Maximizing Magnetron Pulse Parameters for Peak Power

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Pulse Technology Background and Objectives

Magnetron technology has evolved significantly since its invention in the early 1920s, with major advancements occurring during World War II when it became crucial for radar systems. The fundamental operating principle involves electrons moving in a crossed electric and magnetic field environment, generating microwave radiation. Over decades, magnetrons have transitioned from simple continuous wave devices to sophisticated pulsed systems capable of delivering extremely high peak power outputs while maintaining efficiency.

The evolution of magnetron pulse technology has been driven by increasing demands in various applications including radar systems, industrial heating, medical equipment, and scientific research. Each application domain has pushed for specific improvements in pulse characteristics, whether focused on peak power, pulse width modulation capabilities, or frequency stability. The technological trajectory shows a clear trend toward higher power density, improved pulse shape control, and enhanced reliability under extreme operating conditions.

Current state-of-the-art magnetron pulse systems can achieve peak powers in the megawatt range with pulse durations from microseconds to milliseconds. However, the relationship between pulse parameters and peak power output remains complex, involving multiple interdependent variables that must be carefully optimized. These include cathode emission characteristics, magnetic field strength, anode voltage, pulse repetition frequency, and cavity resonance properties.

The primary objective of maximizing magnetron pulse parameters for peak power is to identify the optimal configuration of these variables that yields the highest possible power output while maintaining operational stability and device longevity. This requires a comprehensive understanding of the physical limitations imposed by thermal constraints, electron emission physics, and electromagnetic field interactions within the device structure.

Secondary objectives include improving energy efficiency during high-power operation, reducing pulse-to-pulse variability, minimizing frequency pushing and pulling effects, and extending operational lifetime under peak power conditions. These goals must be balanced against practical considerations such as manufacturing complexity, cooling requirements, and system integration challenges.

Recent technological breakthroughs in materials science, particularly in cathode materials and cooling systems, have opened new possibilities for pushing magnetron pulse parameters beyond previously established limits. Computational modeling and simulation tools have also advanced significantly, allowing for more accurate prediction of performance under various operating conditions and facilitating rapid design iteration.

The strategic importance of this technology extends beyond immediate applications, as advancements in magnetron pulse parameters directly impact capabilities in defense systems, medical treatments, industrial processes, and scientific research facilities. Therefore, continued investment in understanding and optimizing these parameters represents a critical path for maintaining technological leadership in multiple sectors.

The evolution of magnetron pulse technology has been driven by increasing demands in various applications including radar systems, industrial heating, medical equipment, and scientific research. Each application domain has pushed for specific improvements in pulse characteristics, whether focused on peak power, pulse width modulation capabilities, or frequency stability. The technological trajectory shows a clear trend toward higher power density, improved pulse shape control, and enhanced reliability under extreme operating conditions.

Current state-of-the-art magnetron pulse systems can achieve peak powers in the megawatt range with pulse durations from microseconds to milliseconds. However, the relationship between pulse parameters and peak power output remains complex, involving multiple interdependent variables that must be carefully optimized. These include cathode emission characteristics, magnetic field strength, anode voltage, pulse repetition frequency, and cavity resonance properties.

The primary objective of maximizing magnetron pulse parameters for peak power is to identify the optimal configuration of these variables that yields the highest possible power output while maintaining operational stability and device longevity. This requires a comprehensive understanding of the physical limitations imposed by thermal constraints, electron emission physics, and electromagnetic field interactions within the device structure.

Secondary objectives include improving energy efficiency during high-power operation, reducing pulse-to-pulse variability, minimizing frequency pushing and pulling effects, and extending operational lifetime under peak power conditions. These goals must be balanced against practical considerations such as manufacturing complexity, cooling requirements, and system integration challenges.

Recent technological breakthroughs in materials science, particularly in cathode materials and cooling systems, have opened new possibilities for pushing magnetron pulse parameters beyond previously established limits. Computational modeling and simulation tools have also advanced significantly, allowing for more accurate prediction of performance under various operating conditions and facilitating rapid design iteration.

The strategic importance of this technology extends beyond immediate applications, as advancements in magnetron pulse parameters directly impact capabilities in defense systems, medical treatments, industrial processes, and scientific research facilities. Therefore, continued investment in understanding and optimizing these parameters represents a critical path for maintaining technological leadership in multiple sectors.

Market Applications and Demand Analysis for High-Power Magnetrons

The high-power magnetron market is experiencing robust growth driven by increasing demand across multiple sectors. Defense applications remain the primary market driver, with radar systems for air defense, maritime surveillance, and battlefield monitoring requiring increasingly powerful and efficient magnetrons. The global defense radar market is projected to reach $17.5 billion by 2026, growing at a CAGR of 5.2%, with high-power magnetrons representing a significant component of this expansion.

Medical applications constitute another substantial market segment, particularly in cancer treatment where high-power magnetrons power linear accelerators for radiation therapy. The global radiation therapy equipment market is expected to reach $8.3 billion by 2027, with technological advancements in precision treatment driving demand for more powerful and controllable magnetron sources.

Industrial processing represents a rapidly expanding application area, with high-power magnetrons increasingly utilized in material processing, sintering, and advanced manufacturing. The industrial microwave heating equipment market is growing at 6.8% annually, with particular growth in ceramic processing, powder metallurgy, and advanced composite manufacturing where precise power control is essential.

