How to Reduce Magnetron RF Emissions Via Shielded Design

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron RF Shielding Background and Objectives

Magnetron technology has evolved significantly since its invention in the early 1940s, initially developed for radar applications during World War II. Over subsequent decades, magnetrons have become fundamental components in various applications, most notably in microwave ovens for consumer use and in industrial heating systems. However, the inherent radio frequency (RF) emissions generated by magnetrons have increasingly become a concern due to potential electromagnetic interference with other electronic devices and systems, as well as possible health implications from prolonged exposure.

The evolution of magnetron technology has been characterized by continuous improvements in power efficiency, size reduction, and operational stability. Despite these advancements, the challenge of containing RF emissions has persisted as a significant technical hurdle. Recent regulatory frameworks, including those established by the International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC), have imposed stricter limits on electromagnetic emissions from electronic devices, necessitating enhanced shielding solutions for magnetron-based systems.

Current industry trends indicate a growing demand for more effective RF shielding techniques that can be implemented without compromising the performance or increasing the cost of magnetron devices. This demand is particularly acute in sectors such as healthcare, telecommunications, and aerospace, where the reliability of electronic equipment is paramount and where RF interference can have serious consequences.

The primary objective of this technical research is to investigate and evaluate innovative approaches to magnetron RF shielding design that can effectively reduce unwanted emissions while maintaining operational efficiency. Specifically, we aim to identify materials, geometries, and construction techniques that can provide superior electromagnetic containment compared to conventional shielding methods.

Additionally, this research seeks to establish a comprehensive understanding of the relationship between magnetron design parameters and RF emission patterns, enabling more targeted and efficient shielding strategies. By analyzing the propagation characteristics of RF emissions from magnetrons under various operating conditions, we intend to develop predictive models that can inform the design of next-generation shielding solutions.

Furthermore, this investigation will explore the potential for integrating advanced materials, such as metamaterials and composite structures, into magnetron shielding designs to achieve enhanced RF attenuation across a broader frequency spectrum. The ultimate goal is to establish a framework for developing cost-effective, reliable, and high-performance shielding solutions that can be readily adopted by manufacturers across different industries utilizing magnetron technology.

The evolution of magnetron technology has been characterized by continuous improvements in power efficiency, size reduction, and operational stability. Despite these advancements, the challenge of containing RF emissions has persisted as a significant technical hurdle. Recent regulatory frameworks, including those established by the International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC), have imposed stricter limits on electromagnetic emissions from electronic devices, necessitating enhanced shielding solutions for magnetron-based systems.

Current industry trends indicate a growing demand for more effective RF shielding techniques that can be implemented without compromising the performance or increasing the cost of magnetron devices. This demand is particularly acute in sectors such as healthcare, telecommunications, and aerospace, where the reliability of electronic equipment is paramount and where RF interference can have serious consequences.

The primary objective of this technical research is to investigate and evaluate innovative approaches to magnetron RF shielding design that can effectively reduce unwanted emissions while maintaining operational efficiency. Specifically, we aim to identify materials, geometries, and construction techniques that can provide superior electromagnetic containment compared to conventional shielding methods.

Additionally, this research seeks to establish a comprehensive understanding of the relationship between magnetron design parameters and RF emission patterns, enabling more targeted and efficient shielding strategies. By analyzing the propagation characteristics of RF emissions from magnetrons under various operating conditions, we intend to develop predictive models that can inform the design of next-generation shielding solutions.

Furthermore, this investigation will explore the potential for integrating advanced materials, such as metamaterials and composite structures, into magnetron shielding designs to achieve enhanced RF attenuation across a broader frequency spectrum. The ultimate goal is to establish a framework for developing cost-effective, reliable, and high-performance shielding solutions that can be readily adopted by manufacturers across different industries utilizing magnetron technology.

Market Demand Analysis for Low-Emission Magnetron Devices

The global market for low-emission magnetron devices has witnessed substantial growth in recent years, driven primarily by increasing concerns over electromagnetic interference (EMI) and radiofrequency (RF) pollution. Consumer electronics manufacturers face mounting regulatory pressure to comply with stricter electromagnetic compatibility (EMC) standards, particularly in densely populated urban environments where device interference can impact critical infrastructure.

