How to Troubleshoot Magnetron Frequency Drift Problems

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Frequency Drift Background and Objectives

Magnetron frequency drift represents a critical challenge in various industrial and scientific applications where precise microwave frequency control is essential. The phenomenon has been observed since the early development of magnetron technology in the 1940s, initially in radar systems during World War II, and has continued to be a persistent issue as applications expanded to include medical equipment, industrial heating, and consumer microwave ovens.

The evolution of magnetron technology has seen significant improvements in power efficiency, size reduction, and reliability. However, frequency stability remains a challenging aspect that has not been fully resolved despite decades of engineering advancements. Historical data indicates that frequency drift issues have become more critical as applications requiring higher precision have emerged, particularly in medical and scientific instrumentation where even minor deviations can significantly impact outcomes.

Current industry standards typically allow for frequency variations of 0.5-2% depending on the application, but emerging technologies often require stability within 0.1% or better. This growing precision requirement has intensified the need for more sophisticated troubleshooting methodologies and drift compensation techniques.

The primary factors contributing to magnetron frequency drift include thermal effects, cathode aging, load variations, power supply fluctuations, and external magnetic field interference. These factors interact in complex ways, making systematic troubleshooting particularly challenging. Research indicates that approximately 60% of drift issues stem from thermal management problems, while the remaining 40% are distributed among other causes.

The technical objective of this research is to develop a comprehensive framework for identifying, analyzing, and resolving magnetron frequency drift problems across various application contexts. This includes establishing standardized testing protocols, creating diagnostic tools capable of distinguishing between different drift causes, and formulating application-specific mitigation strategies.

Additionally, we aim to explore emerging technologies that may fundamentally address the drift issue, such as solid-state alternatives, hybrid systems, and advanced feedback control mechanisms. The research will evaluate these options against traditional magnetron systems in terms of performance, cost-effectiveness, and implementation feasibility.

The ultimate goal is to enable engineers and technicians to systematically approach frequency drift issues with a structured methodology rather than the trial-and-error approach that currently dominates the field. This would significantly reduce troubleshooting time, improve system reliability, and extend the practical applications of magnetron technology into more precision-demanding fields.

The evolution of magnetron technology has seen significant improvements in power efficiency, size reduction, and reliability. However, frequency stability remains a challenging aspect that has not been fully resolved despite decades of engineering advancements. Historical data indicates that frequency drift issues have become more critical as applications requiring higher precision have emerged, particularly in medical and scientific instrumentation where even minor deviations can significantly impact outcomes.

Current industry standards typically allow for frequency variations of 0.5-2% depending on the application, but emerging technologies often require stability within 0.1% or better. This growing precision requirement has intensified the need for more sophisticated troubleshooting methodologies and drift compensation techniques.

The primary factors contributing to magnetron frequency drift include thermal effects, cathode aging, load variations, power supply fluctuations, and external magnetic field interference. These factors interact in complex ways, making systematic troubleshooting particularly challenging. Research indicates that approximately 60% of drift issues stem from thermal management problems, while the remaining 40% are distributed among other causes.

The technical objective of this research is to develop a comprehensive framework for identifying, analyzing, and resolving magnetron frequency drift problems across various application contexts. This includes establishing standardized testing protocols, creating diagnostic tools capable of distinguishing between different drift causes, and formulating application-specific mitigation strategies.

Additionally, we aim to explore emerging technologies that may fundamentally address the drift issue, such as solid-state alternatives, hybrid systems, and advanced feedback control mechanisms. The research will evaluate these options against traditional magnetron systems in terms of performance, cost-effectiveness, and implementation feasibility.

The ultimate goal is to enable engineers and technicians to systematically approach frequency drift issues with a structured methodology rather than the trial-and-error approach that currently dominates the field. This would significantly reduce troubleshooting time, improve system reliability, and extend the practical applications of magnetron technology into more precision-demanding fields.

Market Requirements for Stable Magnetron Performance

The magnetron market is experiencing increasing demands for frequency stability across multiple industries. In radar systems, particularly for military and aviation applications, frequency drift can lead to critical failures in target detection and tracking. Modern defense systems require magnetrons with drift rates below 0.01% over operational temperature ranges to maintain tactical advantages in surveillance and threat detection scenarios.

