How to Eliminate Contaminants in Lithium Phosphate Synthesis

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Phosphate Synthesis Background and Purification Goals

Lithium phosphate (Li3PO4) has emerged as a critical material in modern energy storage technologies, particularly as a precursor for lithium iron phosphate (LiFePO4) cathodes in lithium-ion batteries. The synthesis of high-purity lithium phosphate dates back to the early 1990s when researchers began exploring phosphate-based cathode materials as alternatives to oxide-based systems. Over the past three decades, the demand for lithium phosphate has grown exponentially, driven by the rapid expansion of the electric vehicle market and stationary energy storage systems.

Traditional synthesis methods for lithium phosphate include solid-state reactions, sol-gel processes, hydrothermal methods, and precipitation techniques. Each approach presents unique challenges regarding contaminant introduction and removal. The evolution of synthesis techniques has been marked by continuous improvements in purity levels, with recent advancements focusing on scalable production methods that maintain high purity standards while reducing energy consumption and environmental impact.

Contaminants in lithium phosphate synthesis typically include transition metal impurities (Fe, Mn, Ni), alkali and alkaline earth metals (Na, K, Ca, Mg), anions (chlorides, sulfates, carbonates), and organic residues from precursors. These impurities significantly impact the electrochemical performance of resulting battery materials, affecting capacity, cycling stability, rate capability, and safety characteristics. Even trace amounts of certain contaminants can trigger unwanted side reactions during battery operation, accelerating capacity fade and reducing battery lifespan.

The primary technical goals for lithium phosphate purification include achieving impurity levels below 10 ppm for critical contaminants, developing scalable purification processes compatible with industrial production volumes, and establishing cost-effective methods that do not significantly increase production costs. Additionally, there is a growing emphasis on environmentally sustainable purification approaches that minimize waste generation and reduce the use of hazardous chemicals.

Recent technological trends in this field include the development of selective chelation techniques for metal impurity removal, advanced membrane filtration systems, electrochemical purification methods, and the application of machine learning algorithms to optimize purification parameters. The integration of in-line quality control systems using spectroscopic techniques has also gained traction, allowing real-time monitoring of contaminant levels during production.

The ultimate objective of contaminant elimination in lithium phosphate synthesis is to enable the production of high-performance, long-lasting, and safe energy storage solutions that can accelerate the global transition to renewable energy and electrified transportation. This goal aligns with broader sustainability initiatives and the increasing regulatory pressure for cleaner production methods in the battery materials industry.

Traditional synthesis methods for lithium phosphate include solid-state reactions, sol-gel processes, hydrothermal methods, and precipitation techniques. Each approach presents unique challenges regarding contaminant introduction and removal. The evolution of synthesis techniques has been marked by continuous improvements in purity levels, with recent advancements focusing on scalable production methods that maintain high purity standards while reducing energy consumption and environmental impact.

Contaminants in lithium phosphate synthesis typically include transition metal impurities (Fe, Mn, Ni), alkali and alkaline earth metals (Na, K, Ca, Mg), anions (chlorides, sulfates, carbonates), and organic residues from precursors. These impurities significantly impact the electrochemical performance of resulting battery materials, affecting capacity, cycling stability, rate capability, and safety characteristics. Even trace amounts of certain contaminants can trigger unwanted side reactions during battery operation, accelerating capacity fade and reducing battery lifespan.

The primary technical goals for lithium phosphate purification include achieving impurity levels below 10 ppm for critical contaminants, developing scalable purification processes compatible with industrial production volumes, and establishing cost-effective methods that do not significantly increase production costs. Additionally, there is a growing emphasis on environmentally sustainable purification approaches that minimize waste generation and reduce the use of hazardous chemicals.

Recent technological trends in this field include the development of selective chelation techniques for metal impurity removal, advanced membrane filtration systems, electrochemical purification methods, and the application of machine learning algorithms to optimize purification parameters. The integration of in-line quality control systems using spectroscopic techniques has also gained traction, allowing real-time monitoring of contaminant levels during production.