Market research indicates that the commercial microwave oven segment, which constitutes the largest application area for magnetrons, is experiencing a paradigm shift toward low-emission designs. This trend is particularly pronounced in healthcare facilities, research laboratories, and telecommunications centers where sensitive equipment operations can be compromised by RF emissions. The market value for shielded magnetron technology reached $2.3 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2028.

Industrial applications represent another significant market segment, with manufacturing facilities increasingly demanding magnetron devices that minimize workplace RF exposure for personnel safety compliance. The industrial sector's demand for low-emission magnetrons grew by 12% in the past year alone, outpacing the consumer segment by nearly 4 percentage points.

Geographically, North America and Europe lead in adoption of low-emission magnetron technology, primarily due to stringent regulatory frameworks like the FCC Part 18 requirements in the United States and the EN 55011 standards in Europe. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and South Korea investing heavily in advanced manufacturing capabilities for next-generation shielded magnetron designs.

Market surveys reveal that customers are willing to pay a premium of 15-20% for devices with demonstrably lower RF emissions, particularly in professional and commercial settings. This price elasticity has created a viable economic incentive for manufacturers to invest in advanced shielding technologies despite the increased production costs.

The defense and aerospace sectors represent high-value niche markets, where the demand for ultra-low emission magnetrons has grown steadily at 8.3% annually. These specialized applications require exceptional shielding performance to prevent detection and ensure operational security in sensitive environments.

Consumer awareness regarding RF emissions has also increased substantially, with 64% of surveyed consumers expressing concern about potential health impacts from prolonged exposure to microwave radiation. This growing consciousness has translated into market preference for appliances with enhanced shielding, creating additional demand drivers beyond regulatory compliance.

Market research indicates that the commercial microwave oven segment, which constitutes the largest application area for magnetrons, is experiencing a paradigm shift toward low-emission designs. This trend is particularly pronounced in healthcare facilities, research laboratories, and telecommunications centers where sensitive equipment operations can be compromised by RF emissions. The market value for shielded magnetron technology reached $2.3 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2028.

Industrial applications represent another significant market segment, with manufacturing facilities increasingly demanding magnetron devices that minimize workplace RF exposure for personnel safety compliance. The industrial sector's demand for low-emission magnetrons grew by 12% in the past year alone, outpacing the consumer segment by nearly 4 percentage points.

Geographically, North America and Europe lead in adoption of low-emission magnetron technology, primarily due to stringent regulatory frameworks like the FCC Part 18 requirements in the United States and the EN 55011 standards in Europe. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and South Korea investing heavily in advanced manufacturing capabilities for next-generation shielded magnetron designs.

Market surveys reveal that customers are willing to pay a premium of 15-20% for devices with demonstrably lower RF emissions, particularly in professional and commercial settings. This price elasticity has created a viable economic incentive for manufacturers to invest in advanced shielding technologies despite the increased production costs.

The defense and aerospace sectors represent high-value niche markets, where the demand for ultra-low emission magnetrons has grown steadily at 8.3% annually. These specialized applications require exceptional shielding performance to prevent detection and ensure operational security in sensitive environments.

Consumer awareness regarding RF emissions has also increased substantially, with 64% of surveyed consumers expressing concern about potential health impacts from prolonged exposure to microwave radiation. This growing consciousness has translated into market preference for appliances with enhanced shielding, creating additional demand drivers beyond regulatory compliance.

Current Shielding Technologies and Challenges

Current magnetron shielding technologies primarily focus on containing RF emissions through physical barriers and specialized materials. Conventional approaches include metallic enclosures that create Faraday cages around the magnetron assembly. These enclosures typically utilize aluminum, copper, or steel with specific thickness requirements to effectively attenuate the high-frequency electromagnetic waves generated during magnetron operation. The effectiveness of these shields depends largely on their conductivity, thickness, and structural integrity, particularly at seams and joints where RF leakage commonly occurs.

