Magnetron Modulation Types vs Applications: Analysis

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Modulation Evolution and Objectives

Magnetron technology has evolved significantly since its invention in the early 20th century, with modulation techniques representing a critical aspect of its development trajectory. Initially developed for radar applications during World War II, magnetrons have undergone substantial transformations in their modulation capabilities to address expanding application requirements across various industries. The evolution of magnetron modulation techniques can be traced through several distinct phases, beginning with simple pulse modulation systems and progressing toward sophisticated digital control mechanisms that enable precise power regulation and frequency stability.

The first generation of magnetron modulation employed basic pulse techniques, where power was simply switched on and off to create radar pulses. This rudimentary approach, while effective for early radar systems, offered limited control over output characteristics. The second evolutionary phase introduced analog modulation methods, including amplitude modulation (AM) and frequency modulation (FM), which expanded the versatility of magnetron applications beyond military use into industrial heating and early microwave ovens.

By the 1970s and 1980s, the development of solid-state electronics facilitated more advanced modulation techniques, including pulse width modulation (PWM) and phase modulation. These innovations enabled finer control over energy delivery and significantly improved efficiency in industrial processing applications. The integration of microprocessors in the 1990s marked another pivotal advancement, allowing for real-time adaptive modulation based on feedback mechanisms.

Current state-of-the-art magnetron modulation incorporates digital signal processing techniques that optimize performance parameters such as frequency stability, power efficiency, and harmonic content. Modern systems employ sophisticated algorithms that can dynamically adjust modulation parameters in response to changing load conditions or application requirements. This adaptive capability has been particularly valuable in medical applications, where precise energy delivery is critical, and in advanced materials processing, where specific heating profiles must be maintained.

The primary objective of ongoing magnetron modulation research is to overcome inherent limitations in traditional designs, particularly regarding frequency stability, power control precision, and operational lifespan. Researchers aim to develop modulation techniques that can rival solid-state alternatives in terms of control precision while maintaining the magnetron's advantages in power efficiency and cost-effectiveness. Additional technical goals include reducing electromagnetic interference, improving energy transfer efficiency, and enabling more sophisticated feedback control systems.

Looking forward, the convergence of magnetron technology with advanced digital control systems presents opportunities for hybrid solutions that combine the raw power capabilities of magnetrons with the precise control characteristics typically associated with solid-state devices. This integration represents a promising direction for addressing the growing demands of emerging applications in fields such as plasma physics, advanced materials manufacturing, and medical therapy systems.

The first generation of magnetron modulation employed basic pulse techniques, where power was simply switched on and off to create radar pulses. This rudimentary approach, while effective for early radar systems, offered limited control over output characteristics. The second evolutionary phase introduced analog modulation methods, including amplitude modulation (AM) and frequency modulation (FM), which expanded the versatility of magnetron applications beyond military use into industrial heating and early microwave ovens.

By the 1970s and 1980s, the development of solid-state electronics facilitated more advanced modulation techniques, including pulse width modulation (PWM) and phase modulation. These innovations enabled finer control over energy delivery and significantly improved efficiency in industrial processing applications. The integration of microprocessors in the 1990s marked another pivotal advancement, allowing for real-time adaptive modulation based on feedback mechanisms.

Current state-of-the-art magnetron modulation incorporates digital signal processing techniques that optimize performance parameters such as frequency stability, power efficiency, and harmonic content. Modern systems employ sophisticated algorithms that can dynamically adjust modulation parameters in response to changing load conditions or application requirements. This adaptive capability has been particularly valuable in medical applications, where precise energy delivery is critical, and in advanced materials processing, where specific heating profiles must be maintained.

The primary objective of ongoing magnetron modulation research is to overcome inherent limitations in traditional designs, particularly regarding frequency stability, power control precision, and operational lifespan. Researchers aim to develop modulation techniques that can rival solid-state alternatives in terms of control precision while maintaining the magnetron's advantages in power efficiency and cost-effectiveness. Additional technical goals include reducing electromagnetic interference, improving energy transfer efficiency, and enabling more sophisticated feedback control systems.