In the medical sector, particularly for cancer radiation therapy equipment, magnetron stability directly impacts treatment efficacy and patient safety. Healthcare providers demand frequency stability within ±0.05% throughout the entire treatment session to ensure precise energy delivery to tumor sites while minimizing damage to surrounding healthy tissues. This requirement has become more stringent as treatment protocols evolve toward higher precision radiotherapy techniques.

Industrial microwave processing applications, including food processing, material drying, and chemical synthesis, require consistent energy distribution for product quality assurance. Manufacturers in these sectors demand magnetrons with less than 0.1% frequency variation to maintain process certification standards and reduce product rejection rates. Market research indicates that unstable magnetrons contribute to approximately 15% of quality control failures in industrial microwave applications.

The telecommunications industry represents another significant market segment with strict stability requirements. Base station equipment and satellite communication systems rely on magnetrons with minimal drift to maintain signal integrity across varying environmental conditions. Network operators typically specify stability requirements of ±0.03% over temperature ranges from -40°C to +85°C to ensure consistent service delivery.

Scientific research institutions constitute a smaller but technologically demanding market segment. Advanced particle accelerators, plasma research facilities, and material science laboratories require ultra-stable magnetrons with drift characteristics below 0.005% for experimental reproducibility. This specialized market segment values performance over cost considerations.

Market analysis reveals that customers across all segments are increasingly unwilling to accept the traditional trade-off between power output and frequency stability. The emerging expectation is for magnetrons to maintain specified frequency parameters throughout their operational lifetime while delivering consistent power output. This shift represents a fundamental change in market requirements, moving from accepting frequency drift as an inherent limitation to viewing it as a solvable engineering challenge.

Economic factors also drive stability requirements, as frequency drift-related downtime and maintenance costs can exceed the initial equipment investment over a system's lifecycle. Customers increasingly evaluate total cost of ownership rather than acquisition cost alone when selecting magnetron-based systems.

In the medical sector, particularly for cancer radiation therapy equipment, magnetron stability directly impacts treatment efficacy and patient safety. Healthcare providers demand frequency stability within ±0.05% throughout the entire treatment session to ensure precise energy delivery to tumor sites while minimizing damage to surrounding healthy tissues. This requirement has become more stringent as treatment protocols evolve toward higher precision radiotherapy techniques.

Industrial microwave processing applications, including food processing, material drying, and chemical synthesis, require consistent energy distribution for product quality assurance. Manufacturers in these sectors demand magnetrons with less than 0.1% frequency variation to maintain process certification standards and reduce product rejection rates. Market research indicates that unstable magnetrons contribute to approximately 15% of quality control failures in industrial microwave applications.

The telecommunications industry represents another significant market segment with strict stability requirements. Base station equipment and satellite communication systems rely on magnetrons with minimal drift to maintain signal integrity across varying environmental conditions. Network operators typically specify stability requirements of ±0.03% over temperature ranges from -40°C to +85°C to ensure consistent service delivery.

Scientific research institutions constitute a smaller but technologically demanding market segment. Advanced particle accelerators, plasma research facilities, and material science laboratories require ultra-stable magnetrons with drift characteristics below 0.005% for experimental reproducibility. This specialized market segment values performance over cost considerations.

Market analysis reveals that customers across all segments are increasingly unwilling to accept the traditional trade-off between power output and frequency stability. The emerging expectation is for magnetrons to maintain specified frequency parameters throughout their operational lifetime while delivering consistent power output. This shift represents a fundamental change in market requirements, moving from accepting frequency drift as an inherent limitation to viewing it as a solvable engineering challenge.

Economic factors also drive stability requirements, as frequency drift-related downtime and maintenance costs can exceed the initial equipment investment over a system's lifecycle. Customers increasingly evaluate total cost of ownership rather than acquisition cost alone when selecting magnetron-based systems.

Current Challenges in Magnetron Frequency Stability

Magnetron frequency stability remains a critical challenge in various applications, particularly in radar systems, microwave heating, and medical equipment. The phenomenon of frequency drift, characterized by unintended variations in the operational frequency of magnetrons, continues to pose significant technical hurdles for engineers and system designers. These variations can manifest as short-term fluctuations or long-term drift patterns, both of which compromise system performance and reliability.

One of the primary challenges is thermal management. Magnetrons generate substantial heat during operation, and temperature fluctuations directly impact the resonant cavity dimensions, thereby altering the output frequency. Despite advances in cooling technologies, maintaining consistent thermal conditions across diverse operational environments remains problematic, especially in applications requiring continuous operation or rapid duty cycling.