Advanced shielding solutions incorporate multi-layered designs that combine different materials to address various frequencies. These may include a combination of conductive layers for high-frequency attenuation and ferromagnetic materials for managing lower frequency components. Specialized RF-absorbent materials such as carbon-loaded polymers and ferrite composites are increasingly being integrated into modern designs to convert RF energy into heat rather than merely reflecting it.

Despite these advancements, significant challenges persist in magnetron shielding design. The primary challenge involves balancing effective RF containment with thermal management requirements. Magnetrons generate substantial heat during operation, and shielding materials that excel at RF containment often impede heat dissipation, potentially leading to operational inefficiencies or device failure. This creates a complex engineering trade-off that must be carefully navigated.

Another major challenge is addressing the inherent resonance issues in shielding enclosures. Cavity resonance can amplify certain frequencies, potentially exacerbating emission problems rather than solving them. Engineers must carefully design enclosure dimensions and incorporate appropriate damping mechanisms to mitigate these resonance effects.

Manufacturing constraints present additional challenges, particularly in creating seamless shields or ensuring consistent electrical continuity across joints. Even small gaps or imperfections in shielding can significantly compromise effectiveness, allowing RF leakage through what is known as the "slot antenna effect."

Cost considerations also limit widespread adoption of optimal shielding solutions, especially in consumer-grade applications. High-performance RF-absorbent materials and precision manufacturing techniques add considerable expense to production, forcing manufacturers to seek balance between emission compliance and economic viability.

Regulatory compliance presents an evolving challenge as standards for electromagnetic compatibility become increasingly stringent across global markets. Manufacturers must continuously adapt shielding designs to meet these evolving requirements while maintaining product performance and cost-effectiveness.

Advanced shielding solutions incorporate multi-layered designs that combine different materials to address various frequencies. These may include a combination of conductive layers for high-frequency attenuation and ferromagnetic materials for managing lower frequency components. Specialized RF-absorbent materials such as carbon-loaded polymers and ferrite composites are increasingly being integrated into modern designs to convert RF energy into heat rather than merely reflecting it.

Despite these advancements, significant challenges persist in magnetron shielding design. The primary challenge involves balancing effective RF containment with thermal management requirements. Magnetrons generate substantial heat during operation, and shielding materials that excel at RF containment often impede heat dissipation, potentially leading to operational inefficiencies or device failure. This creates a complex engineering trade-off that must be carefully navigated.

Another major challenge is addressing the inherent resonance issues in shielding enclosures. Cavity resonance can amplify certain frequencies, potentially exacerbating emission problems rather than solving them. Engineers must carefully design enclosure dimensions and incorporate appropriate damping mechanisms to mitigate these resonance effects.

Manufacturing constraints present additional challenges, particularly in creating seamless shields or ensuring consistent electrical continuity across joints. Even small gaps or imperfections in shielding can significantly compromise effectiveness, allowing RF leakage through what is known as the "slot antenna effect."

Cost considerations also limit widespread adoption of optimal shielding solutions, especially in consumer-grade applications. High-performance RF-absorbent materials and precision manufacturing techniques add considerable expense to production, forcing manufacturers to seek balance between emission compliance and economic viability.

Regulatory compliance presents an evolving challenge as standards for electromagnetic compatibility become increasingly stringent across global markets. Manufacturers must continuously adapt shielding designs to meet these evolving requirements while maintaining product performance and cost-effectiveness.

Existing RF Shielding Design Solutions

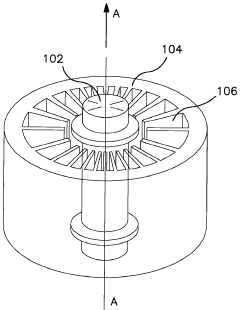

01 Magnetron design for RF emission control

Specific design elements in magnetrons can control and optimize RF emissions. These designs include specialized cathode structures, anode configurations, and resonant cavities that influence the frequency stability and power output of the emitted RF signals. Advanced magnetron designs incorporate features to minimize unwanted emissions while maximizing efficiency in the desired frequency bands.- Magnetron design for RF emission control: Specific design features in magnetrons can control and optimize RF emissions. These include modifications to the cavity structure, electrode configurations, and magnetic field arrangements. Such designs can enhance emission efficiency, reduce unwanted radiation, and improve the directional characteristics of the RF output. Advanced magnetron designs incorporate specialized components that help maintain stable frequency output while minimizing electromagnetic interference.

