How to Handle Magnetron Interference in RF Designs

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Interference Background and Objectives

Magnetron interference represents a significant challenge in radio frequency (RF) design, particularly in environments where high-power microwave sources operate alongside sensitive RF equipment. The magnetron, invented in the early 1940s, has become ubiquitous in applications ranging from radar systems to household microwave ovens, generating electromagnetic radiation in the microwave frequency range (typically 300 MHz to 300 GHz).

The evolution of magnetron technology has followed a trajectory from military applications during World War II to widespread commercial use. Modern magnetrons can generate power levels from hundreds of watts to megawatts, creating substantial electromagnetic interference (EMI) challenges for nearby electronic systems. This interference manifests as noise, signal degradation, and in severe cases, complete system failure in sensitive RF circuits.

The primary objective of addressing magnetron interference is to ensure reliable operation of RF systems in environments where these powerful microwave generators are present. This includes developing effective shielding techniques, implementing robust filtering methods, and designing circuit architectures that maintain signal integrity despite nearby electromagnetic disturbances.

Recent technological trends show increasing integration of RF systems in confined spaces, particularly in industrial settings, medical facilities, and telecommunications infrastructure. This densification exacerbates the challenges of magnetron interference, necessitating more sophisticated mitigation strategies. Additionally, the proliferation of Internet of Things (IoT) devices operating in the same frequency bands further complicates the electromagnetic environment.

The technical goals for handling magnetron interference include developing comprehensive characterization methodologies to accurately model interference patterns, creating standardized testing protocols to evaluate susceptibility, and establishing design guidelines that ensure RF system resilience. These goals align with broader industry initiatives to improve electromagnetic compatibility (EMC) in increasingly crowded spectral environments.

Understanding the physics of magnetron operation—including frequency pushing, pulling effects, and harmonic generation—provides the foundation for effective interference management. The non-linear behavior of magnetrons, particularly during startup and under varying load conditions, creates complex interference patterns that require sophisticated analysis techniques to predict and mitigate.

As RF technologies continue to advance toward higher frequencies and greater sensitivity, the challenges posed by magnetron interference will require increasingly innovative solutions, making this an important area for continued research and development in the RF engineering community.

The evolution of magnetron technology has followed a trajectory from military applications during World War II to widespread commercial use. Modern magnetrons can generate power levels from hundreds of watts to megawatts, creating substantial electromagnetic interference (EMI) challenges for nearby electronic systems. This interference manifests as noise, signal degradation, and in severe cases, complete system failure in sensitive RF circuits.

The primary objective of addressing magnetron interference is to ensure reliable operation of RF systems in environments where these powerful microwave generators are present. This includes developing effective shielding techniques, implementing robust filtering methods, and designing circuit architectures that maintain signal integrity despite nearby electromagnetic disturbances.

Recent technological trends show increasing integration of RF systems in confined spaces, particularly in industrial settings, medical facilities, and telecommunications infrastructure. This densification exacerbates the challenges of magnetron interference, necessitating more sophisticated mitigation strategies. Additionally, the proliferation of Internet of Things (IoT) devices operating in the same frequency bands further complicates the electromagnetic environment.

The technical goals for handling magnetron interference include developing comprehensive characterization methodologies to accurately model interference patterns, creating standardized testing protocols to evaluate susceptibility, and establishing design guidelines that ensure RF system resilience. These goals align with broader industry initiatives to improve electromagnetic compatibility (EMC) in increasingly crowded spectral environments.

Understanding the physics of magnetron operation—including frequency pushing, pulling effects, and harmonic generation—provides the foundation for effective interference management. The non-linear behavior of magnetrons, particularly during startup and under varying load conditions, creates complex interference patterns that require sophisticated analysis techniques to predict and mitigate.

As RF technologies continue to advance toward higher frequencies and greater sensitivity, the challenges posed by magnetron interference will require increasingly innovative solutions, making this an important area for continued research and development in the RF engineering community.

RF Design Market Requirements Analysis

The RF design market is experiencing significant growth driven by the proliferation of wireless technologies across multiple industries. Current market analysis indicates that the global RF design market is projected to reach $45 billion by 2026, with a compound annual growth rate of approximately 8.2%. This growth is primarily fueled by increasing demand for wireless communication systems, IoT devices, radar applications, and medical equipment that rely heavily on RF technology.

