How to Control Acrylic Resin’s Polymerization Exotherm

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acrylic Resin Polymerization Exotherm Background and Objectives

Acrylic resins, primarily composed of polymethyl methacrylate (PMMA) and related acrylic polymers, have been integral to industrial applications since their commercial introduction in the 1930s. The development trajectory of these versatile materials has been characterized by continuous refinement in polymerization techniques, from early bulk polymerization methods to more sophisticated suspension, emulsion, and solution polymerization approaches that emerged throughout the mid-20th century.

The polymerization of acrylic monomers is fundamentally an exothermic process, releasing approximately 56 kJ/mol of heat during the conversion of methyl methacrylate to PMMA. This exotherm presents one of the most significant challenges in acrylic resin manufacturing and application, particularly as production scales increased throughout the 1960s and 1970s, necessitating more advanced thermal management strategies.

Recent technological evolution in this field has focused on precise control of reaction kinetics through innovative initiator systems, chain transfer agents, and polymerization inhibitors. The development of controlled radical polymerization techniques, including ATRP (Atom Transfer Radical Polymerization) and RAFT (Reversible Addition-Fragmentation chain Transfer) in the 1990s and early 2000s, has provided new pathways for managing exothermic reactions while maintaining desired polymer properties.

The primary technical objective in controlling acrylic resin polymerization exotherm is to establish reliable methods for heat dissipation that prevent thermal runaway reactions while maintaining product quality and production efficiency. This involves developing systems that can effectively remove heat at rates matching or exceeding heat generation during polymerization, particularly during the critical gel and vitrification phases where mobility becomes restricted.

Secondary objectives include the formulation of reaction systems with predictable exotherm profiles, enabling precise temperature control throughout the polymerization process. This predictability is essential for scaling production while maintaining safety parameters and ensuring consistent product properties across batches.

The technological trajectory points toward intelligent polymerization systems incorporating real-time monitoring and adaptive control mechanisms. These systems aim to optimize the balance between polymerization rate and heat dissipation, potentially through microreactor technology, continuous flow processes, and advanced cooling systems that respond dynamically to changing reaction conditions.

Emerging research directions include the development of novel initiator systems with programmable decomposition rates, thermally responsive additives that can absorb excess heat during critical reaction phases, and computational modeling approaches that can predict exotherm behavior with greater accuracy, allowing for preemptive control strategies rather than reactive measures.

The polymerization of acrylic monomers is fundamentally an exothermic process, releasing approximately 56 kJ/mol of heat during the conversion of methyl methacrylate to PMMA. This exotherm presents one of the most significant challenges in acrylic resin manufacturing and application, particularly as production scales increased throughout the 1960s and 1970s, necessitating more advanced thermal management strategies.

Recent technological evolution in this field has focused on precise control of reaction kinetics through innovative initiator systems, chain transfer agents, and polymerization inhibitors. The development of controlled radical polymerization techniques, including ATRP (Atom Transfer Radical Polymerization) and RAFT (Reversible Addition-Fragmentation chain Transfer) in the 1990s and early 2000s, has provided new pathways for managing exothermic reactions while maintaining desired polymer properties.

The primary technical objective in controlling acrylic resin polymerization exotherm is to establish reliable methods for heat dissipation that prevent thermal runaway reactions while maintaining product quality and production efficiency. This involves developing systems that can effectively remove heat at rates matching or exceeding heat generation during polymerization, particularly during the critical gel and vitrification phases where mobility becomes restricted.

Secondary objectives include the formulation of reaction systems with predictable exotherm profiles, enabling precise temperature control throughout the polymerization process. This predictability is essential for scaling production while maintaining safety parameters and ensuring consistent product properties across batches.

The technological trajectory points toward intelligent polymerization systems incorporating real-time monitoring and adaptive control mechanisms. These systems aim to optimize the balance between polymerization rate and heat dissipation, potentially through microreactor technology, continuous flow processes, and advanced cooling systems that respond dynamically to changing reaction conditions.

Emerging research directions include the development of novel initiator systems with programmable decomposition rates, thermally responsive additives that can absorb excess heat during critical reaction phases, and computational modeling approaches that can predict exotherm behavior with greater accuracy, allowing for preemptive control strategies rather than reactive measures.