The ultimate objective of contaminant elimination in lithium phosphate synthesis is to enable the production of high-performance, long-lasting, and safe energy storage solutions that can accelerate the global transition to renewable energy and electrified transportation. This goal aligns with broader sustainability initiatives and the increasing regulatory pressure for cleaner production methods in the battery materials industry.

Market Demand Analysis for High-Purity Lithium Phosphate

The global market for high-purity lithium phosphate has experienced significant growth in recent years, primarily driven by the expanding electric vehicle (EV) industry and energy storage systems. The demand for lithium phosphate, especially high-purity variants with minimal contaminants, has surged due to its critical role in lithium iron phosphate (LFP) batteries, which are gaining preference for their safety, longer lifecycle, and cost-effectiveness compared to other lithium-ion battery chemistries.

Market research indicates that the global lithium phosphate market was valued at approximately $230 million in 2022 and is projected to grow at a compound annual growth rate of 12.8% through 2030. This growth trajectory is substantially influenced by the increasing adoption of electric vehicles worldwide, with China leading the market both in consumption and production capacity.

The demand for high-purity lithium phosphate is particularly pronounced in the battery sector, which accounts for over 70% of the total market share. Battery manufacturers require lithium phosphate with purity levels exceeding 99.5%, with stringent limits on metal impurities such as iron, aluminum, and heavy metals that can significantly impact battery performance and safety.

Beyond the battery sector, high-purity lithium phosphate finds applications in pharmaceuticals, ceramics, and specialty glass manufacturing, collectively representing about 20% of the market demand. In these applications, the absence of contaminants is crucial for product quality and performance.

Regional analysis reveals that Asia-Pacific dominates the market with over 65% share, followed by Europe and North America. China's dominance is attributed to its robust EV manufacturing ecosystem and government policies promoting electric mobility. However, recent geopolitical tensions and supply chain vulnerabilities have accelerated efforts in North America and Europe to develop domestic lithium phosphate production capabilities.

Industry forecasts suggest that the demand for high-purity lithium phosphate will continue to rise as global EV penetration increases. Major automotive manufacturers have announced ambitious electrification targets, with some planning to phase out internal combustion engines entirely by 2035, further driving demand for LFP batteries and consequently high-purity lithium phosphate.

The market is also witnessing a shift toward higher purity standards, with manufacturers now targeting 99.9% purity levels to meet the evolving requirements of next-generation batteries. This trend underscores the critical importance of developing advanced contaminant elimination techniques in lithium phosphate synthesis processes to satisfy market demands for higher performance and longer-lasting energy storage solutions.

Market research indicates that the global lithium phosphate market was valued at approximately $230 million in 2022 and is projected to grow at a compound annual growth rate of 12.8% through 2030. This growth trajectory is substantially influenced by the increasing adoption of electric vehicles worldwide, with China leading the market both in consumption and production capacity.

The demand for high-purity lithium phosphate is particularly pronounced in the battery sector, which accounts for over 70% of the total market share. Battery manufacturers require lithium phosphate with purity levels exceeding 99.5%, with stringent limits on metal impurities such as iron, aluminum, and heavy metals that can significantly impact battery performance and safety.

Beyond the battery sector, high-purity lithium phosphate finds applications in pharmaceuticals, ceramics, and specialty glass manufacturing, collectively representing about 20% of the market demand. In these applications, the absence of contaminants is crucial for product quality and performance.

Regional analysis reveals that Asia-Pacific dominates the market with over 65% share, followed by Europe and North America. China's dominance is attributed to its robust EV manufacturing ecosystem and government policies promoting electric mobility. However, recent geopolitical tensions and supply chain vulnerabilities have accelerated efforts in North America and Europe to develop domestic lithium phosphate production capabilities.

Industry forecasts suggest that the demand for high-purity lithium phosphate will continue to rise as global EV penetration increases. Major automotive manufacturers have announced ambitious electrification targets, with some planning to phase out internal combustion engines entirely by 2035, further driving demand for LFP batteries and consequently high-purity lithium phosphate.

The market is also witnessing a shift toward higher purity standards, with manufacturers now targeting 99.9% purity levels to meet the evolving requirements of next-generation batteries. This trend underscores the critical importance of developing advanced contaminant elimination techniques in lithium phosphate synthesis processes to satisfy market demands for higher performance and longer-lasting energy storage solutions.

