Magnetron Limits vs Traveling Wave Tube Performance Specs

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron and TWT Technology Background and Objectives

Microwave vacuum electron devices have been fundamental components in radar systems, communications, and various high-power applications since their inception in the mid-20th century. Among these devices, magnetrons and traveling wave tubes (TWTs) represent two distinct technological approaches with different performance characteristics, applications, and evolutionary paths.

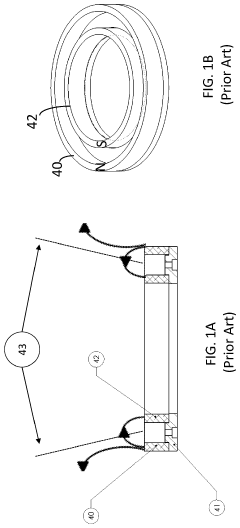

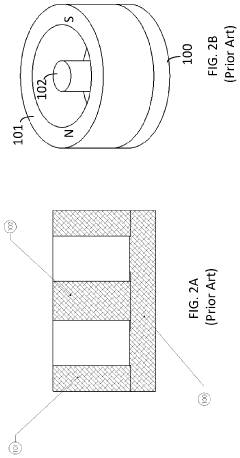

Magnetrons emerged during World War II as revolutionary devices that enabled compact, efficient radar systems. These cross-field devices operate by converting electrical energy into microwave radiation through the interaction of electrons with a magnetic field in a cavity resonator structure. The technology has evolved from the original cavity magnetrons to more sophisticated variants including coaxial magnetrons and frequency-agile designs.

Traveling Wave Tubes, developed shortly after magnetrons, operate on fundamentally different principles. TWTs are slow-wave structures where an electron beam interacts with an electromagnetic wave traveling along a helical delay line. This continuous interaction allows for broadband amplification capabilities that magnetrons inherently lack.

The technological evolution of both devices has been driven by increasing demands for higher frequency operation, improved efficiency, greater bandwidth, and enhanced reliability. Magnetrons have traditionally excelled in applications requiring high power at specific frequencies with emphasis on compactness and cost-effectiveness. Their development trajectory has focused on improving frequency stability, reducing noise, and extending operational lifetime.

TWTs, conversely, have evolved to address applications requiring linear amplification across wide bandwidths, particularly in electronic warfare, satellite communications, and advanced radar systems. Their development has concentrated on improving efficiency, reducing size and weight, and extending frequency range capabilities.

Current technological objectives in this field include addressing the fundamental limitations of magnetrons regarding frequency agility, phase noise, and spectral purity, while simultaneously pursuing improvements in TWT efficiency, size reduction, and thermal management. Research efforts are increasingly focused on hybrid approaches that combine solid-state technology with vacuum electronics to leverage the advantages of both.

The convergence of computational modeling capabilities with advanced materials science has opened new avenues for innovation in both technologies. Simulation-driven design approaches now allow for optimization of electron beam dynamics, interaction structures, and thermal management systems that were previously unattainable through empirical methods alone.

As communication systems and radar applications continue to demand higher performance specifications, understanding the comparative limitations and advantages of magnetrons versus TWTs becomes increasingly critical for appropriate technology selection and future development pathways.

Magnetrons emerged during World War II as revolutionary devices that enabled compact, efficient radar systems. These cross-field devices operate by converting electrical energy into microwave radiation through the interaction of electrons with a magnetic field in a cavity resonator structure. The technology has evolved from the original cavity magnetrons to more sophisticated variants including coaxial magnetrons and frequency-agile designs.

Traveling Wave Tubes, developed shortly after magnetrons, operate on fundamentally different principles. TWTs are slow-wave structures where an electron beam interacts with an electromagnetic wave traveling along a helical delay line. This continuous interaction allows for broadband amplification capabilities that magnetrons inherently lack.