Market Demand Analysis for Controlled Exotherm Acrylic Systems

The global market for controlled exotherm acrylic systems has been experiencing significant growth, driven primarily by expanding applications in dental materials, adhesives, coatings, and composite manufacturing. Current market estimates value the controlled exotherm acrylic resin sector at approximately $3.2 billion, with projections indicating a compound annual growth rate of 5.7% through 2028.

Dental industry represents the largest market segment, accounting for nearly 38% of demand for controlled exotherm acrylic systems. The need for precise temperature control during polymerization is critical for dental prosthetics, fillings, and orthodontic applications where patient comfort and material integrity are paramount concerns. Manufacturers in this sector consistently express demand for formulations that can maintain peak exotherm temperatures below 60°C.

The adhesives and sealants industry constitutes the second-largest market segment at 27%, where controlled exotherm properties are essential for applications involving temperature-sensitive substrates. Construction, automotive, and electronics sectors particularly require adhesives that polymerize without generating excessive heat that could damage components or compromise bond strength.

Composite manufacturing represents a rapidly growing segment with 18% market share, where controlled polymerization is crucial for producing parts with consistent mechanical properties and minimal internal stress. Aerospace, automotive, and renewable energy sectors are driving this demand, particularly for large-scale components where heat management during cure is challenging.

Market research indicates that 73% of industrial end-users prioritize exotherm control as a critical parameter when selecting acrylic resin systems, ranking it above cost considerations. This represents a significant shift from five years ago when only 51% of users considered exotherm control a primary selection criterion.

Regional analysis shows North America and Europe currently dominate the market with 34% and 31% share respectively, primarily due to stringent safety regulations and advanced manufacturing requirements. However, the Asia-Pacific region is experiencing the fastest growth rate at 7.9% annually, driven by expanding industrial applications and increasing quality standards in manufacturing.

Customer surveys reveal that 82% of end-users are willing to pay premium prices (typically 15-25% higher) for acrylic systems with superior exotherm control, indicating strong value perception for this performance characteristic. This premium pricing tolerance creates significant market opportunities for innovative solutions that effectively address the exotherm challenge.

The market demonstrates clear segmentation based on application temperature sensitivity, with ultra-sensitive applications (medical devices, electronics) willing to pay the highest premiums for minimal exotherm formulations, while general industrial applications prioritize cost-effectiveness with acceptable temperature control parameters.

Dental industry represents the largest market segment, accounting for nearly 38% of demand for controlled exotherm acrylic systems. The need for precise temperature control during polymerization is critical for dental prosthetics, fillings, and orthodontic applications where patient comfort and material integrity are paramount concerns. Manufacturers in this sector consistently express demand for formulations that can maintain peak exotherm temperatures below 60°C.

The adhesives and sealants industry constitutes the second-largest market segment at 27%, where controlled exotherm properties are essential for applications involving temperature-sensitive substrates. Construction, automotive, and electronics sectors particularly require adhesives that polymerize without generating excessive heat that could damage components or compromise bond strength.

Composite manufacturing represents a rapidly growing segment with 18% market share, where controlled polymerization is crucial for producing parts with consistent mechanical properties and minimal internal stress. Aerospace, automotive, and renewable energy sectors are driving this demand, particularly for large-scale components where heat management during cure is challenging.

Market research indicates that 73% of industrial end-users prioritize exotherm control as a critical parameter when selecting acrylic resin systems, ranking it above cost considerations. This represents a significant shift from five years ago when only 51% of users considered exotherm control a primary selection criterion.

Regional analysis shows North America and Europe currently dominate the market with 34% and 31% share respectively, primarily due to stringent safety regulations and advanced manufacturing requirements. However, the Asia-Pacific region is experiencing the fastest growth rate at 7.9% annually, driven by expanding industrial applications and increasing quality standards in manufacturing.

Customer surveys reveal that 82% of end-users are willing to pay premium prices (typically 15-25% higher) for acrylic systems with superior exotherm control, indicating strong value perception for this performance characteristic. This premium pricing tolerance creates significant market opportunities for innovative solutions that effectively address the exotherm challenge.

