Testing Magnetron Bandwidth Variability in Applications

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Bandwidth Technology Background and Objectives

Magnetron technology has evolved significantly since its invention in the early 1940s, initially developed for radar applications during World War II. The bandwidth capabilities of magnetrons have been a critical parameter throughout this evolution, directly impacting their performance in various applications ranging from radar systems to industrial heating and domestic microwave ovens. Understanding bandwidth variability has become increasingly important as applications demand more precise frequency control and stability.

The technological trajectory of magnetron bandwidth development shows a clear progression from narrow-band, fixed-frequency devices to more sophisticated variable-frequency systems with enhanced bandwidth capabilities. Early magnetrons operated within strictly limited frequency ranges, while modern variants can achieve significantly broader operational bandwidths through advanced cavity designs and innovative coupling mechanisms.

Current industry trends indicate growing demand for magnetrons with predictable and controllable bandwidth characteristics, particularly in precision industrial applications, medical devices, and advanced radar systems. The ability to accurately test and characterize bandwidth variability has consequently emerged as a critical technological requirement across multiple sectors.

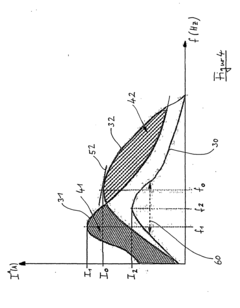

The primary technical objective in testing magnetron bandwidth variability is to develop standardized methodologies that can accurately measure, predict, and control frequency variations under diverse operational conditions. This includes quantifying how bandwidth parameters change across different power levels, temperature ranges, load conditions, and throughout device lifetime.

Secondary objectives include establishing reliable correlations between manufacturing processes and bandwidth stability, identifying key factors that influence frequency drift, and developing predictive models that can anticipate bandwidth behavior in specific application environments. These objectives align with broader industry goals of improving magnetron reliability and performance consistency.

From a historical perspective, bandwidth testing methodologies have evolved from basic frequency measurements to sophisticated spectrum analysis techniques that can capture transient behavior and subtle variations in frequency response. This evolution reflects the increasing importance of bandwidth stability in modern applications where precise energy delivery is essential.

The technological landscape also reveals significant regional differences in magnetron bandwidth research, with notable contributions from research institutions in the United States, Japan, China, and several European countries. These geographical variations have led to diverse approaches to bandwidth testing and characterization methodologies.

Looking forward, the field is moving toward more integrated testing approaches that combine real-time monitoring with advanced predictive analytics, enabling more comprehensive understanding of bandwidth variability factors and their implications for specific applications. This trajectory aligns with broader industry trends toward more precise, reliable, and application-specific microwave energy delivery systems.

The technological trajectory of magnetron bandwidth development shows a clear progression from narrow-band, fixed-frequency devices to more sophisticated variable-frequency systems with enhanced bandwidth capabilities. Early magnetrons operated within strictly limited frequency ranges, while modern variants can achieve significantly broader operational bandwidths through advanced cavity designs and innovative coupling mechanisms.

Current industry trends indicate growing demand for magnetrons with predictable and controllable bandwidth characteristics, particularly in precision industrial applications, medical devices, and advanced radar systems. The ability to accurately test and characterize bandwidth variability has consequently emerged as a critical technological requirement across multiple sectors.

The primary technical objective in testing magnetron bandwidth variability is to develop standardized methodologies that can accurately measure, predict, and control frequency variations under diverse operational conditions. This includes quantifying how bandwidth parameters change across different power levels, temperature ranges, load conditions, and throughout device lifetime.

Secondary objectives include establishing reliable correlations between manufacturing processes and bandwidth stability, identifying key factors that influence frequency drift, and developing predictive models that can anticipate bandwidth behavior in specific application environments. These objectives align with broader industry goals of improving magnetron reliability and performance consistency.

From a historical perspective, bandwidth testing methodologies have evolved from basic frequency measurements to sophisticated spectrum analysis techniques that can capture transient behavior and subtle variations in frequency response. This evolution reflects the increasing importance of bandwidth stability in modern applications where precise energy delivery is essential.

The technological landscape also reveals significant regional differences in magnetron bandwidth research, with notable contributions from research institutions in the United States, Japan, China, and several European countries. These geographical variations have led to diverse approaches to bandwidth testing and characterization methodologies.

