How to Enforce Compliance in Safe Thermite Usage?

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Safety Background and Objectives

Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, has been widely used in various industries for its high-temperature reaction capabilities. The historical development of thermite technology can be traced back to the late 19th century when it was first discovered by German chemist Hans Goldschmidt. Since then, thermite has found applications in welding, metal purification, and military operations.

The evolution of thermite technology has been driven by the need for more efficient and controlled reactions. Early applications focused on simple metal-oxide combinations, while modern formulations incorporate advanced additives and precise particle size control to enhance performance and safety. This progression has led to the development of specialized thermite mixtures tailored for specific industrial and research applications.

In recent years, the focus of thermite technology has shifted towards enhancing safety and compliance in its usage. This shift is primarily due to the inherent risks associated with thermite reactions, including extremely high temperatures, potential for uncontrolled ignition, and the production of molten metals. The technical objectives in this field now encompass the development of safer handling procedures, improved ignition control systems, and the creation of more stable thermite compositions.

The current landscape of thermite safety is characterized by a multifaceted approach, combining material science, process engineering, and regulatory frameworks. Key technical goals include the design of fail-safe ignition mechanisms, the development of containment systems capable of withstanding extreme temperatures, and the implementation of real-time monitoring technologies to ensure reaction control and environmental safety.

Another critical objective in thermite safety is the standardization of usage protocols across different industries. This involves creating comprehensive guidelines that address proper storage, handling, and disposal of thermite materials, as well as establishing training programs for personnel involved in thermite operations. The aim is to minimize the risk of accidents and ensure consistent safety practices across various applications.

Furthermore, research efforts are being directed towards the development of "smart" thermite compositions that incorporate built-in safety features. These may include self-extinguishing properties, reduced sensitivity to accidental ignition, and improved control over reaction rates. Such advancements are crucial in expanding the safe use of thermite in new applications while maintaining its effectiveness.

The evolution of thermite technology has been driven by the need for more efficient and controlled reactions. Early applications focused on simple metal-oxide combinations, while modern formulations incorporate advanced additives and precise particle size control to enhance performance and safety. This progression has led to the development of specialized thermite mixtures tailored for specific industrial and research applications.

In recent years, the focus of thermite technology has shifted towards enhancing safety and compliance in its usage. This shift is primarily due to the inherent risks associated with thermite reactions, including extremely high temperatures, potential for uncontrolled ignition, and the production of molten metals. The technical objectives in this field now encompass the development of safer handling procedures, improved ignition control systems, and the creation of more stable thermite compositions.

The current landscape of thermite safety is characterized by a multifaceted approach, combining material science, process engineering, and regulatory frameworks. Key technical goals include the design of fail-safe ignition mechanisms, the development of containment systems capable of withstanding extreme temperatures, and the implementation of real-time monitoring technologies to ensure reaction control and environmental safety.

Another critical objective in thermite safety is the standardization of usage protocols across different industries. This involves creating comprehensive guidelines that address proper storage, handling, and disposal of thermite materials, as well as establishing training programs for personnel involved in thermite operations. The aim is to minimize the risk of accidents and ensure consistent safety practices across various applications.

Furthermore, research efforts are being directed towards the development of "smart" thermite compositions that incorporate built-in safety features. These may include self-extinguishing properties, reduced sensitivity to accidental ignition, and improved control over reaction rates. Such advancements are crucial in expanding the safe use of thermite in new applications while maintaining its effectiveness.

Market Analysis for Thermite Applications

The global market for thermite applications has been experiencing steady growth, driven by increasing demand in various industrial sectors. The primary industries utilizing thermite include metallurgy, railway welding, and military applications. In the metallurgy sector, thermite reactions are widely used for metal purification and welding of large metal components, contributing significantly to market expansion.

Railway maintenance and construction represent a substantial portion of the thermite market. The process of thermite welding is crucial for joining railway tracks, ensuring their longevity and safety. As countries worldwide continue to invest in railway infrastructure development and maintenance, the demand for thermite in this sector is expected to grow consistently.

The military and defense sector also plays a vital role in the thermite market. Thermite is used in incendiary devices and for breaching purposes, making it an essential component in certain military operations. However, the use of thermite in this sector is highly regulated and subject to strict compliance measures.