Looking forward, the convergence of magnetron technology with advanced digital control systems presents opportunities for hybrid solutions that combine the raw power capabilities of magnetrons with the precise control characteristics typically associated with solid-state devices. This integration represents a promising direction for addressing the growing demands of emerging applications in fields such as plasma physics, advanced materials manufacturing, and medical therapy systems.

Market Applications and Demand Analysis

The global magnetron market is experiencing significant growth, driven primarily by the expanding applications across various industries. The market size was valued at approximately 1.2 billion USD in 2022 and is projected to reach 1.8 billion USD by 2028, representing a compound annual growth rate of 7.2%. This growth trajectory is largely attributed to the diversification of magnetron applications beyond traditional microwave ovens into industrial heating, plasma generation, and advanced medical equipment.

Consumer electronics continues to dominate the magnetron market, with microwave ovens accounting for nearly 65% of total magnetron consumption. However, industrial applications are showing the fastest growth rate at 9.5% annually, particularly in sectors requiring precise heating and material processing. The healthcare sector is emerging as a promising market, with magnetron-based medical devices for cancer treatment witnessing increased adoption in developed economies.

Regional analysis reveals Asia-Pacific as the largest market for magnetrons, contributing approximately 45% of global demand. This dominance is attributed to the region's robust electronics manufacturing ecosystem and increasing consumer appliance adoption. North America and Europe follow with 25% and 20% market shares respectively, with their demand primarily driven by industrial and medical applications requiring advanced modulation technologies.

Different modulation types serve distinct market segments. Continuous Wave (CW) modulation dominates consumer applications due to its simplicity and cost-effectiveness. Pulse modulation systems are experiencing rapid growth in industrial processing and scientific research, where precise energy delivery is critical. Frequency modulation technologies are gaining traction in specialized applications such as radar systems and medical equipment, where they command premium pricing despite smaller volume.

Market research indicates that end-users are increasingly demanding magnetrons with higher energy efficiency, reduced electromagnetic interference, and greater operational stability. This trend is particularly pronounced in industrial applications where energy costs significantly impact operational expenses. Additionally, there is growing demand for compact magnetrons with advanced modulation capabilities for emerging applications in autonomous vehicles, drone technology, and portable medical devices.

The market is also witnessing a shift toward magnetrons with digital control interfaces and smart features, enabling integration with IoT systems and automated production environments. This trend is expected to accelerate as Industry 4.0 adoption increases across manufacturing sectors, creating new opportunities for magnetron technologies with sophisticated modulation capabilities tailored to specific application requirements.

Consumer electronics continues to dominate the magnetron market, with microwave ovens accounting for nearly 65% of total magnetron consumption. However, industrial applications are showing the fastest growth rate at 9.5% annually, particularly in sectors requiring precise heating and material processing. The healthcare sector is emerging as a promising market, with magnetron-based medical devices for cancer treatment witnessing increased adoption in developed economies.

Regional analysis reveals Asia-Pacific as the largest market for magnetrons, contributing approximately 45% of global demand. This dominance is attributed to the region's robust electronics manufacturing ecosystem and increasing consumer appliance adoption. North America and Europe follow with 25% and 20% market shares respectively, with their demand primarily driven by industrial and medical applications requiring advanced modulation technologies.

Different modulation types serve distinct market segments. Continuous Wave (CW) modulation dominates consumer applications due to its simplicity and cost-effectiveness. Pulse modulation systems are experiencing rapid growth in industrial processing and scientific research, where precise energy delivery is critical. Frequency modulation technologies are gaining traction in specialized applications such as radar systems and medical equipment, where they command premium pricing despite smaller volume.

Market research indicates that end-users are increasingly demanding magnetrons with higher energy efficiency, reduced electromagnetic interference, and greater operational stability. This trend is particularly pronounced in industrial applications where energy costs significantly impact operational expenses. Additionally, there is growing demand for compact magnetrons with advanced modulation capabilities for emerging applications in autonomous vehicles, drone technology, and portable medical devices.

