How to Design Thermite Systems for Extreme Environments?

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite System Evolution and Objectives

Thermite systems have undergone significant evolution since their inception in the late 19th century. Initially developed for welding and metal purification, these exothermic mixtures have found diverse applications in extreme environments. The progression of thermite technology has been driven by the need for more efficient, controllable, and adaptable systems capable of withstanding harsh conditions.

Early thermite compositions primarily consisted of aluminum powder and iron oxide. However, as the demand for specialized applications grew, researchers began experimenting with various metal oxides and reducing agents. This led to the development of more advanced thermite formulations tailored for specific extreme environments, such as underwater welding, space applications, and high-temperature industrial processes.

The objectives of modern thermite system design for extreme environments are multifaceted. Firstly, there is a focus on enhancing thermal output and reaction efficiency to ensure optimal performance under challenging conditions. This involves fine-tuning the particle size distribution, stoichiometry, and additives to maximize energy release while maintaining controllability.

Secondly, improving ignition reliability in extreme environments is crucial. Researchers are exploring advanced ignition methods, including laser-induced ignition and electrically triggered systems, to ensure consistent activation in scenarios where traditional ignition techniques may fail.

Thirdly, there is a growing emphasis on developing environmentally friendly and safe thermite compositions. This objective aims to reduce toxic byproducts and minimize the environmental impact of thermite reactions, particularly in sensitive ecosystems or confined spaces.

Another key objective is to enhance the stability and shelf life of thermite mixtures in extreme conditions. This involves developing advanced packaging and storage solutions to protect the reactive components from moisture, temperature fluctuations, and other environmental factors that could compromise their performance.

Furthermore, the integration of smart materials and nanotechnology into thermite systems is an emerging trend. These advancements aim to create responsive thermite compositions that can adapt to changing environmental conditions, providing more precise control over the reaction kinetics and energy release.

Lastly, there is a concerted effort to improve the scalability and customization of thermite systems. This objective focuses on developing modular designs and flexible manufacturing processes that allow for rapid adaptation to different extreme environment scenarios, from deep-sea applications to aerospace missions.

Early thermite compositions primarily consisted of aluminum powder and iron oxide. However, as the demand for specialized applications grew, researchers began experimenting with various metal oxides and reducing agents. This led to the development of more advanced thermite formulations tailored for specific extreme environments, such as underwater welding, space applications, and high-temperature industrial processes.

The objectives of modern thermite system design for extreme environments are multifaceted. Firstly, there is a focus on enhancing thermal output and reaction efficiency to ensure optimal performance under challenging conditions. This involves fine-tuning the particle size distribution, stoichiometry, and additives to maximize energy release while maintaining controllability.

Secondly, improving ignition reliability in extreme environments is crucial. Researchers are exploring advanced ignition methods, including laser-induced ignition and electrically triggered systems, to ensure consistent activation in scenarios where traditional ignition techniques may fail.

Thirdly, there is a growing emphasis on developing environmentally friendly and safe thermite compositions. This objective aims to reduce toxic byproducts and minimize the environmental impact of thermite reactions, particularly in sensitive ecosystems or confined spaces.

Another key objective is to enhance the stability and shelf life of thermite mixtures in extreme conditions. This involves developing advanced packaging and storage solutions to protect the reactive components from moisture, temperature fluctuations, and other environmental factors that could compromise their performance.

Furthermore, the integration of smart materials and nanotechnology into thermite systems is an emerging trend. These advancements aim to create responsive thermite compositions that can adapt to changing environmental conditions, providing more precise control over the reaction kinetics and energy release.

Lastly, there is a concerted effort to improve the scalability and customization of thermite systems. This objective focuses on developing modular designs and flexible manufacturing processes that allow for rapid adaptation to different extreme environment scenarios, from deep-sea applications to aerospace missions.

Market Analysis for Extreme Environment Applications

The market for thermite systems in extreme environments is experiencing significant growth, driven by increasing demand across various industries. These systems are crucial in applications where conventional materials and methods fail due to harsh conditions such as extreme temperatures, high pressures, or corrosive environments.

In the oil and gas sector, thermite systems are extensively used for well perforation and downhole cutting operations. The global oil and gas market, valued at $5.9 trillion in 2021, is projected to reach $9.5 trillion by 2030, indicating a substantial potential for thermite system applications. Offshore drilling activities, which often involve extreme conditions, are expected to grow at a CAGR of 6.8% from 2022 to 2030, further boosting the demand for specialized thermite systems.