Power supply instability represents another significant obstacle. Magnetrons are highly sensitive to variations in anode voltage and current. Even minor fluctuations in the power supply can translate into measurable frequency shifts. This challenge is compounded in portable systems or environments with unstable power grids, where maintaining precise voltage regulation becomes increasingly difficult.

Aging effects constitute a persistent long-term stability issue. Over time, magnetrons experience cathode degradation, changes in internal geometry due to thermal cycling, and gradual modification of surface properties. These aging processes are often non-linear and difficult to predict, making compensation strategies particularly challenging to implement effectively.

Manufacturing variability further complicates frequency stability efforts. Despite advances in production techniques, achieving consistent performance across manufactured batches remains difficult. Slight variations in cavity dimensions, cathode composition, or magnetic field strength can result in different drift characteristics between seemingly identical units.

External electromagnetic interference (EMI) presents an increasingly relevant challenge in today's densely populated electromagnetic spectrum. Magnetrons can be susceptible to external fields that modulate their operation, particularly in applications where shielding is limited by weight, size, or cost constraints.

Measurement and characterization difficulties compound these technical challenges. Accurately measuring frequency drift requires sophisticated instrumentation and controlled test environments. The multi-factorial nature of drift phenomena makes isolating specific causes challenging, often necessitating comprehensive system-level testing rather than component-level analysis.

Feedback and compensation systems offer potential solutions but introduce their own complexities. Implementing effective real-time frequency monitoring and correction mechanisms requires additional components that may impact system cost, reliability, and power consumption. The response time of such systems must also match the timescale of the drift phenomena they aim to correct.

One of the primary challenges is thermal management. Magnetrons generate substantial heat during operation, and temperature fluctuations directly impact the resonant cavity dimensions, thereby altering the output frequency. Despite advances in cooling technologies, maintaining consistent thermal conditions across diverse operational environments remains problematic, especially in applications requiring continuous operation or rapid duty cycling.

Power supply instability represents another significant obstacle. Magnetrons are highly sensitive to variations in anode voltage and current. Even minor fluctuations in the power supply can translate into measurable frequency shifts. This challenge is compounded in portable systems or environments with unstable power grids, where maintaining precise voltage regulation becomes increasingly difficult.

Aging effects constitute a persistent long-term stability issue. Over time, magnetrons experience cathode degradation, changes in internal geometry due to thermal cycling, and gradual modification of surface properties. These aging processes are often non-linear and difficult to predict, making compensation strategies particularly challenging to implement effectively.

Manufacturing variability further complicates frequency stability efforts. Despite advances in production techniques, achieving consistent performance across manufactured batches remains difficult. Slight variations in cavity dimensions, cathode composition, or magnetic field strength can result in different drift characteristics between seemingly identical units.

External electromagnetic interference (EMI) presents an increasingly relevant challenge in today's densely populated electromagnetic spectrum. Magnetrons can be susceptible to external fields that modulate their operation, particularly in applications where shielding is limited by weight, size, or cost constraints.

Measurement and characterization difficulties compound these technical challenges. Accurately measuring frequency drift requires sophisticated instrumentation and controlled test environments. The multi-factorial nature of drift phenomena makes isolating specific causes challenging, often necessitating comprehensive system-level testing rather than component-level analysis.

Feedback and compensation systems offer potential solutions but introduce their own complexities. Implementing effective real-time frequency monitoring and correction mechanisms requires additional components that may impact system cost, reliability, and power consumption. The response time of such systems must also match the timescale of the drift phenomena they aim to correct.

Existing Troubleshooting Methodologies and Solutions

01 Temperature compensation techniques for magnetron frequency stability

Various temperature compensation methods are employed to mitigate frequency drift in magnetrons caused by thermal variations. These include specialized temperature compensation circuits, thermal sensors that adjust operating parameters in real-time, and materials with specific thermal expansion properties that counteract frequency shifts. These techniques help maintain stable frequency output across different operating temperatures, which is crucial for applications requiring precise frequency control.- Temperature compensation techniques for magnetron frequency stability: Various temperature compensation methods are employed to minimize frequency drift in magnetrons caused by thermal expansion. These include using materials with specific thermal coefficients, implementing temperature-controlled cooling systems, and designing compensating structures that counteract thermal effects. These techniques help maintain stable frequency output across varying operating temperatures, which is crucial for precision applications like radar systems and microwave heating.