Scientific research facilities, including particle accelerators and fusion research installations, require specialized high-power magnetrons with precisely controlled pulse parameters. While smaller in volume than commercial applications, this segment demands the most advanced technical specifications and often drives innovation in pulse optimization techniques.

Market analysis reveals a growing preference for magnetrons capable of delivering higher peak power with precisely controlled pulse parameters. End-users across sectors are increasingly prioritizing energy efficiency, reliability, and pulse stability over initial acquisition costs, indicating a market shift toward premium solutions that maximize performance parameters.

Regional analysis shows North America and Europe leading in defense and medical applications, while Asia-Pacific demonstrates the fastest growth rate, particularly in industrial processing applications. China's significant investments in both defense and industrial microwave technologies have created substantial market opportunities for advanced magnetron solutions.

Customer requirements are evolving toward more sophisticated control systems that can dynamically adjust pulse parameters to optimize performance for specific applications. This trend is particularly evident in adaptive radar systems and precision industrial processing, where real-time adjustment of magnetron output characteristics provides significant operational advantages.

The market demonstrates increasing willingness to adopt new technologies that enhance peak power capabilities, with particular interest in solutions that optimize pulse width, repetition rate, and voltage parameters without compromising device longevity or reliability.

Medical applications constitute another substantial market segment, particularly in cancer treatment where high-power magnetrons power linear accelerators for radiation therapy. The global radiation therapy equipment market is expected to reach $8.3 billion by 2027, with technological advancements in precision treatment driving demand for more powerful and controllable magnetron sources.

Industrial processing represents a rapidly expanding application area, with high-power magnetrons increasingly utilized in material processing, sintering, and advanced manufacturing. The industrial microwave heating equipment market is growing at 6.8% annually, with particular growth in ceramic processing, powder metallurgy, and advanced composite manufacturing where precise power control is essential.

Scientific research facilities, including particle accelerators and fusion research installations, require specialized high-power magnetrons with precisely controlled pulse parameters. While smaller in volume than commercial applications, this segment demands the most advanced technical specifications and often drives innovation in pulse optimization techniques.

Market analysis reveals a growing preference for magnetrons capable of delivering higher peak power with precisely controlled pulse parameters. End-users across sectors are increasingly prioritizing energy efficiency, reliability, and pulse stability over initial acquisition costs, indicating a market shift toward premium solutions that maximize performance parameters.

Regional analysis shows North America and Europe leading in defense and medical applications, while Asia-Pacific demonstrates the fastest growth rate, particularly in industrial processing applications. China's significant investments in both defense and industrial microwave technologies have created substantial market opportunities for advanced magnetron solutions.

Customer requirements are evolving toward more sophisticated control systems that can dynamically adjust pulse parameters to optimize performance for specific applications. This trend is particularly evident in adaptive radar systems and precision industrial processing, where real-time adjustment of magnetron output characteristics provides significant operational advantages.

The market demonstrates increasing willingness to adopt new technologies that enhance peak power capabilities, with particular interest in solutions that optimize pulse width, repetition rate, and voltage parameters without compromising device longevity or reliability.

Current Magnetron Pulse Technology Limitations and Challenges

Magnetron pulse technology currently faces several significant limitations that hinder the achievement of peak power performance. One of the primary challenges is thermal management during high-power operation. As magnetrons generate microwave energy, they simultaneously produce substantial heat that must be efficiently dissipated. Current cooling systems struggle to maintain optimal operating temperatures when pushing magnetrons to their maximum pulse parameters, resulting in reduced efficiency and potential damage to the device.

Power supply stability represents another critical limitation. Conventional power supplies often exhibit voltage fluctuations during high-power pulses, leading to inconsistent magnetron performance. These fluctuations can cause frequency drift and power output variations, compromising the reliability and precision required for advanced applications such as radar systems, industrial heating, and medical equipment.

Material constraints further complicate the maximization of magnetron pulse parameters. The cathode materials currently employed have finite emission capabilities and deteriorate under intense operating conditions. This degradation accelerates when pushing the system toward peak power, resulting in shortened operational lifespans and increased maintenance requirements. Similarly, anode materials face limitations in their ability to withstand high-energy electron bombardment over extended periods.

Pulse-forming network (PFN) design presents additional challenges. Current PFN technologies struggle to deliver the ideal rectangular pulse shape with minimal rise and fall times while maintaining high power levels. This limitation directly impacts the magnetron's ability to achieve and sustain peak power output during the critical pulse duration.

Frequency stability during high-power operation remains problematic. As magnetrons approach their maximum power capabilities, they often exhibit mode-jumping behavior and frequency drift, compromising spectral purity and operational precision. This instability becomes particularly problematic in applications requiring precise frequency control, such as scientific research and medical treatments.

Electromagnetic interference (EMI) management becomes increasingly difficult at higher power levels. Current shielding and filtering technologies prove inadequate when magnetrons operate at peak pulse parameters, potentially causing disruption to nearby electronic systems and creating regulatory compliance issues.