The aerospace and defense industries also present significant opportunities for thermite systems designed for extreme environments. These systems are utilized in emergency escape mechanisms, pyrotechnic devices, and specialized welding applications. The global aerospace and defense market, valued at $1.6 trillion in 2021, is forecast to reach $2.0 trillion by 2025, with a CAGR of 5.7%.

In the mining sector, thermite systems find applications in rock fragmentation and emergency sealing of mine shafts. The global mining market size was $1.84 trillion in 2021 and is expected to expand at a CAGR of 3.7% from 2022 to 2030. This growth, particularly in deep mining operations, will drive the demand for thermite systems capable of withstanding extreme underground conditions.

The automotive industry, especially in the development of hypersonic vehicles and advanced propulsion systems, is another key market for extreme environment thermite systems. The global automotive market, valued at $2.86 trillion in 2021, is projected to reach $3.8 trillion by 2030, with a CAGR of 3.7%.

Emerging applications in space exploration, deep-sea research, and advanced manufacturing processes are also contributing to the expanding market for thermite systems in extreme environments. These sectors require highly specialized solutions capable of operating in conditions far beyond normal terrestrial limits.

However, the market faces challenges such as stringent safety regulations, high development costs, and the need for continuous innovation to meet evolving industry requirements. Despite these challenges, the overall market outlook remains positive, driven by technological advancements and the increasing need for reliable solutions in extreme operational environments across multiple industries.

In the oil and gas sector, thermite systems are extensively used for well perforation and downhole cutting operations. The global oil and gas market, valued at $5.9 trillion in 2021, is projected to reach $9.5 trillion by 2030, indicating a substantial potential for thermite system applications. Offshore drilling activities, which often involve extreme conditions, are expected to grow at a CAGR of 6.8% from 2022 to 2030, further boosting the demand for specialized thermite systems.

The aerospace and defense industries also present significant opportunities for thermite systems designed for extreme environments. These systems are utilized in emergency escape mechanisms, pyrotechnic devices, and specialized welding applications. The global aerospace and defense market, valued at $1.6 trillion in 2021, is forecast to reach $2.0 trillion by 2025, with a CAGR of 5.7%.

In the mining sector, thermite systems find applications in rock fragmentation and emergency sealing of mine shafts. The global mining market size was $1.84 trillion in 2021 and is expected to expand at a CAGR of 3.7% from 2022 to 2030. This growth, particularly in deep mining operations, will drive the demand for thermite systems capable of withstanding extreme underground conditions.

The automotive industry, especially in the development of hypersonic vehicles and advanced propulsion systems, is another key market for extreme environment thermite systems. The global automotive market, valued at $2.86 trillion in 2021, is projected to reach $3.8 trillion by 2030, with a CAGR of 3.7%.

Emerging applications in space exploration, deep-sea research, and advanced manufacturing processes are also contributing to the expanding market for thermite systems in extreme environments. These sectors require highly specialized solutions capable of operating in conditions far beyond normal terrestrial limits.

However, the market faces challenges such as stringent safety regulations, high development costs, and the need for continuous innovation to meet evolving industry requirements. Despite these challenges, the overall market outlook remains positive, driven by technological advancements and the increasing need for reliable solutions in extreme operational environments across multiple industries.

Current Challenges in Extreme Environment Thermite Systems

Designing thermite systems for extreme environments presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is maintaining the stability and performance of thermite reactions under harsh conditions, such as extreme temperatures, pressures, or corrosive environments. These conditions can significantly alter the reaction kinetics and energy output of thermite systems, potentially leading to unpredictable or inefficient performance.

Material selection is another critical challenge in extreme environment thermite systems. Traditional thermite compositions may not be suitable for use in certain extreme conditions, necessitating the development of novel materials that can withstand and function effectively in these environments. This includes identifying fuel and oxidizer combinations that remain stable and reactive under extreme conditions while also considering factors such as thermal conductivity, melting points, and chemical compatibility.

The ignition and propagation of thermite reactions in extreme environments pose additional challenges. Conventional ignition methods may be ineffective or unreliable under extreme conditions, requiring the development of specialized ignition systems that can function reliably in these environments. Furthermore, ensuring consistent and controlled propagation of the thermite reaction throughout the system becomes more complex in extreme conditions, as environmental factors can significantly influence reaction rates and heat transfer mechanisms.