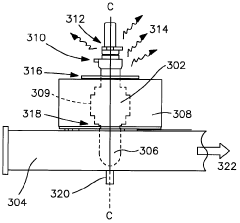

- Shielding and containment of magnetron emissions: Various shielding techniques are employed to contain and direct magnetron RF emissions. These include metallic enclosures, specialized absorbing materials, and resonant cavity designs that prevent leakage of electromagnetic radiation. Proper shielding is essential for both operational efficiency and compliance with electromagnetic compatibility standards. Advanced containment systems can significantly reduce interference with other electronic equipment while ensuring that RF energy is directed where needed.

- Magnetron RF emission applications in plasma processing: Magnetron RF emissions are utilized in various plasma processing applications, including thin film deposition, etching, and surface modification. The controlled RF energy generates and sustains plasma that can be used for precise material processing. By adjusting the emission characteristics, the plasma properties can be tailored for specific manufacturing requirements, enabling advanced semiconductor fabrication, coating technologies, and materials science applications.

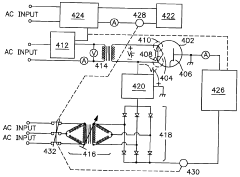

- Power supply and control systems for magnetron emissions: Specialized power supply and control systems are crucial for managing magnetron RF emissions. These systems regulate input power, frequency stability, and pulse characteristics. Advanced control mechanisms include feedback loops that monitor and adjust emission parameters in real-time, ensuring consistent output despite variations in operating conditions. Modern magnetron power systems incorporate solid-state components that provide precise control over emission characteristics while improving energy efficiency.

- Measurement and monitoring of magnetron RF emissions: Various techniques and instruments are used to measure and monitor magnetron RF emissions. These include spectrum analyzers, power meters, and specialized sensors that can detect emission characteristics such as frequency, power density, and harmonic content. Continuous monitoring systems help ensure that emissions remain within specified parameters and comply with regulatory requirements. Advanced diagnostic tools can identify potential issues before they affect performance or create interference problems.

02 RF emission shielding and containment techniques

Various shielding and containment methods are employed to prevent unwanted RF emissions from magnetrons. These techniques include specialized enclosures, electromagnetic shields, and absorption materials that contain the RF energy within designated areas. Proper shielding is crucial for preventing interference with other electronic devices and ensuring compliance with electromagnetic compatibility standards.Expand Specific Solutions03 Plasma generation and control using magnetron RF emissions

Magnetron RF emissions are utilized for generating and controlling plasma in various applications. The RF energy ionizes gases to create plasma, which can be manipulated through frequency modulation and power control. This controlled plasma is essential for processes such as thin film deposition, etching, and surface modification in semiconductor manufacturing and other industrial applications.Expand Specific Solutions04 RF emission measurement and monitoring systems

Specialized systems for measuring and monitoring RF emissions from magnetrons ensure optimal performance and safety. These systems include sensors, detectors, and analytical instruments that provide real-time data on emission characteristics such as frequency, power density, and stability. Continuous monitoring helps identify potential issues before they affect system performance or create safety hazards.Expand Specific Solutions05 RF emission frequency tuning and stabilization methods

Various methods are employed to tune and stabilize the frequency of RF emissions from magnetrons. These include electronic control circuits, mechanical tuning mechanisms, and feedback systems that maintain consistent frequency output despite variations in operating conditions. Frequency stabilization is critical for applications requiring precise RF energy delivery, such as in communication systems, industrial heating, and scientific research.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The magnetron RF shielding technology market is currently in a growth phase, driven by increasing concerns about electromagnetic interference across multiple industries. The market size is expanding steadily, with projections indicating significant growth as electronic devices proliferate globally. From a technical maturity perspective, established aerospace and defense players like Boeing and defense-focused research organizations (CEA, CNRS) lead with advanced shielding solutions, while consumer electronics manufacturers (LG Electronics, Midea Group) are rapidly adopting these technologies. Specialized companies like ETS-Lindgren and Gaven Industries offer dedicated RF shielding expertise, while semiconductor leaders (Applied Materials, Qorvo, NXP) are integrating shielding directly into component design. The competitive landscape shows a clear division between high-performance military/aerospace applications and mass-market consumer implementations, with cross-industry collaboration accelerating innovation.