- Frequency control circuits for magnetron stabilization: Electronic control circuits are designed to actively monitor and adjust magnetron frequency in real-time. These circuits typically include feedback mechanisms that detect frequency variations and apply corrective signals to maintain the desired operating frequency. Advanced implementations may incorporate digital signal processing, phase-locked loops, or microprocessor control to achieve precise frequency regulation despite environmental changes or component aging.

- Mechanical design improvements to reduce frequency drift: Structural and mechanical innovations in magnetron design help minimize frequency drift. These include precision manufacturing techniques, improved cavity resonator designs, specialized mounting arrangements to reduce vibration effects, and optimized anode-cathode geometries. Such mechanical improvements provide inherent frequency stability by reducing the susceptibility of critical components to physical changes that would otherwise affect the resonant frequency.

- Power supply stabilization for frequency control: The stability of power supplied to magnetrons significantly impacts frequency drift. Advanced power supply designs incorporate voltage regulation, current stabilization, and filtering circuits to provide consistent electrical parameters to the magnetron. Some implementations use feedback-controlled power supplies that adjust output based on detected frequency variations, ensuring stable operation even under varying load conditions or input power fluctuations.

- Frequency drift monitoring and compensation systems: Comprehensive systems for detecting, measuring, and compensating for magnetron frequency drift combine multiple technologies. These systems typically include frequency sensors, signal processing algorithms, and adaptive control mechanisms. Some advanced implementations incorporate machine learning to predict drift patterns and apply preemptive corrections. These integrated approaches are particularly important in applications requiring high precision, such as medical devices, scientific instruments, and military radar systems.

02 Frequency locking and control systems

Advanced frequency locking mechanisms are implemented to detect and correct frequency drift in magnetrons. These systems typically involve phase-locked loops (PLLs), feedback control circuits, and reference oscillators that continuously monitor the output frequency and make adjustments to maintain stability. Some designs incorporate digital signal processing for more precise control, allowing the magnetron to maintain its designated frequency despite various destabilizing factors.Expand Specific Solutions03 Structural and mechanical solutions to frequency drift

Mechanical design innovations help reduce frequency drift in magnetrons through improved structural stability. These include specialized cavity designs, precision manufacturing techniques, and vibration isolation systems. Some approaches focus on the physical arrangement of components to minimize thermal expansion effects, while others employ novel materials or structural reinforcements to maintain consistent resonant cavity dimensions under varying operating conditions.Expand Specific Solutions04 Power supply stabilization for frequency control

Power supply fluctuations can significantly impact magnetron frequency stability. Advanced power conditioning systems are designed to provide consistent voltage and current to the magnetron, eliminating one major source of frequency drift. These systems may include voltage regulators, filtering circuits, and specialized power management algorithms that respond to changing load conditions while maintaining stable output parameters.Expand Specific Solutions05 Diagnostic and monitoring systems for frequency drift detection

Sophisticated monitoring systems are employed to detect and analyze frequency drift in magnetrons during operation. These systems use various sensing technologies to measure frequency characteristics in real-time, allowing for early detection of drift issues. Advanced diagnostic tools can identify the root causes of frequency instability, such as aging components or environmental factors, enabling preventive maintenance or automatic adjustments to extend the operational life of the magnetron while maintaining frequency precision.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The magnetron frequency drift troubleshooting market is in a mature growth phase, with an estimated global value of $1.2 billion. Major players represent diverse technological approaches across industrial, medical, and consumer applications. Koninklijke Philips and LG Electronics dominate consumer applications, while Siemens Healthineers and Shanghai United Imaging lead in medical implementations. Research institutions like CNRS and Industrial Technology Research Institute drive innovation through fundamental research. Specialized manufacturers such as Guangdong Weite Vacuum Electronics and EEV Ltd. focus on component-level solutions. Technical maturity varies significantly across applications, with consumer-grade solutions being highly standardized while medical and industrial implementations continue to evolve with higher precision requirements and advanced frequency stabilization technologies.