The market is also witnessing a shift toward magnetrons with digital control interfaces and smart features, enabling integration with IoT systems and automated production environments. This trend is expected to accelerate as Industry 4.0 adoption increases across manufacturing sectors, creating new opportunities for magnetron technologies with sophisticated modulation capabilities tailored to specific application requirements.

Current Modulation Techniques and Limitations

Magnetron modulation techniques have evolved significantly over the past decades, with several distinct approaches now established in industrial and commercial applications. The most prevalent modulation technique remains pulse width modulation (PWM), which controls the average power delivered to the load by varying the duty cycle of the magnetron's operation. This approach offers precise power control while maintaining operational efficiency across various power levels, making it particularly suitable for industrial heating processes requiring variable energy input.

Frequency modulation represents another significant technique, allowing for the adjustment of the magnetron's operating frequency within a narrow band. This method proves especially valuable in applications requiring selective heating of materials with frequency-dependent dielectric properties, though it faces limitations in implementation due to the inherent frequency stability constraints of conventional magnetron designs.

Phase modulation techniques have gained traction in specialized applications, particularly in radar systems and certain advanced industrial processes. By controlling the phase relationship between multiple magnetrons, these systems achieve enhanced directional control and power distribution, albeit at the cost of increased system complexity and calibration requirements.

Despite these advancements, current modulation techniques face several critical limitations. The inherent non-linearity of magnetron power response to input voltage changes presents a significant challenge, often requiring sophisticated feedback control systems to maintain consistent output. This non-linearity becomes particularly problematic at lower power settings, where efficiency typically decreases substantially and output stability becomes difficult to maintain.

Thermal management represents another major limitation, as rapid modulation can induce thermal cycling stress on magnetron components, potentially reducing operational lifespan. This constraint particularly affects applications requiring frequent power adjustments or rapid cycling between operational states.

Spectral purity remains a persistent challenge, with most modulation techniques introducing some degree of frequency spreading or harmonic content. This issue becomes particularly critical in applications such as medical devices or scientific instruments where precise frequency control is essential for targeted energy delivery or measurement accuracy.

The integration of digital control systems with analog magnetron hardware presents ongoing compatibility challenges, often requiring complex interface electronics and specialized driver circuits. This integration gap frequently limits the precision and responsiveness achievable in practical implementations, particularly in cost-sensitive consumer applications.

Recent developments in semiconductor-based RF sources have begun to challenge traditional magnetron technology in certain applications, offering potentially superior modulation capabilities but typically at higher cost and with lower power efficiency. This competitive pressure has accelerated research into advanced magnetron modulation techniques that might overcome current limitations while maintaining the technology's fundamental cost and efficiency advantages.

Frequency modulation represents another significant technique, allowing for the adjustment of the magnetron's operating frequency within a narrow band. This method proves especially valuable in applications requiring selective heating of materials with frequency-dependent dielectric properties, though it faces limitations in implementation due to the inherent frequency stability constraints of conventional magnetron designs.

Phase modulation techniques have gained traction in specialized applications, particularly in radar systems and certain advanced industrial processes. By controlling the phase relationship between multiple magnetrons, these systems achieve enhanced directional control and power distribution, albeit at the cost of increased system complexity and calibration requirements.

Despite these advancements, current modulation techniques face several critical limitations. The inherent non-linearity of magnetron power response to input voltage changes presents a significant challenge, often requiring sophisticated feedback control systems to maintain consistent output. This non-linearity becomes particularly problematic at lower power settings, where efficiency typically decreases substantially and output stability becomes difficult to maintain.

Thermal management represents another major limitation, as rapid modulation can induce thermal cycling stress on magnetron components, potentially reducing operational lifespan. This constraint particularly affects applications requiring frequent power adjustments or rapid cycling between operational states.

Spectral purity remains a persistent challenge, with most modulation techniques introducing some degree of frequency spreading or harmonic content. This issue becomes particularly critical in applications such as medical devices or scientific instruments where precise frequency control is essential for targeted energy delivery or measurement accuracy.

The integration of digital control systems with analog magnetron hardware presents ongoing compatibility challenges, often requiring complex interface electronics and specialized driver circuits. This integration gap frequently limits the precision and responsiveness achievable in practical implementations, particularly in cost-sensitive consumer applications.