Midea Group Co. Ltd.

Technical Solution: Midea Group has developed advanced magnetron shielding technology through their "Total Shield" approach, which addresses RF emissions through multiple complementary mechanisms. Their design incorporates a primary Faraday cage structure with specialized conductive coatings that maintain electrical continuity even after thermal cycling. Midea's innovation includes strategically placed RF absorption materials that target specific frequency bands most prone to leakage. The company has pioneered automated manufacturing processes for shield components that ensure consistent grounding and eliminate variation in shielding effectiveness between production units. Their "Smart Shield" technology incorporates sensors that detect potential shield failures or degradation before emissions exceed safety thresholds. Midea's research has demonstrated that their optimized cavity design combined with precision-engineered waveguide ports reduces emissions by up to 15dB compared to conventional designs. The company has also developed specialized conductive gaskets that maintain flexibility through thousands of operational cycles while preserving RF sealing integrity at access points and service interfaces.

Strengths: Highly optimized manufacturing processes that enable cost-effective implementation of advanced shielding in mass-produced consumer products. Their integrated sensor approach provides preventative maintenance capabilities not found in most competing solutions. Weaknesses: Some of their most effective solutions require proprietary components that create supply chain dependencies, and their designs are primarily optimized for standard consumer appliance applications rather than specialized industrial environments.

Guangdong Galanz Enterprises Co., Ltd.

Technical Solution: Galanz has pioneered innovative magnetron shielding technology specifically for microwave oven applications, where RF emissions control is critical for consumer safety and regulatory compliance. Their approach incorporates a dual-layer shielding system with a primary conductive enclosure and secondary absorption layer. The company's proprietary "Shield-Lock" design ensures complete RF containment at door interfaces—historically a vulnerable point for emissions leakage. Galanz utilizes precision-stamped metal shields with specialized coating treatments that enhance conductivity while resisting corrosion in high-temperature environments. Their manufacturing process includes automated quality control systems that verify shield integrity and consistent grounding across production units. Recent innovations include their "Quiet-Shield" technology that reduces both RF emissions and acoustic noise through integrated dampening materials that serve dual purposes. Galanz has achieved compliance with the strictest international standards for RF emissions (including IEC/EN 60335-2-25) while maintaining cost-effective mass production capabilities.

Strengths: Extensive practical experience in high-volume manufacturing of shielded magnetron systems with proven reliability in consumer products. Their solutions balance effective shielding with cost considerations essential for consumer electronics. Weaknesses: Technologies are primarily optimized for standard household microwave frequencies rather than specialized industrial or scientific applications, limiting adaptability to non-standard magnetron implementations.

Critical Patents and Technical Literature on Magnetron Shielding

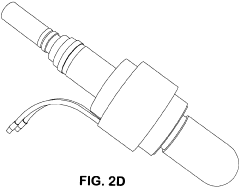

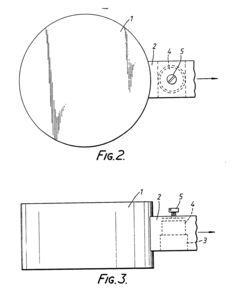

RF suppressor for a magnetron

PatentInactiveGB2413432A

Innovation

- An insulated RF suppressor is designed with a two-layered annular structure, featuring an inner insulating sleeve made of PTFE and a coaxial outer RF-absorbing shell, which enhances voltage breakdown resistance and reduces arcing, while maintaining effective RF suppression capabilities.