Looking forward, the field is moving toward more integrated testing approaches that combine real-time monitoring with advanced predictive analytics, enabling more comprehensive understanding of bandwidth variability factors and their implications for specific applications. This trajectory aligns with broader industry trends toward more precise, reliable, and application-specific microwave energy delivery systems.

Market Analysis for Magnetron Applications

The global magnetron market is experiencing robust growth, driven primarily by increasing applications in microwave ovens, radar systems, and industrial heating processes. Current market valuations place the magnetron industry at approximately 1.2 billion USD, with projections indicating a compound annual growth rate of 4.7% through 2028. This growth trajectory is supported by expanding applications in emerging technologies and increasing demand for efficient microwave energy solutions across various sectors.

The consumer electronics segment, particularly microwave ovens, continues to dominate magnetron demand, accounting for roughly 65% of total market volume. This segment remains stable with moderate growth in developing economies where household penetration of microwave appliances is still increasing. The industrial heating and drying applications represent the second-largest market segment at 18%, showing stronger growth potential due to energy efficiency advantages over conventional heating methods.

Bandwidth variability in magnetrons has emerged as a critical factor influencing market dynamics. Industries requiring precise frequency control, such as medical equipment and scientific research instrumentation, are driving demand for magnetrons with consistent bandwidth performance. This trend is reflected in premium pricing for magnetrons with tighter bandwidth specifications, commanding up to 40% higher prices compared to standard variants.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, producing approximately 72% of global magnetron supply, with China leading production volume. However, North America and Europe maintain technological leadership in high-precision magnetrons with advanced bandwidth control capabilities, particularly for defense and medical applications.

The market is experiencing a notable shift toward magnetrons with enhanced bandwidth stability for specialized applications. This trend is evidenced by increasing patent filings related to bandwidth control technologies, which have grown by 23% over the past five years. Companies investing in bandwidth testing and quality control technologies are gaining competitive advantages in high-value market segments.

Customer requirements are increasingly diverging between mass-market applications tolerant of bandwidth variability and specialized applications requiring precise performance parameters. This market bifurcation is creating opportunities for manufacturers capable of delivering consistent bandwidth performance, particularly in aerospace, defense, and medical imaging sectors where performance reliability directly impacts system functionality.

The consumer electronics segment, particularly microwave ovens, continues to dominate magnetron demand, accounting for roughly 65% of total market volume. This segment remains stable with moderate growth in developing economies where household penetration of microwave appliances is still increasing. The industrial heating and drying applications represent the second-largest market segment at 18%, showing stronger growth potential due to energy efficiency advantages over conventional heating methods.

Bandwidth variability in magnetrons has emerged as a critical factor influencing market dynamics. Industries requiring precise frequency control, such as medical equipment and scientific research instrumentation, are driving demand for magnetrons with consistent bandwidth performance. This trend is reflected in premium pricing for magnetrons with tighter bandwidth specifications, commanding up to 40% higher prices compared to standard variants.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, producing approximately 72% of global magnetron supply, with China leading production volume. However, North America and Europe maintain technological leadership in high-precision magnetrons with advanced bandwidth control capabilities, particularly for defense and medical applications.

The market is experiencing a notable shift toward magnetrons with enhanced bandwidth stability for specialized applications. This trend is evidenced by increasing patent filings related to bandwidth control technologies, which have grown by 23% over the past five years. Companies investing in bandwidth testing and quality control technologies are gaining competitive advantages in high-value market segments.

Customer requirements are increasingly diverging between mass-market applications tolerant of bandwidth variability and specialized applications requiring precise performance parameters. This market bifurcation is creating opportunities for manufacturers capable of delivering consistent bandwidth performance, particularly in aerospace, defense, and medical imaging sectors where performance reliability directly impacts system functionality.

Current Challenges in Magnetron Bandwidth Variability

Magnetron bandwidth variability presents significant challenges in modern applications, particularly in radar systems, microwave heating, and medical equipment. The inconsistency in bandwidth performance across identical magnetron models creates unpredictable operational outcomes, affecting system reliability and performance metrics. Testing procedures currently employed often fail to adequately characterize these variations, leading to suboptimal implementation in critical applications.