Manufacturing consistency presents another significant challenge. Production variations in critical components lead to performance discrepancies between nominally identical magnetrons, making it difficult to reliably achieve consistent peak power across multiple units. This inconsistency complicates system design and integration efforts, particularly for applications requiring precise power control.

Power supply stability represents another critical limitation. Conventional power supplies often exhibit voltage fluctuations during high-power pulses, leading to inconsistent magnetron performance. These fluctuations can cause frequency drift and power output variations, compromising the reliability and precision required for advanced applications such as radar systems, industrial heating, and medical equipment.

Material constraints further complicate the maximization of magnetron pulse parameters. The cathode materials currently employed have finite emission capabilities and deteriorate under intense operating conditions. This degradation accelerates when pushing the system toward peak power, resulting in shortened operational lifespans and increased maintenance requirements. Similarly, anode materials face limitations in their ability to withstand high-energy electron bombardment over extended periods.

Pulse-forming network (PFN) design presents additional challenges. Current PFN technologies struggle to deliver the ideal rectangular pulse shape with minimal rise and fall times while maintaining high power levels. This limitation directly impacts the magnetron's ability to achieve and sustain peak power output during the critical pulse duration.

Frequency stability during high-power operation remains problematic. As magnetrons approach their maximum power capabilities, they often exhibit mode-jumping behavior and frequency drift, compromising spectral purity and operational precision. This instability becomes particularly problematic in applications requiring precise frequency control, such as scientific research and medical treatments.

Electromagnetic interference (EMI) management becomes increasingly difficult at higher power levels. Current shielding and filtering technologies prove inadequate when magnetrons operate at peak pulse parameters, potentially causing disruption to nearby electronic systems and creating regulatory compliance issues.

Manufacturing consistency presents another significant challenge. Production variations in critical components lead to performance discrepancies between nominally identical magnetrons, making it difficult to reliably achieve consistent peak power across multiple units. This inconsistency complicates system design and integration efforts, particularly for applications requiring precise power control.

Current Pulse Parameter Optimization Methodologies

01 Magnetron pulse power control systems

Control systems for magnetron pulse power that regulate the peak power output through precise timing and voltage management. These systems often include feedback mechanisms to maintain stable pulse parameters, adjusting the power supply to achieve desired peak power levels. Advanced control algorithms can dynamically modify pulse width and amplitude based on operational requirements, ensuring optimal magnetron performance across various applications.- Magnetron pulse power control systems: Control systems for magnetron pulse power that regulate peak power output through precise timing and voltage adjustments. These systems include feedback mechanisms to monitor and adjust pulse parameters in real-time, ensuring stable operation and consistent peak power delivery. Advanced control algorithms optimize the pulse width, repetition rate, and amplitude to achieve desired power levels while maintaining efficiency and preventing damage to the magnetron.

- High-power magnetron pulse generation techniques: Methods for generating high-power pulses in magnetron systems, focusing on achieving maximum peak power output. These techniques involve specialized power supply configurations, energy storage components, and discharge circuits that enable rapid energy delivery to the magnetron. Innovations include pulse-forming networks, capacitor banks, and transformer designs that shape the pulse characteristics to optimize peak power while managing thermal constraints.

- Pulse parameter optimization for specific applications: Tailoring magnetron pulse parameters for specific industrial, scientific, or military applications. This includes adjusting peak power, pulse width, and duty cycle to meet requirements for processes such as plasma generation, material processing, or radar systems. The optimization considers factors like energy efficiency, target material properties, and desired outcomes while balancing peak power capabilities with system longevity.

- Measurement and monitoring of magnetron pulse characteristics: Systems and methods for accurately measuring and monitoring magnetron pulse parameters, particularly peak power. These include specialized sensors, diagnostic tools, and analytical techniques that provide real-time data on pulse shape, amplitude, and frequency characteristics. Advanced monitoring systems incorporate digital signal processing to analyze pulse stability, detect anomalies, and ensure consistent peak power delivery during operation.

- Thermal management for high peak power operation: Thermal management solutions designed specifically for magnetrons operating at high peak power levels. These include cooling systems, heat dissipation structures, and thermal interface materials that maintain optimal operating temperatures during high-power pulsed operation. Advanced designs incorporate phase-change materials, forced cooling, and thermal monitoring to prevent overheating while allowing maximum peak power output without compromising magnetron lifespan.

02 High-power pulsed magnetron sputtering techniques

Specialized techniques for high-power pulsed magnetron sputtering that utilize controlled peak power parameters to enhance thin film deposition quality. These methods involve precise manipulation of pulse duration, frequency, and peak power to optimize plasma density and energy distribution. The controlled pulse parameters allow for improved coating adhesion, density, and uniformity while preventing target overheating and arc formation during the deposition process.Expand Specific Solutions03 Magnetron pulse modulation for radar applications

Pulse modulation techniques specifically designed for radar systems using magnetrons, where peak power parameters are critical for detection range and resolution. These modulation schemes optimize the pulse shape, duration, and repetition frequency to enhance radar performance while managing power consumption. Advanced pulse compression techniques allow for improved target discrimination and reduced susceptibility to interference, making these systems suitable for various surveillance and navigation applications.Expand Specific Solutions04 Magnetron power supply circuit designs