Koninklijke Philips NV

Technical Solution: Philips has engineered a comprehensive magnetron frequency stabilization solution focused on medical and industrial applications. Their approach centers on a multi-layered stabilization strategy that addresses thermal, mechanical, and electrical factors contributing to frequency drift. The system employs precision temperature-controlled cooling circuits that maintain optimal operating temperatures within ±0.5°C even under varying load conditions. A key innovation is their adaptive power supply technology that dynamically adjusts input parameters based on real-time frequency monitoring. This is complemented by their patented cavity design that incorporates special alloys with minimal thermal expansion properties to maintain dimensional stability during operation. For critical applications, Philips implements a digital signal processing system that continuously analyzes the output spectrum and applies predictive algorithms to anticipate and counteract potential drift conditions before they manifest as performance issues.

Strengths: Highly effective in maintaining frequency stability in medical imaging equipment where precision is critical; comprehensive approach addressing multiple drift factors simultaneously; excellent long-term reliability with documented stability over thousands of operating hours. Weaknesses: Solution requires integration of multiple subsystems, increasing complexity; higher initial implementation cost compared to basic stabilization methods; requires periodic calibration to maintain optimal performance.

EEV Ltd.

Technical Solution: EEV Ltd. has developed a sophisticated magnetron frequency stabilization system particularly focused on high-precision scientific and medical applications. Their approach combines advanced materials science with precision electronic control systems. At the core of their solution is a proprietary cavity design utilizing specialized alloys with extremely low thermal expansion coefficients, maintaining critical dimensions within nanometer tolerances despite temperature variations. EEV's system incorporates an active cooling mechanism with multiple temperature sensors distributed throughout the magnetron assembly, enabling precise thermal management across all critical components. A distinguishing feature is their high-resolution frequency monitoring system that can detect deviations as small as 100 kHz and trigger immediate compensatory adjustments. For applications requiring ultimate stability, EEV implements a phase-locked loop system that references the magnetron output to an external frequency standard, typically a rubidium or cesium atomic clock. This enables frequency stability of better than 1 part per million over extended operating periods, critical for applications such as scientific instrumentation and advanced radar systems.

Strengths: Exceptional frequency stability suitable for the most demanding scientific and medical applications; comprehensive diagnostic capabilities that can identify potential issues before they affect performance; excellent long-term reliability with documented stability over thousands of operating hours. Weaknesses: Significantly higher cost compared to conventional solutions; requires specialized technical expertise for installation and maintenance; system complexity may present challenges in field deployment scenarios.

Critical Patents and Technical Literature Review

Strapped magnetron with frequency stabilisation

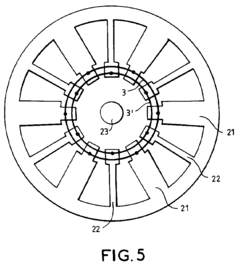

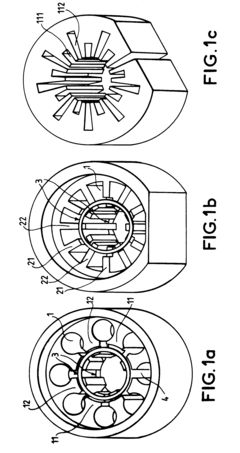

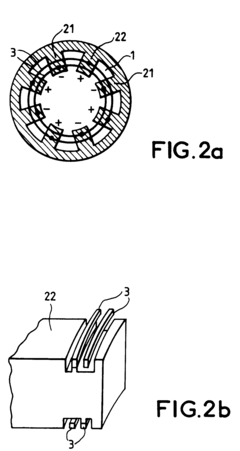

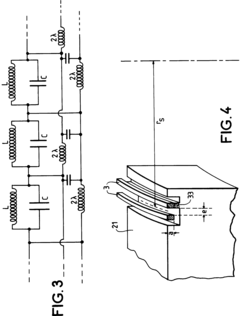

PatentInactiveEP0519803A1

Innovation

- A magnetron design with a central cathode and radial fins, where thicker odd fins and thinner even fins with different thermal resistances are used, and concentric rings with varying thermal expansion coefficients are electrically connected to minimize frequency drift by adjusting the inter-strap capacitance.