Emerging applications in the aerospace industry are opening new avenues for thermite usage. The material's high heat generation capabilities make it suitable for specialized welding and cutting operations in aircraft manufacturing and maintenance. This diversification is expected to contribute to market growth in the coming years.

Geographically, North America and Europe currently dominate the thermite market due to their advanced industrial infrastructure and significant investments in railway networks. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, primarily driven by rapid industrialization and extensive railway expansion projects in countries like China and India.

The market is characterized by a mix of large multinational corporations and specialized regional players. Key market players are focusing on research and development to enhance the safety and efficiency of thermite applications, addressing the growing concerns regarding compliance and safe usage.

Environmental regulations and safety concerns pose challenges to market growth. Stringent regulations regarding the handling, storage, and transportation of thermite materials are influencing market dynamics. This has led to increased emphasis on developing safer formulations and improved handling procedures, which is expected to shape the future of the thermite market.

Railway maintenance and construction represent a substantial portion of the thermite market. The process of thermite welding is crucial for joining railway tracks, ensuring their longevity and safety. As countries worldwide continue to invest in railway infrastructure development and maintenance, the demand for thermite in this sector is expected to grow consistently.

The military and defense sector also plays a vital role in the thermite market. Thermite is used in incendiary devices and for breaching purposes, making it an essential component in certain military operations. However, the use of thermite in this sector is highly regulated and subject to strict compliance measures.

Emerging applications in the aerospace industry are opening new avenues for thermite usage. The material's high heat generation capabilities make it suitable for specialized welding and cutting operations in aircraft manufacturing and maintenance. This diversification is expected to contribute to market growth in the coming years.

Geographically, North America and Europe currently dominate the thermite market due to their advanced industrial infrastructure and significant investments in railway networks. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, primarily driven by rapid industrialization and extensive railway expansion projects in countries like China and India.

The market is characterized by a mix of large multinational corporations and specialized regional players. Key market players are focusing on research and development to enhance the safety and efficiency of thermite applications, addressing the growing concerns regarding compliance and safe usage.

Environmental regulations and safety concerns pose challenges to market growth. Stringent regulations regarding the handling, storage, and transportation of thermite materials are influencing market dynamics. This has led to increased emphasis on developing safer formulations and improved handling procedures, which is expected to shape the future of the thermite market.

Current Challenges in Thermite Safety Compliance

The enforcement of compliance in safe thermite usage faces several significant challenges in today's industrial and research environments. One of the primary obstacles is the lack of standardized regulations across different jurisdictions. While some countries have strict guidelines for thermite handling, others have more lenient or even non-existent regulations, creating a complex landscape for international organizations to navigate.

Another major challenge is the rapid advancement of thermite technology and applications. As new formulations and uses for thermite are developed, safety protocols struggle to keep pace. This lag between innovation and regulation can lead to potentially dangerous situations where proper safety measures are not yet in place for novel applications.

The inherent hazardous nature of thermite compounds also presents a unique set of compliance challenges. The high reactivity and extreme heat generated during thermite reactions require specialized handling procedures and safety equipment. Ensuring that all personnel are adequately trained and consistently follow these procedures can be difficult, especially in large organizations or those with high employee turnover.

Furthermore, the dual-use nature of thermite technology complicates compliance efforts. Many thermite compounds have legitimate industrial applications but can also be misused for destructive purposes. This dual-use potential necessitates stringent control measures, which can be challenging to implement without impeding legitimate research and industrial processes.

The cost of implementing and maintaining comprehensive safety measures is another significant hurdle. Small businesses and research institutions may struggle to afford the necessary equipment, training, and personnel required to ensure full compliance with thermite safety regulations. This financial burden can lead to corners being cut or safety measures being neglected.

Additionally, the storage and transportation of thermite materials pose unique compliance challenges. Proper storage facilities must meet specific requirements for temperature control, humidity regulation, and fire suppression. Transportation of thermite compounds is subject to strict regulations, which can vary significantly between different modes of transport and across international borders.

Lastly, the enforcement of compliance itself is a challenge due to the limited resources of regulatory bodies. Regular inspections, audits, and monitoring of thermite usage require significant manpower and expertise. Many regulatory agencies struggle to maintain adequate oversight, particularly in regions with a high concentration of thermite-using industries or research facilities.