The technological evolution of both devices has been driven by increasing demands for higher frequency operation, improved efficiency, greater bandwidth, and enhanced reliability. Magnetrons have traditionally excelled in applications requiring high power at specific frequencies with emphasis on compactness and cost-effectiveness. Their development trajectory has focused on improving frequency stability, reducing noise, and extending operational lifetime.

TWTs, conversely, have evolved to address applications requiring linear amplification across wide bandwidths, particularly in electronic warfare, satellite communications, and advanced radar systems. Their development has concentrated on improving efficiency, reducing size and weight, and extending frequency range capabilities.

Current technological objectives in this field include addressing the fundamental limitations of magnetrons regarding frequency agility, phase noise, and spectral purity, while simultaneously pursuing improvements in TWT efficiency, size reduction, and thermal management. Research efforts are increasingly focused on hybrid approaches that combine solid-state technology with vacuum electronics to leverage the advantages of both.

The convergence of computational modeling capabilities with advanced materials science has opened new avenues for innovation in both technologies. Simulation-driven design approaches now allow for optimization of electron beam dynamics, interaction structures, and thermal management systems that were previously unattainable through empirical methods alone.

As communication systems and radar applications continue to demand higher performance specifications, understanding the comparative limitations and advantages of magnetrons versus TWTs becomes increasingly critical for appropriate technology selection and future development pathways.

Market Analysis for Microwave Amplification Technologies

The microwave amplification technology market is experiencing robust growth, driven by increasing demand across multiple sectors including telecommunications, defense, aerospace, and medical applications. The global market for microwave amplifiers was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2027, representing a compound annual growth rate (CAGR) of 8.5%.

Within this market, magnetrons and traveling wave tubes (TWTs) represent two distinct technological approaches with different market positioning. Magnetrons currently dominate in terms of unit volume, primarily due to their widespread use in consumer microwave ovens and certain industrial heating applications. This segment accounts for roughly 65% of the total microwave amplification device market by volume, though significantly less by value.

Traveling wave tubes, while representing a smaller portion of the market by unit volume (approximately 20%), command a substantially higher market share by value (estimated at 45%) due to their higher unit costs and performance capabilities. The TWT market is primarily driven by defense applications, satellite communications, and radar systems where their superior performance specifications justify the higher cost.

Regional analysis reveals that North America leads the high-performance microwave amplification market with approximately 38% market share, followed by Asia-Pacific at 32% and Europe at 24%. The Asia-Pacific region, however, is experiencing the fastest growth rate at 10.2% annually, primarily due to increasing defense modernization programs and expanding telecommunications infrastructure.

Customer segmentation shows distinct preferences: defense and aerospace sectors prioritize performance specifications over cost, making them the primary consumers of TWTs. Commercial telecommunications and broadcasting industries balance performance requirements with cost considerations, while consumer and industrial heating applications remain almost exclusively magnetron territory due to cost sensitivity.

Market forecasts indicate that the performance gap between magnetrons and TWTs will continue to drive market segmentation. The TWT market is expected to grow at a faster rate (9.7% CAGR) compared to magnetrons (6.8% CAGR) through 2027, reflecting increasing demand for higher performance specifications in emerging applications such as 5G infrastructure, advanced radar systems, and satellite communications.

Emerging market opportunities exist in developing regions where telecommunications infrastructure expansion is accelerating, particularly in South Asia and parts of Africa. Additionally, the growing interest in small satellites and the commercialization of space is creating new demand for compact, high-efficiency microwave amplification technologies that can bridge the performance-cost gap between traditional magnetrons and TWTs.

Within this market, magnetrons and traveling wave tubes (TWTs) represent two distinct technological approaches with different market positioning. Magnetrons currently dominate in terms of unit volume, primarily due to their widespread use in consumer microwave ovens and certain industrial heating applications. This segment accounts for roughly 65% of the total microwave amplification device market by volume, though significantly less by value.