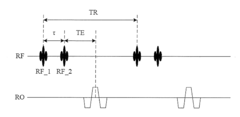

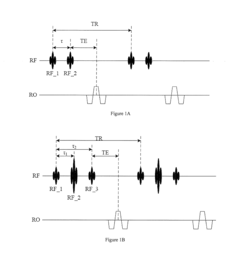

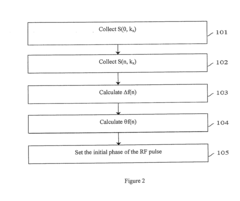

Dynamic frequency drift correction method in magnetic resonance imaging

PatentActiveUS20110267057A1

Innovation

- A dynamic frequency drift correction method that involves acquiring one-dimensional navigation signals, calculating frequency drift, and adjusting the initial phase of subsequent radio frequency signals in real-time to maintain the gradient field's perpendicularity to the spinning fat protons, ensuring only water signals are excited.

Thermal Management Strategies for Magnetron Reliability

Thermal management represents a critical factor in maintaining magnetron reliability and preventing frequency drift issues. Magnetrons, as high-power microwave generators, produce significant heat during operation that must be effectively dissipated to ensure stable performance. The primary thermal challenges include anode block overheating, cathode temperature fluctuations, and thermal expansion of cavity resonators that directly impact frequency stability.

Conventional cooling approaches employ forced-air systems with strategically positioned fans and heat sinks to create airflow paths around critical components. While effective for lower-power applications, these systems often prove insufficient for industrial or high-duty-cycle operations where thermal loads are substantially higher.

Liquid cooling systems offer superior thermal management capabilities for high-power magnetrons. These systems typically utilize a closed-loop configuration with deionized water or specialized coolants circulating through channels integrated into the magnetron assembly. Research indicates that liquid-cooled systems can maintain temperature variations within ±2°C even under continuous operation, significantly reducing frequency drift compared to air-cooled alternatives.

Advanced thermal interface materials (TIMs) have emerged as essential components in magnetron cooling strategies. Modern ceramic-based TIMs with thermal conductivities exceeding 5 W/m·K provide efficient heat transfer between the magnetron and cooling system while maintaining electrical isolation properties critical for high-voltage operation.

Temperature monitoring and feedback control systems represent the latest advancement in magnetron thermal management. These systems employ thermistors or infrared sensors to continuously monitor critical component temperatures, adjusting cooling parameters in real-time. Implementing predictive thermal modeling allows for anticipatory cooling adjustments before thermal thresholds are reached, preventing the temperature gradients that typically precede frequency drift events.

Material selection plays a crucial role in thermal management strategies. Copper-tungsten composites for anode blocks offer an optimal balance between thermal conductivity and structural stability under high-temperature conditions. Similarly, specialized ceramic materials with controlled thermal expansion coefficients help maintain dimensional stability of resonant cavities across operating temperature ranges.

For next-generation magnetrons, phase-change cooling technologies and microfluidic cooling channels integrated directly into magnetron structures are being developed. These approaches promise to address localized hotspots that conventional cooling methods cannot effectively manage, potentially extending magnetron service life by 30-40% while maintaining frequency stability within industry-required tolerances.

Conventional cooling approaches employ forced-air systems with strategically positioned fans and heat sinks to create airflow paths around critical components. While effective for lower-power applications, these systems often prove insufficient for industrial or high-duty-cycle operations where thermal loads are substantially higher.

Liquid cooling systems offer superior thermal management capabilities for high-power magnetrons. These systems typically utilize a closed-loop configuration with deionized water or specialized coolants circulating through channels integrated into the magnetron assembly. Research indicates that liquid-cooled systems can maintain temperature variations within ±2°C even under continuous operation, significantly reducing frequency drift compared to air-cooled alternatives.

Advanced thermal interface materials (TIMs) have emerged as essential components in magnetron cooling strategies. Modern ceramic-based TIMs with thermal conductivities exceeding 5 W/m·K provide efficient heat transfer between the magnetron and cooling system while maintaining electrical isolation properties critical for high-voltage operation.

Temperature monitoring and feedback control systems represent the latest advancement in magnetron thermal management. These systems employ thermistors or infrared sensors to continuously monitor critical component temperatures, adjusting cooling parameters in real-time. Implementing predictive thermal modeling allows for anticipatory cooling adjustments before thermal thresholds are reached, preventing the temperature gradients that typically precede frequency drift events.

Material selection plays a crucial role in thermal management strategies. Copper-tungsten composites for anode blocks offer an optimal balance between thermal conductivity and structural stability under high-temperature conditions. Similarly, specialized ceramic materials with controlled thermal expansion coefficients help maintain dimensional stability of resonant cavities across operating temperature ranges.