Recent developments in semiconductor-based RF sources have begun to challenge traditional magnetron technology in certain applications, offering potentially superior modulation capabilities but typically at higher cost and with lower power efficiency. This competitive pressure has accelerated research into advanced magnetron modulation techniques that might overcome current limitations while maintaining the technology's fundamental cost and efficiency advantages.

Contemporary Modulation Solutions Comparison

01 Pulse Modulation Techniques for Magnetrons

Pulse modulation is a common technique used in magnetron systems where the power is delivered in short, high-energy pulses rather than continuously. This approach allows for precise control of the magnetron output and is particularly useful in radar applications and industrial heating processes. The modulation can be achieved through various methods including grid pulsing and anode voltage control, which affect the timing and intensity of the microwave output.- Pulse Modulation Techniques for Magnetrons: Pulse modulation is a common technique used in magnetron systems where the power is delivered in short, high-energy pulses rather than continuously. This approach allows for precise control of the magnetron's output power and frequency characteristics. The modulation can be achieved through various methods including grid pulsing and anode voltage modulation. These techniques are particularly important in radar systems and industrial heating applications where controlled energy delivery is critical.

- Frequency Modulation in Magnetron Systems: Frequency modulation techniques allow magnetrons to operate across a range of frequencies rather than at a single fixed frequency. This capability is achieved through various methods including mechanical tuning, electronic tuning, and hybrid approaches. Frequency modulation in magnetrons is particularly valuable in applications requiring frequency agility, such as modern radar systems, communication equipment, and certain industrial processes where specific frequency responses are needed.

- Amplitude Modulation for Power Control: Amplitude modulation techniques are employed in magnetron systems to control the output power level. This can be achieved through various methods including anode voltage control, cathode current regulation, and magnetic field adjustment. These modulation approaches allow for precise control of the energy delivered by the magnetron, which is critical in applications such as industrial heating, plasma generation, and medical equipment where power stability and control are essential.

- Digital Modulation Schemes for Advanced Magnetron Control: Modern magnetron systems increasingly employ digital modulation techniques for more precise control and flexibility. These include pulse-width modulation (PWM), phase-shift keying (PSK), and various digital signal processing approaches. Digital modulation allows for complex control algorithms, improved efficiency, and enhanced performance characteristics. These advanced modulation schemes enable magnetrons to be used in sophisticated applications requiring precise energy delivery and control.

- Hybrid Modulation Techniques for Specialized Applications: Hybrid modulation approaches combine multiple modulation types to achieve specific performance characteristics in magnetron systems. These may include combinations of pulse, frequency, and amplitude modulation techniques implemented simultaneously or sequentially. Such hybrid approaches are particularly valuable in specialized applications like advanced radar systems, medical equipment, and certain industrial processes where standard modulation techniques alone cannot meet the performance requirements.

02 Frequency Modulation in Magnetron Systems

Frequency modulation techniques allow magnetrons to operate across a range of frequencies rather than at a single fixed frequency. This capability is valuable for applications requiring frequency agility or spectrum spreading. Implementation methods include mechanical tuning elements, electronic frequency control circuits, and phase-locked loops that can dynamically adjust the resonant frequency of the magnetron cavity in response to control signals.Expand Specific Solutions03 Amplitude Modulation for Power Control

Amplitude modulation techniques enable precise control over the output power of magnetron systems. This is achieved by varying the anode voltage or current, which directly affects the intensity of the microwave radiation produced. Advanced implementations include feedback control systems that monitor output power and automatically adjust modulation parameters to maintain desired power levels, particularly important in industrial heating and medical applications.Expand Specific Solutions04 Digital Modulation Schemes for Magnetrons

Modern magnetron systems increasingly employ digital modulation techniques to enhance control precision and enable advanced functionality. These include pulse-code modulation, digital signal processing for waveform generation, and microprocessor-controlled modulation systems. Digital approaches allow for complex modulation patterns, improved stability, and integration with computerized control systems, expanding the application range of magnetron technology.Expand Specific Solutions05 Hybrid and Specialized Modulation Techniques