The primary technical challenge lies in developing standardized testing methodologies that can accurately measure and quantify bandwidth variability across different operational conditions. Traditional testing approaches typically focus on center frequency and power output, neglecting the comprehensive bandwidth profile that significantly impacts application performance. This gap in testing protocols has resulted in inconsistent field performance even among magnetrons that passed conventional quality control measures.

Environmental factors substantially compound these challenges, as temperature fluctuations, power supply variations, and electromagnetic interference can dramatically alter magnetron bandwidth characteristics during operation. Current testing frameworks rarely account for these dynamic conditions, creating a disconnect between laboratory performance metrics and real-world application behavior. This discrepancy is particularly problematic in precision applications such as medical radiation therapy where consistency is paramount.

Manufacturing inconsistencies represent another major obstacle, with slight variations in cavity dimensions, cathode composition, and magnetic field strength contributing to bandwidth variability. The industry currently lacks robust methodologies to correlate these manufacturing parameters with resulting bandwidth performance, making quality control processes less effective than required for high-precision applications.

Aging effects further complicate the testing landscape, as magnetron bandwidth characteristics evolve over operational lifetime. Current testing protocols predominantly focus on initial performance, neglecting the degradation patterns that emerge through extended use. This oversight leads to unexpected performance shifts in deployed systems, particularly problematic in long-term installations where maintenance intervals are extended.

Measurement equipment limitations also pose significant technical barriers. Conventional spectrum analyzers and power meters used in production environments often lack the resolution and accuracy needed to detect subtle bandwidth variations that can significantly impact application performance. The high cost of precision measurement equipment has limited widespread adoption of more rigorous testing protocols across the industry.

Computational modeling approaches that could potentially predict bandwidth variability remain underdeveloped, with current simulation tools struggling to accurately represent the complex physical interactions within magnetron devices. This gap between theoretical models and physical behavior hinders the development of predictive testing methodologies that could identify problematic units before deployment.

The primary technical challenge lies in developing standardized testing methodologies that can accurately measure and quantify bandwidth variability across different operational conditions. Traditional testing approaches typically focus on center frequency and power output, neglecting the comprehensive bandwidth profile that significantly impacts application performance. This gap in testing protocols has resulted in inconsistent field performance even among magnetrons that passed conventional quality control measures.

Environmental factors substantially compound these challenges, as temperature fluctuations, power supply variations, and electromagnetic interference can dramatically alter magnetron bandwidth characteristics during operation. Current testing frameworks rarely account for these dynamic conditions, creating a disconnect between laboratory performance metrics and real-world application behavior. This discrepancy is particularly problematic in precision applications such as medical radiation therapy where consistency is paramount.

Manufacturing inconsistencies represent another major obstacle, with slight variations in cavity dimensions, cathode composition, and magnetic field strength contributing to bandwidth variability. The industry currently lacks robust methodologies to correlate these manufacturing parameters with resulting bandwidth performance, making quality control processes less effective than required for high-precision applications.

Aging effects further complicate the testing landscape, as magnetron bandwidth characteristics evolve over operational lifetime. Current testing protocols predominantly focus on initial performance, neglecting the degradation patterns that emerge through extended use. This oversight leads to unexpected performance shifts in deployed systems, particularly problematic in long-term installations where maintenance intervals are extended.

Measurement equipment limitations also pose significant technical barriers. Conventional spectrum analyzers and power meters used in production environments often lack the resolution and accuracy needed to detect subtle bandwidth variations that can significantly impact application performance. The high cost of precision measurement equipment has limited widespread adoption of more rigorous testing protocols across the industry.

Computational modeling approaches that could potentially predict bandwidth variability remain underdeveloped, with current simulation tools struggling to accurately represent the complex physical interactions within magnetron devices. This gap between theoretical models and physical behavior hinders the development of predictive testing methodologies that could identify problematic units before deployment.

Current Testing Methods for Magnetron Bandwidth

01 Magnetron design for bandwidth control

Specific design elements in magnetrons can be implemented to control and adjust bandwidth variability. These designs may include modifications to the cavity structure, anode block configurations, or cathode arrangements. By optimizing these design parameters, manufacturers can achieve desired bandwidth characteristics, allowing for more stable operation across various applications. These design improvements help reduce unwanted frequency shifts and enhance overall performance stability.- Magnetron design for bandwidth control: Specific design elements in magnetrons can be implemented to control and adjust bandwidth variability. These designs may include modifications to the cavity structure, cathode configuration, or anode block to achieve desired bandwidth characteristics. By optimizing these design parameters, engineers can create magnetrons with more predictable and stable bandwidth performance across various operating conditions.

