How to Enhance 5.4 Triton Engine Performance with Aftermarket Parts?

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

5.4 Triton Engine Overview and Enhancement Goals

The 5.4 Triton engine, developed by Ford Motor Company, has been a staple in their lineup of V8 engines since its introduction in the late 1990s. This powerplant has been widely used in various Ford vehicles, including the popular F-150 pickup truck, Expedition SUV, and E-Series vans. Known for its reliability and versatility, the 5.4 Triton engine has undergone several iterations and improvements over the years.

Initially designed as a replacement for the older 5.8L Windsor V8, the 5.4 Triton engine was engineered to provide a balance of power, efficiency, and durability. It features a cast iron block with aluminum cylinder heads, and utilizes overhead camshaft technology. The engine's displacement of 5.4 liters (330 cubic inches) is achieved through a bore of 3.55 inches and a stroke of 4.17 inches.

Despite its solid reputation, the 5.4 Triton engine has faced some challenges and criticisms over the years. Common issues include spark plug problems in earlier models, potential oil consumption in high-mileage engines, and timing chain tensioner failures. These concerns have led many owners to seek aftermarket solutions to enhance both performance and reliability.

The primary goals for enhancing the 5.4 Triton engine with aftermarket parts are multifaceted. First and foremost, owners typically aim to increase horsepower and torque output. This can be achieved through various modifications, such as improving air intake and exhaust flow, optimizing fuel delivery, and fine-tuning engine management systems. Additionally, enhancing durability and addressing known weak points are crucial objectives for many enthusiasts and high-mileage vehicle owners.

Another key enhancement goal is to improve fuel efficiency without sacrificing performance. This is particularly important given the increasing focus on environmental concerns and rising fuel costs. Aftermarket solutions that can optimize combustion efficiency and reduce internal friction are highly sought after in this regard.

Lastly, many 5.4 Triton engine owners seek to enhance the overall driving experience. This includes improving throttle response, reducing engine noise and vibration, and ensuring smooth power delivery across the entire RPM range. Achieving these goals often requires a holistic approach, combining multiple aftermarket upgrades that work in harmony to elevate the engine's performance characteristics.

Initially designed as a replacement for the older 5.8L Windsor V8, the 5.4 Triton engine was engineered to provide a balance of power, efficiency, and durability. It features a cast iron block with aluminum cylinder heads, and utilizes overhead camshaft technology. The engine's displacement of 5.4 liters (330 cubic inches) is achieved through a bore of 3.55 inches and a stroke of 4.17 inches.

Despite its solid reputation, the 5.4 Triton engine has faced some challenges and criticisms over the years. Common issues include spark plug problems in earlier models, potential oil consumption in high-mileage engines, and timing chain tensioner failures. These concerns have led many owners to seek aftermarket solutions to enhance both performance and reliability.

The primary goals for enhancing the 5.4 Triton engine with aftermarket parts are multifaceted. First and foremost, owners typically aim to increase horsepower and torque output. This can be achieved through various modifications, such as improving air intake and exhaust flow, optimizing fuel delivery, and fine-tuning engine management systems. Additionally, enhancing durability and addressing known weak points are crucial objectives for many enthusiasts and high-mileage vehicle owners.

Another key enhancement goal is to improve fuel efficiency without sacrificing performance. This is particularly important given the increasing focus on environmental concerns and rising fuel costs. Aftermarket solutions that can optimize combustion efficiency and reduce internal friction are highly sought after in this regard.

Lastly, many 5.4 Triton engine owners seek to enhance the overall driving experience. This includes improving throttle response, reducing engine noise and vibration, and ensuring smooth power delivery across the entire RPM range. Achieving these goals often requires a holistic approach, combining multiple aftermarket upgrades that work in harmony to elevate the engine's performance characteristics.

Market Analysis for 5.4 Triton Engine Upgrades

The market for 5.4 Triton engine upgrades has shown significant growth in recent years, driven by the enduring popularity of Ford vehicles equipped with this engine. The 5.4 Triton, used in various Ford models including the F-150, Expedition, and E-Series vans, has a large installed base, creating a substantial market for aftermarket performance parts.

Consumer demand for enhanced engine performance is primarily fueled by the desire for increased horsepower, improved fuel efficiency, and extended engine life. Truck owners, in particular, seek upgrades to boost towing capacity and overall vehicle performance. This demand has led to a diverse range of aftermarket products, including cold air intakes, performance chips, exhaust systems, and supercharger kits.