Traveling wave tubes, while representing a smaller portion of the market by unit volume (approximately 20%), command a substantially higher market share by value (estimated at 45%) due to their higher unit costs and performance capabilities. The TWT market is primarily driven by defense applications, satellite communications, and radar systems where their superior performance specifications justify the higher cost.

Regional analysis reveals that North America leads the high-performance microwave amplification market with approximately 38% market share, followed by Asia-Pacific at 32% and Europe at 24%. The Asia-Pacific region, however, is experiencing the fastest growth rate at 10.2% annually, primarily due to increasing defense modernization programs and expanding telecommunications infrastructure.

Customer segmentation shows distinct preferences: defense and aerospace sectors prioritize performance specifications over cost, making them the primary consumers of TWTs. Commercial telecommunications and broadcasting industries balance performance requirements with cost considerations, while consumer and industrial heating applications remain almost exclusively magnetron territory due to cost sensitivity.

Market forecasts indicate that the performance gap between magnetrons and TWTs will continue to drive market segmentation. The TWT market is expected to grow at a faster rate (9.7% CAGR) compared to magnetrons (6.8% CAGR) through 2027, reflecting increasing demand for higher performance specifications in emerging applications such as 5G infrastructure, advanced radar systems, and satellite communications.

Emerging market opportunities exist in developing regions where telecommunications infrastructure expansion is accelerating, particularly in South Asia and parts of Africa. Additionally, the growing interest in small satellites and the commercialization of space is creating new demand for compact, high-efficiency microwave amplification technologies that can bridge the performance-cost gap between traditional magnetrons and TWTs.

Current Technical Limitations and Challenges

Magnetrons and Traveling Wave Tubes (TWTs) represent two distinct approaches to microwave generation, each with specific technical limitations that define their application boundaries. Magnetrons, while cost-effective and efficient, face significant frequency stability challenges. Their oscillation mechanism inherently produces frequency drift under varying load conditions, with typical stability ranges of ±5-10 MHz, making them unsuitable for applications requiring precise frequency control. Additionally, magnetrons exhibit limited bandwidth capabilities, typically operating within narrow frequency bands and requiring physical modifications for frequency adjustments.

Power output consistency presents another critical limitation for magnetrons. These devices demonstrate significant pulse-to-pulse variations, with power fluctuations commonly reaching 5-10% under standard operating conditions. This inconsistency creates challenges for applications requiring highly stable power delivery, such as medical linear accelerators or precision radar systems.

Lifetime constraints further restrict magnetron applications, with typical operational lifespans ranging from 2,000-5,000 hours before performance degradation necessitates replacement. The cathode deterioration mechanism accelerates under high-power operation, creating an inverse relationship between power output and device longevity.

Traveling Wave Tubes, while addressing many magnetron limitations, face their own set of technical challenges. The complex helical slow-wave structure that enables their broadband operation introduces manufacturing complexities that significantly increase production costs, typically 5-10 times higher than comparable magnetron systems. This cost differential remains a substantial barrier to widespread TWT adoption in consumer and commercial applications.

Thermal management represents perhaps the most significant engineering challenge for TWTs. Operating efficiencies typically range from 15-40%, meaning 60-85% of input power converts to heat rather than useful RF output. This necessitates sophisticated cooling systems that add weight, complexity, and cost to TWT implementations, particularly in space-constrained applications like satellite communications.

High voltage requirements present additional implementation challenges for TWTs, with typical operating voltages ranging from 3-10kV. These high voltages necessitate specialized power supplies and introduce safety considerations that complicate system integration. The voltage requirements also create startup delays, with typical warm-up times of 90-180 seconds before stable operation, limiting their suitability for applications requiring rapid activation.

Size and weight constraints further restrict TWT applications, particularly in mobile or airborne systems. Despite advances in miniaturization, TWTs remain significantly larger and heavier than solid-state alternatives, with typical weights 3-5 times greater than comparable semiconductor solutions. This physical footprint limits their deployment in weight-sensitive platforms like small satellites or unmanned aerial vehicles.