Current Contamination Challenges in Synthesis Processes

The synthesis of high-purity lithium phosphate faces significant contamination challenges that impact product quality, performance, and production efficiency. Current industrial processes struggle with several types of contaminants that enter at various stages of production. Metal impurities, particularly iron, aluminum, calcium, and magnesium, represent the most prevalent contaminants, originating from raw materials or equipment corrosion during processing. These metallic contaminants can significantly alter the electrochemical properties of lithium phosphate when used in battery applications.

Organic contaminants present another major challenge, typically introduced through solvents, additives, or from environmental exposure during processing. These organic compounds can interfere with crystallization processes and reduce the purity of the final product. Even trace amounts of certain organic contaminants can compromise the performance characteristics of lithium phosphate in high-precision applications.

Particulate matter contamination occurs frequently during handling, filtering, and drying operations. These microscopic particles can become embedded in the crystal structure, creating defects that affect material properties. Current filtration technologies struggle to completely eliminate ultra-fine particulates without significantly increasing production costs or reducing throughput.

Cross-contamination between production batches represents an ongoing challenge in continuous manufacturing environments. Inadequate cleaning protocols between production runs can lead to the carryover of contaminants, resulting in inconsistent product quality and unpredictable performance characteristics. This issue is particularly problematic in facilities that produce multiple grades or formulations of lithium compounds.

Water-based contamination, including dissolved ions and hydroxides, significantly impacts synthesis purity. The hygroscopic nature of many lithium compounds makes moisture control particularly challenging throughout the production process. Humidity variations in production environments can lead to inconsistent water content in the final product, affecting both chemical composition and physical properties.

Current analytical detection methods present limitations in real-time monitoring of contaminants during synthesis. Many facilities rely on post-production quality control testing, which delays identification of contamination issues until after significant resources have been invested in production. The sensitivity threshold of commonly employed analytical techniques may miss trace contaminants that still impact product performance in sensitive applications.

Scale-up challenges exacerbate contamination issues when transitioning from laboratory to industrial production. Processes that maintain high purity at small scales often encounter new contamination vectors when implemented in large-scale manufacturing environments, requiring significant process modifications and additional purification steps that increase production costs and complexity.

Organic contaminants present another major challenge, typically introduced through solvents, additives, or from environmental exposure during processing. These organic compounds can interfere with crystallization processes and reduce the purity of the final product. Even trace amounts of certain organic contaminants can compromise the performance characteristics of lithium phosphate in high-precision applications.

Particulate matter contamination occurs frequently during handling, filtering, and drying operations. These microscopic particles can become embedded in the crystal structure, creating defects that affect material properties. Current filtration technologies struggle to completely eliminate ultra-fine particulates without significantly increasing production costs or reducing throughput.

Cross-contamination between production batches represents an ongoing challenge in continuous manufacturing environments. Inadequate cleaning protocols between production runs can lead to the carryover of contaminants, resulting in inconsistent product quality and unpredictable performance characteristics. This issue is particularly problematic in facilities that produce multiple grades or formulations of lithium compounds.

Water-based contamination, including dissolved ions and hydroxides, significantly impacts synthesis purity. The hygroscopic nature of many lithium compounds makes moisture control particularly challenging throughout the production process. Humidity variations in production environments can lead to inconsistent water content in the final product, affecting both chemical composition and physical properties.

Current analytical detection methods present limitations in real-time monitoring of contaminants during synthesis. Many facilities rely on post-production quality control testing, which delays identification of contamination issues until after significant resources have been invested in production. The sensitivity threshold of commonly employed analytical techniques may miss trace contaminants that still impact product performance in sensitive applications.

Scale-up challenges exacerbate contamination issues when transitioning from laboratory to industrial production. Processes that maintain high purity at small scales often encounter new contamination vectors when implemented in large-scale manufacturing environments, requiring significant process modifications and additional purification steps that increase production costs and complexity.