Magnetron interference presents a critical challenge in this expanding market. End-users across various sectors are demanding RF designs that can maintain signal integrity even in environments with high electromagnetic interference. The telecommunications sector, representing about 35% of the RF design market, requires solutions that can handle magnetron interference to ensure reliable 5G network deployment, especially in urban environments where microwave devices are abundant.

The industrial automation sector has emerged as another significant market segment, with requirements for RF designs that can operate flawlessly in factory settings where multiple magnetrons and other interference sources are present. These environments demand RF systems with enhanced immunity to interference to maintain operational efficiency and prevent costly downtime.

Consumer electronics manufacturers are increasingly prioritizing RF designs with robust magnetron interference handling capabilities. With the average household now containing 7-10 wireless devices, consumers expect seamless connectivity regardless of microwave oven usage or other potential interference sources. This market segment values cost-effective solutions that don't compromise on performance or reliability.

The automotive industry represents a rapidly growing segment for RF design, particularly with the advancement of autonomous vehicles. These systems rely on radar and other RF technologies that must function perfectly despite potential magnetron interference from nearby vehicles or infrastructure. Market research indicates that automotive RF component demand is growing at 12% annually, with interference management being a key requirement.

Healthcare applications present unique challenges and opportunities, with medical devices requiring exceptionally reliable RF performance in environments where magnetrons from imaging equipment may cause interference. This segment demands the highest standards of interference mitigation, with regulatory compliance adding another layer of complexity to market requirements.

Defense and aerospace applications continue to drive innovation in RF design, particularly in handling sophisticated interference scenarios. This sector values advanced solutions that can operate in contested electromagnetic environments, with budgets that can accommodate premium technologies for superior interference handling capabilities.

Magnetron interference presents a critical challenge in this expanding market. End-users across various sectors are demanding RF designs that can maintain signal integrity even in environments with high electromagnetic interference. The telecommunications sector, representing about 35% of the RF design market, requires solutions that can handle magnetron interference to ensure reliable 5G network deployment, especially in urban environments where microwave devices are abundant.

The industrial automation sector has emerged as another significant market segment, with requirements for RF designs that can operate flawlessly in factory settings where multiple magnetrons and other interference sources are present. These environments demand RF systems with enhanced immunity to interference to maintain operational efficiency and prevent costly downtime.

Consumer electronics manufacturers are increasingly prioritizing RF designs with robust magnetron interference handling capabilities. With the average household now containing 7-10 wireless devices, consumers expect seamless connectivity regardless of microwave oven usage or other potential interference sources. This market segment values cost-effective solutions that don't compromise on performance or reliability.

The automotive industry represents a rapidly growing segment for RF design, particularly with the advancement of autonomous vehicles. These systems rely on radar and other RF technologies that must function perfectly despite potential magnetron interference from nearby vehicles or infrastructure. Market research indicates that automotive RF component demand is growing at 12% annually, with interference management being a key requirement.

Healthcare applications present unique challenges and opportunities, with medical devices requiring exceptionally reliable RF performance in environments where magnetrons from imaging equipment may cause interference. This segment demands the highest standards of interference mitigation, with regulatory compliance adding another layer of complexity to market requirements.

Defense and aerospace applications continue to drive innovation in RF design, particularly in handling sophisticated interference scenarios. This sector values advanced solutions that can operate in contested electromagnetic environments, with budgets that can accommodate premium technologies for superior interference handling capabilities.

Current Magnetron Interference Challenges

Magnetron interference presents significant challenges in modern RF design environments, particularly as wireless technologies proliferate across consumer, industrial, and military applications. The primary source of this interference stems from magnetrons in microwave ovens operating at 2.45 GHz, which can generate noise levels exceeding 60 dBm—powerful enough to disrupt nearby wireless systems operating in similar frequency bands.

Engineers face increasing difficulty in designing RF systems that maintain performance integrity when exposed to magnetron interference. This challenge is particularly acute in densely populated urban environments where multiple microwave ovens may operate simultaneously in close proximity to sensitive wireless equipment. Testing data indicates that signal degradation can occur at distances up to 30 meters from an active magnetron source, depending on shielding conditions and environmental factors.

