How to Break Ground in Eco-Solutions with Cellulose Acetate?

Cellulose Acetate Eco-Solutions: Background and Objectives

Cellulose acetate, a versatile biopolymer derived from natural cellulose, has been a staple in various industries for over a century. Its journey began in the late 19th century when it was first synthesized, marking a significant milestone in the development of semi-synthetic materials. As environmental concerns have grown in recent decades, cellulose acetate has garnered renewed interest for its potential in eco-friendly solutions.

The evolution of cellulose acetate technology has been driven by the increasing demand for sustainable alternatives to petroleum-based plastics. Initially used in photographic films and fibers, its applications have expanded to include filters, textiles, and packaging materials. The biodegradability of cellulose acetate, although slower than some natural materials, presents a compelling advantage over conventional plastics in addressing environmental challenges.

Recent technological advancements have focused on enhancing the properties of cellulose acetate to broaden its eco-solution applications. Researchers have been exploring methods to improve its mechanical strength, thermal stability, and degradation rate. These efforts aim to position cellulose acetate as a viable substitute for single-use plastics and other environmentally harmful materials.

The primary objective in the field of cellulose acetate eco-solutions is to develop innovative products and processes that leverage its unique properties while minimizing environmental impact. This includes creating fully biodegradable alternatives for everyday items, improving the material's compatibility with existing recycling systems, and reducing the energy consumption in its production.

Another crucial goal is to optimize the sourcing and processing of cellulose to ensure a sustainable supply chain. This involves developing more efficient methods for extracting cellulose from plant-based sources and refining the acetylation process to reduce chemical usage and waste generation.

Furthermore, there is a growing emphasis on understanding and controlling the degradation mechanisms of cellulose acetate in various environmental conditions. This knowledge is essential for designing products with predictable lifespans and ensuring they break down into harmless components at the end of their useful life.

As we look to break new ground in eco-solutions with cellulose acetate, the overarching aim is to create a circular economy model where this material can be produced, used, and disposed of or recycled with minimal environmental footprint. This ambitious objective requires interdisciplinary collaboration, combining expertise in materials science, chemical engineering, and environmental studies to unlock the full potential of cellulose acetate in addressing global sustainability challenges.

Market Analysis for Sustainable Cellulose Acetate Products

The market for sustainable cellulose acetate products is experiencing significant growth, driven by increasing environmental awareness and stringent regulations on plastic usage. Cellulose acetate, derived from natural cellulose fibers, offers a biodegradable alternative to conventional plastics in various applications. The global market for cellulose acetate is projected to expand at a compound annual growth rate of 5.2% from 2021 to 2028, reaching a value of $6.3 billion by the end of the forecast period.

Consumer goods represent a key sector for sustainable cellulose acetate products. The material's versatility and eco-friendly properties make it an attractive option for packaging, textiles, and personal care items. In the packaging industry, cellulose acetate films are gaining traction as a replacement for single-use plastics, particularly in food packaging and disposable cutlery. The textile sector is also embracing cellulose acetate fibers for sustainable fashion, with major brands incorporating the material into their product lines.

The automotive industry presents another promising market for cellulose acetate products. As automakers strive to reduce vehicle weight and improve fuel efficiency, cellulose acetate composites are being explored as lightweight alternatives to traditional materials in interior components and trim. This trend is expected to accelerate as regulations on vehicle emissions become more stringent globally.

In the electronics sector, cellulose acetate is finding applications in biodegradable casings and components for smartphones and other devices. With the growing emphasis on circular economy principles, manufacturers are increasingly seeking materials that can be easily recycled or composted at the end of their lifecycle.

Geographically, North America and Europe lead the market for sustainable cellulose acetate products, owing to advanced environmental regulations and consumer preferences for eco-friendly alternatives. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing disposable incomes, and growing environmental consciousness in countries like China and India.

Challenges in the market include the higher production costs of cellulose acetate compared to conventional plastics and the need for improved recycling infrastructure. However, ongoing research and development efforts are focused on enhancing the material's properties and reducing production costs, which is likely to boost market growth in the coming years.

Current Challenges in Cellulose Acetate Biodegradability

Cellulose acetate, despite its widespread use in various industries, faces significant challenges in terms of biodegradability. The primary issue lies in its slow decomposition rate in natural environments, which can take several decades to complete. This prolonged degradation process contributes to the accumulation of plastic waste in ecosystems, posing threats to wildlife and environmental health.

One of the main obstacles in improving cellulose acetate's biodegradability is its chemical structure. The acetylation process, which converts cellulose into cellulose acetate, creates a material that is resistant to microbial attack. This resistance is beneficial for product durability but problematic for end-of-life disposal. The challenge lies in finding a balance between maintaining the desirable properties of cellulose acetate and enhancing its biodegradability.