Power output consistency presents another critical limitation for magnetrons. These devices demonstrate significant pulse-to-pulse variations, with power fluctuations commonly reaching 5-10% under standard operating conditions. This inconsistency creates challenges for applications requiring highly stable power delivery, such as medical linear accelerators or precision radar systems.

Lifetime constraints further restrict magnetron applications, with typical operational lifespans ranging from 2,000-5,000 hours before performance degradation necessitates replacement. The cathode deterioration mechanism accelerates under high-power operation, creating an inverse relationship between power output and device longevity.

Traveling Wave Tubes, while addressing many magnetron limitations, face their own set of technical challenges. The complex helical slow-wave structure that enables their broadband operation introduces manufacturing complexities that significantly increase production costs, typically 5-10 times higher than comparable magnetron systems. This cost differential remains a substantial barrier to widespread TWT adoption in consumer and commercial applications.

Thermal management represents perhaps the most significant engineering challenge for TWTs. Operating efficiencies typically range from 15-40%, meaning 60-85% of input power converts to heat rather than useful RF output. This necessitates sophisticated cooling systems that add weight, complexity, and cost to TWT implementations, particularly in space-constrained applications like satellite communications.

High voltage requirements present additional implementation challenges for TWTs, with typical operating voltages ranging from 3-10kV. These high voltages necessitate specialized power supplies and introduce safety considerations that complicate system integration. The voltage requirements also create startup delays, with typical warm-up times of 90-180 seconds before stable operation, limiting their suitability for applications requiring rapid activation.

Size and weight constraints further restrict TWT applications, particularly in mobile or airborne systems. Despite advances in miniaturization, TWTs remain significantly larger and heavier than solid-state alternatives, with typical weights 3-5 times greater than comparable semiconductor solutions. This physical footprint limits their deployment in weight-sensitive platforms like small satellites or unmanned aerial vehicles.

Comparative Analysis of Magnetron and TWT Solutions

01 Frequency and power specifications of magnetrons

Magnetrons are characterized by their operating frequency and power output capabilities. These specifications are critical for determining the suitability of a magnetron for specific applications. Magnetrons can operate across various frequency bands, from low to high frequencies, and can deliver different power levels depending on their design and construction. The performance of magnetrons is often measured by their efficiency in converting electrical energy to microwave energy, their frequency stability, and their power output consistency.- Frequency and power specifications for magnetrons: Magnetrons are characterized by specific frequency ranges and power output capabilities. These specifications determine their suitability for various applications. Key performance parameters include operating frequency stability, power output levels, and efficiency ratings. Advanced magnetrons can achieve high power outputs while maintaining precise frequency control, which is crucial for applications in radar systems, industrial heating, and communication equipment.

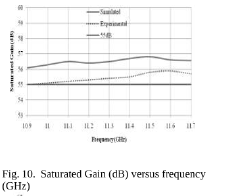

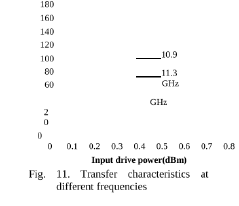

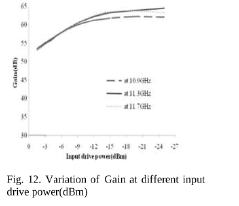

- Traveling Wave Tube (TWT) amplification characteristics: Traveling Wave Tubes are designed with specific amplification characteristics that define their performance. These include gain parameters, bandwidth capabilities, and signal-to-noise ratios. TWTs typically offer broad bandwidth operation with high gain across wide frequency ranges. Their performance specifications also include linearity measurements, phase noise characteristics, and intermodulation distortion levels, which are critical for applications in satellite communications, radar systems, and electronic warfare equipment.