The unpredictable nature of magnetron interference compounds design challenges. Unlike consistent background noise, magnetron emissions exhibit pulsed characteristics with rapid on-off cycling that creates complex interference patterns. These patterns can trigger false positives in signal detection systems and compromise data integrity in wireless communications. Recent field measurements show that interference patterns vary significantly based on magnetron age, manufacturing quality, and operational conditions.

Current filtering technologies demonstrate limited effectiveness against magnetron interference. Traditional bandpass filters struggle to provide adequate rejection without introducing excessive insertion loss, creating an engineering trade-off between interference immunity and system performance. Advanced adaptive filtering techniques show promise but require substantial computational resources that may be impractical for many portable or low-power applications.

Regulatory frameworks have not kept pace with the proliferation of devices operating in the 2.4 GHz ISM band. While FCC and ETSI regulations establish emission limits for magnetron-based appliances, enforcement mechanisms remain inadequate, and legacy devices often exceed modern standards. This regulatory gap leaves RF designers with the burden of developing robust solutions without consistent protection from excessive interference sources.

The economic impact of magnetron interference extends beyond technical considerations. Product returns and customer dissatisfaction due to unexplained wireless performance issues cost manufacturers an estimated $1.2 billion annually. Engineering teams must allocate significant resources to interference mitigation strategies, increasing development costs and time-to-market for new wireless products.

Emerging technologies like 5G networks face particular vulnerability to magnetron interference in specific deployment scenarios. The higher data rates and more complex modulation schemes employed by these systems create lower tolerance for interference, potentially limiting performance in residential and commercial environments where microwave ovens are common.

Engineers face increasing difficulty in designing RF systems that maintain performance integrity when exposed to magnetron interference. This challenge is particularly acute in densely populated urban environments where multiple microwave ovens may operate simultaneously in close proximity to sensitive wireless equipment. Testing data indicates that signal degradation can occur at distances up to 30 meters from an active magnetron source, depending on shielding conditions and environmental factors.

The unpredictable nature of magnetron interference compounds design challenges. Unlike consistent background noise, magnetron emissions exhibit pulsed characteristics with rapid on-off cycling that creates complex interference patterns. These patterns can trigger false positives in signal detection systems and compromise data integrity in wireless communications. Recent field measurements show that interference patterns vary significantly based on magnetron age, manufacturing quality, and operational conditions.

Current filtering technologies demonstrate limited effectiveness against magnetron interference. Traditional bandpass filters struggle to provide adequate rejection without introducing excessive insertion loss, creating an engineering trade-off between interference immunity and system performance. Advanced adaptive filtering techniques show promise but require substantial computational resources that may be impractical for many portable or low-power applications.

Regulatory frameworks have not kept pace with the proliferation of devices operating in the 2.4 GHz ISM band. While FCC and ETSI regulations establish emission limits for magnetron-based appliances, enforcement mechanisms remain inadequate, and legacy devices often exceed modern standards. This regulatory gap leaves RF designers with the burden of developing robust solutions without consistent protection from excessive interference sources.

The economic impact of magnetron interference extends beyond technical considerations. Product returns and customer dissatisfaction due to unexplained wireless performance issues cost manufacturers an estimated $1.2 billion annually. Engineering teams must allocate significant resources to interference mitigation strategies, increasing development costs and time-to-market for new wireless products.

Emerging technologies like 5G networks face particular vulnerability to magnetron interference in specific deployment scenarios. The higher data rates and more complex modulation schemes employed by these systems create lower tolerance for interference, potentially limiting performance in residential and commercial environments where microwave ovens are common.

Existing Magnetron Interference Mitigation Solutions

01 Shielding techniques for magnetron interference reduction

Various shielding techniques can be employed to reduce magnetron interference in electronic systems. These include using specialized materials and structures to contain electromagnetic radiation emitted by magnetrons. Proper shielding designs can prevent interference with nearby electronic components and systems, ensuring stable operation of devices that utilize or are located near magnetron sources.- Shielding techniques for magnetron interference reduction: Various shielding techniques are employed to reduce magnetron interference in electronic systems. These include specialized shield designs, conductive enclosures, and electromagnetic barriers that prevent the leakage of microwave radiation from magnetrons. Proper shielding configurations can significantly minimize interference with nearby electronic components and systems, ensuring stable operation of sensitive equipment in proximity to magnetron sources.