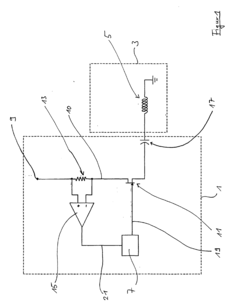

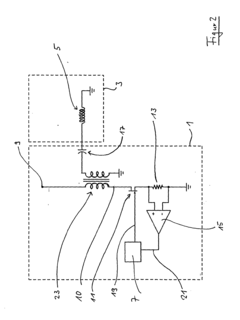

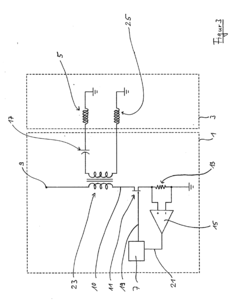

- Power supply and frequency control systems: The power supply and frequency control systems significantly impact magnetron bandwidth variability. Advanced control circuits can be implemented to regulate the input power, voltage stability, and frequency response of magnetrons. These systems can compensate for variations in operating conditions, helping to maintain consistent bandwidth performance even under fluctuating loads or environmental conditions.

- Environmental and operational factors affecting bandwidth: Various environmental and operational factors can influence magnetron bandwidth variability, including temperature fluctuations, pressure changes, and operational duration. Understanding these factors allows for the development of compensation mechanisms or operational protocols that minimize unwanted bandwidth variations. Proper management of these factors can lead to more consistent magnetron performance in practical applications.

- Measurement and monitoring techniques: Advanced measurement and monitoring techniques are essential for characterizing and controlling magnetron bandwidth variability. These techniques may include real-time spectrum analysis, impedance matching measurements, and feedback control systems. By implementing sophisticated monitoring approaches, operators can detect bandwidth variations early and make necessary adjustments to maintain optimal performance.

- Material selection and manufacturing processes: The selection of materials and manufacturing processes plays a crucial role in determining magnetron bandwidth characteristics. Precision manufacturing techniques, material purity, and component tolerances all contribute to bandwidth stability. Innovations in materials science and fabrication methods can lead to magnetrons with reduced bandwidth variability and improved performance consistency across production batches.

02 Frequency tuning mechanisms in magnetrons

Various mechanisms can be implemented to tune the operating frequency of magnetrons, thereby managing bandwidth variability. These include mechanical tuning elements, electronic frequency control systems, and adaptive feedback loops. Such tuning mechanisms allow for real-time adjustments to compensate for environmental factors, load variations, or aging effects that might otherwise cause bandwidth drift. These approaches enable more precise control over the magnetron's spectral output characteristics.Expand Specific Solutions03 Power supply regulation for bandwidth stability

The stability and regulation of power supplies significantly impact magnetron bandwidth variability. Advanced power control circuits, voltage stabilization techniques, and current regulation methods can minimize fluctuations in the magnetron's operating parameters. By maintaining consistent power delivery to the magnetron, these approaches reduce frequency variations caused by power fluctuations, leading to more predictable bandwidth characteristics and improved operational reliability.Expand Specific Solutions04 Thermal management for frequency stability

Thermal effects can significantly influence magnetron bandwidth variability. Advanced cooling systems, temperature-compensated components, and thermal isolation techniques help maintain stable operating temperatures. By controlling thermal gradients and preventing overheating, these approaches minimize thermal expansion effects that could alter cavity dimensions and resonant frequencies. Effective thermal management ensures consistent bandwidth performance across varying operational conditions and duty cycles.Expand Specific Solutions05 Monitoring and feedback systems for bandwidth control

Sophisticated monitoring and feedback systems can be implemented to detect and correct bandwidth variations in real-time. These systems may include frequency sensors, spectrum analyzers, and adaptive control algorithms that continuously adjust magnetron parameters to maintain desired bandwidth characteristics. By creating closed-loop control systems, these approaches enable dynamic compensation for factors affecting bandwidth stability, ensuring consistent performance even under changing operational conditions.Expand Specific Solutions