Existing Contaminant Elimination Methods and Techniques

01 Removal of metal impurities in lithium phosphate synthesis

Various methods are employed to remove metal contaminants during lithium phosphate synthesis. These include precipitation techniques, ion exchange processes, and selective chelation to capture metal ions such as iron, aluminum, calcium, and magnesium. Purification steps often involve pH control to selectively precipitate metal hydroxides while keeping lithium in solution. Advanced filtration and washing protocols help achieve high-purity lithium phosphate suitable for battery applications.- Removal of metal impurities in lithium phosphate synthesis: Various methods are employed to remove metal contaminants during lithium phosphate synthesis. These include precipitation techniques, ion exchange processes, and selective chelation to capture metal ions such as iron, aluminum, calcium, and magnesium. Purification steps often involve pH control to selectively precipitate metal hydroxides while keeping lithium in solution. These methods are critical for producing high-purity lithium phosphate suitable for battery applications.

- Carbon and organic contaminant reduction techniques: Carbon and organic contaminants can significantly impact lithium phosphate performance in batteries. Techniques for their removal include thermal treatment processes, controlled calcination, solvent washing, and oxidative treatments. These methods effectively decompose organic materials and remove carbon residues that could otherwise interfere with electrochemical performance. Proper removal of these contaminants results in improved cycling stability and capacity retention in lithium phosphate-based battery materials.

- Phosphate precursor purification methods: The purity of phosphate precursors significantly affects the quality of synthesized lithium phosphate. Purification methods include recrystallization of phosphate salts, controlled precipitation, and liquid-liquid extraction techniques. Advanced filtration systems and membrane separation technologies are also employed to remove insoluble impurities and unwanted ionic species. These purification steps ensure consistent phosphate source quality, which directly impacts the electrochemical performance of the final lithium phosphate product.

- Nitrogen and halide contaminant control: Nitrogen compounds and halides (fluoride, chloride, bromide) can be detrimental contaminants in lithium phosphate synthesis. Control methods include vacuum treatment, inert gas processing, and specialized washing procedures to remove these impurities. Halide removal often requires specific precipitation reactions or ion exchange processes. Controlling these contaminants is essential for achieving optimal electrochemical performance and preventing side reactions in battery applications that could lead to capacity fading and safety issues.

- In-process monitoring and quality control techniques: Advanced analytical techniques are employed throughout the lithium phosphate synthesis process to monitor and control contaminant levels. These include inductively coupled plasma spectroscopy, X-ray diffraction, electron microscopy, and thermal analysis methods. Real-time monitoring allows for process adjustments to maintain quality standards. Post-synthesis quality control involves comprehensive testing of physical properties, chemical composition, and electrochemical performance to ensure the final lithium phosphate product meets stringent purity requirements for battery applications.

02 Carbon and organic contaminant reduction techniques

Carbon and organic contaminants can significantly impact lithium phosphate performance in batteries. Synthesis methods incorporate thermal treatment processes, controlled calcination, and oxidative environments to decompose and remove organic impurities. Some approaches use specific solvents or extraction techniques to dissolve organic compounds while leaving the inorganic lithium phosphate intact. Carbon content is carefully monitored and controlled through precise reaction conditions and post-synthesis treatments.Expand Specific Solutions03 Hydrothermal and solvothermal synthesis for purity control

Hydrothermal and solvothermal synthesis methods provide controlled environments for lithium phosphate formation with minimal contaminants. These approaches use elevated temperatures and pressures in sealed vessels to create optimal crystallization conditions. The controlled reaction environment limits the introduction of external contaminants and allows precise control of reaction parameters. These methods often result in well-formed crystals with high purity and specific morphologies beneficial for battery applications.Expand Specific Solutions04 Precursor selection and preparation to minimize contaminants

The selection and preparation of precursor materials significantly impact the final purity of lithium phosphate. High-purity starting materials are essential, with specific focus on lithium sources (carbonate, hydroxide, or chloride) and phosphate sources. Pre-treatment of precursors through recrystallization, filtration, or chemical modification helps remove initial contaminants before the main synthesis. Some methods incorporate specific additives that bind to potential contaminants, preventing their incorporation into the final product.Expand Specific Solutions05 Post-synthesis purification and quality control