- Magnetron power supply design for interference mitigation: Advanced power supply designs for magnetrons incorporate filtering circuits and stabilization mechanisms to reduce electrical interference. These designs focus on controlling voltage fluctuations, current spikes, and electromagnetic emissions that can cause interference. By implementing specialized power conditioning components and circuit topologies, the electrical noise generated during magnetron operation can be significantly reduced, preventing disruption to nearby electronic systems.

- Sputtering system configurations to minimize magnetron interference: Specific configurations in magnetron sputtering systems are designed to minimize interference issues. These include optimized placement of components, specialized chamber designs, and controlled plasma confinement techniques. By carefully arranging the magnetron assembly and implementing proper grounding schemes, the electromagnetic interference generated during the sputtering process can be contained, allowing for more precise and stable deposition processes without affecting nearby equipment.

- Frequency control methods for reducing magnetron interference: Frequency control and modulation techniques are implemented to manage magnetron interference. These methods involve precise adjustment of operating frequencies, pulse modulation, and frequency hopping to prevent interference with sensitive equipment. By controlling the spectral characteristics of magnetron emissions and implementing synchronization with other systems, interference patterns can be minimized or shifted away from critical frequency bands used by other devices.

- Grounding and isolation strategies for magnetron systems: Effective grounding and electrical isolation strategies are crucial for managing magnetron interference. These include specialized grounding configurations, isolation transformers, and electrical barriers that prevent the propagation of interference through power lines and conductive paths. Proper implementation of these techniques ensures that electromagnetic noise generated by magnetrons remains contained within the intended system boundaries, protecting sensitive electronic equipment from performance degradation.

02 Power supply filtering and stabilization methods

Implementing filtering and stabilization methods in magnetron power supplies can significantly reduce interference issues. These methods include using specialized circuits to filter out noise, stabilize voltage fluctuations, and prevent power-related interference from affecting magnetron operation or propagating to other systems. Advanced power management techniques help maintain consistent magnetron performance while minimizing electromagnetic interference.Expand Specific Solutions03 Magnetron design optimization for interference reduction

Optimizing the design of magnetrons themselves can reduce inherent interference issues. This includes modifications to the internal structure, electrode configurations, and resonant cavity designs. Advanced magnetron designs incorporate features specifically intended to minimize unwanted electromagnetic emissions while maintaining or improving performance characteristics for the intended application.Expand Specific Solutions04 Grounding and isolation strategies

Effective grounding and isolation strategies are crucial for managing magnetron interference. These include implementing proper grounding paths, using isolation transformers, and creating physical separation between sensitive components. Such techniques help prevent ground loops and provide paths for unwanted currents to dissipate safely without affecting other electronic systems.Expand Specific Solutions05 Frequency control and modulation techniques

Controlling the operating frequency and implementing modulation techniques can help manage magnetron interference. These approaches include frequency hopping, pulse modulation, and precise frequency control systems that prevent interference with specific frequency bands used by other devices. By carefully managing the spectral characteristics of magnetron operation, interference with other systems can be minimized.Expand Specific Solutions

Leading RF Design and Magnetron Manufacturers

The magnetron interference management in RF designs is currently in a growth phase, with the market expected to reach significant size due to increasing wireless communication demands. The technology maturity varies across players, with established companies like Ericsson, Samsung, and NXP Semiconductors demonstrating advanced solutions for mitigating magnetron interference in telecommunications equipment. Silicon Laboratories and Skyworks Solutions have developed specialized RF isolation techniques, while companies like Siemens Healthineers and Naval Research Laboratory focus on interference management in medical and military applications respectively. Emerging players such as OPPO, vivo, and LG Electronics are investing in consumer electronics applications, particularly for mobile devices. The competitive landscape shows a mix of telecommunications giants, semiconductor specialists, and application-specific solution providers working to address this critical RF design challenge.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed a multi-layered approach to handling magnetron interference in their RF designs, particularly for consumer electronics and mobile devices that may operate in proximity to microwave ovens. Their solution combines hardware isolation techniques with advanced signal processing algorithms. At the hardware level, Samsung employs specialized RF shields with proprietary composite materials that provide superior attenuation of 2.45 GHz magnetron emissions while maintaining minimal impact on desired wireless signals. Their designs incorporate strategically placed ground planes and carefully routed signal paths to minimize susceptibility to magnetron radiation. Samsung's approach also includes adaptive notch filtering that can dynamically identify and suppress magnetron interference patterns in real-time. Their Galaxy series devices feature specialized RF front-end modules with enhanced linearity characteristics to prevent saturation when exposed to high-power magnetron pulses. Additionally, Samsung has developed machine learning algorithms that can recognize the characteristic signature of magnetron interference and apply appropriate mitigation techniques, improving over time as the system encounters various interference scenarios. Their solution also includes frequency-hopping techniques for wireless communications that can automatically avoid channels most affected by magnetron interference.