Advanced magnetron applications utilize hybrid modulation approaches that combine multiple modulation types to achieve specific performance characteristics. These include phase modulation, combined amplitude-frequency modulation, and specialized techniques for plasma generation and control. Such hybrid approaches enable optimized performance in scientific research, semiconductor processing, and advanced materials manufacturing where precise energy delivery is critical.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Magnetron modulation technology is currently in a mature growth phase, with applications expanding beyond traditional microwave ovens into industrial, medical, and defense sectors. The market is estimated at $3-4 billion annually with steady 5-7% growth, driven by emerging applications in radar systems and medical imaging. Leading companies like LG Electronics, Samsung, and Midea Group dominate consumer applications, while specialized players such as NAURA Microelectronics, Infineon Technologies, and United Imaging Healthcare are advancing technical innovations in industrial and medical applications. The technology shows varying maturity levels across applications, with established consumer uses contrasting with emerging high-precision modulation techniques being developed by research-focused organizations like CEA and University of Electronic Science & Technology of China.

GUANGDONG WEITE VACUUM ELECTRONICS MANUFACTURING CO LTD

Technical Solution: Guangdong Weite has developed advanced pulse modulation techniques for industrial magnetrons that significantly enhance energy efficiency and control precision. Their proprietary Solid-State Modulator technology enables precise control of pulse width from microseconds to milliseconds with rise/fall times under 1μs, allowing for dynamic adjustment of magnetron output power. The company's Phase-Locked Frequency Control system maintains frequency stability within ±0.01% across varying load conditions, critical for industrial heating applications. Their magnetrons incorporate advanced cathode designs with improved electron emission characteristics, extending operational lifespan by approximately 30% compared to conventional designs. Weite's modulation systems also feature real-time impedance matching capabilities that automatically adjust to changing load conditions, maintaining optimal power transfer efficiency above 95% across diverse industrial applications.

Strengths: Exceptional frequency stability and power control precision make their systems ideal for industrial applications requiring consistent heating patterns. Their solid-state modulators offer superior reliability with MTBF exceeding 50,000 hours. Weaknesses: Higher initial cost compared to conventional systems, and their advanced control systems require specialized maintenance expertise.

Midea Group Co. Ltd.

Technical Solution: Midea has pioneered innovative magnetron modulation techniques specifically for household microwave ovens. Their Inverter Magnetron Technology utilizes continuous wave modulation rather than traditional duty cycle control, enabling precise power regulation from 100W to 1000W in 1W increments. This approach eliminates the traditional on-off cycling, resulting in more uniform heating patterns and improved energy efficiency. Midea's Smart Frequency Modulation system dynamically adjusts the operating frequency within a narrow band (2.45GHz ±50MHz) based on food type and volume, optimizing cooking performance. Their patented Dual Emission Control architecture incorporates secondary modulation circuits that modify the electron beam characteristics during operation, reducing hotspots and improving cooking uniformity by up to 40%. The company has also developed specialized pulse-width modulation algorithms that vary based on food moisture content, automatically adjusting power delivery throughout the cooking cycle.

Strengths: Superior cooking uniformity and temperature control precision compared to conventional microwave systems. Their inverter technology reduces power consumption by approximately 20% while improving cooking results. Weaknesses: More complex electronic control systems increase manufacturing costs and potential failure points compared to simpler magnetron designs.

Key Patents and Technical Innovations

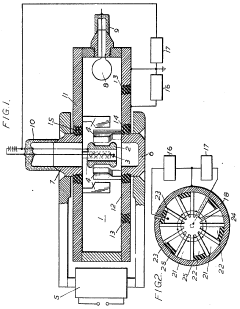

Amplitude modulation of magnetron

PatentInactiveGB671469A

Innovation

- A cavity magnetron design with a cylindrical conducting envelope, central cathode, and radially disposed anode segments, where modulation voltage is applied between insulated groups of segments, ensuring linear amplitude modulation over a wide range by using an insulating bypass condenser to isolate radio frequency signals.