- Thermal management and reliability specifications: Both magnetrons and TWTs generate significant heat during operation, requiring effective thermal management solutions to maintain performance specifications. Key reliability parameters include operating temperature ranges, cooling requirements, and mean time between failures (MTBF). Advanced thermal management techniques, such as liquid cooling systems and specialized heat sinks, help maintain stable operation and extend device lifespan. Reliability specifications also include environmental tolerance factors such as shock resistance, vibration tolerance, and altitude operation capabilities.

- Efficiency and power consumption metrics: Efficiency metrics are critical performance specifications for both magnetrons and TWTs. These include conversion efficiency (RF output power versus DC input power), power consumption rates, and standby power requirements. Modern designs focus on improving efficiency while maintaining output performance, with advanced cathode materials and optimized electron beam focusing techniques. Power consumption specifications also include warm-up time requirements and power supply stability needs, which affect overall system performance in applications ranging from radar to communication systems.

- Signal quality and modulation capabilities: Signal quality specifications for magnetrons and TWTs include phase noise characteristics, harmonic distortion levels, and spurious emission measurements. These parameters are crucial for applications requiring high signal purity. Modulation capabilities include specifications for amplitude modulation, frequency modulation, and pulse modulation performance. Advanced devices offer improved signal quality with reduced noise floors and enhanced modulation bandwidth, enabling more complex communication protocols and higher data rates in modern systems.

02 Traveling Wave Tubes (TWTs) bandwidth and gain characteristics

Traveling Wave Tubes are evaluated based on their bandwidth capabilities and gain characteristics. TWTs typically offer broader bandwidth compared to magnetrons, making them suitable for applications requiring frequency agility. The gain of a TWT refers to its ability to amplify input signals, which is a critical performance parameter. TWTs can provide high gain over wide frequency ranges, with specifications often detailing the gain flatness across the operating bandwidth. These characteristics determine the TWT's suitability for various communication and radar applications.Expand Specific Solutions03 Efficiency and thermal management in microwave tubes

Efficiency and thermal management are crucial performance specifications for both magnetrons and traveling wave tubes. Higher efficiency means better conversion of input power to output power, reducing waste heat generation. Thermal management specifications detail how the device handles heat dissipation, which directly impacts reliability and operational lifetime. Advanced cooling techniques and materials are employed to maintain optimal operating temperatures. Efficiency is typically expressed as a percentage, while thermal specifications include maximum operating temperatures and cooling requirements.Expand Specific Solutions04 Noise and signal purity characteristics

Noise and signal purity are important performance specifications for magnetrons and traveling wave tubes. These parameters affect the quality of the output signal and the device's suitability for sensitive applications. Specifications typically include phase noise, amplitude noise, harmonic distortion, and spurious signal levels. Lower noise and higher signal purity are desirable for applications requiring precise signal control. These characteristics are particularly important in communication systems, scientific instruments, and radar applications where signal integrity is critical.Expand Specific Solutions05 Reliability and operational lifetime specifications

Reliability and operational lifetime are key performance specifications for magnetrons and traveling wave tubes. These specifications include mean time between failures (MTBF), expected operational hours, and performance stability over time. Factors affecting reliability include cathode life, vacuum integrity, and structural robustness. Manufacturers often provide specifications on how performance parameters may change over the device's lifetime. These specifications are crucial for applications where continuous operation is required or where replacement is difficult or costly.Expand Specific Solutions

Major Industry Players and Competitive Landscape

The magnetron versus traveling wave tube (TWT) technology landscape is currently in a mature market phase with established applications but experiencing renewed innovation. The global market for these microwave vacuum electronic devices exceeds $1 billion annually, with steady growth driven by defense, communications, and industrial applications. Technologically, magnetrons have reached maturity with companies like LG Electronics, Midea Group, and Guangdong Galanz dominating consumer applications, while TWTs represent more advanced technology with superior bandwidth and power capabilities. Thales Electron Devices, Teledyne UK, and Raytheon lead in high-performance TWT development for defense and aerospace applications. Research institutions like University of Electronic Science & Technology of China and Commissariat à l'énergie atomique are advancing next-generation solutions that bridge performance gaps between these competing technologies.