Strengths: Highly effective in consumer environments with common magnetron sources like microwave ovens; seamless integration with existing wireless technologies; minimal impact on user experience. Weaknesses: Some solutions increase component cost and power consumption; most effective techniques require significant processing resources; primarily optimized for consumer rather than industrial or scientific applications.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has developed advanced RF shielding techniques specifically designed to mitigate magnetron interference in military and naval communication systems. Their approach combines physical isolation methods with adaptive filtering algorithms that can identify and suppress magnetron-generated noise in real-time. The technology employs specialized cavity resonators that trap and dissipate unwanted electromagnetic energy while allowing desired signals to pass through. Additionally, NRL has pioneered frequency-selective surface (FSS) materials that can be integrated into RF system enclosures to block specific frequency bands associated with magnetron interference. Their digital signal processing solutions include predictive cancellation algorithms that model the characteristic signature of magnetron noise and subtract it from the received signal, significantly improving signal-to-noise ratios in environments with active magnetron sources.

Strengths: Exceptional performance in high-interference naval environments; proven effectiveness in mission-critical military applications; comprehensive approach combining hardware and software solutions. Weaknesses: Solutions may be cost-prohibitive for commercial applications; some technologies remain classified and unavailable for civilian use; implementation requires specialized expertise.

Key Patents in RF Interference Management

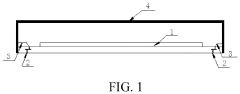

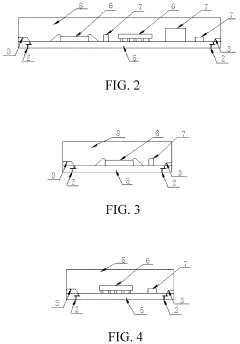

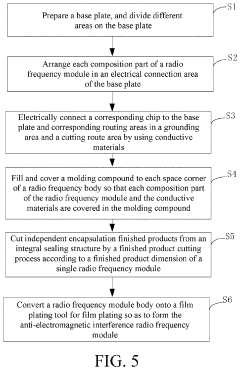

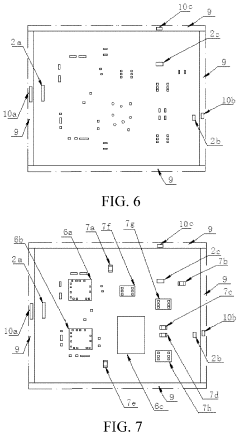

Anti-electromagnetic interference radio frequency module and implementation method therefor

PatentActiveUS11264335B2

Innovation

- An anti-electromagnetic interference radio frequency module with a metal thin film structure integrated into the module body, connected to a grounding area via conductive materials, forming an anti-electromagnetic interference shielding layer, which is formed using a metal thin film sputtering process to reduce electromagnetic interference effectively.