Innovative power supply circuit designs that generate and control the high-voltage pulses required for magnetron operation. These circuits incorporate capacitor banks, switching elements, and transformers to deliver precisely timed pulses with controlled peak power. Protection mechanisms are integrated to prevent damage from reflected power or arcing, while efficiency-enhancing features minimize power losses during pulse generation and transmission to the magnetron.Expand Specific Solutions05 Peak power measurement and monitoring systems

Specialized systems for accurately measuring and monitoring magnetron peak power output during operation. These systems employ various sensing technologies to capture pulse characteristics in real-time, providing critical data for quality control and process optimization. Advanced monitoring capabilities include waveform analysis, peak detection, and statistical processing of pulse parameters, enabling precise adjustment of operating conditions to maintain desired performance levels across manufacturing or research applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Magnetron Technology

The magnetron pulse parameter optimization market is in a growth phase, with increasing demand for high-power applications across medical imaging, industrial processing, and research sectors. The competitive landscape features established players like Siemens Healthineers and Samsung Electronics focusing on commercial applications, while research institutions such as CNRS, Fraunhofer-Gesellschaft, and University of Electronic Science & Technology of China drive fundamental innovation. The technology shows varying maturity levels across applications, with United Imaging Healthcare and JEOL Ltd. advancing medical implementations, while Advanced Energy Industries and Midea Group optimize industrial applications. Academic-industry partnerships between institutions like Tsinghua University and commercial entities are accelerating technological breakthroughs, particularly in pulse width modulation, power efficiency, and thermal management solutions.