Another major challenge is the rapid advancement of thermite technology and applications. As new formulations and uses for thermite are developed, safety protocols struggle to keep pace. This lag between innovation and regulation can lead to potentially dangerous situations where proper safety measures are not yet in place for novel applications.

The inherent hazardous nature of thermite compounds also presents a unique set of compliance challenges. The high reactivity and extreme heat generated during thermite reactions require specialized handling procedures and safety equipment. Ensuring that all personnel are adequately trained and consistently follow these procedures can be difficult, especially in large organizations or those with high employee turnover.

Furthermore, the dual-use nature of thermite technology complicates compliance efforts. Many thermite compounds have legitimate industrial applications but can also be misused for destructive purposes. This dual-use potential necessitates stringent control measures, which can be challenging to implement without impeding legitimate research and industrial processes.

The cost of implementing and maintaining comprehensive safety measures is another significant hurdle. Small businesses and research institutions may struggle to afford the necessary equipment, training, and personnel required to ensure full compliance with thermite safety regulations. This financial burden can lead to corners being cut or safety measures being neglected.

Additionally, the storage and transportation of thermite materials pose unique compliance challenges. Proper storage facilities must meet specific requirements for temperature control, humidity regulation, and fire suppression. Transportation of thermite compounds is subject to strict regulations, which can vary significantly between different modes of transport and across international borders.

Lastly, the enforcement of compliance itself is a challenge due to the limited resources of regulatory bodies. Regular inspections, audits, and monitoring of thermite usage require significant manpower and expertise. Many regulatory agencies struggle to maintain adequate oversight, particularly in regions with a high concentration of thermite-using industries or research facilities.

Existing Compliance Enforcement Strategies

01 Thermite composition and ignition systems

Advancements in thermite compositions and ignition systems for improved performance and safety. This includes optimized mixtures of metal oxides and reducing agents, as well as innovative ignition mechanisms designed to enhance control and reliability in various applications.- Thermite composition and manufacturing: This category focuses on the development and production of thermite compositions. It includes innovations in the formulation of thermite mixtures, methods for manufacturing thermite materials, and techniques for enhancing the performance and safety of thermite reactions. These advancements aim to improve the efficiency and controllability of thermite-based applications while ensuring compliance with safety regulations.

- Thermite ignition systems: This area covers the design and implementation of ignition systems for thermite reactions. It includes innovations in initiators, detonators, and ignition mechanisms specifically tailored for thermite applications. The focus is on developing reliable, safe, and controllable ignition methods that comply with industry standards and regulations for handling energetic materials.

- Thermite welding and metal joining: This category encompasses the use of thermite reactions in welding and metal joining processes. It includes advancements in thermite welding techniques, equipment, and materials for joining rails, pipes, and other metal structures. The focus is on improving weld quality, efficiency, and safety while ensuring compliance with industry standards for thermite welding applications.

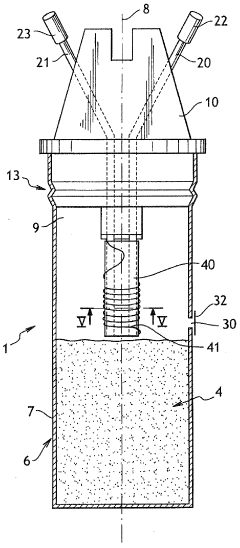

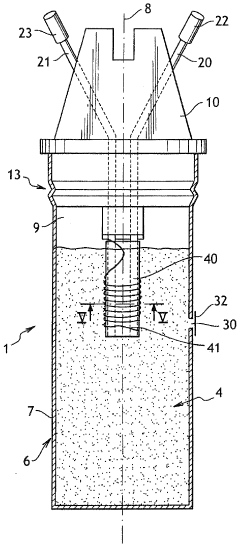

- Safety and containment systems for thermite reactions: This area focuses on the development of safety measures and containment systems for thermite reactions. It includes innovations in reaction vessels, protective equipment, and monitoring systems designed to mitigate risks associated with thermite use. These advancements aim to enhance the safety of thermite applications and ensure compliance with regulatory requirements for handling and using energetic materials.

- Thermite disposal and environmental compliance: This category addresses the safe disposal of thermite materials and byproducts, as well as environmental compliance issues related to thermite use. It includes methods for neutralizing or recycling thermite residues, techniques for minimizing environmental impact, and strategies for meeting regulatory requirements regarding the handling and disposal of thermite-related materials.