After initial synthesis, lithium phosphate undergoes various purification steps to remove residual contaminants. These include multiple washing cycles with specific solvents, recrystallization processes, and selective dissolution-precipitation techniques. Advanced analytical methods such as ICP-MS, XRD, and electron microscopy are employed for quality control to verify contaminant levels. Some approaches use membrane filtration or centrifugation to separate impurities based on particle size or density differences.Expand Specific Solutions

Key Industry Players in Lithium Phosphate Production

The lithium phosphate synthesis contaminant elimination market is in a growth phase, driven by increasing demand for high-purity materials in battery applications. The global market is expanding rapidly, with projections exceeding $5 billion by 2025. Technologically, the field shows varying maturity levels across different purification approaches. Leading players include POSCO Holdings, which has developed advanced hydrometallurgical processes, and Guangdong Bangpu Recycling Technology, pioneering in sustainable recycling methods. Sungeel Hitech and Sumitomo Metal Mining have established proprietary contaminant removal techniques, while research institutions like RIST and Kyushu University are advancing novel purification methodologies. Corning and Süd-Chemie contribute specialized filtration and catalyst technologies that enhance purity levels in industrial-scale production.

POSCO Holdings, Inc.

Technical Solution: POSCO has developed a proprietary PosLX process for lithium phosphate synthesis that focuses on contaminant elimination through a multi-stage purification approach. Their technology employs selective precipitation methods to remove impurities like iron, aluminum, and calcium from lithium-rich brines before phosphate conversion. The process incorporates advanced filtration systems with nano-membrane technology that can eliminate particles down to 10nm in size, significantly reducing metal contaminants. POSCO's method also includes a thermal treatment step (450-550°C) that decomposes organic impurities while preserving the lithium phosphate crystal structure. Their closed-loop water recycling system prevents secondary contamination during processing, achieving 99.9% purity levels in the final lithium phosphate product while reducing water consumption by approximately 30% compared to conventional methods.

Strengths: High purity output (99.9%) with excellent scalability for industrial production; integrated water recycling reduces environmental impact and operational costs. Weaknesses: Energy-intensive thermal treatment stage increases production costs; process requires specialized equipment and expertise for optimal operation, limiting adoption by smaller manufacturers.

Guangdong Guanghua Sci-Tech Co., Ltd.

Technical Solution: Guangdong Guanghua Sci-Tech has pioneered a chemical precipitation approach to eliminate contaminants in lithium phosphate synthesis. Their method employs a controlled pH adjustment protocol (maintaining pH between 4.2-4.8) that selectively precipitates metal impurities while keeping lithium in solution. The company utilizes proprietary chelating agents that bind specifically to transition metal contaminants like iron, copper and manganese, forming complexes that can be easily filtered out. Their process incorporates ultrasonic-assisted crystallization technology that enhances purity by disrupting the incorporation of impurities into the crystal lattice during lithium phosphate formation. The final purification stage employs recrystallization under precisely controlled temperature gradients (15-25°C/hour cooling rate) that further excludes contaminants from the crystal structure. This comprehensive approach achieves lithium phosphate with impurity levels below 50ppm for critical contaminants.

Strengths: Achieves high purity without requiring expensive equipment; process operates at near-ambient conditions, reducing energy costs; scalable for large production volumes. Weaknesses: Multiple precipitation steps extend production time; requires precise pH control systems; generates significant amounts of waste filtrate that requires additional treatment before disposal.

Critical Patents and Research on Purification Innovations

Method for removing particulate contaminants from particulate mixed lithium metal phosphate material

PatentActiveJP2013507247A

Innovation

- A method involving fluidization and screening stages, with intermittent cessation of feeding to a fluidized bed chamber, followed by repeated fluidization and screening, effectively removes particulate contaminants to levels below 1 ppm, using a jet mill and sorting devices like classifier wheels or cyclones.

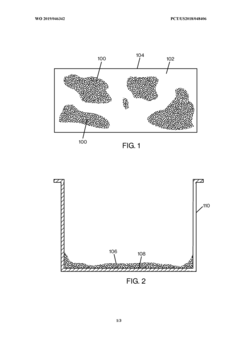

Method of removing residue containing lithium phosphate compounds from a surface

PatentWO2019046342A2

Innovation

- A method involving soaking the surface in a cleaning aqueous solution with a pH less than 5, converting insoluble lithium phosphate compounds into soluble lithium hydrogen phosphate, which is then dissolved, followed by rinsing with deionized water to remove the residue.