The market size for 5.4 Triton engine upgrades is estimated to be in the hundreds of millions of dollars annually. This figure encompasses both direct parts sales and installation services. The market has experienced steady growth, with a compound annual growth rate (CAGR) exceeding the overall automotive aftermarket average.

Key market segments include performance enthusiasts, work truck owners, and off-road vehicle modifiers. Each segment has distinct preferences and priorities, influencing product development and marketing strategies. Performance enthusiasts typically seek maximum horsepower gains, while work truck owners prioritize durability and towing capacity improvements.

The competitive landscape is characterized by a mix of large automotive aftermarket companies and specialized performance parts manufacturers. Major players include well-known brands like K&N, Borla, and Edelbrock, alongside niche manufacturers focusing exclusively on Ford engine upgrades.

E-commerce has significantly impacted the market, allowing for direct-to-consumer sales and providing a platform for smaller manufacturers to reach a broader audience. Online marketplaces and automotive forums have become crucial channels for product discovery and customer reviews, influencing purchasing decisions.

Looking ahead, the market for 5.4 Triton engine upgrades is expected to continue its growth trajectory. Factors driving this growth include the aging fleet of vehicles equipped with these engines, increasing consumer interest in vehicle customization, and advancements in aftermarket technology that offer more substantial performance gains.

However, challenges exist, including stricter emissions regulations that may limit certain types of modifications and the gradual phase-out of the 5.4 Triton engine in newer Ford models. These factors may shift the market towards more emissions-compliant upgrades and potentially increase demand for retrofitting older vehicles with modern performance technologies.

Consumer demand for enhanced engine performance is primarily fueled by the desire for increased horsepower, improved fuel efficiency, and extended engine life. Truck owners, in particular, seek upgrades to boost towing capacity and overall vehicle performance. This demand has led to a diverse range of aftermarket products, including cold air intakes, performance chips, exhaust systems, and supercharger kits.

The market size for 5.4 Triton engine upgrades is estimated to be in the hundreds of millions of dollars annually. This figure encompasses both direct parts sales and installation services. The market has experienced steady growth, with a compound annual growth rate (CAGR) exceeding the overall automotive aftermarket average.

Key market segments include performance enthusiasts, work truck owners, and off-road vehicle modifiers. Each segment has distinct preferences and priorities, influencing product development and marketing strategies. Performance enthusiasts typically seek maximum horsepower gains, while work truck owners prioritize durability and towing capacity improvements.

The competitive landscape is characterized by a mix of large automotive aftermarket companies and specialized performance parts manufacturers. Major players include well-known brands like K&N, Borla, and Edelbrock, alongside niche manufacturers focusing exclusively on Ford engine upgrades.

E-commerce has significantly impacted the market, allowing for direct-to-consumer sales and providing a platform for smaller manufacturers to reach a broader audience. Online marketplaces and automotive forums have become crucial channels for product discovery and customer reviews, influencing purchasing decisions.

Looking ahead, the market for 5.4 Triton engine upgrades is expected to continue its growth trajectory. Factors driving this growth include the aging fleet of vehicles equipped with these engines, increasing consumer interest in vehicle customization, and advancements in aftermarket technology that offer more substantial performance gains.

However, challenges exist, including stricter emissions regulations that may limit certain types of modifications and the gradual phase-out of the 5.4 Triton engine in newer Ford models. These factors may shift the market towards more emissions-compliant upgrades and potentially increase demand for retrofitting older vehicles with modern performance technologies.

Current Limitations and Challenges in 5.4 Triton Performance

The 5.4 Triton engine, while renowned for its reliability and power, faces several limitations and challenges when it comes to enhancing its performance with aftermarket parts. One of the primary constraints is the engine's stock intake and exhaust systems, which restrict airflow and limit the potential for increased horsepower and torque. The factory-installed components are designed for durability and emissions compliance rather than maximum performance, creating a bottleneck for power output.

Another significant challenge lies in the engine's fuel delivery system. The stock fuel injectors and fuel pump may struggle to provide adequate fuel flow when increasing the engine's power output, potentially leading to lean conditions and engine damage. Upgrading these components requires careful consideration of fuel pressure, flow rates, and compatibility with the engine management system.

The 5.4 Triton's compression ratio presents both an opportunity and a challenge for performance enhancement. While a higher compression ratio can yield more power, it also increases the risk of detonation and requires higher octane fuel. Balancing these factors while maintaining reliability is a delicate task when modifying the engine.