02 Thermite welding techniques

Developments in thermite welding methods for joining metal components, particularly in rail and pipeline industries. These techniques focus on improving weld quality, reducing defects, and enhancing overall structural integrity while ensuring compliance with industry standards.Expand Specific Solutions03 Safety measures and containment systems

Innovations in safety protocols and containment systems for handling and using thermite reactions. This includes specialized equipment, protective gear, and monitoring systems designed to minimize risks associated with high-temperature exothermic reactions and ensure compliance with safety regulations.Expand Specific Solutions04 Environmental considerations and waste management

Approaches to address environmental concerns related to thermite use, including methods for proper disposal of byproducts, recycling of materials, and reduction of emissions. These developments aim to ensure compliance with environmental regulations while maintaining the effectiveness of thermite applications.Expand Specific Solutions05 Quality control and testing procedures

Establishment of standardized quality control measures and testing procedures for thermite materials and processes. This includes methods for verifying composition, assessing reaction characteristics, and evaluating the performance of thermite products to ensure consistency and compliance with industry standards.Expand Specific Solutions

Key Stakeholders in Thermite Industry

The competitive landscape for enforcing compliance in safe thermite usage is in a developing stage, with a growing market driven by increasing safety regulations and industrial applications. The technology's maturity varies across sectors, with companies like Robertson Intellectual Properties LLC, Xi'an Modern Chemistry Research Institute, and ConocoPhillips Co. leading in research and development. The market size is expanding as more industries adopt thermite-based processes, necessitating advanced safety measures. Companies such as Applied Materials, Inc. and Pangang Group Research Institute Co., Ltd. are contributing to technological advancements, focusing on improving safety protocols and compliance mechanisms for thermite handling and usage across various industrial applications.

ConocoPhillips Co.

Technical Solution: ConocoPhillips Co. has developed a robust compliance system for safe thermite usage in the oil and gas industry. Their approach focuses on integrating thermite safety into their broader process safety management framework. This includes the development of detailed standard operating procedures (SOPs) for thermite handling, storage, and application, tailored to specific oil and gas operations. ConocoPhillips has also implemented a rigorous training and certification program for personnel involved in thermite operations, ensuring a high level of competency and safety awareness. Their system incorporates advanced risk assessment tools that consider factors such as environmental conditions, proximity to sensitive equipment, and potential interaction with other materials present in oil and gas facilities.

Strengths: Industry-specific expertise, integration with existing safety frameworks, and comprehensive personnel training programs. Weaknesses: Potential limitations in applicability outside the oil and gas sector.

Applied Materials, Inc.

Technical Solution: Applied Materials, Inc. has engineered a cutting-edge compliance system for safe thermite usage in semiconductor manufacturing and materials engineering applications. Their approach leverages advanced process control technologies and automation to minimize human exposure and error in thermite handling. The company has developed specialized containment and reaction chambers that integrate seamlessly with existing semiconductor manufacturing equipment, ensuring safe thermite usage without compromising production efficiency. Applied Materials has also created a proprietary software suite that manages thermite inventory, tracks usage patterns, and automatically generates compliance reports for regulatory bodies. This system is complemented by AI-driven predictive maintenance algorithms that identify potential safety risks before they materialize.

Strengths: High level of automation and integration with existing manufacturing processes, advanced predictive maintenance capabilities, and specialized solutions for high-tech industries. Weaknesses: Potentially limited applicability in less technologically advanced sectors or smaller-scale operations.

Innovative Approaches to Thermite Safety

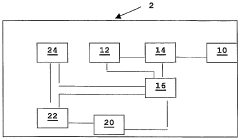

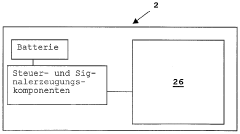

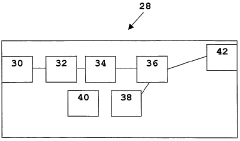

System and method for accident prevention

PatentWO2004010387A1

Innovation

- A system that continuously checks user authorization through operator-integrated authorization, using a user terminal that transmits signals via the body, and ensures safety conditions are met by integrating protective clothing, allowing operation only when both are verified, and a handle device with pressure-sensitive zones to detect gripping states for power control.