Another significant challenge is the containment and control of thermite reactions in extreme environments. The high temperatures and pressures generated during thermite reactions can be further exacerbated by extreme environmental conditions, potentially leading to system failure or uncontrolled reactions. Designing robust containment systems that can withstand both the thermite reaction and the external environmental stresses is crucial for safe and effective operation.

The long-term stability and storage of thermite systems in extreme environments also present challenges. Exposure to harsh conditions over extended periods can lead to degradation of thermite components, potentially affecting their performance or safety. Developing storage solutions and packaging materials that can protect thermite systems from environmental factors while maintaining their reactivity is essential for practical applications in extreme environments.

Finally, the integration of thermite systems with other components or structures in extreme environments poses significant engineering challenges. This includes designing interfaces that can withstand both the thermite reaction and environmental stresses, as well as ensuring compatibility with surrounding materials and systems. Additionally, the development of monitoring and control systems that can function reliably in extreme conditions is crucial for the safe and effective operation of thermite systems in these environments.

Material selection is another critical challenge in extreme environment thermite systems. Traditional thermite compositions may not be suitable for use in certain extreme conditions, necessitating the development of novel materials that can withstand and function effectively in these environments. This includes identifying fuel and oxidizer combinations that remain stable and reactive under extreme conditions while also considering factors such as thermal conductivity, melting points, and chemical compatibility.

The ignition and propagation of thermite reactions in extreme environments pose additional challenges. Conventional ignition methods may be ineffective or unreliable under extreme conditions, requiring the development of specialized ignition systems that can function reliably in these environments. Furthermore, ensuring consistent and controlled propagation of the thermite reaction throughout the system becomes more complex in extreme conditions, as environmental factors can significantly influence reaction rates and heat transfer mechanisms.

Another significant challenge is the containment and control of thermite reactions in extreme environments. The high temperatures and pressures generated during thermite reactions can be further exacerbated by extreme environmental conditions, potentially leading to system failure or uncontrolled reactions. Designing robust containment systems that can withstand both the thermite reaction and the external environmental stresses is crucial for safe and effective operation.

The long-term stability and storage of thermite systems in extreme environments also present challenges. Exposure to harsh conditions over extended periods can lead to degradation of thermite components, potentially affecting their performance or safety. Developing storage solutions and packaging materials that can protect thermite systems from environmental factors while maintaining their reactivity is essential for practical applications in extreme environments.

Finally, the integration of thermite systems with other components or structures in extreme environments poses significant engineering challenges. This includes designing interfaces that can withstand both the thermite reaction and environmental stresses, as well as ensuring compatibility with surrounding materials and systems. Additionally, the development of monitoring and control systems that can function reliably in extreme conditions is crucial for the safe and effective operation of thermite systems in these environments.

Existing Thermite System Designs for Harsh Conditions

01 Thermite composition and ignition systems

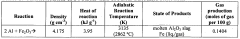

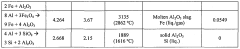

Thermite systems often involve specific compositions of reactive materials and ignition mechanisms. These systems can include various metal oxides and reducing agents, designed to produce high-temperature reactions. Advanced ignition systems may incorporate electronic or pyrotechnic initiators to ensure reliable and controlled ignition of the thermite mixture.- Thermite composition and ignition systems: Thermite systems often involve specific compositions of reactive materials and ignition mechanisms. These systems can include various metal oxides and reducing agents, as well as advanced ignition methods to control the reaction. The composition and ignition system are crucial for achieving desired performance in applications such as welding, metal purification, and incendiary devices.

- Thermite applications in oil and gas industry: Thermite reactions are utilized in the oil and gas industry for various purposes, including well perforation, cutting operations, and sealing. These systems can be designed to operate in harsh downhole environments and provide controlled, high-temperature reactions for specific tasks such as creating perforations in well casings or cutting through tubulars.

- Thermite-based welding and repair techniques: Thermite reactions are employed in specialized welding and repair processes, particularly for large metal structures or components. These systems can be used for joining rails, repairing heavy machinery, or creating strong metal bonds in situations where traditional welding methods are impractical. The process typically involves a controlled exothermic reaction to produce molten metal for the weld.

- Safety and control mechanisms for thermite systems: Given the high temperatures and reactive nature of thermite reactions, safety and control mechanisms are critical components of thermite systems. These can include specialized containment vessels, remote ignition systems, and precise mixture controls to ensure safe and effective operation. Advanced monitoring and shutdown systems may also be incorporated to prevent accidents or uncontrolled reactions.