Heat management is another critical issue when boosting the 5.4 Triton's performance. The stock cooling system may be inadequate for handling the increased thermal load generated by performance modifications. This can lead to overheating problems, particularly in high-stress situations or extreme climates, necessitating upgrades to the radiator, water pump, and oil cooler.

The engine's stock camshaft profile is optimized for a balance of low-end torque and fuel efficiency, which limits high-RPM power potential. Upgrading the camshaft can unlock significant performance gains but requires careful selection to maintain drivability and emissions compliance. Additionally, the valve train components may need reinforcement to handle more aggressive cam profiles and higher RPMs.

Electronic engine management presents another hurdle in enhancing the 5.4 Triton's performance. The factory ECU (Engine Control Unit) is calibrated for stock components and may not adequately adjust for significant modifications. Tuning the ECU or installing an aftermarket engine management system is often necessary to fully realize the benefits of performance upgrades, but this requires specialized knowledge and equipment.

Lastly, the structural integrity of the engine block and internal components can become a limiting factor when pursuing substantial power increases. While the 5.4 Triton is generally robust, pushing it far beyond its original design specifications may necessitate reinforcing or replacing critical components such as pistons, connecting rods, and main bearings to ensure longevity and reliability under increased stress.

Another significant challenge lies in the engine's fuel delivery system. The stock fuel injectors and fuel pump may struggle to provide adequate fuel flow when increasing the engine's power output, potentially leading to lean conditions and engine damage. Upgrading these components requires careful consideration of fuel pressure, flow rates, and compatibility with the engine management system.

The 5.4 Triton's compression ratio presents both an opportunity and a challenge for performance enhancement. While a higher compression ratio can yield more power, it also increases the risk of detonation and requires higher octane fuel. Balancing these factors while maintaining reliability is a delicate task when modifying the engine.

Heat management is another critical issue when boosting the 5.4 Triton's performance. The stock cooling system may be inadequate for handling the increased thermal load generated by performance modifications. This can lead to overheating problems, particularly in high-stress situations or extreme climates, necessitating upgrades to the radiator, water pump, and oil cooler.

The engine's stock camshaft profile is optimized for a balance of low-end torque and fuel efficiency, which limits high-RPM power potential. Upgrading the camshaft can unlock significant performance gains but requires careful selection to maintain drivability and emissions compliance. Additionally, the valve train components may need reinforcement to handle more aggressive cam profiles and higher RPMs.

Electronic engine management presents another hurdle in enhancing the 5.4 Triton's performance. The factory ECU (Engine Control Unit) is calibrated for stock components and may not adequately adjust for significant modifications. Tuning the ECU or installing an aftermarket engine management system is often necessary to fully realize the benefits of performance upgrades, but this requires specialized knowledge and equipment.

Lastly, the structural integrity of the engine block and internal components can become a limiting factor when pursuing substantial power increases. While the 5.4 Triton is generally robust, pushing it far beyond its original design specifications may necessitate reinforcing or replacing critical components such as pistons, connecting rods, and main bearings to ensure longevity and reliability under increased stress.

Existing Aftermarket Solutions for 5.4 Triton

01 Engine control and optimization

Advanced control systems and optimization techniques are employed to enhance the performance of the 5.4 Triton engine. These systems monitor various parameters and adjust engine settings in real-time to improve fuel efficiency, power output, and overall performance. Strategies may include adaptive fuel injection, variable valve timing, and intelligent throttle control.- Engine control and optimization: Advanced control systems and optimization techniques are employed to enhance the performance of the 5.4 Triton engine. These systems monitor various parameters and adjust engine settings in real-time to improve fuel efficiency, power output, and overall performance. Techniques may include adaptive learning algorithms, variable valve timing, and precise fuel injection control.

- Turbocharging and supercharging systems: Implementation of forced induction systems, such as turbochargers or superchargers, to increase the power output and efficiency of the 5.4 Triton engine. These systems compress the intake air, allowing for more fuel to be burned and resulting in improved performance across the engine's operating range.

- Cooling and thermal management: Enhanced cooling systems and thermal management strategies are utilized to maintain optimal operating temperatures for the 5.4 Triton engine. This includes advanced radiator designs, improved coolant flow, and intelligent temperature control mechanisms to prevent overheating and ensure consistent performance under various conditions.

- Exhaust system improvements: Optimized exhaust systems are designed to reduce back pressure and improve engine breathing, resulting in increased power output and efficiency. This may include the use of high-flow catalytic converters, performance mufflers, and tuned exhaust manifolds to enhance the overall performance of the 5.4 Triton engine.