Magnetrons

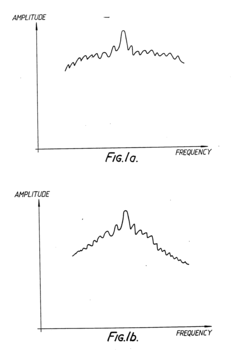

PatentInactiveEP0361953A2

Innovation

- Incorporating a resonator element in the output waveguide with a resonant frequency matching the desired operating frequency of the magnetron, which can be a dielectric solid cylinder, to stabilize and narrow the output frequency spectrum.

Electromagnetic Compatibility Standards and Regulations

Electromagnetic Compatibility (EMC) standards and regulations form a critical framework governing the design and operation of electronic devices, including magnetrons. These standards are established to ensure that electronic equipment functions properly in its intended electromagnetic environment without causing interference to other systems. For magnetron shielding design, several key regulatory bodies provide essential guidelines.

The International Electrotechnical Commission (IEC) has developed the IEC 61000 series, which specifically addresses electromagnetic compatibility requirements. IEC 61000-4-3 focuses on radiated, radio-frequency electromagnetic field immunity tests, while IEC 61000-4-6 covers immunity to conducted disturbances induced by radio-frequency fields. These standards provide testing methodologies and acceptable emission limits that magnetron shielding designs must meet.

In the United States, the Federal Communications Commission (FCC) regulates electromagnetic emissions through Title 47 CFR Part 15 for unintentional radiators and Part 18 for Industrial, Scientific, and Medical (ISM) equipment, which includes magnetrons used in microwave ovens. These regulations establish specific emission limits across various frequency bands and mandate compliance testing before market entry.

The European Union enforces the Electromagnetic Compatibility Directive (2014/30/EU), which requires all electronic equipment sold within the EU to meet harmonized EMC standards. This directive references EN 55011 (CISPR 11), which specifically addresses industrial, scientific, and medical equipment RF emission limits and measurement methods applicable to magnetron-based systems.

Military applications involving magnetrons must comply with more stringent standards such as MIL-STD-461G, which provides detailed requirements for the control of electromagnetic interference characteristics of subsystems and equipment. This standard includes specific test methods like RE102 for radiated emissions and RS103 for radiated susceptibility.

Japan's VCCI (Voluntary Control Council for Interference) and China's GB standards also provide region-specific requirements that manufacturers must consider when designing shielded magnetrons for global markets. These standards often align with international frameworks but may include unique national requirements.

Compliance with these standards necessitates comprehensive shielding design approaches that address both near-field and far-field emissions across the operational frequency spectrum of magnetrons. Manufacturers must conduct pre-compliance and formal compliance testing using calibrated equipment in certified testing facilities to verify that their shielded designs meet all applicable regulatory requirements before product certification and market release.

The International Electrotechnical Commission (IEC) has developed the IEC 61000 series, which specifically addresses electromagnetic compatibility requirements. IEC 61000-4-3 focuses on radiated, radio-frequency electromagnetic field immunity tests, while IEC 61000-4-6 covers immunity to conducted disturbances induced by radio-frequency fields. These standards provide testing methodologies and acceptable emission limits that magnetron shielding designs must meet.

In the United States, the Federal Communications Commission (FCC) regulates electromagnetic emissions through Title 47 CFR Part 15 for unintentional radiators and Part 18 for Industrial, Scientific, and Medical (ISM) equipment, which includes magnetrons used in microwave ovens. These regulations establish specific emission limits across various frequency bands and mandate compliance testing before market entry.

The European Union enforces the Electromagnetic Compatibility Directive (2014/30/EU), which requires all electronic equipment sold within the EU to meet harmonized EMC standards. This directive references EN 55011 (CISPR 11), which specifically addresses industrial, scientific, and medical equipment RF emission limits and measurement methods applicable to magnetron-based systems.

Military applications involving magnetrons must comply with more stringent standards such as MIL-STD-461G, which provides detailed requirements for the control of electromagnetic interference characteristics of subsystems and equipment. This standard includes specific test methods like RE102 for radiated emissions and RS103 for radiated susceptibility.