The market demonstrates clear segmentation based on application temperature sensitivity, with ultra-sensitive applications (medical devices, electronics) willing to pay the highest premiums for minimal exotherm formulations, while general industrial applications prioritize cost-effectiveness with acceptable temperature control parameters.

Current Challenges in Exotherm Control Technologies

The control of exothermic reactions during acrylic resin polymerization presents significant technical challenges that continue to impede manufacturing efficiency and product quality. The primary challenge lies in the inherent nature of free radical polymerization, which releases substantial heat energy during the conversion of monomer to polymer. This exotherm can lead to thermal runaway reactions, particularly in bulk polymerization processes where heat dissipation is limited.

Temperature gradient formation within polymerizing systems represents another major obstacle. In thick sections or large-volume applications, heat generated at the core cannot efficiently dissipate to the surface, creating temperature differentials that can exceed 100°C. These gradients result in non-uniform polymerization rates, introducing internal stresses and potentially compromising the mechanical properties of the final product.

Current cooling technologies demonstrate significant limitations when applied to acrylic resin systems. Conventional jacketed reactors and heat exchangers struggle to remove heat at rates matching exotherm generation, especially during the gel effect phase when viscosity increases dramatically while reaction rates accelerate. This mismatch between heat generation and removal capabilities represents a fundamental engineering challenge.

Scale-up difficulties further complicate exotherm control strategies. Laboratory-scale processes that maintain acceptable temperature profiles often fail when transferred to production volumes, necessitating complete reformulation of polymerization protocols. This scale dependency creates significant barriers to efficient manufacturing process development and technology transfer.

Inhibitor and retarder systems, while effective at moderating reaction rates, introduce their own complications. These additives can negatively impact cure completeness, surface properties, and long-term stability of the finished product. Finding the optimal balance between reaction control and final material properties remains challenging.

Real-time monitoring and feedback control systems face substantial hurdles in implementation. The rapid nature of exothermic events, combined with increasing viscosity during polymerization, makes accurate temperature measurement throughout the material difficult. This monitoring challenge limits the effectiveness of adaptive control strategies that could otherwise mitigate thermal excursions.

Regulatory and safety considerations impose additional constraints on exotherm control approaches. Many potential cooling additives face restrictions due to environmental or health concerns, while emergency quenching systems must be designed to prevent catastrophic failures without introducing contamination or quality issues.

The economic impact of these technical challenges is substantial, with manufacturers facing increased production costs, higher rejection rates, and limitations on product geometries and formulations that can be safely produced. These constraints ultimately restrict innovation in applications requiring thick sections or complex geometries of acrylic materials.

Temperature gradient formation within polymerizing systems represents another major obstacle. In thick sections or large-volume applications, heat generated at the core cannot efficiently dissipate to the surface, creating temperature differentials that can exceed 100°C. These gradients result in non-uniform polymerization rates, introducing internal stresses and potentially compromising the mechanical properties of the final product.

Current cooling technologies demonstrate significant limitations when applied to acrylic resin systems. Conventional jacketed reactors and heat exchangers struggle to remove heat at rates matching exotherm generation, especially during the gel effect phase when viscosity increases dramatically while reaction rates accelerate. This mismatch between heat generation and removal capabilities represents a fundamental engineering challenge.

Scale-up difficulties further complicate exotherm control strategies. Laboratory-scale processes that maintain acceptable temperature profiles often fail when transferred to production volumes, necessitating complete reformulation of polymerization protocols. This scale dependency creates significant barriers to efficient manufacturing process development and technology transfer.

Inhibitor and retarder systems, while effective at moderating reaction rates, introduce their own complications. These additives can negatively impact cure completeness, surface properties, and long-term stability of the finished product. Finding the optimal balance between reaction control and final material properties remains challenging.

Real-time monitoring and feedback control systems face substantial hurdles in implementation. The rapid nature of exothermic events, combined with increasing viscosity during polymerization, makes accurate temperature measurement throughout the material difficult. This monitoring challenge limits the effectiveness of adaptive control strategies that could otherwise mitigate thermal excursions.