Environmental Impact Assessment of Purification Processes

The purification processes employed in lithium phosphate synthesis have significant environmental implications that must be thoroughly assessed. Traditional purification methods often involve extensive use of chemicals such as acids, bases, and organic solvents, which can lead to substantial environmental burdens if not properly managed. These chemicals, when released into the environment, may contaminate water bodies, affect soil quality, and potentially harm aquatic and terrestrial ecosystems.

Water consumption represents another critical environmental concern in purification processes. Many conventional methods require large volumes of water for washing and rinsing steps, contributing to water scarcity issues in regions where water resources are already limited. The wastewater generated typically contains dissolved contaminants, requiring additional treatment before discharge to prevent environmental pollution.

Energy requirements for purification processes also contribute significantly to their environmental footprint. High-temperature treatments, vacuum filtration, and centrifugation all demand considerable energy inputs, often derived from fossil fuel sources, thus increasing greenhouse gas emissions and contributing to climate change impacts. Modern approaches are increasingly focusing on reducing energy intensity through process optimization and renewable energy integration.

Solid waste generation presents another environmental challenge. Precipitated impurities, spent filter media, and other process residues require proper disposal or recycling. The composition of these wastes varies depending on the specific contaminants being removed, potentially including heavy metals or other hazardous substances that necessitate specialized handling procedures.

Recent life cycle assessments of various purification technologies reveal that membrane-based processes generally have lower environmental impacts compared to traditional chemical precipitation methods. However, membrane fouling and limited lifespan issues can offset some of these benefits if not properly addressed through appropriate maintenance protocols.

Emerging green chemistry approaches show promising environmental profiles, with reduced chemical usage and waste generation. Bioleaching and phytoremediation techniques, while still in developmental stages for lithium phosphate applications, demonstrate potential for significantly lower environmental footprints compared to conventional methods.

Regulatory frameworks worldwide are increasingly demanding comprehensive environmental impact assessments before implementing industrial purification processes. Companies must now consider not only the effectiveness of contaminant removal but also the broader ecological consequences of their chosen purification technologies, driving innovation toward more sustainable practices in lithium phosphate synthesis.

Water consumption represents another critical environmental concern in purification processes. Many conventional methods require large volumes of water for washing and rinsing steps, contributing to water scarcity issues in regions where water resources are already limited. The wastewater generated typically contains dissolved contaminants, requiring additional treatment before discharge to prevent environmental pollution.

Energy requirements for purification processes also contribute significantly to their environmental footprint. High-temperature treatments, vacuum filtration, and centrifugation all demand considerable energy inputs, often derived from fossil fuel sources, thus increasing greenhouse gas emissions and contributing to climate change impacts. Modern approaches are increasingly focusing on reducing energy intensity through process optimization and renewable energy integration.

Solid waste generation presents another environmental challenge. Precipitated impurities, spent filter media, and other process residues require proper disposal or recycling. The composition of these wastes varies depending on the specific contaminants being removed, potentially including heavy metals or other hazardous substances that necessitate specialized handling procedures.

Recent life cycle assessments of various purification technologies reveal that membrane-based processes generally have lower environmental impacts compared to traditional chemical precipitation methods. However, membrane fouling and limited lifespan issues can offset some of these benefits if not properly addressed through appropriate maintenance protocols.

Emerging green chemistry approaches show promising environmental profiles, with reduced chemical usage and waste generation. Bioleaching and phytoremediation techniques, while still in developmental stages for lithium phosphate applications, demonstrate potential for significantly lower environmental footprints compared to conventional methods.

Regulatory frameworks worldwide are increasingly demanding comprehensive environmental impact assessments before implementing industrial purification processes. Companies must now consider not only the effectiveness of contaminant removal but also the broader ecological consequences of their chosen purification technologies, driving innovation toward more sustainable practices in lithium phosphate synthesis.

