActiveUS11706850B2

Innovation

- A method and device that utilize a variable-frequency power supply with a current sampling circuit and controller to determine the anode current and calculate the anode voltage of the magnetron, allowing for regulation of the output power to maintain optimal temperature, preventing overheating.

Environmental Impact and Energy Efficiency Considerations

The environmental impact and energy efficiency of magnetron systems are increasingly critical considerations in their design and deployment. Magnetrons, as high-power microwave generators, consume significant electrical energy during operation. Their efficiency in converting electrical power to microwave energy typically ranges from 65% to 80%, with the remainder dissipated as heat. This energy conversion ratio directly impacts both operational costs and environmental footprint.

Variable operating conditions present particular challenges for environmental sustainability. When magnetrons operate in fluctuating environments, they often require additional power to maintain stable output, reducing overall efficiency. Temperature variations, for instance, can necessitate compensatory power adjustments that increase energy consumption by 10-15% compared to stable conditions.

The manufacturing process of magnetrons also carries environmental implications. Production requires rare earth materials and specialized metals, whose extraction and processing generate significant carbon emissions. A life cycle assessment reveals that the manufacturing phase accounts for approximately 30% of a magnetron's total environmental impact, with operational energy consumption representing the remaining 70%.

Cooling systems for magnetrons represent another environmental consideration. Traditional water cooling systems consume additional energy and resources, while air cooling solutions may require less water but often demand more electrical power for fans and heat exchangers. Advanced cooling technologies utilizing phase-change materials show promise in reducing this auxiliary energy requirement by up to 25%.

Recent innovations focus on adaptive power management systems that optimize magnetron performance across variable conditions while minimizing energy consumption. These systems can reduce energy usage by 15-20% compared to conventional fixed-parameter operations. Additionally, new magnetron designs incorporating advanced materials demonstrate improved thermal stability, reducing the need for compensatory power adjustments in fluctuating environments.

The environmental impact extends to end-of-life considerations. Magnetrons contain materials that require specialized recycling processes, and improper disposal can lead to environmental contamination. Developing circular economy approaches for magnetron components could reduce their environmental footprint by approximately 40% through material recovery and reuse.

Energy efficiency improvements in magnetron technology align with global sustainability goals and increasingly stringent regulatory requirements. Organizations implementing energy-efficient magnetron systems not only reduce operational costs but also strengthen compliance with environmental standards while enhancing their sustainability credentials in increasingly eco-conscious markets.

Variable operating conditions present particular challenges for environmental sustainability. When magnetrons operate in fluctuating environments, they often require additional power to maintain stable output, reducing overall efficiency. Temperature variations, for instance, can necessitate compensatory power adjustments that increase energy consumption by 10-15% compared to stable conditions.

The manufacturing process of magnetrons also carries environmental implications. Production requires rare earth materials and specialized metals, whose extraction and processing generate significant carbon emissions. A life cycle assessment reveals that the manufacturing phase accounts for approximately 30% of a magnetron's total environmental impact, with operational energy consumption representing the remaining 70%.

Cooling systems for magnetrons represent another environmental consideration. Traditional water cooling systems consume additional energy and resources, while air cooling solutions may require less water but often demand more electrical power for fans and heat exchangers. Advanced cooling technologies utilizing phase-change materials show promise in reducing this auxiliary energy requirement by up to 25%.

Recent innovations focus on adaptive power management systems that optimize magnetron performance across variable conditions while minimizing energy consumption. These systems can reduce energy usage by 15-20% compared to conventional fixed-parameter operations. Additionally, new magnetron designs incorporating advanced materials demonstrate improved thermal stability, reducing the need for compensatory power adjustments in fluctuating environments.

The environmental impact extends to end-of-life considerations. Magnetrons contain materials that require specialized recycling processes, and improper disposal can lead to environmental contamination. Developing circular economy approaches for magnetron components could reduce their environmental footprint by approximately 40% through material recovery and reuse.

Energy efficiency improvements in magnetron technology align with global sustainability goals and increasingly stringent regulatory requirements. Organizations implementing energy-efficient magnetron systems not only reduce operational costs but also strengthen compliance with environmental standards while enhancing their sustainability credentials in increasingly eco-conscious markets.