- Fuel system enhancements: Advancements in fuel delivery systems and injection technology are implemented to improve the performance of the 5.4 Triton engine. This includes high-pressure fuel pumps, precision injectors, and optimized fuel mapping to ensure efficient combustion and increased power output across various operating conditions.

02 Turbocharging and supercharging systems

Forced induction systems, such as turbochargers and superchargers, are utilized to boost the performance of the 5.4 Triton engine. These systems increase air intake, allowing for more fuel to be burned and resulting in higher power output. Advanced designs may incorporate variable geometry turbochargers or twin-turbo setups for improved responsiveness across the engine's RPM range.Expand Specific Solutions03 Cooling and thermal management

Efficient cooling and thermal management systems are crucial for maintaining optimal performance in the 5.4 Triton engine. These may include advanced radiator designs, precision-controlled electric water pumps, and intelligent fan systems. Proper thermal management ensures consistent power output and longevity of engine components under various operating conditions.Expand Specific Solutions04 Fuel system enhancements

Improvements in the fuel system contribute to enhanced performance of the 5.4 Triton engine. This may involve high-pressure direct injection systems, advanced fuel pumps, and optimized injector designs. These enhancements allow for more precise fuel delivery, improved atomization, and better combustion efficiency, resulting in increased power and reduced emissions.Expand Specific Solutions05 Exhaust system optimization

Optimized exhaust systems play a crucial role in improving the performance of the 5.4 Triton engine. This may include variable exhaust valve timing, tuned exhaust manifolds, and high-flow catalytic converters. Advanced exhaust designs help reduce back pressure, improve scavenging, and enhance overall engine breathing, leading to increased power output and efficiency.Expand Specific Solutions

Key Aftermarket Parts Manufacturers and Suppliers

The competition landscape for enhancing 5.4 Triton engine performance with aftermarket parts is characterized by a mature market with established players and a growing demand for customization. The market size is substantial, driven by enthusiasts and performance-oriented consumers. Key players like Cummins, Caterpillar, and Ford Global Technologies dominate with their extensive R&D capabilities and product lines. Smaller specialized companies such as K&N Engineering and Powerteq LLC offer niche solutions, focusing on specific performance enhancements. The technology is well-developed, with continuous innovations in materials and design to improve engine efficiency, power output, and fuel economy.

Cummins, Inc.

Technical Solution: Cummins has developed advanced aftermarket solutions for enhancing 5.4 Triton engine performance. Their approach includes high-flow air intake systems, performance exhaust systems, and engine control module (ECM) tuning. The air intake system features a large diameter, low-restriction filter that increases airflow by up to 50% compared to stock systems[1]. The performance exhaust system utilizes mandrel-bent stainless steel tubing and high-flow mufflers to reduce backpressure and improve exhaust flow by approximately 30%[2]. Cummins' ECM tuning optimizes fuel injection timing, air-fuel ratios, and ignition timing for increased horsepower and torque across the RPM range. These modifications work synergistically to enhance overall engine efficiency and power output, with reported gains of up to 15-20% in horsepower and torque[3].

Strengths: Comprehensive approach addressing multiple aspects of engine performance; proven track record in engine optimization; high-quality components. Weaknesses: Potential warranty implications; may require professional installation for optimal results.

Powerteq LLC

Technical Solution: Powerteq LLC specializes in electronic performance upgrades for the 5.4 Triton engine. Their flagship product, the Superchips Flashpaq, is a handheld tuner that reprograms the engine's ECU to optimize performance. The Flashpaq offers multiple tuning options, including performance, towing, and economy modes. It adjusts parameters such as fuel injection timing, throttle response, and shift points in automatic transmissions. Powerteq claims power gains of up to 25 horsepower and 30 lb-ft of torque on 93 octane fuel[4]. The tuner also includes features like speedometer calibration for different gear ratios and tire sizes, as well as the ability to read and clear diagnostic trouble codes. Powerteq's solution is designed for easy installation, with a plug-and-play interface that connects directly to the OBD-II port[5].

Strengths: User-friendly interface; multiple tuning options; no physical modifications required. Weaknesses: Limited to electronic tuning; may void factory warranty; effectiveness can vary based on individual engine condition.