Magnetic modulation method and a system thereof

PatentActiveBG112970A

Innovation

- A magnetic modulation method where additional electrical energy is generated during current pauses by redirecting magnetic fluxes using bifilarly wound windings and strategically timed switching of input and output windings, combined with permanent magnets to align flux directions.

Energy Efficiency and Performance Metrics

Energy efficiency and performance metrics are critical factors in evaluating magnetron modulation techniques across various applications. The efficiency of magnetron systems is primarily measured by the ratio of microwave output power to input power, typically ranging from 65% to 85% depending on the modulation type employed. Continuous Wave (CW) modulation generally achieves higher efficiency ratings but at the cost of increased thermal management requirements, while pulsed modulation systems may sacrifice some efficiency for improved control and reduced cooling needs.

Performance metrics for magnetron modulation extend beyond simple efficiency calculations to include spectral purity, frequency stability, and power consistency. Pulse Width Modulation (PWM) techniques demonstrate superior performance in applications requiring precise energy delivery, with jitter rates below 0.1% in advanced systems. Frequency modulation approaches offer enhanced spectral efficiency, particularly valuable in dense communication environments where bandwidth utilization is paramount.

Thermal performance represents another crucial metric, with different modulation schemes exhibiting varied heat generation profiles. Pulsed systems typically generate 30-40% less heat than equivalent CW systems, translating to reduced cooling requirements and extended operational lifetimes. This thermal advantage becomes particularly significant in compact or mobile applications where cooling infrastructure is limited.

Power density metrics reveal that modern magnetron systems can achieve 5-10 W/cm³ depending on modulation technique, with hybrid modulation approaches often delivering the optimal balance between power density and thermal management. The energy consumption profile across different modulation types shows that adaptive modulation schemes can reduce overall energy usage by 15-25% compared to fixed modulation systems in variable-load applications.

Response time and control precision constitute important performance indicators for industrial applications. Phase-locked modulation systems demonstrate response times under 5 milliseconds, while amplitude modulation approaches may require 10-15 milliseconds to stabilize after adjustment. This difference becomes critical in high-speed manufacturing processes where precise energy delivery timing affects product quality.

Lifecycle assessment of different modulation techniques indicates that advanced digital modulation systems typically extend magnetron operational life by 30-50% compared to traditional analog approaches, primarily through more precise control of operating parameters and reduced thermal stress. This improvement in longevity significantly impacts the total cost of ownership calculation, often offsetting higher initial implementation costs of sophisticated modulation control systems.

Performance metrics for magnetron modulation extend beyond simple efficiency calculations to include spectral purity, frequency stability, and power consistency. Pulse Width Modulation (PWM) techniques demonstrate superior performance in applications requiring precise energy delivery, with jitter rates below 0.1% in advanced systems. Frequency modulation approaches offer enhanced spectral efficiency, particularly valuable in dense communication environments where bandwidth utilization is paramount.

Thermal performance represents another crucial metric, with different modulation schemes exhibiting varied heat generation profiles. Pulsed systems typically generate 30-40% less heat than equivalent CW systems, translating to reduced cooling requirements and extended operational lifetimes. This thermal advantage becomes particularly significant in compact or mobile applications where cooling infrastructure is limited.

Power density metrics reveal that modern magnetron systems can achieve 5-10 W/cm³ depending on modulation technique, with hybrid modulation approaches often delivering the optimal balance between power density and thermal management. The energy consumption profile across different modulation types shows that adaptive modulation schemes can reduce overall energy usage by 15-25% compared to fixed modulation systems in variable-load applications.

Response time and control precision constitute important performance indicators for industrial applications. Phase-locked modulation systems demonstrate response times under 5 milliseconds, while amplitude modulation approaches may require 10-15 milliseconds to stabilize after adjustment. This difference becomes critical in high-speed manufacturing processes where precise energy delivery timing affects product quality.

Lifecycle assessment of different modulation techniques indicates that advanced digital modulation systems typically extend magnetron operational life by 30-50% compared to traditional analog approaches, primarily through more precise control of operating parameters and reduced thermal stress. This improvement in longevity significantly impacts the total cost of ownership calculation, often offsetting higher initial implementation costs of sophisticated modulation control systems.