Japan's VCCI (Voluntary Control Council for Interference) and China's GB standards also provide region-specific requirements that manufacturers must consider when designing shielded magnetrons for global markets. These standards often align with international frameworks but may include unique national requirements.

Compliance with these standards necessitates comprehensive shielding design approaches that address both near-field and far-field emissions across the operational frequency spectrum of magnetrons. Manufacturers must conduct pre-compliance and formal compliance testing using calibrated equipment in certified testing facilities to verify that their shielded designs meet all applicable regulatory requirements before product certification and market release.

Health and Safety Implications of RF Emissions

Radio frequency (RF) emissions from magnetrons present significant health and safety concerns that must be addressed through proper shielded design. The primary concern relates to the potential biological effects of RF radiation exposure, which can cause tissue heating when absorbed by the human body. At high levels, this thermal effect can lead to burns, cataracts, and other serious health issues. Even at lower levels, prolonged exposure may contribute to various health problems including headaches, fatigue, and potential long-term effects that remain under scientific investigation.

Regulatory bodies worldwide have established strict exposure limits for RF emissions. The International Commission on Non-Ionizing Radiation Protection (ICNIRP) and the IEEE have developed standards that manufacturers must comply with. These regulations specify maximum permissible exposure levels for both occupational settings and the general public, with particular attention to vulnerable populations such as children, the elderly, and individuals with medical implants.

Properly shielded magnetron designs significantly mitigate these health risks. Effective RF shielding prevents leakage that could otherwise expose users and nearby individuals to harmful radiation levels. In industrial settings where high-power magnetrons are utilized, inadequate shielding can create hazardous work environments and potential liability issues for employers and equipment manufacturers.

Beyond direct human health impacts, uncontrolled RF emissions can interfere with medical devices such as pacemakers and insulin pumps, potentially creating life-threatening situations. This electromagnetic interference (EMI) risk extends to critical communication systems, navigation equipment, and other electronic devices essential for safety operations.

The economic implications of addressing these health and safety concerns are substantial. While implementing comprehensive shielding solutions increases initial manufacturing costs, these investments typically result in long-term savings by reducing workplace incidents, liability claims, regulatory penalties, and product recalls. Companies demonstrating commitment to radiation safety also benefit from enhanced brand reputation and consumer trust.

As magnetron technology continues to evolve and find new applications, the importance of RF emission control through effective shielding design becomes increasingly critical to public health protection. Future shielding technologies must adapt to more compact designs while maintaining or improving safety performance to address emerging health concerns identified through ongoing epidemiological research.

Regulatory bodies worldwide have established strict exposure limits for RF emissions. The International Commission on Non-Ionizing Radiation Protection (ICNIRP) and the IEEE have developed standards that manufacturers must comply with. These regulations specify maximum permissible exposure levels for both occupational settings and the general public, with particular attention to vulnerable populations such as children, the elderly, and individuals with medical implants.

Properly shielded magnetron designs significantly mitigate these health risks. Effective RF shielding prevents leakage that could otherwise expose users and nearby individuals to harmful radiation levels. In industrial settings where high-power magnetrons are utilized, inadequate shielding can create hazardous work environments and potential liability issues for employers and equipment manufacturers.

Beyond direct human health impacts, uncontrolled RF emissions can interfere with medical devices such as pacemakers and insulin pumps, potentially creating life-threatening situations. This electromagnetic interference (EMI) risk extends to critical communication systems, navigation equipment, and other electronic devices essential for safety operations.

The economic implications of addressing these health and safety concerns are substantial. While implementing comprehensive shielding solutions increases initial manufacturing costs, these investments typically result in long-term savings by reducing workplace incidents, liability claims, regulatory penalties, and product recalls. Companies demonstrating commitment to radiation safety also benefit from enhanced brand reputation and consumer trust.

As magnetron technology continues to evolve and find new applications, the importance of RF emission control through effective shielding design becomes increasingly critical to public health protection. Future shielding technologies must adapt to more compact designs while maintaining or improving safety performance to address emerging health concerns identified through ongoing epidemiological research.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!