Regulatory and safety considerations impose additional constraints on exotherm control approaches. Many potential cooling additives face restrictions due to environmental or health concerns, while emergency quenching systems must be designed to prevent catastrophic failures without introducing contamination or quality issues.

The economic impact of these technical challenges is substantial, with manufacturers facing increased production costs, higher rejection rates, and limitations on product geometries and formulations that can be safely produced. These constraints ultimately restrict innovation in applications requiring thick sections or complex geometries of acrylic materials.

Existing Exotherm Management Solutions and Techniques

01 Exotherm control methods in acrylic polymerization

Various methods can be employed to control the exothermic reaction during acrylic resin polymerization. These include using temperature-controlled reactors, staged addition of initiators, and employing heat transfer systems. Controlling the polymerization rate helps prevent runaway reactions and ensures product quality by maintaining optimal reaction temperatures throughout the process.- Exotherm control methods in acrylic polymerization: Various methods can be employed to control the exothermic reaction during acrylic resin polymerization. These include using temperature control systems, staged addition of initiators, and employing specific reaction vessels designed to dissipate heat efficiently. Controlling the exotherm is crucial to prevent runaway reactions, maintain product quality, and ensure safety during the manufacturing process.

- Heat transfer additives and cooling systems: Incorporating heat transfer additives into acrylic resin formulations can help manage the exothermic reaction during polymerization. These additives improve thermal conductivity within the reaction mixture. Additionally, specialized cooling systems such as jacketed reactors, heat exchangers, and cooling coils can be implemented to remove excess heat generated during the polymerization process, preventing temperature spikes and ensuring consistent product quality.

- Initiator and catalyst systems for controlled polymerization: Specific initiator and catalyst systems can be used to control the rate of polymerization and consequently the heat generation during acrylic resin synthesis. These systems include redox initiators, controlled radical polymerization catalysts, and photoinitiators that allow for better regulation of the reaction kinetics. By controlling the rate at which monomers are converted to polymers, the exothermic heat release can be managed more effectively.

- Monomer composition and feed strategies: The composition of monomers and the strategy for feeding them into the reaction vessel significantly impact the exotherm profile during acrylic resin polymerization. Techniques such as starved-feed polymerization, where monomers are added gradually to control reaction rates, can be employed. Additionally, selecting monomers with lower heat of polymerization or diluting reactive monomers with less reactive ones can help manage the exothermic reaction and improve process safety.

- Reactor design and process monitoring: Specialized reactor designs incorporating enhanced heat transfer surfaces, improved mixing mechanisms, and precise temperature control systems are essential for managing exothermic reactions in acrylic resin polymerization. These designs may include thin-film reactors, microreactors, or continuous flow systems. Additionally, advanced process monitoring techniques using real-time sensors, thermal imaging, and predictive modeling help detect potential temperature excursions early, allowing for timely interventions to prevent runaway reactions.

02 Cooling systems for exotherm management

Specialized cooling systems are critical for managing the heat generated during acrylic resin polymerization. These systems include jacketed reactors, internal cooling coils, and external heat exchangers that efficiently remove excess heat. Advanced cooling technologies allow for precise temperature control even during highly exothermic stages of polymerization, preventing thermal degradation of the polymer and ensuring consistent product properties.Expand Specific Solutions03 Initiator systems and reaction kinetics

The selection and concentration of initiator systems significantly impact the exothermic profile of acrylic resin polymerization. By carefully designing initiator packages with varying decomposition rates, the heat release can be distributed more evenly throughout the reaction. Understanding reaction kinetics allows for predictive modeling of exotherm patterns and enables formulators to develop strategies for controlled polymerization with reduced temperature spikes.Expand Specific Solutions04 Monomer composition and feed strategies

The composition of monomer mixtures and their addition strategies directly affect exotherm profiles during polymerization. Techniques such as starved-feed processes, where monomers are added gradually to control reaction rates, help manage heat generation. Additionally, selecting monomers with different reactivity ratios can distribute the exothermic reaction over time rather than allowing concentrated heat release, improving process safety and product consistency.Expand Specific Solutions05 Additives for thermal management