Thales Electron Devices SA

Technical Solution: Thales Electron Devices has developed advanced Traveling Wave Tube (TWT) technology that significantly outperforms traditional magnetrons in several key areas. Their TWTs utilize helical slow-wave structures and advanced electron beam focusing techniques to achieve broadband operation from 2-40 GHz with output powers ranging from tens to thousands of watts. The company's proprietary cathode technology enables longer operational lifetimes (>100,000 hours) compared to magnetrons (typically 5,000-10,000 hours). Thales has implemented advanced thermal management systems using diamond heat spreaders and liquid cooling for high-power TWTs, allowing sustained operation at higher power levels without the thermal limitations faced by magnetrons. Their TWTs achieve efficiencies of 60-70% through multi-stage collectors that recover unused energy from the electron beam, compared to magnetron's typical 65-70% efficiency but with much narrower bandwidth capabilities.

Strengths: Superior bandwidth, frequency agility, higher power capabilities at higher frequencies, and significantly longer operational lifetime. Weaknesses: Higher cost of production, larger size and weight compared to magnetrons, requires more complex power supplies, and higher operating voltages.

Teledyne UK Ltd.

Technical Solution: Teledyne UK has pioneered advanced TWT technology that addresses the fundamental limitations of magnetrons. Their TWTs employ proprietary coupled-cavity designs that enable operation at frequencies up to 95 GHz with peak powers exceeding 100 kW in pulsed mode. Unlike magnetrons which typically operate in a narrow 5-10% bandwidth, Teledyne's TWTs achieve operational bandwidths of 30-40% through precision-engineered slow-wave structures. The company has developed specialized manufacturing techniques for creating ultra-precise internal components with tolerances measured in microns, enabling consistent performance across production units. Teledyne's TWTs incorporate advanced beam focusing using periodic permanent magnet (PPM) structures that maintain precise electron beam control without requiring bulky electromagnets, resulting in compact packages despite the inherently more complex TWT architecture. Their devices achieve 50-60% efficiency through multi-stage depressed collectors that recover energy from the spent electron beam, partially offsetting the efficiency advantage of simpler magnetron designs.

Strengths: Exceptional frequency range and bandwidth capabilities, precise frequency and phase control suitable for advanced radar and communication systems, and ability to operate reliably in harsh environments. Weaknesses: Higher production costs, more complex power supply requirements, and generally lower efficiency than magnetrons in simple heating applications.

Key Patents and Technical Innovations in Microwave Tubes

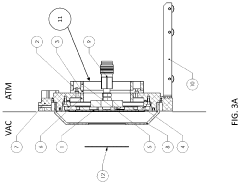

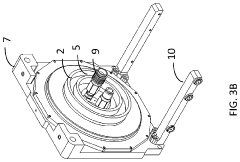

Multifocal magnetron design for physical vapor deposition processing on a single cathode

PatentActiveUS20220406582A1

Innovation

- The design incorporates a keeper plate with strategically positioned annular magnet arrays and inner magnets of opposing polarities, focusing magnetic flux to enhance plasma confinement and minimize fringing fields, allowing for independent plasma zones and improved ionization of sputtered species across a substrate.

Power characteristics of a high-performance helix space travelling wave tube

PatentPendingIN202411031707A

Innovation

- The optimization of helix circuit length and pitch in TWTs is achieved by adjusting the helix pitch in the center region for maximum small-signal gain and bunching current, while lowering it in the output region for improved efficiency, using simulation tools like HFSS and CST-MWS to match beam velocity with RF wave phase velocity, and employing anisotropic materials like APBN for higher interaction impedance.