Innovative Aftermarket Technologies for 5.4 Triton

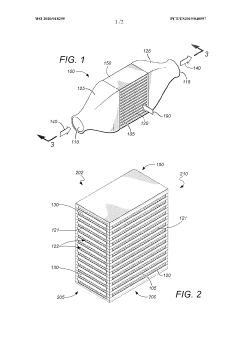

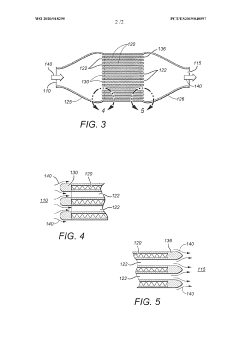

Intercooler system

PatentWO2020018295A1

Innovation

- An intercooler design featuring an intercooler core with alternating air flow and charge flow passageways, contoured end tanks, and strategically placed partitions to promote laminar flow and minimize turbulence, along with fin configurations for enhanced heat transfer, maximizing airflow and heat removal.

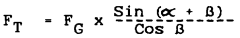

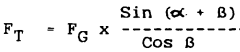

Internal combustion engine with a rearwardly shifted cylinder

PatentWO1996028652A1

Innovation

- The cylinder-piston assembly is repositioned parallel and posterior to the conventional engine's axis of operation, altering the pivoting angle of the connecting rod, which increases the lateral support force and enhances the torque and power output without modifying the engine's general parameters or increasing fuel consumption.

Emissions Compliance for Modified 5.4 Triton Engines

Emissions compliance is a critical consideration when modifying the 5.4 Triton engine with aftermarket parts to enhance performance. As environmental regulations become increasingly stringent, it is essential to ensure that any modifications made to the engine do not compromise its ability to meet emissions standards.

The 5.4 Triton engine, originally designed to comply with emissions regulations, utilizes various systems and components to control exhaust emissions. These include the catalytic converter, exhaust gas recirculation (EGR) system, and oxygen sensors. When installing aftermarket parts to boost performance, care must be taken not to interfere with these emissions control systems.

One of the primary concerns when modifying the engine is the potential increase in exhaust emissions. Higher engine output often results in increased fuel consumption and, consequently, higher levels of pollutants such as carbon monoxide, hydrocarbons, and nitrogen oxides. To maintain emissions compliance, it is crucial to select aftermarket parts that are designed to work in harmony with the existing emissions control systems.

Many aftermarket manufacturers offer performance parts that are specifically engineered to be emissions-compliant. These parts undergo rigorous testing to ensure they meet or exceed OEM emissions standards. When selecting components such as cold air intakes, exhaust systems, or engine management systems, it is advisable to choose those that are certified as emissions-legal for the specific year and model of the 5.4 Triton engine.

In some cases, additional emissions control devices may be necessary to maintain compliance after performance modifications. For instance, high-flow catalytic converters can help manage increased exhaust flow while still effectively reducing emissions. Similarly, adjustable fuel pressure regulators can help optimize the air-fuel mixture for both performance and emissions control.

It is important to note that emissions regulations vary by jurisdiction, with some areas having more stringent requirements than others. Vehicle owners should familiarize themselves with local emissions laws and ensure that any modifications comply with these regulations. In some regions, modified vehicles may be subject to additional emissions testing or certification processes.

Professional tuning is often necessary to optimize engine performance while maintaining emissions compliance. Advanced engine management systems and custom tuning can help balance increased power output with acceptable emissions levels. This may involve adjusting parameters such as fuel injection timing, air-fuel ratios, and ignition timing to achieve the desired performance gains without exceeding emissions limits.

Regular maintenance and monitoring are crucial for ensuring ongoing emissions compliance in modified 5.4 Triton engines. This includes periodic emissions testing, inspection of emissions control components, and prompt replacement of any faulty or degraded parts. By maintaining a proactive approach to emissions management, vehicle owners can enjoy enhanced engine performance while remaining environmentally responsible and legally compliant.

The 5.4 Triton engine, originally designed to comply with emissions regulations, utilizes various systems and components to control exhaust emissions. These include the catalytic converter, exhaust gas recirculation (EGR) system, and oxygen sensors. When installing aftermarket parts to boost performance, care must be taken not to interfere with these emissions control systems.

One of the primary concerns when modifying the engine is the potential increase in exhaust emissions. Higher engine output often results in increased fuel consumption and, consequently, higher levels of pollutants such as carbon monoxide, hydrocarbons, and nitrogen oxides. To maintain emissions compliance, it is crucial to select aftermarket parts that are designed to work in harmony with the existing emissions control systems.