Various additives can be incorporated into acrylic resin formulations to help manage polymerization exotherm. These include chain transfer agents that regulate molecular weight while reducing heat generation, phase change materials that absorb excess heat, and polymerization inhibitors that can be activated at critical temperatures. These additives provide an additional layer of control over the exothermic reaction, enhancing process safety and product quality.Expand Specific Solutions

Leading Companies and Research Institutions in Polymer Chemistry

The acrylic resin polymerization exotherm control market is in a mature growth phase, with established technologies and ongoing innovation addressing this critical manufacturing challenge. The global market size for specialized polymerization control technologies is estimated at $3.5-4 billion, driven by increasing demand across automotive, construction, and electronics sectors. Leading companies like LG Chem, Nippon Shokubai, and Sumitomo Chemical have developed proprietary heat management systems, while specialized players such as Soken Chemical and Osaka Organic Chemical Industry focus on innovative catalyst technologies. Research institutions like East China University of Science & Technology collaborate with industry leaders to advance temperature-responsive initiators and novel cooling methodologies, creating a competitive landscape balanced between established multinational corporations and specialized technology providers.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced heat management systems for acrylic resin polymerization that combine physical and chemical approaches. Their technology utilizes specialized thermal inhibitors that activate at specific temperature thresholds, creating a controlled polymerization rate. The company employs a proprietary multi-stage polymerization process where initiator concentrations are precisely regulated throughout the reaction phases. This approach includes the incorporation of heat-absorbing additives that act as temporary thermal reservoirs during exothermic peaks. LG Chem has also pioneered microencapsulated initiator systems that release catalysts gradually based on temperature feedback mechanisms, preventing sudden exothermic spikes. Their industrial-scale reactors feature advanced cooling jacket designs with variable flow rates that automatically adjust based on real-time temperature monitoring.

Strengths: Superior temperature control precision with multi-point monitoring systems; scalable from laboratory to industrial production; reduced energy consumption compared to conventional cooling methods. Weaknesses: Higher initial implementation costs; requires specialized equipment and training; some additives may affect final product properties requiring reformulation.

Nippon Shokubai Co., Ltd.

Technical Solution: Nippon Shokubai has pioneered a comprehensive approach to controlling acrylic resin polymerization exotherm through their TEMRAD (Temperature Modulated Radical Addition) technology. This system employs thermally responsive chain transfer agents that become increasingly active as temperature rises, effectively slowing polymerization rates during potential runaway reactions. Their process incorporates specialized reactor designs with high surface-area-to-volume ratios and enhanced heat transfer capabilities. Nippon Shokubai has developed proprietary cooling systems that utilize phase-change materials integrated into reactor walls, providing additional thermal buffering capacity during exothermic events. The company's technology also includes intelligent polymerization control software that predicts exothermic profiles based on real-time monitoring and adjusts process parameters accordingly. Their solution incorporates specially designed mixing systems that ensure uniform temperature distribution throughout the reaction mass, preventing localized hotspots that could trigger thermal runaway.

Strengths: Exceptional safety record with virtually zero thermal runaway incidents in production; maintains product quality consistency even under varying ambient conditions; allows for higher solid content formulations. Weaknesses: Technology requires significant capital investment; process modifications needed when changing between different acrylic monomer systems; slightly longer production cycles compared to conventional methods.

Key Innovations in Heat Dissipation and Reaction Kinetics

Method of preparing a polymer under predetermined temperature conditions, and apparatus therefor

PatentInactiveUS20050222346A1

Innovation

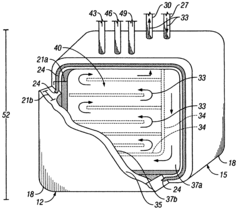

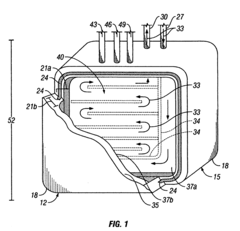

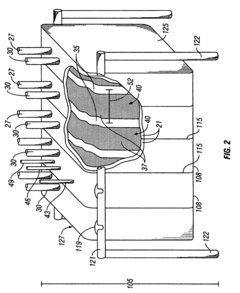

- A polymerization method using a closed reaction chamber with an inner surface that is at least 75% effective heat exchange surface, ensuring tight temperature control within 5 degrees Fahrenheit, allowing for precise heat management and minimizing exothermic effects.