Key Industry Players in Magnetron Manufacturing

The magnetron bandwidth variability testing market is currently in a growth phase, driven by increasing demand for precision microwave applications across telecommunications, medical, and industrial sectors. The market size is estimated to be expanding at 5-7% annually, with technological advancements pushing capabilities forward. Leading players demonstrate varying levels of technical maturity: established electronics giants like Samsung Electronics, LG Electronics, and Philips have developed sophisticated testing platforms, while specialized equipment manufacturers such as Advantest Corp. and Agilent Technologies offer advanced measurement solutions. Research institutions including Wisconsin Alumni Research Foundation and Kanazawa University are contributing breakthrough innovations. Chinese companies like NAURA Microelectronics and Megmeet Electrical are rapidly advancing their capabilities, narrowing the technology gap with traditional Western and Japanese market leaders.

Koninklijke Philips NV

Technical Solution: Philips has developed an innovative magnetron bandwidth testing solution specifically designed for consumer and medical applications. Their approach combines compact microwave measurement systems with application-specific test fixtures that simulate actual operating environments. The technology employs digital signal processing techniques to analyze frequency pulling effects under various load conditions, providing insights into how magnetrons perform in real-world applications. Philips' system features integrated thermal imaging capabilities that correlate bandwidth variations with thermal gradients across the magnetron structure, helping identify design or manufacturing issues affecting performance consistency. Their solution includes specialized software that can model the impact of bandwidth variations on specific applications, such as microwave ovens or medical therapy systems, translating technical measurements into application-relevant metrics. The platform supports accelerated life testing protocols that can predict long-term bandwidth stability based on statistical analysis of early performance data.

Strengths: Application-focused testing methodology provides directly relevant performance data; integrated thermal analysis capabilities; excellent correlation between test results and real-world performance. Weaknesses: Less suitable for fundamental research applications; limited customization options for specialized testing requirements; moderate measurement resolution compared to dedicated test equipment.

Advantest Corp.

Technical Solution: Advantest has developed advanced magnetron bandwidth testing solutions that integrate high-precision vector network analyzers with specialized test fixtures designed specifically for magnetron characterization. Their approach employs real-time frequency domain analysis to measure bandwidth variations across different operating conditions. The system utilizes adaptive impedance matching networks that can simulate various load conditions to evaluate magnetron performance stability. Advantest's technology incorporates automated temperature control chambers to assess thermal effects on bandwidth consistency, allowing for comprehensive environmental testing. Their solution features proprietary signal processing algorithms that can detect subtle variations in frequency response and power output across production batches, enabling statistical process control for manufacturing quality assurance. The system provides high-resolution spectral analysis capabilities with measurement sensitivity down to sub-MHz variations in bandwidth characteristics.

Strengths: Superior measurement accuracy with industry-leading resolution capabilities; comprehensive environmental testing capabilities; automated test sequences reduce operator error. Weaknesses: Higher implementation cost compared to simpler testing solutions; requires specialized training for operators; system complexity may impact maintenance requirements.

Critical Patents in Magnetron Bandwidth Control

Method and driving apparatus for testing an antenna

PatentInactiveEP1777532A1

Innovation

- A test method involving the application of a voltage with varying frequencies to measure the amplitude of the current flowing through the antenna, with the frequency dependency being evaluated to assess functionality, position, and structure, using a driver device equipped with a microprocessor to compare the results with a reference profile for detecting deviations and triggering warnings or adjustments.

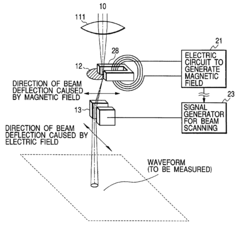

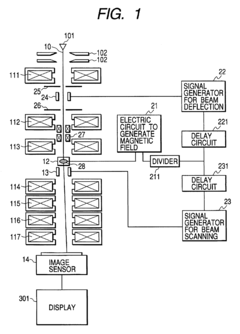

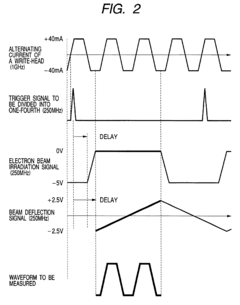

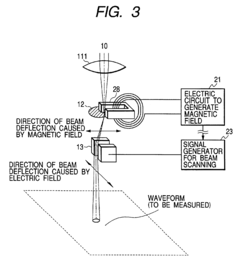

Method and instrument for measuring a magnetic field, a method for measuring a current waveform, and method for measuring an electric field

PatentInactiveUS6744249B2

Innovation

- The use of a charged particle beam instrument that deflects the beam in a direction different from the magnetic field's deflection, with a two-dimensional sensor to detect and display the beam's displacement, allowing for high time-resolution measurement without converting the electron beam into a stroboscopic pulse and without using a current transformer.