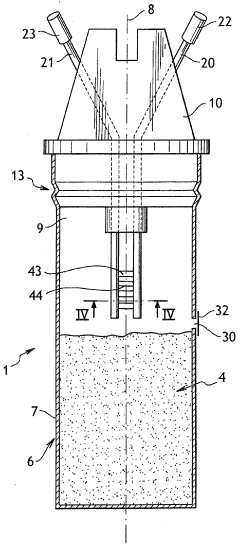

Device for igniting an alumino-thermal composition, crucible containing same and related methods

PatentWO2008113653A1

Innovation

- A device comprising an electrical resistor connecting two electrodes, exposed to a medium with oxygen and carbon, generates carbon monoxide through Joule heating, triggering an exothermic reaction that ignites the thermite composition, with a design that prevents direct contact between electrodes and the thermite charge to avoid short circuits and uncontrolled reactions.

Regulatory Framework for Thermite Usage

The regulatory framework for thermite usage is a critical component in ensuring safe and responsible handling of this highly reactive substance. At the federal level in the United States, the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) plays a pivotal role in overseeing the manufacture, distribution, and use of thermite. The ATF classifies thermite as a regulated explosive material, subject to strict licensing and storage requirements under the Federal Explosives Law.

State and local governments often impose additional regulations on thermite usage, creating a multi-layered approach to compliance. These regulations typically address issues such as transportation, storage facilities, and specific application protocols. For instance, many states require special permits for the possession and use of thermite, with stringent background checks and safety training prerequisites.

In the industrial sector, the Occupational Safety and Health Administration (OSHA) provides guidelines for workplace safety when handling thermite. These guidelines encompass proper personal protective equipment (PPE), handling procedures, and emergency response protocols. OSHA's standards are complemented by industry-specific best practices developed by organizations such as the American Welding Society (AWS) for welding applications.

International regulations also play a significant role, particularly for companies operating globally. The United Nations recommendations on the Transport of Dangerous Goods classify thermite under Class 4.1 (flammable solids), influencing international shipping and handling requirements. Countries like Canada and the European Union have their own regulatory bodies and frameworks, often aligning with or exceeding U.S. standards.

Environmental considerations are increasingly shaping the regulatory landscape for thermite usage. The Environmental Protection Agency (EPA) in the U.S. and similar agencies worldwide monitor the potential environmental impacts of thermite reactions, particularly in terms of air quality and waste disposal. This has led to the development of more stringent protocols for containment and cleanup in industrial applications.

Enforcement of these regulations relies on a combination of regular inspections, documentation requirements, and severe penalties for non-compliance. Companies dealing with thermite must maintain detailed records of acquisition, usage, and disposal, subject to audit by regulatory authorities. Violations can result in hefty fines, license revocations, and even criminal charges in severe cases.

As technology and industrial practices evolve, so too does the regulatory framework. Recent trends indicate a move towards more harmonized international standards and increased focus on cybersecurity measures to prevent unauthorized access to thermite and related materials. This dynamic regulatory environment necessitates ongoing vigilance and adaptation from all stakeholders involved in thermite usage.

State and local governments often impose additional regulations on thermite usage, creating a multi-layered approach to compliance. These regulations typically address issues such as transportation, storage facilities, and specific application protocols. For instance, many states require special permits for the possession and use of thermite, with stringent background checks and safety training prerequisites.

In the industrial sector, the Occupational Safety and Health Administration (OSHA) provides guidelines for workplace safety when handling thermite. These guidelines encompass proper personal protective equipment (PPE), handling procedures, and emergency response protocols. OSHA's standards are complemented by industry-specific best practices developed by organizations such as the American Welding Society (AWS) for welding applications.

International regulations also play a significant role, particularly for companies operating globally. The United Nations recommendations on the Transport of Dangerous Goods classify thermite under Class 4.1 (flammable solids), influencing international shipping and handling requirements. Countries like Canada and the European Union have their own regulatory bodies and frameworks, often aligning with or exceeding U.S. standards.

Environmental considerations are increasingly shaping the regulatory landscape for thermite usage. The Environmental Protection Agency (EPA) in the U.S. and similar agencies worldwide monitor the potential environmental impacts of thermite reactions, particularly in terms of air quality and waste disposal. This has led to the development of more stringent protocols for containment and cleanup in industrial applications.