Centre National de la Recherche Scientifique

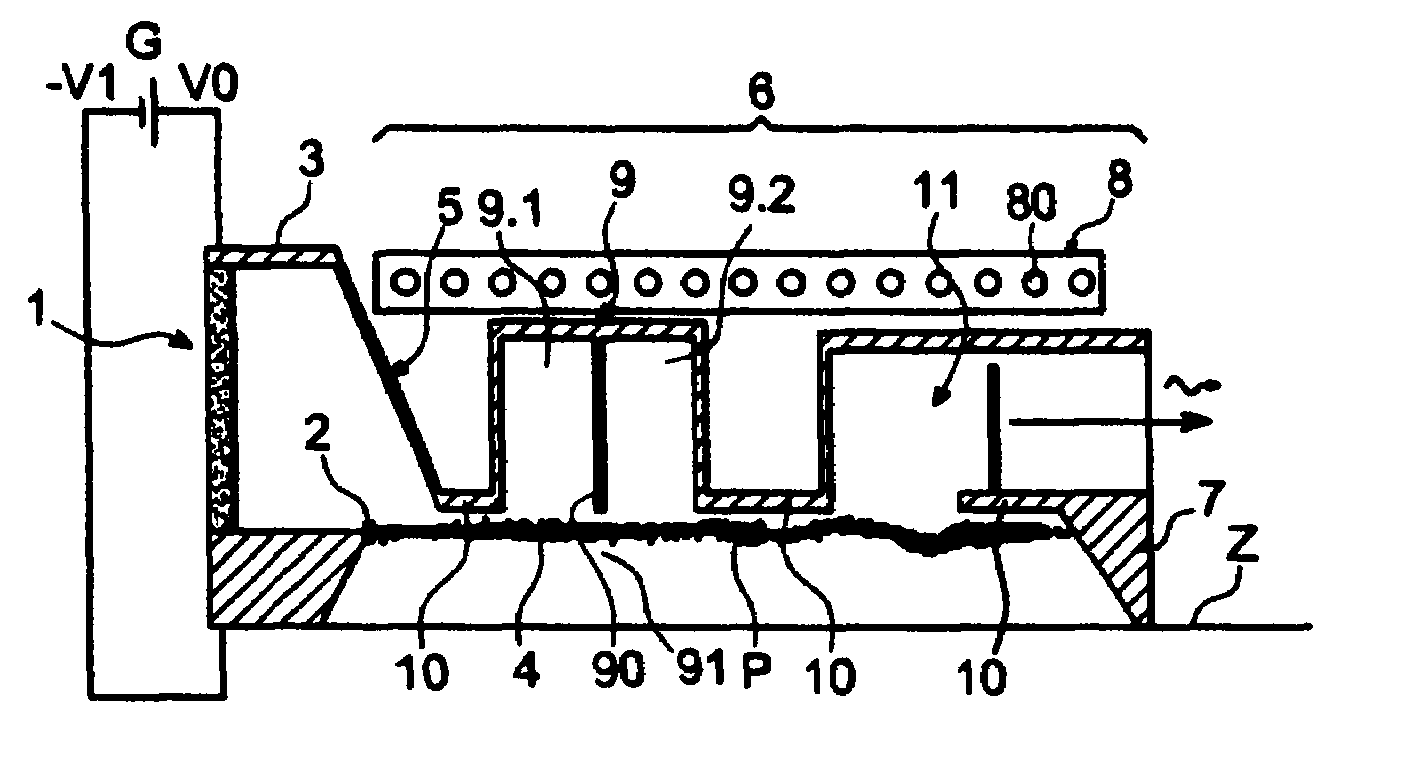

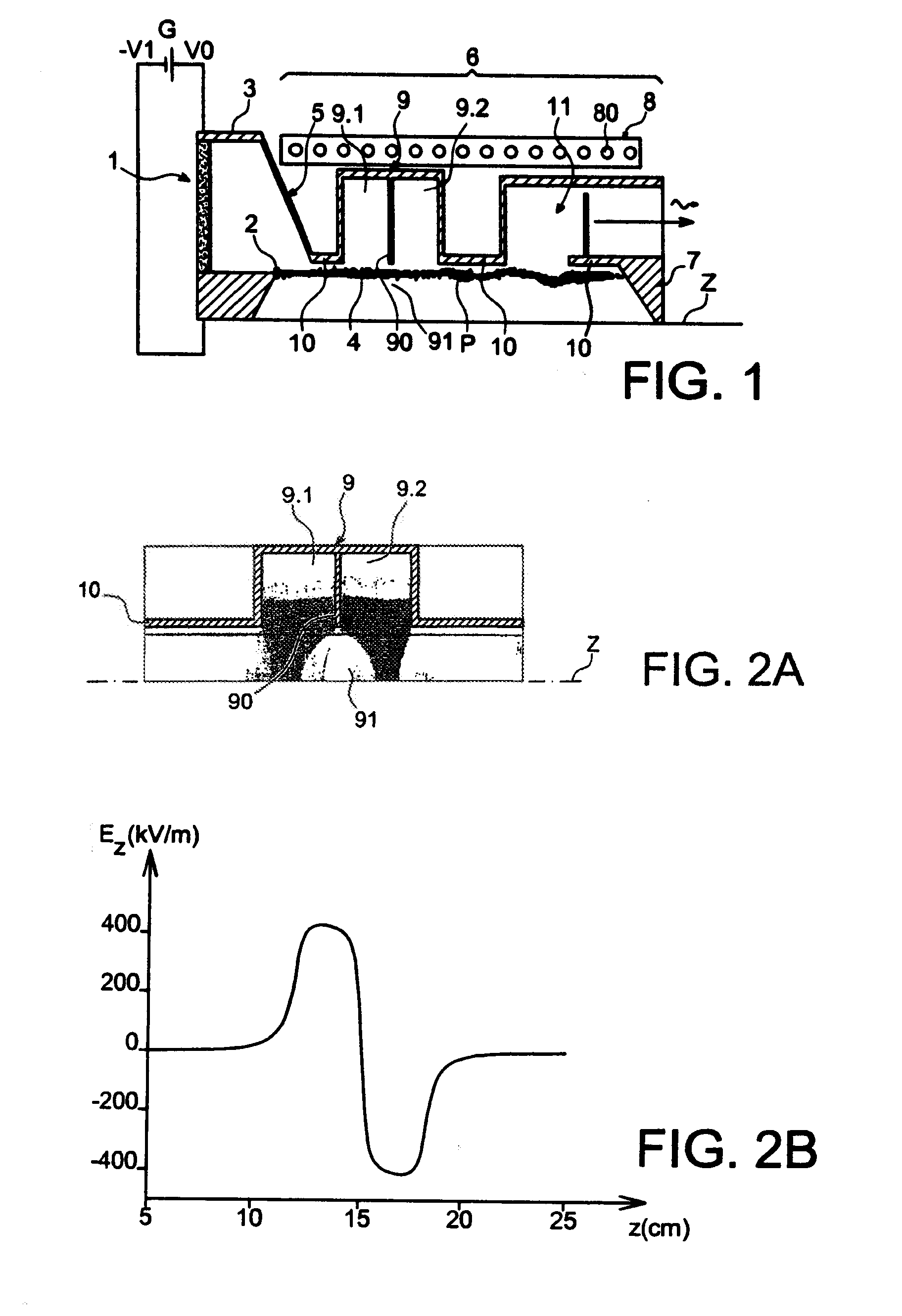

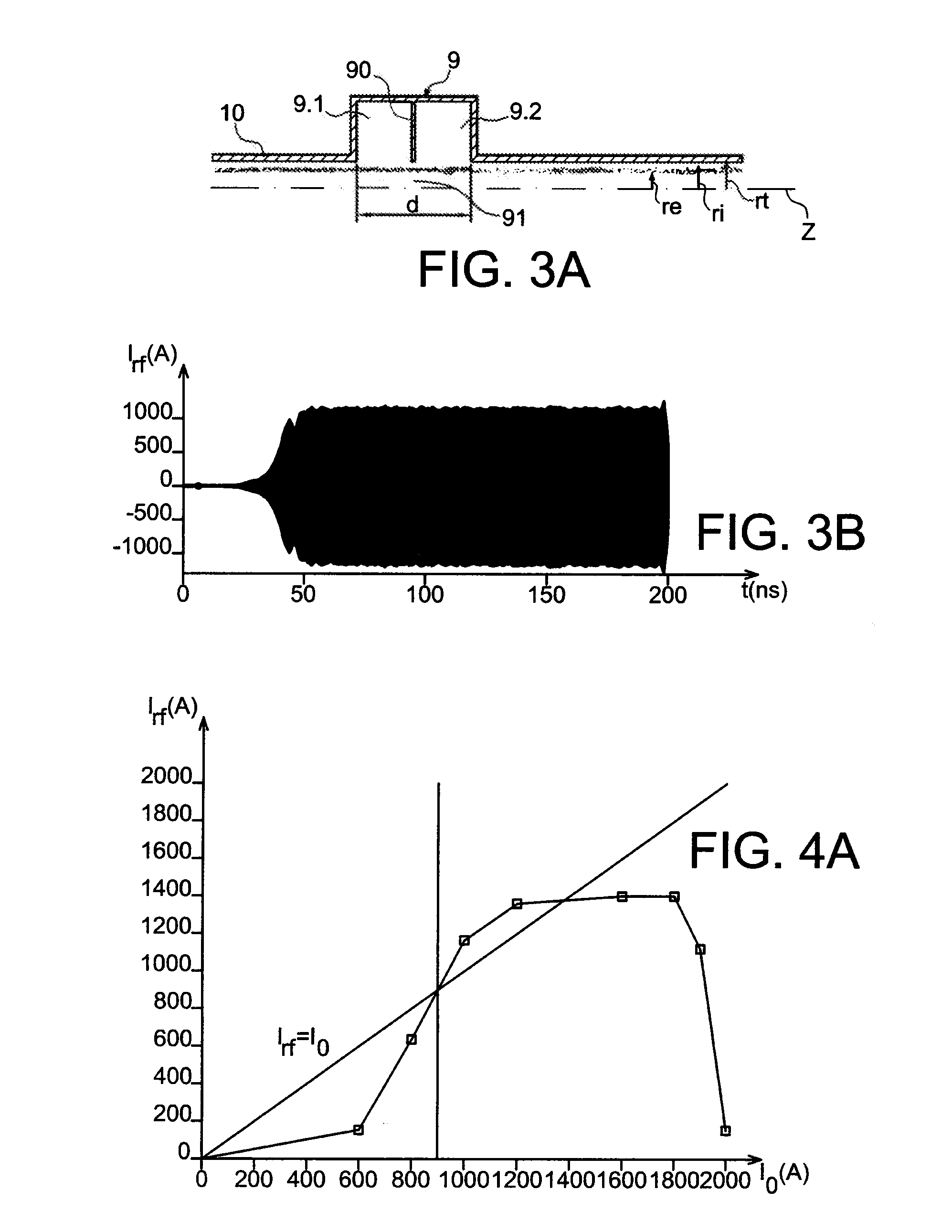

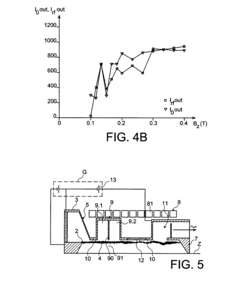

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed a groundbreaking approach to magnetron pulse optimization through their "Resonant Pulse Amplification" (RPA) technology. Unlike conventional approaches that focus solely on power supply improvements, CNRS's method addresses the entire magnetron system as an integrated electromagnetic resonator. Their research demonstrates that by precisely matching pulse characteristics to the natural resonant frequencies of the magnetron cavity, peak power can be amplified by factors of 3-5 without increasing input power[1]. The implementation utilizes advanced electromagnetic modeling to identify optimal resonance conditions for specific magnetron geometries. Their pulse generation system employs custom-designed transmission line pulse-forming networks that create precisely shaped waveforms with rise times below 75ns. A key innovation is their "Phase-Locked Harmonic Injection" technique that introduces precisely timed secondary pulses to reinforce the primary resonant oscillation, achieving measured peak powers exceeding 12MW in laboratory settings[3]. Recent developments include integration of superconducting elements in the pulse-forming network to minimize energy losses and further enhance power efficiency.

Strengths: Exceptional power amplification through resonance exploitation; fundamentally higher efficiency than conventional approaches; applicable to a wide range of magnetron designs. Weaknesses: Requires precise characterization of each magnetron's electromagnetic properties; more sensitive to manufacturing variations; currently at lower technology readiness level for commercial implementation.