- Novel thermite compositions and additives: Research in thermite systems includes the development of new compositions and additives to enhance performance or tailor reactions for specific applications. This can involve the use of nanomaterials, novel metal oxide combinations, or additives to control reaction rates and temperatures. These innovations aim to improve efficiency, safety, and versatility of thermite systems across various industries.

02 Applications in welding and metal joining

Thermite reactions are utilized in specialized welding and metal joining processes. These systems can be designed for joining rails, pipes, or other large metal structures. The high heat generated by the thermite reaction allows for effective fusion of metal components, often in field conditions where traditional welding methods may be impractical.Expand Specific Solutions03 Thermite-based cutting and perforation tools

Thermite systems are employed in cutting and perforation tools, particularly in oil and gas industries. These tools use the intense heat and pressure generated by thermite reactions to create precise cuts or perforations in well casings or other structures. The design of these tools often focuses on directing the thermite reaction energy for controlled and efficient cutting operations.Expand Specific Solutions04 Safety and control mechanisms in thermite systems

Given the high-energy nature of thermite reactions, safety and control mechanisms are crucial components of thermite systems. These can include specialized containment vessels, precise mixing and deployment methods, and fail-safe ignition controls. Advanced systems may incorporate sensors and automated safety features to prevent accidental ignition or contain the reaction products.Expand Specific Solutions05 Novel thermite compositions and manufacturing methods

Research in thermite systems includes the development of novel compositions and manufacturing methods. This can involve the use of nanomaterials to enhance reaction rates, the incorporation of additives to modify reaction properties, or new production techniques to improve the consistency and performance of thermite mixtures. These innovations aim to expand the applications and efficiency of thermite systems across various industries.Expand Specific Solutions

Key Players in Extreme Environment Thermite Industry

The development of thermite systems for extreme environments is in a mature stage, with ongoing research to enhance performance and safety. The market size is substantial, driven by applications in aerospace, defense, and industrial sectors. Technologically, the field is advanced but still evolving. Companies like Dow Global Technologies LLC, Xi'an Modern Chemistry Research Institute, and The Regents of the University of California are at the forefront, focusing on improving thermal stability, reaction control, and material compatibility. Research institutions such as Chongqing University and Nanjing University of Science & Technology are contributing to innovations in formulation and ignition mechanisms, while industry players like Lockheed Martin Corp. and Northrop Grumman Systems Corp. are integrating these advancements into practical applications for extreme environments.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced thermite systems using nano-scale aluminum particles and metal oxide fuels. Their technology incorporates precise particle size control and surface modification techniques to enhance reactivity and stability in extreme environments. The system includes a protective coating that prevents premature ignition while allowing rapid reaction initiation when needed. Dow's thermite formulations are designed to generate high temperatures and maintain performance under high pressure and corrosive conditions.

Strengths: High energy density, rapid reaction rates, and stability in harsh environments. Weaknesses: Potential safety concerns during handling and storage, and relatively high production costs.

Battelle Memorial Institute

Technical Solution: Battelle has engineered a novel thermite system utilizing a combination of reactive metal powders and oxidizers encapsulated in a temperature-resistant polymer matrix. This design allows for controlled energy release and improved safety in extreme environments. The system incorporates phase-change materials to manage heat distribution and prolong operational life. Battelle's approach also includes the integration of smart sensors for real-time monitoring of system integrity and performance in high-temperature and high-pressure scenarios.

Strengths: Enhanced safety features, controlled energy release, and integrated monitoring capabilities. Weaknesses: Complex manufacturing process and potentially higher unit costs compared to traditional thermite systems.

Innovative Materials for Extreme Environment Thermites

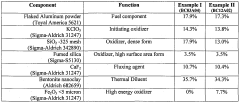

Solid-state thermite composition based heating device

PatentWO2010117857A2

Innovation

- A solid-state thermite reaction composition comprising a fuel component, primary oxidizer, initiating oxidizers, thermal diluent, and fluxing agents, integrated with a heating device featuring a reaction chamber and actuable trigger mechanism, allowing controlled thermite reactions for precise heat generation, with activation mechanisms like piezoelectric spark ignitors or exothermic couples to initiate the reaction safely.