Radio frequency identification device

PatentInactiveUS20080143488A1

Innovation

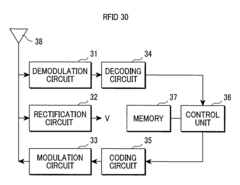

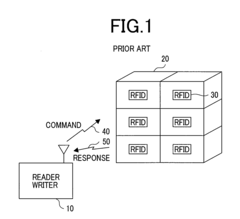

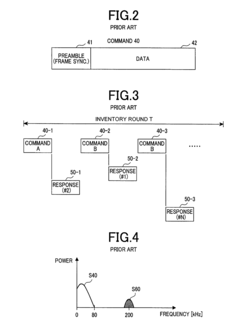

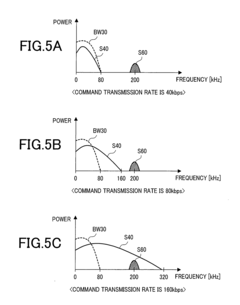

- Incorporating a demodulation circuit with a variable low-pass filter (LPF) unit, a transmission rate detection circuit, and a control circuit that sets and adjusts the reception bandwidth to match the detected transmission rate, ensuring the LPF's bandwidth covers the occupied bandwidth of the received command, thereby reducing interference effects.

EMC Standards and Compliance Requirements

Electromagnetic Compatibility (EMC) standards play a crucial role in managing magnetron interference in RF designs. The International Electrotechnical Commission (IEC) has established comprehensive standards, particularly IEC 61000 series, which addresses various aspects of electromagnetic compatibility. For RF designs affected by magnetron interference, IEC 61000-4-3 specifically covers immunity to radiated radio-frequency electromagnetic fields, providing essential testing methodologies and compliance levels.

In the United States, the Federal Communications Commission (FCC) regulates EMC requirements through Title 47 CFR Part 15 for unintentional radiators and Part 18 for industrial, scientific, and medical equipment including magnetrons. These regulations establish emission limits across different frequency bands and operational environments. Similarly, the European Union enforces the EMC Directive 2014/30/EU, requiring all electronic equipment to maintain electromagnetic compatibility without causing interference to other devices.

Military and aerospace applications follow more stringent standards such as MIL-STD-461G, which provides detailed requirements for the control of electromagnetic interference characteristics of subsystems and equipment. This standard includes specific test methods like RS103 for radiated susceptibility, essential when designing RF systems that must operate in proximity to magnetron sources.

Compliance testing for magnetron interference typically involves both conducted and radiated emission measurements. CISPR 11 specifically addresses industrial, scientific, and medical equipment operating in the frequency range 9 kHz to 400 GHz, categorizing equipment into Groups 1 and 2, with magnetrons falling under Group 2. This standard defines measurement techniques and limits for both conducted and radiated disturbances.

For consumer electronics potentially affected by magnetron interference, CISPR 32 provides electromagnetic compatibility requirements, categorizing equipment into Class A (commercial/industrial) and Class B (residential) with corresponding emission limits. Additionally, IEC 61000-4-6 addresses immunity to conducted disturbances induced by radio-frequency fields, complementing radiated immunity requirements.

Emerging standards are increasingly addressing specific frequency bands used in modern wireless communications, particularly as 5G networks expand into higher frequency ranges where magnetron interference becomes more problematic. The IEEE has developed standards like IEEE 299 for measuring the effectiveness of electromagnetic shielding enclosures, providing valuable guidance for RF designers implementing shielding solutions against magnetron interference.

In the United States, the Federal Communications Commission (FCC) regulates EMC requirements through Title 47 CFR Part 15 for unintentional radiators and Part 18 for industrial, scientific, and medical equipment including magnetrons. These regulations establish emission limits across different frequency bands and operational environments. Similarly, the European Union enforces the EMC Directive 2014/30/EU, requiring all electronic equipment to maintain electromagnetic compatibility without causing interference to other devices.

Military and aerospace applications follow more stringent standards such as MIL-STD-461G, which provides detailed requirements for the control of electromagnetic interference characteristics of subsystems and equipment. This standard includes specific test methods like RS103 for radiated susceptibility, essential when designing RF systems that must operate in proximity to magnetron sources.

Compliance testing for magnetron interference typically involves both conducted and radiated emission measurements. CISPR 11 specifically addresses industrial, scientific, and medical equipment operating in the frequency range 9 kHz to 400 GHz, categorizing equipment into Groups 1 and 2, with magnetrons falling under Group 2. This standard defines measurement techniques and limits for both conducted and radiated disturbances.

For consumer electronics potentially affected by magnetron interference, CISPR 32 provides electromagnetic compatibility requirements, categorizing equipment into Class A (commercial/industrial) and Class B (residential) with corresponding emission limits. Additionally, IEC 61000-4-6 addresses immunity to conducted disturbances induced by radio-frequency fields, complementing radiated immunity requirements.