Another significant hurdle is the lack of standardized testing methods for assessing the biodegradability of cellulose acetate products. Different environmental conditions can greatly affect the rate of decomposition, making it difficult to accurately predict and compare biodegradation rates across various scenarios. This inconsistency hampers efforts to develop and validate more biodegradable formulations.

The presence of additives in cellulose acetate products further complicates biodegradability issues. Plasticizers, stabilizers, and other compounds added to enhance performance characteristics can interfere with the natural breakdown process. Developing eco-friendly additives that do not impede biodegradation while maintaining product functionality remains a significant challenge for researchers and manufacturers.

Additionally, the current recycling infrastructure is not well-equipped to handle cellulose acetate waste effectively. Many recycling facilities lack the specialized processes required to separate and recycle this material, leading to its disposal in landfills or incineration. This gap in recycling capabilities exacerbates the environmental impact of cellulose acetate products.

The economic viability of producing more biodegradable cellulose acetate alternatives is also a major challenge. Current manufacturing processes are optimized for traditional formulations, and transitioning to more environmentally friendly options often involves significant investment in research, development, and retooling of production lines. The higher costs associated with these changes can be a deterrent for companies, especially in competitive markets.

Lastly, there is a need for greater consumer awareness and demand for biodegradable cellulose acetate products. Without strong market pressure, manufacturers may have less incentive to invest in developing and producing more eco-friendly alternatives. Educating consumers about the environmental impact of their choices and the benefits of biodegradable options is crucial for driving innovation in this field.

Existing Eco-Friendly Cellulose Acetate Solutions

01 Production methods for cellulose acetate

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.

- Cellulose acetate fiber applications: Cellulose acetate fibers are utilized in diverse applications, such as textiles, filters, and packaging materials. The properties of these fibers can be tailored through modifications in the production process or post-treatment methods to suit specific end-use requirements.

- Cellulose acetate film and membrane technology: Advancements in cellulose acetate film and membrane technology focus on improving properties such as permeability, selectivity, and durability. These developments are particularly relevant for applications in separation processes, water treatment, and gas purification.

- Cellulose acetate composites and blends: Research on cellulose acetate composites and blends explores the combination of cellulose acetate with other materials to create products with enhanced properties. This includes improvements in mechanical strength, thermal stability, and biodegradability for various industrial and consumer applications.

- Cellulose acetate modification and functionalization: Chemical and physical modifications of cellulose acetate are investigated to impart new functionalities or improve existing properties. These modifications can include grafting, crosslinking, or the incorporation of additives to enhance the material's performance in specific applications.

02 Cellulose acetate fibers and films

Techniques for manufacturing cellulose acetate fibers and films are detailed, covering aspects such as spinning processes, film formation, and modification of properties. These innovations focus on improving the characteristics and performance of cellulose acetate-based materials for textile and packaging applications.Expand Specific Solutions03 Cellulose acetate composites and blends

Development of cellulose acetate composites and blends with other materials to enhance properties such as strength, flexibility, and biodegradability. These innovations aim to expand the range of applications for cellulose acetate-based materials in various industries.Expand Specific Solutions04 Modification and functionalization of cellulose acetate

Methods for modifying and functionalizing cellulose acetate to impart specific properties or introduce new functionalities. These techniques include chemical modifications, surface treatments, and incorporation of additives to tailor cellulose acetate for specialized applications.Expand Specific Solutions05 Cellulose acetate in membrane and filtration applications

Utilization of cellulose acetate in the development of membranes and filtration systems. This includes innovations in membrane structure, porosity control, and surface modifications to enhance separation performance and durability in various filtration processes.Expand Specific Solutions

Key Players in Cellulose Acetate Industry

The eco-solutions market utilizing cellulose acetate is in a growth phase, driven by increasing demand for sustainable materials. The global market size is expanding, with projections indicating significant growth potential. Technologically, cellulose acetate applications are evolving, with companies like Daicel Corp., Eastman Chemical Co., and BASF Corp. leading innovation. These firms, along with emerging players such as Nantong Cellulose Fibers Co. Ltd. and Zhuhai Cellulose Fibers Co. Ltd., are advancing the technology's maturity. Research institutions like the Centre National de la Recherche Scientifique and the Chinese Academy of Sciences are contributing to breakthroughs, pushing the boundaries of cellulose acetate's eco-friendly applications and enhancing its market competitiveness.

Daicel Corp.

BASF Corp.