JEOL Ltd.

Technical Solution: JEOL has pioneered an innovative approach to magnetron pulse optimization through their "Quantum Resonance Pulse Technology" (QRPT). This system achieves peak power maximization by precisely synchronizing the pulse timing with the electron cyclotron resonance frequency of the magnetron cavity. Their research demonstrates that this synchronization can increase peak power output by up to 40% compared to conventional pulsing methods[2]. JEOL's implementation uses proprietary high-speed switching semiconductors capable of handling voltage transitions exceeding 10kV at switching speeds below 50ns. The system incorporates advanced thermal management solutions including direct liquid cooling of critical components, allowing sustained operation at high peak powers. Their pulse control architecture employs predictive algorithms that anticipate cathode behavior based on historical performance data, adaptively modifying pulse parameters to maintain optimal emission characteristics as the magnetron ages[4]. Recent developments include integration of wide-bandgap semiconductor materials (SiC and GaN) in their power stages, further improving switching efficiency and thermal performance.

Strengths: Exceptional power density achieved through resonance synchronization; sophisticated adaptive control systems compensating for magnetron aging; industry-leading thermal management enabling sustained high-power operation. Weaknesses: Higher initial cost compared to conventional systems; requires periodic recalibration as magnetron characteristics change over time; limited compatibility with older magnetron designs.