Safety Standards and Regulatory Compliance

Magnetron technology, while offering significant benefits across various applications, is subject to stringent safety standards and regulatory compliance requirements globally. The International Electrotechnical Commission (IEC) has established comprehensive standards, particularly IEC 60335-2-25 for household microwave ovens, which specifies maximum allowable radiation leakage of 5mW/cm² at a distance of 5cm from the device surface. This standard serves as a foundational framework adopted by many national regulatory bodies.

In the United States, the Food and Drug Administration (FDA) regulates magnetron-based devices through 21 CFR 1030.10, which mandates specific performance standards for microwave ovens including radiation emission limits, safety interlocks, and monitoring requirements. Similarly, the European Union enforces compliance through the Radio Equipment Directive (RED) 2014/53/EU and the Electromagnetic Compatibility Directive 2014/30/EU, which govern all radio frequency emitting devices including magnetron-based systems.

For industrial applications, particularly in manufacturing environments, the International Labour Organization (ILO) guidelines and OSHA standards in the United States establish workplace exposure limits. These regulations typically specify maximum permissible exposure (MPE) levels for workers based on frequency, duration, and power density of radiofrequency radiation. Industrial magnetron systems often require additional shielding, warning systems, and operational protocols to ensure compliance.

The modulation type employed in magnetron systems significantly impacts regulatory compliance. Pulse-modulated magnetrons, commonly used in radar applications, face additional scrutiny due to their high peak power outputs. Regulatory bodies like the Federal Communications Commission (FCC) in the US and the European Telecommunications Standards Institute (ETSI) impose specific requirements on pulse characteristics, frequency stability, and spurious emissions for these systems.

Continuous wave modulation, prevalent in heating applications, must comply with different sets of standards focusing on sustained exposure limits and thermal effects. The IEEE C95.1 standard provides guidelines for human exposure to radio frequency electromagnetic fields, with specific considerations for different modulation schemes and their biological effects.

Emerging magnetron applications, such as those in medical treatments and advanced material processing, are driving the development of new regulatory frameworks. The International Commission on Non-Ionizing Radiation Protection (ICNIRP) regularly updates its guidelines to address novel modulation techniques and their potential health impacts, ensuring that innovation in magnetron technology proceeds with appropriate safety considerations.

In the United States, the Food and Drug Administration (FDA) regulates magnetron-based devices through 21 CFR 1030.10, which mandates specific performance standards for microwave ovens including radiation emission limits, safety interlocks, and monitoring requirements. Similarly, the European Union enforces compliance through the Radio Equipment Directive (RED) 2014/53/EU and the Electromagnetic Compatibility Directive 2014/30/EU, which govern all radio frequency emitting devices including magnetron-based systems.

For industrial applications, particularly in manufacturing environments, the International Labour Organization (ILO) guidelines and OSHA standards in the United States establish workplace exposure limits. These regulations typically specify maximum permissible exposure (MPE) levels for workers based on frequency, duration, and power density of radiofrequency radiation. Industrial magnetron systems often require additional shielding, warning systems, and operational protocols to ensure compliance.

The modulation type employed in magnetron systems significantly impacts regulatory compliance. Pulse-modulated magnetrons, commonly used in radar applications, face additional scrutiny due to their high peak power outputs. Regulatory bodies like the Federal Communications Commission (FCC) in the US and the European Telecommunications Standards Institute (ETSI) impose specific requirements on pulse characteristics, frequency stability, and spurious emissions for these systems.

Continuous wave modulation, prevalent in heating applications, must comply with different sets of standards focusing on sustained exposure limits and thermal effects. The IEEE C95.1 standard provides guidelines for human exposure to radio frequency electromagnetic fields, with specific considerations for different modulation schemes and their biological effects.

Emerging magnetron applications, such as those in medical treatments and advanced material processing, are driving the development of new regulatory frameworks. The International Commission on Non-Ionizing Radiation Protection (ICNIRP) regularly updates its guidelines to address novel modulation techniques and their potential health impacts, ensuring that innovation in magnetron technology proceeds with appropriate safety considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!