Innovative Approaches in Cellulose Acetate Modification

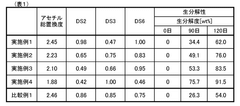

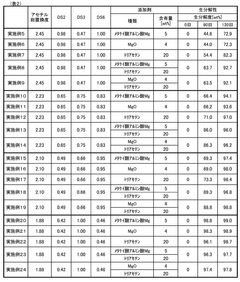

- A cellulose acetate with a total degree of acetyl substitution not greater than 2.7, a specific ratio of acetyl substitution at different positions, and a sulfate component content of 20-400 ppm, along with additives like magnesium oxide and triacetin, enhances biodegradability in seawater.

- Introducing acetyl groups heterogeneously into the 2nd, 3rd, and 6th carbon atoms of the glucose ring in cellulose acetate with a total degree of acetyl substitution between 1.75 and 2.55, and at least one position having a degree of acetyl substitution of 0.7 or less, combined with additives like magnesium oxide and triacetin to enhance biodegradability in seawater.

Environmental Impact Assessment of Cellulose Acetate

The environmental impact assessment of cellulose acetate is crucial for understanding its potential as an eco-friendly solution. Cellulose acetate, derived from natural cellulose fibers, has gained attention for its biodegradable properties and versatile applications.

In terms of production, cellulose acetate manufacturing processes have shown improvements in energy efficiency and reduced emissions compared to traditional plastics. The use of renewable resources, primarily wood pulp or cotton linters, as raw materials contributes to a lower carbon footprint. However, the acetylation process still involves chemical treatments that require careful management to minimize environmental risks.

During its use phase, cellulose acetate products demonstrate favorable characteristics. They are durable, resistant to degradation under normal conditions, and can be recycled in some instances. This longevity reduces the need for frequent replacements, potentially decreasing overall resource consumption and waste generation.

End-of-life considerations for cellulose acetate are particularly promising. Unlike conventional plastics, cellulose acetate is biodegradable under specific conditions. In industrial composting facilities, it can break down into harmless components within months. This biodegradability significantly reduces the long-term environmental impact associated with plastic pollution, especially in marine ecosystems.

Water consumption and quality are important factors to consider. The production of cellulose acetate requires substantial amounts of water, which necessitates efficient water management practices. However, the biodegradability of the material means it poses less risk to aquatic environments compared to persistent plastics.

Land use impacts of cellulose acetate production are generally positive when sourced from sustainably managed forests or agricultural byproducts. This can promote responsible land management practices and potentially contribute to carbon sequestration.

In terms of air quality, cellulose acetate production typically results in lower emissions of volatile organic compounds (VOCs) compared to petroleum-based plastics. This can lead to reduced smog formation and improved air quality in manufacturing regions.

While cellulose acetate offers numerous environmental benefits, it is essential to consider the entire life cycle of products made from this material. Factors such as transportation, energy sources used in production, and consumer behavior all play roles in determining the overall environmental impact.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials, particularly in the context of cellulose acetate-based eco-solutions, is a complex and evolving landscape. Governments and international organizations are increasingly recognizing the importance of sustainable materials and are developing policies to support their adoption and proper disposal.

At the forefront of these regulations is the European Union, which has implemented the Single-Use Plastics Directive. This directive aims to reduce the environmental impact of certain plastic products and promotes the transition to a circular economy. While cellulose acetate is not explicitly mentioned, the directive's focus on biodegradable alternatives creates opportunities for cellulose acetate-based products to gain market share.

In the United States, the Federal Trade Commission (FTC) has established guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims, ensuring transparency and preventing greenwashing. This regulatory environment encourages innovation in cellulose acetate applications, as companies strive to develop products that meet both performance and environmental standards.

Japan has taken a proactive approach with its "Law for Promotion of Effective Utilization of Resources," which encourages the use of biodegradable materials and sets standards for their disposal. This law has spurred research and development in biodegradable plastics, including cellulose acetate derivatives, positioning Japan as a leader in eco-friendly material innovation.

Internationally, the ISO 14855 standard provides a method for determining the ultimate aerobic biodegradability of plastic materials under controlled composting conditions. This standard is crucial for cellulose acetate products, as it offers a standardized way to assess and communicate their biodegradability to consumers and regulators alike.

Emerging economies are also developing their regulatory frameworks. China, for instance, has announced plans to ban single-use plastics, creating a potential market for biodegradable alternatives like cellulose acetate. India has implemented the Plastic Waste Management Rules, which promote the use of compostable plastics and set standards for their certification.

As the regulatory landscape continues to evolve, companies working with cellulose acetate must stay informed of regional and global changes. Compliance with these regulations not only ensures market access but also drives innovation in product design and manufacturing processes. The challenge lies in navigating the diverse and sometimes conflicting regulations across different jurisdictions while maintaining product performance and economic viability.