Regulatory Standards for Magnetron Applications

Regulatory standards for magnetron applications have evolved significantly to address the increasing concerns about bandwidth variability in different operational environments. The International Electrotechnical Commission (IEC) has established comprehensive guidelines under IEC 60335-2-25 specifically for microwave appliances, which include detailed specifications for acceptable bandwidth variations during operation. These standards mandate that magnetrons must maintain frequency stability within ±10 MHz of their rated frequency under various load conditions to ensure consistent performance and minimize interference with other electronic systems.

The Federal Communications Commission (FCC) in the United States enforces Part 18 regulations for Industrial, Scientific, and Medical (ISM) equipment, which includes magnetrons. These regulations specify that magnetrons operating in the 2.45 GHz band must maintain their emissions within designated frequency boundaries, with strict limits on out-of-band emissions. The FCC has recently updated these standards to include specific testing protocols for bandwidth variability under different power levels and temperature conditions, recognizing the critical nature of this parameter in modern applications.

In Europe, the European Telecommunications Standards Institute (ETSI) has implemented EN 55011 standards that categorize magnetron devices based on their bandwidth stability characteristics. Class A devices, intended for industrial environments, have more lenient bandwidth variation allowances compared to Class B devices designed for residential applications. This tiered approach acknowledges the different sensitivity requirements across application domains while ensuring electromagnetic compatibility in all settings.

The Japanese Industrial Standards Committee (JISC) has developed JIS C 9335-2-25, which includes specific provisions for testing magnetron bandwidth stability over the device's expected lifetime. These standards recognize that bandwidth characteristics may change as magnetrons age, potentially affecting both performance and compliance with electromagnetic interference regulations.

For medical applications, the International Organization for Standardization (ISO) has established ISO 13485 guidelines that include specific requirements for magnetrons used in therapeutic devices. These standards are particularly stringent regarding bandwidth stability, as frequency variations could significantly impact treatment efficacy and patient safety. Regular calibration and verification procedures are mandated to ensure ongoing compliance with these standards.

Emerging regulations are beginning to address the challenges of magnetron applications in advanced communication systems and automotive radar. The Society of Automotive Engineers (SAE) is developing standards specifically for automotive radar systems that utilize magnetron technology, with particular emphasis on bandwidth stability requirements to prevent interference with critical vehicle safety systems and communication infrastructure.

The Federal Communications Commission (FCC) in the United States enforces Part 18 regulations for Industrial, Scientific, and Medical (ISM) equipment, which includes magnetrons. These regulations specify that magnetrons operating in the 2.45 GHz band must maintain their emissions within designated frequency boundaries, with strict limits on out-of-band emissions. The FCC has recently updated these standards to include specific testing protocols for bandwidth variability under different power levels and temperature conditions, recognizing the critical nature of this parameter in modern applications.

In Europe, the European Telecommunications Standards Institute (ETSI) has implemented EN 55011 standards that categorize magnetron devices based on their bandwidth stability characteristics. Class A devices, intended for industrial environments, have more lenient bandwidth variation allowances compared to Class B devices designed for residential applications. This tiered approach acknowledges the different sensitivity requirements across application domains while ensuring electromagnetic compatibility in all settings.

The Japanese Industrial Standards Committee (JISC) has developed JIS C 9335-2-25, which includes specific provisions for testing magnetron bandwidth stability over the device's expected lifetime. These standards recognize that bandwidth characteristics may change as magnetrons age, potentially affecting both performance and compliance with electromagnetic interference regulations.

For medical applications, the International Organization for Standardization (ISO) has established ISO 13485 guidelines that include specific requirements for magnetrons used in therapeutic devices. These standards are particularly stringent regarding bandwidth stability, as frequency variations could significantly impact treatment efficacy and patient safety. Regular calibration and verification procedures are mandated to ensure ongoing compliance with these standards.