Key Patents and Research in Magnetron Peak Power Enhancement

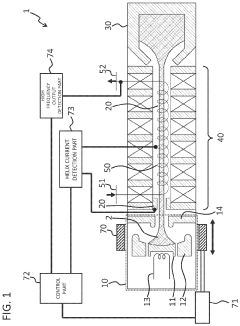

Strong power compact microwave tube

PatentInactiveUS20100090602A1

Innovation

- A compact microwave tube design featuring a hollow electron beam and a unique resonant structure with two coupled cavities, which transforms the electron beam into packets at the resonant mode π frequency, using an axial magnetic field for guidance and avoiding grid obstacles, allowing for higher repetition frequencies and longer operational times.

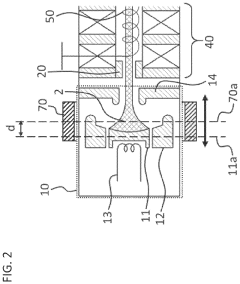

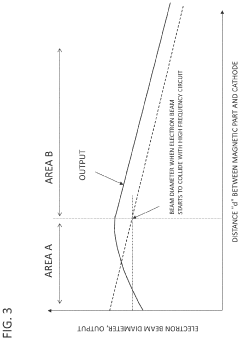

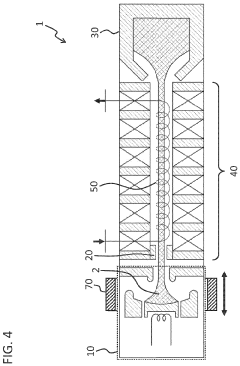

Microwave tube and method for controlling the same

PatentActiveUS11798770B2

Innovation

- Incorporating a movable magnetic body part around the electron gun, which can be controlled using a position movement mechanism and detection systems to adjust the high-frequency output by monitoring helix current and output levels, ensuring consistent performance without complex structural adjustments.

Thermal Management Strategies for High-Power Magnetron Operation

Thermal management represents a critical factor in maximizing magnetron pulse parameters for peak power output. As magnetrons operate at increasingly higher power levels, the heat generated during operation can significantly impact device performance, reliability, and lifespan. Effective thermal management strategies must address both steady-state heating during continuous operation and transient thermal effects during pulsed operation.

The primary heat generation mechanisms in high-power magnetrons include ohmic losses in the anode block, cathode heating, and RF losses at output windows. These thermal loads can lead to dimensional changes in critical components, altering the resonant characteristics of the device and potentially causing frequency drift or mode jumping during operation.

Advanced cooling techniques have evolved significantly to address these challenges. Liquid cooling systems utilizing deionized water or specialized coolants provide superior heat transfer capabilities compared to traditional air cooling methods. These systems typically incorporate precision-engineered cooling channels within the anode block to maximize thermal transfer efficiency while maintaining structural integrity.

For extremely high-power applications, advanced cooling strategies such as microchannel cooling, phase-change materials, and direct immersion cooling have demonstrated promising results. Microchannel cooling employs microscale fluid passages to dramatically increase the surface area available for heat transfer, while phase-change materials absorb thermal energy through state transitions without significant temperature increases.

Thermal simulation and modeling have become essential tools in optimizing magnetron cooling systems. Computational fluid dynamics (CFD) coupled with electromagnetic simulations enable engineers to identify hotspots and optimize cooling channel geometries before physical prototyping. These simulation approaches have significantly reduced development cycles while improving thermal management effectiveness.

Material selection plays a crucial role in thermal management strategy. Copper-based alloys remain the standard for anode blocks due to their excellent thermal and electrical conductivity. However, composite materials incorporating diamond particles or carbon nanostructures have shown potential for next-generation devices requiring enhanced thermal performance without sacrificing electrical characteristics.

Temperature monitoring and active thermal management systems represent another frontier in magnetron thermal control. Real-time temperature sensing using embedded thermocouples or infrared imaging allows for dynamic adjustment of cooling parameters, optimizing performance while preventing thermal damage. These systems can modulate coolant flow rates or adjust pulse parameters in response to detected thermal conditions.

For pulsed magnetron operation specifically, thermal transient management becomes particularly important. Pulse shaping techniques that incorporate pre-heating periods or carefully controlled rise times can minimize thermal shock while maintaining peak power capabilities. The development of advanced pulse control algorithms that account for thermal constraints has enabled significant improvements in average power handling while maintaining peak performance parameters.

The primary heat generation mechanisms in high-power magnetrons include ohmic losses in the anode block, cathode heating, and RF losses at output windows. These thermal loads can lead to dimensional changes in critical components, altering the resonant characteristics of the device and potentially causing frequency drift or mode jumping during operation.

Advanced cooling techniques have evolved significantly to address these challenges. Liquid cooling systems utilizing deionized water or specialized coolants provide superior heat transfer capabilities compared to traditional air cooling methods. These systems typically incorporate precision-engineered cooling channels within the anode block to maximize thermal transfer efficiency while maintaining structural integrity.

For extremely high-power applications, advanced cooling strategies such as microchannel cooling, phase-change materials, and direct immersion cooling have demonstrated promising results. Microchannel cooling employs microscale fluid passages to dramatically increase the surface area available for heat transfer, while phase-change materials absorb thermal energy through state transitions without significant temperature increases.