Enforcement of these regulations relies on a combination of regular inspections, documentation requirements, and severe penalties for non-compliance. Companies dealing with thermite must maintain detailed records of acquisition, usage, and disposal, subject to audit by regulatory authorities. Violations can result in hefty fines, license revocations, and even criminal charges in severe cases.

As technology and industrial practices evolve, so too does the regulatory framework. Recent trends indicate a move towards more harmonized international standards and increased focus on cybersecurity measures to prevent unauthorized access to thermite and related materials. This dynamic regulatory environment necessitates ongoing vigilance and adaptation from all stakeholders involved in thermite usage.

Environmental Impact of Thermite Operations

The environmental impact of thermite operations is a critical consideration in ensuring safe and responsible usage of this highly reactive substance. Thermite reactions, characterized by their intense heat and rapid oxidation, can have significant effects on the surrounding ecosystem if not properly managed.

One of the primary environmental concerns associated with thermite operations is the release of particulate matter into the atmosphere. The high-temperature reaction produces fine metal oxide particles, which can remain suspended in the air for extended periods. These particles may contribute to air pollution and potentially affect local air quality, particularly in areas with frequent thermite usage.

Soil contamination is another potential environmental issue arising from thermite operations. The residual metal oxides and other byproducts of the reaction can accumulate in the soil, potentially altering its chemical composition and affecting plant growth. In cases where thermite is used for welding or metal cutting applications, there is a risk of contaminating the soil with heavy metals, which can have long-lasting effects on the local ecosystem.

Water pollution is also a concern, especially when thermite operations are conducted near water bodies. The high-temperature reaction can cause rapid heating of nearby water, potentially disrupting aquatic ecosystems. Additionally, if thermite residues or byproducts enter water systems, they may alter water chemistry and impact aquatic life.

The intense heat generated by thermite reactions can have localized effects on vegetation and wildlife. In areas where thermite is frequently used, there may be a risk of accidental fires or damage to surrounding plant life. The sudden and extreme temperature changes can also disrupt local microclimates, potentially affecting small-scale ecosystems.

To mitigate these environmental impacts, strict compliance measures must be implemented. These may include conducting operations in controlled environments, using containment systems to capture particulate matter, and implementing proper disposal protocols for thermite residues. Regular environmental monitoring and assessment should be carried out in areas where thermite is frequently used to track any long-term effects on the ecosystem.

Developing more environmentally friendly thermite formulations is an area of ongoing research. Some efforts focus on creating thermite mixtures that produce less harmful byproducts or have a reduced environmental footprint. Additionally, exploring alternative technologies that can achieve similar results with less environmental impact is crucial for long-term sustainability in industries reliant on thermite reactions.

One of the primary environmental concerns associated with thermite operations is the release of particulate matter into the atmosphere. The high-temperature reaction produces fine metal oxide particles, which can remain suspended in the air for extended periods. These particles may contribute to air pollution and potentially affect local air quality, particularly in areas with frequent thermite usage.

Soil contamination is another potential environmental issue arising from thermite operations. The residual metal oxides and other byproducts of the reaction can accumulate in the soil, potentially altering its chemical composition and affecting plant growth. In cases where thermite is used for welding or metal cutting applications, there is a risk of contaminating the soil with heavy metals, which can have long-lasting effects on the local ecosystem.

Water pollution is also a concern, especially when thermite operations are conducted near water bodies. The high-temperature reaction can cause rapid heating of nearby water, potentially disrupting aquatic ecosystems. Additionally, if thermite residues or byproducts enter water systems, they may alter water chemistry and impact aquatic life.

The intense heat generated by thermite reactions can have localized effects on vegetation and wildlife. In areas where thermite is frequently used, there may be a risk of accidental fires or damage to surrounding plant life. The sudden and extreme temperature changes can also disrupt local microclimates, potentially affecting small-scale ecosystems.

To mitigate these environmental impacts, strict compliance measures must be implemented. These may include conducting operations in controlled environments, using containment systems to capture particulate matter, and implementing proper disposal protocols for thermite residues. Regular environmental monitoring and assessment should be carried out in areas where thermite is frequently used to track any long-term effects on the ecosystem.

Developing more environmentally friendly thermite formulations is an area of ongoing research. Some efforts focus on creating thermite mixtures that produce less harmful byproducts or have a reduced environmental footprint. Additionally, exploring alternative technologies that can achieve similar results with less environmental impact is crucial for long-term sustainability in industries reliant on thermite reactions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!