Emerging regulations are beginning to address the challenges of magnetron applications in advanced communication systems and automotive radar. The Society of Automotive Engineers (SAE) is developing standards specifically for automotive radar systems that utilize magnetron technology, with particular emphasis on bandwidth stability requirements to prevent interference with critical vehicle safety systems and communication infrastructure.

Environmental Impact of Magnetron Technology

The environmental impact of magnetron technology extends far beyond its primary applications in radar systems and microwave ovens. As magnetron bandwidth variability testing becomes more sophisticated, understanding the ecological footprint of these devices throughout their lifecycle becomes increasingly important. Magnetrons consume significant electrical energy during operation, with efficiency rates typically ranging between 65-70% for modern units. This means approximately one-third of input energy converts to heat rather than useful microwave radiation, contributing to energy waste and increased carbon emissions from power generation.

Manufacturing processes for magnetrons involve several environmentally concerning materials, including beryllium oxide ceramics, which pose significant health and environmental hazards if improperly handled or disposed of. The production phase also requires precision metalworking and vacuum technology that consumes substantial energy and resources. Testing procedures for bandwidth variability further add to this footprint, as specialized equipment and controlled environments are necessary for accurate measurements.

End-of-life considerations present another environmental challenge. Magnetrons contain valuable metals including copper and rare earth elements used in magnets, but recycling rates remain suboptimal. Many units end up in landfills where they can potentially leach harmful substances. The beryllium compounds in particular represent a long-term environmental liability if not properly managed through specialized recycling channels.

Recent advancements in magnetron design have begun addressing these environmental concerns. Energy-efficient magnetrons with improved bandwidth stability require less frequent replacement and testing, reducing waste generation. Some manufacturers have implemented design for disassembly principles, making component recovery more feasible at end-of-life. Additionally, alternative materials research aims to replace beryllium oxide with less hazardous ceramics while maintaining performance characteristics.

The environmental impact varies significantly across different application sectors. Consumer microwave ovens represent the largest volume of magnetrons in use globally, with an estimated 1 billion units in operation. Industrial heating applications, while fewer in number, typically involve higher-power magnetrons with correspondingly larger environmental footprints. Medical and scientific applications often require more precise bandwidth control, necessitating more resource-intensive testing procedures throughout the device lifecycle.

Regulatory frameworks addressing the environmental aspects of magnetron technology remain fragmented globally. The European Union's RoHS and WEEE directives provide the most comprehensive approach to managing electronic waste including magnetrons, while regulations in other regions focus primarily on operational safety rather than environmental considerations. This regulatory gap presents both challenges and opportunities for developing more sustainable approaches to magnetron technology deployment and testing.

Manufacturing processes for magnetrons involve several environmentally concerning materials, including beryllium oxide ceramics, which pose significant health and environmental hazards if improperly handled or disposed of. The production phase also requires precision metalworking and vacuum technology that consumes substantial energy and resources. Testing procedures for bandwidth variability further add to this footprint, as specialized equipment and controlled environments are necessary for accurate measurements.

End-of-life considerations present another environmental challenge. Magnetrons contain valuable metals including copper and rare earth elements used in magnets, but recycling rates remain suboptimal. Many units end up in landfills where they can potentially leach harmful substances. The beryllium compounds in particular represent a long-term environmental liability if not properly managed through specialized recycling channels.

Recent advancements in magnetron design have begun addressing these environmental concerns. Energy-efficient magnetrons with improved bandwidth stability require less frequent replacement and testing, reducing waste generation. Some manufacturers have implemented design for disassembly principles, making component recovery more feasible at end-of-life. Additionally, alternative materials research aims to replace beryllium oxide with less hazardous ceramics while maintaining performance characteristics.

The environmental impact varies significantly across different application sectors. Consumer microwave ovens represent the largest volume of magnetrons in use globally, with an estimated 1 billion units in operation. Industrial heating applications, while fewer in number, typically involve higher-power magnetrons with correspondingly larger environmental footprints. Medical and scientific applications often require more precise bandwidth control, necessitating more resource-intensive testing procedures throughout the device lifecycle.

Regulatory frameworks addressing the environmental aspects of magnetron technology remain fragmented globally. The European Union's RoHS and WEEE directives provide the most comprehensive approach to managing electronic waste including magnetrons, while regulations in other regions focus primarily on operational safety rather than environmental considerations. This regulatory gap presents both challenges and opportunities for developing more sustainable approaches to magnetron technology deployment and testing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!