Military and Defense Applications Assessment

In the military and defense sector, the comparative analysis between magnetrons and traveling wave tubes (TWTs) reveals critical implications for operational capabilities. Magnetrons, while offering cost-effectiveness and compact design advantages, present significant limitations in electronic warfare and advanced radar applications where precision and adaptability are paramount. Their fixed frequency operation and susceptibility to frequency pulling under varying load conditions restrict their utility in sophisticated electronic countermeasure systems.

Traveling wave tubes demonstrate superior performance specifications that align with modern military requirements. Their wide bandwidth capability enables frequency agility essential for radar jamming and secure communications in contested electromagnetic environments. The higher power output stability of TWTs at microwave frequencies provides extended operational range for surveillance systems and missile guidance platforms, offering tactical advantages in battlefield scenarios.

Defense applications particularly benefit from TWTs' linear amplification characteristics, which support complex signal modulation schemes necessary for encrypted military communications. This linearity also facilitates the implementation of advanced electronic protection measures against hostile jamming attempts, enhancing force protection capabilities. The longer operational lifespan of TWTs compared to magnetrons translates to reduced maintenance cycles for deployed systems, a critical factor in remote or hostile deployment zones.

Military radar systems utilizing TWTs demonstrate enhanced detection capabilities against stealth targets due to their ability to operate across multiple frequency bands with minimal signal distortion. This multi-band operation provides resilience against frequency-specific countermeasures employed by adversary platforms. Additionally, the phase stability inherent in TWT design enables more accurate target tracking and identification, critical for precision strike operations.

Naval and airborne defense systems particularly benefit from TWTs' superior performance in harsh environmental conditions. Their resistance to shock, vibration, and temperature fluctuations ensures reliable operation in combat scenarios, from submarine-based electronic intelligence gathering to airborne early warning systems. The higher mean time between failures (MTBF) rates for TWTs significantly reduces mission-critical system downtime during extended deployments.

Despite their performance advantages, the integration of TWTs into tactical systems presents challenges related to power supply requirements and thermal management. Defense contractors are addressing these limitations through the development of more efficient power conditioning modules and advanced cooling systems, enabling the deployment of TWT-based systems in smaller platforms including unmanned aerial vehicles and compact electronic warfare pods.

Traveling wave tubes demonstrate superior performance specifications that align with modern military requirements. Their wide bandwidth capability enables frequency agility essential for radar jamming and secure communications in contested electromagnetic environments. The higher power output stability of TWTs at microwave frequencies provides extended operational range for surveillance systems and missile guidance platforms, offering tactical advantages in battlefield scenarios.

Defense applications particularly benefit from TWTs' linear amplification characteristics, which support complex signal modulation schemes necessary for encrypted military communications. This linearity also facilitates the implementation of advanced electronic protection measures against hostile jamming attempts, enhancing force protection capabilities. The longer operational lifespan of TWTs compared to magnetrons translates to reduced maintenance cycles for deployed systems, a critical factor in remote or hostile deployment zones.

Military radar systems utilizing TWTs demonstrate enhanced detection capabilities against stealth targets due to their ability to operate across multiple frequency bands with minimal signal distortion. This multi-band operation provides resilience against frequency-specific countermeasures employed by adversary platforms. Additionally, the phase stability inherent in TWT design enables more accurate target tracking and identification, critical for precision strike operations.

Naval and airborne defense systems particularly benefit from TWTs' superior performance in harsh environmental conditions. Their resistance to shock, vibration, and temperature fluctuations ensures reliable operation in combat scenarios, from submarine-based electronic intelligence gathering to airborne early warning systems. The higher mean time between failures (MTBF) rates for TWTs significantly reduces mission-critical system downtime during extended deployments.

Despite their performance advantages, the integration of TWTs into tactical systems presents challenges related to power supply requirements and thermal management. Defense contractors are addressing these limitations through the development of more efficient power conditioning modules and advanced cooling systems, enabling the deployment of TWT-based systems in smaller platforms including unmanned aerial vehicles and compact electronic warfare pods.