For next-generation magnetrons, phase-change cooling technologies and microfluidic cooling channels integrated directly into magnetron structures are being developed. These approaches promise to address localized hotspots that conventional cooling methods cannot effectively manage, potentially extending magnetron service life by 30-40% while maintaining frequency stability within industry-required tolerances.

Environmental Factors Affecting Magnetron Performance

Magnetron performance is significantly influenced by various environmental factors that can induce frequency drift and operational instability. Temperature variations represent one of the most critical environmental parameters affecting magnetron frequency stability. When ambient temperatures fluctuate, thermal expansion and contraction of magnetron components occur, particularly affecting the resonant cavity dimensions. Research indicates that for typical X-band magnetrons, frequency drift rates of 200-300 kHz per degree Celsius are common, with higher-frequency devices exhibiting even greater sensitivity to thermal changes.

Humidity levels present another substantial environmental challenge for magnetron operation. Excessive moisture can lead to condensation on electrical components, potentially causing arcing, corrosion of contact surfaces, and impedance changes in the RF circuit. Studies have demonstrated that relative humidity exceeding 85% can reduce magnetron efficiency by up to 7% and contribute to frequency instability, particularly in non-hermetically sealed systems.

Barometric pressure variations, though often overlooked, can impact magnetron performance in precision applications. Changes in atmospheric pressure alter the breakdown voltage characteristics within the vacuum envelope and can modify the electron cloud behavior. This effect becomes particularly pronounced in high-altitude operations or during significant weather events, where pressure differentials can induce frequency shifts of up to 50 kHz in sensitive systems.

Electromagnetic interference (EMI) from surrounding equipment represents a significant environmental concern for magnetron stability. External RF fields can couple with magnetron circuits, introducing noise and modulation effects that manifest as frequency instability. Industrial environments with heavy machinery, welding equipment, or other high-power RF generators often create challenging operational conditions requiring comprehensive EMI shielding and filtering solutions.

Mechanical vibration and shock constitute environmental factors that can physically alter magnetron geometry and mounting integrity. Continuous vibration can lead to component fatigue, loosening of mechanical connections, and microphonic effects where mechanical energy translates into electrical noise. Research has shown that vibrations exceeding 2G can induce frequency variations of up to 1 MHz in standard commercial magnetrons, with effects persisting even after the vibration source is removed.

Power supply stability represents a critical environmental parameter that directly influences magnetron frequency characteristics. Voltage fluctuations, line noise, and transients can modulate the electron beam energy, directly affecting the oscillation frequency. Industry standards typically recommend power supply regulation better than ±0.5% for applications requiring frequency stability better than ±1 MHz.

Humidity levels present another substantial environmental challenge for magnetron operation. Excessive moisture can lead to condensation on electrical components, potentially causing arcing, corrosion of contact surfaces, and impedance changes in the RF circuit. Studies have demonstrated that relative humidity exceeding 85% can reduce magnetron efficiency by up to 7% and contribute to frequency instability, particularly in non-hermetically sealed systems.

Barometric pressure variations, though often overlooked, can impact magnetron performance in precision applications. Changes in atmospheric pressure alter the breakdown voltage characteristics within the vacuum envelope and can modify the electron cloud behavior. This effect becomes particularly pronounced in high-altitude operations or during significant weather events, where pressure differentials can induce frequency shifts of up to 50 kHz in sensitive systems.

Electromagnetic interference (EMI) from surrounding equipment represents a significant environmental concern for magnetron stability. External RF fields can couple with magnetron circuits, introducing noise and modulation effects that manifest as frequency instability. Industrial environments with heavy machinery, welding equipment, or other high-power RF generators often create challenging operational conditions requiring comprehensive EMI shielding and filtering solutions.

Mechanical vibration and shock constitute environmental factors that can physically alter magnetron geometry and mounting integrity. Continuous vibration can lead to component fatigue, loosening of mechanical connections, and microphonic effects where mechanical energy translates into electrical noise. Research has shown that vibrations exceeding 2G can induce frequency variations of up to 1 MHz in standard commercial magnetrons, with effects persisting even after the vibration source is removed.

Power supply stability represents a critical environmental parameter that directly influences magnetron frequency characteristics. Voltage fluctuations, line noise, and transients can modulate the electron beam energy, directly affecting the oscillation frequency. Industry standards typically recommend power supply regulation better than ±0.5% for applications requiring frequency stability better than ±1 MHz.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!