Quality Control Standards and Testing Methodologies

Effective quality control is paramount in lithium phosphate synthesis to ensure product purity and performance. Industry standards such as ASTM International, ISO, and USP have established specific guidelines for lithium phosphate production, with particular emphasis on contaminant detection and elimination. These standards typically specify maximum allowable concentrations for impurities like heavy metals, transition metals, and organic compounds, often in the parts-per-million (ppm) or parts-per-billion (ppb) range.

Testing methodologies for contaminant detection in lithium phosphate synthesis have evolved significantly, incorporating both traditional analytical techniques and advanced instrumentation. Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) represent the gold standard for trace metal analysis, capable of detecting contaminants at concentrations below 1 ppb. These techniques are particularly valuable for identifying transition metal impurities that can significantly impact battery performance.

X-ray Diffraction (XRD) analysis serves as a critical tool for crystalline phase identification and purity assessment, enabling manufacturers to verify the structural integrity of synthesized lithium phosphate. Complementary techniques such as Fourier Transform Infrared Spectroscopy (FTIR) and Raman spectroscopy provide valuable insights into molecular bonding and potential organic contaminants that may be present in the final product.

In-process testing protocols have become increasingly sophisticated, with real-time monitoring systems now standard in advanced manufacturing facilities. These systems typically incorporate automated sampling at critical process points, with immediate analysis to enable rapid intervention when contaminant levels exceed predetermined thresholds. Statistical Process Control (SPC) methodologies are widely implemented to track trends in contaminant levels and identify potential process drift before specification limits are breached.

Validation protocols for quality control methods follow rigorous guidelines, typically requiring demonstration of method specificity, accuracy, precision, linearity, range, and robustness. Method transfer between laboratories necessitates careful standardization to ensure consistent results across different testing facilities. Proficiency testing programs and round-robin studies are commonly employed to verify inter-laboratory consistency and maintain testing integrity across the industry.

Emerging technologies in quality control include portable spectroscopic instruments for rapid on-site analysis, machine learning algorithms for predictive quality control, and automated vision systems for physical inspection. These innovations are gradually being incorporated into standard operating procedures, though regulatory acceptance often lags behind technological capability. The trend toward continuous manufacturing in lithium phosphate synthesis has driven development of Process Analytical Technology (PAT) approaches that enable real-time quality assurance rather than relying solely on end-product testing.

Testing methodologies for contaminant detection in lithium phosphate synthesis have evolved significantly, incorporating both traditional analytical techniques and advanced instrumentation. Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) represent the gold standard for trace metal analysis, capable of detecting contaminants at concentrations below 1 ppb. These techniques are particularly valuable for identifying transition metal impurities that can significantly impact battery performance.

X-ray Diffraction (XRD) analysis serves as a critical tool for crystalline phase identification and purity assessment, enabling manufacturers to verify the structural integrity of synthesized lithium phosphate. Complementary techniques such as Fourier Transform Infrared Spectroscopy (FTIR) and Raman spectroscopy provide valuable insights into molecular bonding and potential organic contaminants that may be present in the final product.

In-process testing protocols have become increasingly sophisticated, with real-time monitoring systems now standard in advanced manufacturing facilities. These systems typically incorporate automated sampling at critical process points, with immediate analysis to enable rapid intervention when contaminant levels exceed predetermined thresholds. Statistical Process Control (SPC) methodologies are widely implemented to track trends in contaminant levels and identify potential process drift before specification limits are breached.

Validation protocols for quality control methods follow rigorous guidelines, typically requiring demonstration of method specificity, accuracy, precision, linearity, range, and robustness. Method transfer between laboratories necessitates careful standardization to ensure consistent results across different testing facilities. Proficiency testing programs and round-robin studies are commonly employed to verify inter-laboratory consistency and maintain testing integrity across the industry.

Emerging technologies in quality control include portable spectroscopic instruments for rapid on-site analysis, machine learning algorithms for predictive quality control, and automated vision systems for physical inspection. These innovations are gradually being incorporated into standard operating procedures, though regulatory acceptance often lags behind technological capability. The trend toward continuous manufacturing in lithium phosphate synthesis has driven development of Process Analytical Technology (PAT) approaches that enable real-time quality assurance rather than relying solely on end-product testing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!