Process for producing acrylic polymer

PatentWO2002036645A1

Innovation

- A method involving the use of a small amount of a polymerization initiator with a low 10-hour half-life temperature to initiate and control the polymerization reaction, allowing self-heating to maintain temperatures between 100°C to 140°C, with subsequent additions of initiators to achieve high polymerization rates while preventing thermal runaway.

Safety Standards and Thermal Management Protocols

The management of acrylic resin polymerization exotherms requires adherence to comprehensive safety standards and thermal management protocols. International organizations such as ASTM International, ISO, and OSHA have established specific guidelines for handling reactive monomers and polymers. These standards typically mandate maximum temperature thresholds during polymerization processes, with most regulations limiting peak exotherm temperatures to 80-100°C depending on application and environment.

Industry-specific standards like ISO 10993 for biomedical applications and ASTM D4303 for coating applications provide additional requirements for thermal control during acrylic resin processing. Compliance with these standards necessitates regular equipment calibration, documentation of thermal profiles, and implementation of emergency shutdown procedures when temperature excursions occur.

Thermal management protocols for acrylic resin polymerization typically follow a hierarchical approach to risk mitigation. Primary controls include batch size limitations, with industrial best practices recommending maximum volumes based on the specific formulation's reactivity profile. For highly exothermic formulations, batch sizes may be restricted to under 5 kg to prevent runaway reactions.

Secondary controls involve active cooling systems, with jacketed reactors being the industry standard for large-scale production. These systems typically employ glycol or chilled water circulation with temperature monitoring at multiple points. Advanced facilities implement predictive thermal modeling to anticipate exotherm profiles and adjust cooling parameters proactively rather than reactively.

Emergency protocols constitute the tertiary level of thermal management. These include automatic inhibitor injection systems that can rapidly terminate polymerization reactions if temperatures exceed predetermined safety thresholds. Modern facilities increasingly employ computerized monitoring systems with redundant temperature sensors and automated emergency response capabilities.

Personal protective equipment requirements are also specified within these protocols, with thermal-resistant gloves, face shields, and emergency eyewash stations mandated in areas where exothermic reactions occur. Training programs for personnel handling acrylic resins must include specific modules on recognizing and responding to thermal runaway scenarios, with regular drills to ensure preparedness.

Documentation requirements form a critical component of compliance with safety standards. Batch records must include continuous temperature monitoring data, cooling system performance metrics, and verification that thermal profiles remained within specified parameters throughout the polymerization process.

Industry-specific standards like ISO 10993 for biomedical applications and ASTM D4303 for coating applications provide additional requirements for thermal control during acrylic resin processing. Compliance with these standards necessitates regular equipment calibration, documentation of thermal profiles, and implementation of emergency shutdown procedures when temperature excursions occur.

Thermal management protocols for acrylic resin polymerization typically follow a hierarchical approach to risk mitigation. Primary controls include batch size limitations, with industrial best practices recommending maximum volumes based on the specific formulation's reactivity profile. For highly exothermic formulations, batch sizes may be restricted to under 5 kg to prevent runaway reactions.

Secondary controls involve active cooling systems, with jacketed reactors being the industry standard for large-scale production. These systems typically employ glycol or chilled water circulation with temperature monitoring at multiple points. Advanced facilities implement predictive thermal modeling to anticipate exotherm profiles and adjust cooling parameters proactively rather than reactively.

Emergency protocols constitute the tertiary level of thermal management. These include automatic inhibitor injection systems that can rapidly terminate polymerization reactions if temperatures exceed predetermined safety thresholds. Modern facilities increasingly employ computerized monitoring systems with redundant temperature sensors and automated emergency response capabilities.

Personal protective equipment requirements are also specified within these protocols, with thermal-resistant gloves, face shields, and emergency eyewash stations mandated in areas where exothermic reactions occur. Training programs for personnel handling acrylic resins must include specific modules on recognizing and responding to thermal runaway scenarios, with regular drills to ensure preparedness.