Emerging standards are increasingly addressing specific frequency bands used in modern wireless communications, particularly as 5G networks expand into higher frequency ranges where magnetron interference becomes more problematic. The IEEE has developed standards like IEEE 299 for measuring the effectiveness of electromagnetic shielding enclosures, providing valuable guidance for RF designers implementing shielding solutions against magnetron interference.

Cost-Benefit Analysis of Interference Solutions

When evaluating magnetron interference mitigation strategies in RF designs, a comprehensive cost-benefit analysis is essential for making informed implementation decisions. The initial investment costs for shielding solutions vary significantly, with basic Faraday cages starting at approximately $500 for small applications, while custom-designed comprehensive shielding systems for industrial environments can exceed $10,000. These capital expenditures must be weighed against the potential costs of interference-related failures, which include equipment damage, production downtime, and compromised data integrity.

Filtering solutions present a different cost structure, with passive filters typically ranging from $50 to $500 per component, while active filtering systems may cost between $1,000 and $5,000 depending on complexity and performance requirements. The operational benefits include extended equipment lifespan, reduced maintenance frequency, and improved signal quality, which collectively contribute to enhanced system reliability and performance consistency.

Implementation complexity represents another critical factor in the analysis. Retrofitting existing systems with interference mitigation measures typically costs 30-50% more than incorporating these solutions during initial design phases. Organizations must also consider the training requirements for technical staff, which may add $1,000-$3,000 per employee in specialized education costs.

The return on investment timeline varies by industry and application. Healthcare and aerospace sectors typically see ROI within 12-18 months due to the high costs associated with equipment failures in these critical environments. Commercial applications generally require 18-36 months to realize full financial benefits, while consumer electronics may see returns in as little as 6-12 months through reduced warranty claims and improved customer satisfaction.

Regulatory compliance represents an often-overlooked benefit that significantly impacts the cost-benefit equation. Non-compliance with electromagnetic compatibility standards can result in penalties ranging from $10,000 to over $1 million depending on jurisdiction and violation severity. Proactive interference management not only avoids these penalties but also streamlines certification processes, potentially reducing time-to-market by 15-30%.

Energy efficiency improvements represent another quantifiable benefit, with properly shielded and filtered systems typically demonstrating 5-15% lower power consumption compared to unprotected equivalents. This translates to operational cost savings that accumulate significantly over equipment lifespans, particularly in large-scale deployments or energy-intensive applications where magnetron interference mitigation contributes to overall system optimization.

Filtering solutions present a different cost structure, with passive filters typically ranging from $50 to $500 per component, while active filtering systems may cost between $1,000 and $5,000 depending on complexity and performance requirements. The operational benefits include extended equipment lifespan, reduced maintenance frequency, and improved signal quality, which collectively contribute to enhanced system reliability and performance consistency.

Implementation complexity represents another critical factor in the analysis. Retrofitting existing systems with interference mitigation measures typically costs 30-50% more than incorporating these solutions during initial design phases. Organizations must also consider the training requirements for technical staff, which may add $1,000-$3,000 per employee in specialized education costs.

The return on investment timeline varies by industry and application. Healthcare and aerospace sectors typically see ROI within 12-18 months due to the high costs associated with equipment failures in these critical environments. Commercial applications generally require 18-36 months to realize full financial benefits, while consumer electronics may see returns in as little as 6-12 months through reduced warranty claims and improved customer satisfaction.

Regulatory compliance represents an often-overlooked benefit that significantly impacts the cost-benefit equation. Non-compliance with electromagnetic compatibility standards can result in penalties ranging from $10,000 to over $1 million depending on jurisdiction and violation severity. Proactive interference management not only avoids these penalties but also streamlines certification processes, potentially reducing time-to-market by 15-30%.

Energy efficiency improvements represent another quantifiable benefit, with properly shielded and filtered systems typically demonstrating 5-15% lower power consumption compared to unprotected equivalents. This translates to operational cost savings that accumulate significantly over equipment lifespans, particularly in large-scale deployments or energy-intensive applications where magnetron interference mitigation contributes to overall system optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!