Reliability and Lifecycle Analysis

Reliability and lifecycle analysis represents a critical dimension when comparing magnetrons and traveling wave tubes (TWTs) for microwave applications. Magnetrons typically demonstrate a Mean Time Between Failures (MTBF) of 5,000-7,000 hours in commercial applications, while military-grade units may reach up to 10,000 hours under optimal conditions. This reliability profile is significantly influenced by cathode degradation and filament burnout, which constitute the primary failure mechanisms in magnetron operation.

In contrast, traveling wave tubes exhibit substantially longer operational lifespans, with modern TWTs routinely achieving MTBF values of 30,000-50,000 hours in satellite communications applications. The extended lifecycle of TWTs derives from their more sophisticated electron beam management and lower operating temperatures at the cathode, reducing the rate of component degradation over time.

Environmental factors dramatically impact the reliability profiles of both technologies. Magnetrons demonstrate notable vulnerability to temperature fluctuations, with reliability decreasing by approximately 15-20% for every 10°C increase above optimal operating temperature. TWTs, while more resilient to temperature variations, show greater sensitivity to mechanical shock and vibration, particularly in mobile deployment scenarios.

Maintenance requirements further differentiate these technologies. Magnetrons typically require replacement rather than repair when failures occur, resulting in lower per-unit maintenance costs but higher lifetime operational expenses due to more frequent replacement cycles. TWTs, despite higher initial acquisition costs, often prove more economical over extended operational periods due to their superior longevity and the possibility of component-level repairs in certain applications.

Lifecycle cost analysis reveals that despite magnetrons' lower initial procurement costs (typically 20-30% of equivalent TWT systems), the total ownership cost over a 10-year operational window frequently favors TWTs for continuous-use applications. This advantage becomes particularly pronounced in space-based systems where replacement opportunities are limited or nonexistent, making the TWT's superior reliability profile a mission-critical consideration.

Recent advancements in materials science have yielded promising improvements in magnetron reliability, with experimental designs incorporating advanced cathode materials demonstrating potential MTBF increases of 40-60%. However, these developments remain insufficient to close the substantial reliability gap with TWTs in high-performance applications requiring extended operational lifespans.

In contrast, traveling wave tubes exhibit substantially longer operational lifespans, with modern TWTs routinely achieving MTBF values of 30,000-50,000 hours in satellite communications applications. The extended lifecycle of TWTs derives from their more sophisticated electron beam management and lower operating temperatures at the cathode, reducing the rate of component degradation over time.

Environmental factors dramatically impact the reliability profiles of both technologies. Magnetrons demonstrate notable vulnerability to temperature fluctuations, with reliability decreasing by approximately 15-20% for every 10°C increase above optimal operating temperature. TWTs, while more resilient to temperature variations, show greater sensitivity to mechanical shock and vibration, particularly in mobile deployment scenarios.

Maintenance requirements further differentiate these technologies. Magnetrons typically require replacement rather than repair when failures occur, resulting in lower per-unit maintenance costs but higher lifetime operational expenses due to more frequent replacement cycles. TWTs, despite higher initial acquisition costs, often prove more economical over extended operational periods due to their superior longevity and the possibility of component-level repairs in certain applications.

Lifecycle cost analysis reveals that despite magnetrons' lower initial procurement costs (typically 20-30% of equivalent TWT systems), the total ownership cost over a 10-year operational window frequently favors TWTs for continuous-use applications. This advantage becomes particularly pronounced in space-based systems where replacement opportunities are limited or nonexistent, making the TWT's superior reliability profile a mission-critical consideration.

Recent advancements in materials science have yielded promising improvements in magnetron reliability, with experimental designs incorporating advanced cathode materials demonstrating potential MTBF increases of 40-60%. However, these developments remain insufficient to close the substantial reliability gap with TWTs in high-performance applications requiring extended operational lifespans.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!