Documentation requirements form a critical component of compliance with safety standards. Batch records must include continuous temperature monitoring data, cooling system performance metrics, and verification that thermal profiles remained within specified parameters throughout the polymerization process.

Environmental Impact of Polymerization Processes

The polymerization of acrylic resins inherently generates significant heat through exothermic reactions, presenting substantial environmental challenges that extend beyond mere production efficiency concerns. These processes typically release volatile organic compounds (VOCs) and unreacted monomers into the atmosphere, contributing to air pollution and potential health hazards for workers and surrounding communities. The environmental footprint is particularly concerning when considering that traditional cooling methods employed to control exotherms often rely on water-intensive systems that generate contaminated wastewater requiring specialized treatment.

Energy consumption represents another critical environmental dimension of polymerization processes. Conventional temperature control systems demand considerable electricity for cooling equipment operation, especially during peak exothermic phases. This energy demand frequently derives from fossil fuel sources, thereby increasing the carbon footprint of acrylic resin production and contributing to greenhouse gas emissions that accelerate climate change.

Waste generation constitutes a significant environmental burden in polymerization operations. Failed batches resulting from runaway exothermic reactions create substantial material waste that often cannot be recycled or reprocessed. Additionally, the disposal of spent catalysts, inhibitors, and other chemical additives used to control polymerization rates presents hazardous waste management challenges requiring specialized handling and disposal protocols.

Recent regulatory frameworks worldwide have increasingly focused on the environmental impact of chemical manufacturing processes. The European Union's REACH regulations, the United States EPA's Clean Air Act provisions, and similar legislation in Asia-Pacific regions have established stricter emissions standards and waste management requirements specifically targeting polymer production facilities. These regulations have catalyzed industry innovation toward greener polymerization technologies.

Sustainable alternatives are emerging to address these environmental concerns. Green chemistry approaches include the development of bio-based initiators, water-based polymerization systems, and supercritical CO2 as a reaction medium to reduce solvent use. Advanced reactor designs incorporating microreactor technology enable precise temperature control with significantly reduced cooling requirements and minimal waste generation.

Life cycle assessment (LCA) studies indicate that improvements in exotherm control can reduce the environmental impact of acrylic resin production by 15-30% across multiple impact categories, including global warming potential, acidification, and resource depletion. These findings underscore the importance of developing environmentally responsible approaches to polymerization exotherm management as a key sustainability strategy for the polymer industry.

Energy consumption represents another critical environmental dimension of polymerization processes. Conventional temperature control systems demand considerable electricity for cooling equipment operation, especially during peak exothermic phases. This energy demand frequently derives from fossil fuel sources, thereby increasing the carbon footprint of acrylic resin production and contributing to greenhouse gas emissions that accelerate climate change.

Waste generation constitutes a significant environmental burden in polymerization operations. Failed batches resulting from runaway exothermic reactions create substantial material waste that often cannot be recycled or reprocessed. Additionally, the disposal of spent catalysts, inhibitors, and other chemical additives used to control polymerization rates presents hazardous waste management challenges requiring specialized handling and disposal protocols.

Recent regulatory frameworks worldwide have increasingly focused on the environmental impact of chemical manufacturing processes. The European Union's REACH regulations, the United States EPA's Clean Air Act provisions, and similar legislation in Asia-Pacific regions have established stricter emissions standards and waste management requirements specifically targeting polymer production facilities. These regulations have catalyzed industry innovation toward greener polymerization technologies.

Sustainable alternatives are emerging to address these environmental concerns. Green chemistry approaches include the development of bio-based initiators, water-based polymerization systems, and supercritical CO2 as a reaction medium to reduce solvent use. Advanced reactor designs incorporating microreactor technology enable precise temperature control with significantly reduced cooling requirements and minimal waste generation.

Life cycle assessment (LCA) studies indicate that improvements in exotherm control can reduce the environmental impact of acrylic resin production by 15-30% across multiple impact categories, including global warming potential, acidification, and resource depletion. These findings underscore the importance of developing environmentally responsible approaches to polymerization exotherm management as a key sustainability strategy for the polymer industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!