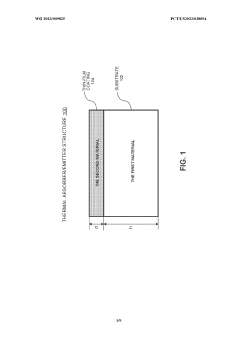

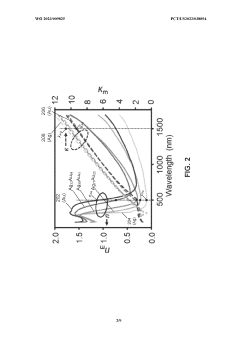

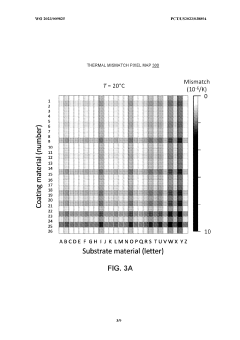

Thin-film-based optical structures for thermal emitter applications

PatentWO2023009825A1

Innovation

- A thin-film-coating/substrate two-layer thermal absorber/emitter structure with controllable emission properties, using high-melting-point materials and a single thin-film layer that serves as both a protective barrier and primary optical layer, allowing for tunable emission properties and scalability for ultra-high temperature applications.

Safety Regulations for Extreme Environment Thermites

Safety regulations for extreme environment thermites are critical to ensure the safe handling, storage, and use of these highly reactive materials in challenging conditions. These regulations typically encompass a wide range of considerations, including material composition, storage requirements, handling procedures, and emergency response protocols.

One of the primary focuses of safety regulations is the proper storage of thermite materials. Extreme environments often present unique challenges, such as high temperatures, high humidity, or corrosive atmospheres. Regulations may mandate specific storage containers designed to withstand these conditions while preventing accidental ignition or contamination of the thermite mixture.

Handling procedures are another crucial aspect of safety regulations. Personnel working with thermite systems in extreme environments must be adequately trained and equipped with appropriate personal protective equipment (PPE). This may include specialized heat-resistant suits, respiratory protection, and eye protection designed to withstand potential thermite reactions.

Transportation of thermite materials to and within extreme environments is subject to strict regulations. These may include requirements for specialized packaging, labeling, and documentation to ensure safe transport and proper identification of the materials. Additionally, regulations often specify maximum quantities that can be transported or stored in a single location.

Emergency response protocols form a significant part of safety regulations for extreme environment thermites. These protocols outline procedures for dealing with accidental ignitions, spills, or other incidents involving thermite materials. They may include specific fire suppression techniques, evacuation procedures, and decontamination methods tailored to the unique properties of thermite reactions in extreme conditions.

Environmental considerations are also addressed in safety regulations. This includes guidelines for proper disposal of unused thermite materials and residues from reactions, as well as measures to prevent contamination of surrounding areas in case of accidental release or reaction.

Regulations often require regular safety audits and inspections of facilities and equipment used in thermite systems for extreme environments. These audits ensure ongoing compliance with safety standards and help identify potential hazards before they lead to incidents.

Lastly, safety regulations typically mandate comprehensive documentation and record-keeping practices. This includes maintaining detailed logs of thermite material usage, storage conditions, and any incidents or near-misses. Such documentation is crucial for ongoing safety improvements and regulatory compliance.

One of the primary focuses of safety regulations is the proper storage of thermite materials. Extreme environments often present unique challenges, such as high temperatures, high humidity, or corrosive atmospheres. Regulations may mandate specific storage containers designed to withstand these conditions while preventing accidental ignition or contamination of the thermite mixture.

Handling procedures are another crucial aspect of safety regulations. Personnel working with thermite systems in extreme environments must be adequately trained and equipped with appropriate personal protective equipment (PPE). This may include specialized heat-resistant suits, respiratory protection, and eye protection designed to withstand potential thermite reactions.

Transportation of thermite materials to and within extreme environments is subject to strict regulations. These may include requirements for specialized packaging, labeling, and documentation to ensure safe transport and proper identification of the materials. Additionally, regulations often specify maximum quantities that can be transported or stored in a single location.

Emergency response protocols form a significant part of safety regulations for extreme environment thermites. These protocols outline procedures for dealing with accidental ignitions, spills, or other incidents involving thermite materials. They may include specific fire suppression techniques, evacuation procedures, and decontamination methods tailored to the unique properties of thermite reactions in extreme conditions.

Environmental considerations are also addressed in safety regulations. This includes guidelines for proper disposal of unused thermite materials and residues from reactions, as well as measures to prevent contamination of surrounding areas in case of accidental release or reaction.

Regulations often require regular safety audits and inspections of facilities and equipment used in thermite systems for extreme environments. These audits ensure ongoing compliance with safety standards and help identify potential hazards before they lead to incidents.