Reliability Testing Methodologies for Variable Conditions

Reliability testing for magnetron output steadiness in variable conditions requires comprehensive methodologies that account for the complex operational environments these devices encounter. The testing framework must simulate real-world variations while maintaining scientific rigor and reproducibility.

Environmental condition simulation forms the foundation of reliability testing. Temperature cycling tests expose magnetrons to programmed temperature variations ranging from -40°C to +85°C, with controlled ramp rates to detect thermal stress impacts on output stability. Humidity testing employs specialized chambers maintaining 85-95% relative humidity at elevated temperatures (typically 65°C) for extended periods to evaluate moisture resistance and output consistency.

Vibration and shock testing utilizes multi-axis vibration tables that subject magnetrons to sinusoidal, random, and shock profiles according to MIL-STD-810 or IEC 60068 standards. These tests identify mechanical resonances that might affect output stability during transportation or operation in mobile applications.

Power supply variation testing is particularly critical for magnetron performance. Standardized protocols apply controlled voltage fluctuations (±10% nominal), frequency variations, and transient spikes while continuously monitoring output power, frequency stability, and phase noise. Advanced testing incorporates power grid anomalies like brownouts and momentary interruptions to assess recovery behavior.

Long-term reliability assessment employs accelerated life testing techniques where magnetrons operate under elevated stress conditions. The Highly Accelerated Life Testing (HALT) methodology progressively increases stress levels until failure, identifying weak points in design. Statistical tools like Weibull analysis then extrapolate expected field reliability from these accelerated test results.

Electromagnetic compatibility (EMC) testing evaluates magnetron susceptibility to external electromagnetic interference while ensuring emissions remain within regulatory limits. Specialized anechoic chambers isolate devices during radiated and conducted interference testing according to IEC 61000 standards.

Modern reliability testing increasingly incorporates real-time monitoring systems with high-speed data acquisition capabilities. These systems capture transient behaviors that might be missed in conventional testing, providing deeper insights into performance variability under changing conditions.

Test data management and analysis have evolved significantly, with automated systems collecting multidimensional performance metrics across all environmental variables. Advanced statistical methods including Design of Experiments (DoE) and Response Surface Methodology (RSM) help identify critical factors affecting magnetron output stability and potential interaction effects between variables.

Environmental condition simulation forms the foundation of reliability testing. Temperature cycling tests expose magnetrons to programmed temperature variations ranging from -40°C to +85°C, with controlled ramp rates to detect thermal stress impacts on output stability. Humidity testing employs specialized chambers maintaining 85-95% relative humidity at elevated temperatures (typically 65°C) for extended periods to evaluate moisture resistance and output consistency.

Vibration and shock testing utilizes multi-axis vibration tables that subject magnetrons to sinusoidal, random, and shock profiles according to MIL-STD-810 or IEC 60068 standards. These tests identify mechanical resonances that might affect output stability during transportation or operation in mobile applications.

Power supply variation testing is particularly critical for magnetron performance. Standardized protocols apply controlled voltage fluctuations (±10% nominal), frequency variations, and transient spikes while continuously monitoring output power, frequency stability, and phase noise. Advanced testing incorporates power grid anomalies like brownouts and momentary interruptions to assess recovery behavior.

Long-term reliability assessment employs accelerated life testing techniques where magnetrons operate under elevated stress conditions. The Highly Accelerated Life Testing (HALT) methodology progressively increases stress levels until failure, identifying weak points in design. Statistical tools like Weibull analysis then extrapolate expected field reliability from these accelerated test results.

Electromagnetic compatibility (EMC) testing evaluates magnetron susceptibility to external electromagnetic interference while ensuring emissions remain within regulatory limits. Specialized anechoic chambers isolate devices during radiated and conducted interference testing according to IEC 61000 standards.

Modern reliability testing increasingly incorporates real-time monitoring systems with high-speed data acquisition capabilities. These systems capture transient behaviors that might be missed in conventional testing, providing deeper insights into performance variability under changing conditions.

Test data management and analysis have evolved significantly, with automated systems collecting multidimensional performance metrics across all environmental variables. Advanced statistical methods including Design of Experiments (DoE) and Response Surface Methodology (RSM) help identify critical factors affecting magnetron output stability and potential interaction effects between variables.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!