Thermal simulation and modeling have become essential tools in optimizing magnetron cooling systems. Computational fluid dynamics (CFD) coupled with electromagnetic simulations enable engineers to identify hotspots and optimize cooling channel geometries before physical prototyping. These simulation approaches have significantly reduced development cycles while improving thermal management effectiveness.

Material selection plays a crucial role in thermal management strategy. Copper-based alloys remain the standard for anode blocks due to their excellent thermal and electrical conductivity. However, composite materials incorporating diamond particles or carbon nanostructures have shown potential for next-generation devices requiring enhanced thermal performance without sacrificing electrical characteristics.

Temperature monitoring and active thermal management systems represent another frontier in magnetron thermal control. Real-time temperature sensing using embedded thermocouples or infrared imaging allows for dynamic adjustment of cooling parameters, optimizing performance while preventing thermal damage. These systems can modulate coolant flow rates or adjust pulse parameters in response to detected thermal conditions.

For pulsed magnetron operation specifically, thermal transient management becomes particularly important. Pulse shaping techniques that incorporate pre-heating periods or carefully controlled rise times can minimize thermal shock while maintaining peak power capabilities. The development of advanced pulse control algorithms that account for thermal constraints has enabled significant improvements in average power handling while maintaining peak performance parameters.

Efficiency and Energy Conservation Considerations

Efficiency and energy conservation represent critical dimensions in magnetron pulse parameter optimization. The conversion efficiency of magnetrons—typically ranging from 65% to 85% depending on design and operating conditions—directly impacts both operational costs and system thermal management requirements. When maximizing pulse parameters for peak power, engineers must carefully balance power output against energy consumption to avoid diminishing returns. Recent advancements in pulse-forming networks have demonstrated potential efficiency improvements of 7-12% through precise impedance matching and reduced switching losses.

Thermal considerations play a significant role in efficiency optimization. High-power magnetron operations generate substantial heat that must be effectively managed to maintain performance and extend device lifespan. Advanced cooling systems incorporating liquid cooling circuits with optimized flow dynamics have shown the ability to reduce operating temperatures by up to 30°C compared to conventional cooling methods, allowing for higher sustained power levels without efficiency degradation.

Power supply design represents another crucial efficiency factor. Modern switch-mode power supplies with advanced control algorithms can achieve regulation precision within ±0.5%, significantly reducing energy waste compared to traditional linear supplies. Additionally, implementing energy recovery circuits that capture and recycle energy from pulse fall times has demonstrated energy savings of 8-15% in laboratory settings, though commercial implementation remains challenging due to added system complexity.

Pulse shape optimization offers substantial efficiency benefits. Research indicates that trapezoidal pulse profiles with optimized rise and fall times can reduce energy consumption by 5-9% compared to rectangular pulses while maintaining equivalent peak power output. This approach minimizes energy waste during transition periods and reduces stress on system components.

Material selection also impacts efficiency metrics. Recent developments in cathode materials incorporating advanced rare-earth compounds have demonstrated electron emission efficiency improvements of 10-18% while operating at lower temperatures, directly translating to reduced energy requirements and extended operational lifespans. Similarly, innovations in magnetic circuit materials have yielded improvements in field strength and uniformity while reducing core losses.

From a system-level perspective, implementing intelligent power management systems that dynamically adjust pulse parameters based on real-time performance metrics has shown potential energy savings of 12-20% in variable-load applications. These adaptive systems optimize duty cycles and pulse characteristics to match specific operational requirements rather than continuously operating at maximum capacity.

Thermal considerations play a significant role in efficiency optimization. High-power magnetron operations generate substantial heat that must be effectively managed to maintain performance and extend device lifespan. Advanced cooling systems incorporating liquid cooling circuits with optimized flow dynamics have shown the ability to reduce operating temperatures by up to 30°C compared to conventional cooling methods, allowing for higher sustained power levels without efficiency degradation.

Power supply design represents another crucial efficiency factor. Modern switch-mode power supplies with advanced control algorithms can achieve regulation precision within ±0.5%, significantly reducing energy waste compared to traditional linear supplies. Additionally, implementing energy recovery circuits that capture and recycle energy from pulse fall times has demonstrated energy savings of 8-15% in laboratory settings, though commercial implementation remains challenging due to added system complexity.

Pulse shape optimization offers substantial efficiency benefits. Research indicates that trapezoidal pulse profiles with optimized rise and fall times can reduce energy consumption by 5-9% compared to rectangular pulses while maintaining equivalent peak power output. This approach minimizes energy waste during transition periods and reduces stress on system components.

Material selection also impacts efficiency metrics. Recent developments in cathode materials incorporating advanced rare-earth compounds have demonstrated electron emission efficiency improvements of 10-18% while operating at lower temperatures, directly translating to reduced energy requirements and extended operational lifespans. Similarly, innovations in magnetic circuit materials have yielded improvements in field strength and uniformity while reducing core losses.

From a system-level perspective, implementing intelligent power management systems that dynamically adjust pulse parameters based on real-time performance metrics has shown potential energy savings of 12-20% in variable-load applications. These adaptive systems optimize duty cycles and pulse characteristics to match specific operational requirements rather than continuously operating at maximum capacity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!