Lastly, safety regulations typically mandate comprehensive documentation and record-keeping practices. This includes maintaining detailed logs of thermite material usage, storage conditions, and any incidents or near-misses. Such documentation is crucial for ongoing safety improvements and regulatory compliance.

Environmental Impact Assessment

The environmental impact assessment of thermite systems designed for extreme environments is a critical aspect that requires thorough consideration. These systems, while effective for their intended purposes, can potentially have significant effects on the surrounding ecosystem and human health if not properly managed.

Thermite reactions produce high temperatures and generate various byproducts, including metal oxides and gases. In extreme environments, such as deep-sea or arctic conditions, the dispersion and interaction of these byproducts with the local environment can be complex and far-reaching. The assessment must consider both immediate and long-term effects on air, water, and soil quality.

One primary concern is the release of particulate matter during thermite reactions. These particles can remain suspended in the air or settle on surfaces, potentially affecting air quality and respiratory health of nearby organisms. In aquatic environments, the particles may alter water chemistry and impact marine life. The assessment should quantify the expected emissions and model their dispersion patterns under various environmental conditions.

The thermal impact of thermite systems is another crucial factor. Extreme heat generated during reactions can cause localized temperature spikes, potentially disrupting local ecosystems or damaging infrastructure. In sensitive environments like permafrost regions, this could lead to accelerated thawing and associated ecological changes. The assessment must evaluate the extent of thermal effects and propose mitigation strategies.

Chemical byproducts from thermite reactions, such as metal oxides, may persist in the environment long after the initial reaction. Their potential for bioaccumulation in food chains and long-term ecological effects must be thoroughly investigated. This includes assessing the toxicity of these byproducts to various species and their potential to alter soil or water chemistry.

The environmental impact assessment should also consider the lifecycle of thermite systems, from production to disposal. This includes evaluating the environmental footprint of manufacturing processes, transportation to extreme environments, and proper disposal or recycling of spent materials. Sustainable design principles should be incorporated to minimize overall environmental impact.

Mitigation strategies play a crucial role in the assessment. These may include containment systems to limit the spread of byproducts, filtration technologies to reduce emissions, and cooling mechanisms to manage thermal effects. The effectiveness of these strategies under extreme environmental conditions must be rigorously tested and validated.

Lastly, the assessment should outline a comprehensive monitoring plan to track environmental impacts over time. This may involve deploying sensors, conducting regular sampling, and utilizing remote sensing technologies to detect any unforeseen environmental changes. Such monitoring will provide valuable data for refining future designs and improving environmental safeguards.

Thermite reactions produce high temperatures and generate various byproducts, including metal oxides and gases. In extreme environments, such as deep-sea or arctic conditions, the dispersion and interaction of these byproducts with the local environment can be complex and far-reaching. The assessment must consider both immediate and long-term effects on air, water, and soil quality.

One primary concern is the release of particulate matter during thermite reactions. These particles can remain suspended in the air or settle on surfaces, potentially affecting air quality and respiratory health of nearby organisms. In aquatic environments, the particles may alter water chemistry and impact marine life. The assessment should quantify the expected emissions and model their dispersion patterns under various environmental conditions.

The thermal impact of thermite systems is another crucial factor. Extreme heat generated during reactions can cause localized temperature spikes, potentially disrupting local ecosystems or damaging infrastructure. In sensitive environments like permafrost regions, this could lead to accelerated thawing and associated ecological changes. The assessment must evaluate the extent of thermal effects and propose mitigation strategies.

Chemical byproducts from thermite reactions, such as metal oxides, may persist in the environment long after the initial reaction. Their potential for bioaccumulation in food chains and long-term ecological effects must be thoroughly investigated. This includes assessing the toxicity of these byproducts to various species and their potential to alter soil or water chemistry.

The environmental impact assessment should also consider the lifecycle of thermite systems, from production to disposal. This includes evaluating the environmental footprint of manufacturing processes, transportation to extreme environments, and proper disposal or recycling of spent materials. Sustainable design principles should be incorporated to minimize overall environmental impact.

Mitigation strategies play a crucial role in the assessment. These may include containment systems to limit the spread of byproducts, filtration technologies to reduce emissions, and cooling mechanisms to manage thermal effects. The effectiveness of these strategies under extreme environmental conditions must be rigorously tested and validated.

Lastly, the assessment should outline a comprehensive monitoring plan to track environmental impacts over time. This may involve deploying sensors, conducting regular sampling, and utilizing remote sensing technologies to detect any unforeseen environmental changes. Such monitoring will provide valuable data for refining future designs and improving environmental safeguards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!