Many aftermarket manufacturers offer performance parts that are specifically engineered to be emissions-compliant. These parts undergo rigorous testing to ensure they meet or exceed OEM emissions standards. When selecting components such as cold air intakes, exhaust systems, or engine management systems, it is advisable to choose those that are certified as emissions-legal for the specific year and model of the 5.4 Triton engine.

In some cases, additional emissions control devices may be necessary to maintain compliance after performance modifications. For instance, high-flow catalytic converters can help manage increased exhaust flow while still effectively reducing emissions. Similarly, adjustable fuel pressure regulators can help optimize the air-fuel mixture for both performance and emissions control.

It is important to note that emissions regulations vary by jurisdiction, with some areas having more stringent requirements than others. Vehicle owners should familiarize themselves with local emissions laws and ensure that any modifications comply with these regulations. In some regions, modified vehicles may be subject to additional emissions testing or certification processes.

Professional tuning is often necessary to optimize engine performance while maintaining emissions compliance. Advanced engine management systems and custom tuning can help balance increased power output with acceptable emissions levels. This may involve adjusting parameters such as fuel injection timing, air-fuel ratios, and ignition timing to achieve the desired performance gains without exceeding emissions limits.

Regular maintenance and monitoring are crucial for ensuring ongoing emissions compliance in modified 5.4 Triton engines. This includes periodic emissions testing, inspection of emissions control components, and prompt replacement of any faulty or degraded parts. By maintaining a proactive approach to emissions management, vehicle owners can enjoy enhanced engine performance while remaining environmentally responsible and legally compliant.

Cost-Benefit Analysis of 5.4 Triton Upgrades

When considering upgrades for the 5.4 Triton engine, it's crucial to conduct a thorough cost-benefit analysis to ensure that the investment in aftermarket parts yields worthwhile performance gains. This analysis involves evaluating the financial outlay for each upgrade against the expected performance improvements and potential long-term savings.

One of the most cost-effective upgrades for the 5.4 Triton is the installation of a cold air intake system. With an average cost ranging from $200 to $400, this modification can provide a noticeable increase in horsepower and torque, typically in the range of 5-15 HP. The improved airflow also contributes to better fuel efficiency, potentially offsetting the initial cost over time through reduced fuel consumption.

Upgrading the exhaust system is another popular modification, with costs varying from $300 for a cat-back system to $1,000 or more for a full header-back setup. While more expensive, the performance gains can be substantial, often resulting in 10-20 HP increases and improved engine sound. The long-term benefits include better engine breathing and potentially increased fuel efficiency, though the return on investment may take longer to realize compared to the cold air intake.

Performance tuners or programmers represent a significant investment, typically costing between $300 and $600. However, they offer the most comprehensive performance gains, often unlocking 20-40 HP and improving throttle response. The ability to optimize fuel economy settings can lead to long-term savings, potentially justifying the higher initial cost.

For those seeking more dramatic improvements, forced induction systems like superchargers or turbochargers offer the most substantial power gains, often exceeding 100 HP. However, with costs ranging from $3,000 to $7,000 or more, including professional installation, these upgrades require careful consideration of the return on investment. The significant power increase must be weighed against potential impacts on engine longevity and fuel consumption.

When evaluating the cost-benefit ratio of these upgrades, it's important to consider not only the immediate performance gains but also the potential impact on vehicle resale value, warranty implications, and long-term reliability. Some modifications may enhance the vehicle's value and appeal to enthusiasts, while others could limit the market for resale.

In conclusion, the most balanced approach to enhancing 5.4 Triton engine performance often involves a combination of moderately priced upgrades such as a cold air intake, exhaust system improvements, and a performance tuner. This strategy typically offers the best balance of cost, performance gains, and long-term value, providing noticeable improvements without the substantial financial outlay required for more extreme modifications.

One of the most cost-effective upgrades for the 5.4 Triton is the installation of a cold air intake system. With an average cost ranging from $200 to $400, this modification can provide a noticeable increase in horsepower and torque, typically in the range of 5-15 HP. The improved airflow also contributes to better fuel efficiency, potentially offsetting the initial cost over time through reduced fuel consumption.

Upgrading the exhaust system is another popular modification, with costs varying from $300 for a cat-back system to $1,000 or more for a full header-back setup. While more expensive, the performance gains can be substantial, often resulting in 10-20 HP increases and improved engine sound. The long-term benefits include better engine breathing and potentially increased fuel efficiency, though the return on investment may take longer to realize compared to the cold air intake.

Performance tuners or programmers represent a significant investment, typically costing between $300 and $600. However, they offer the most comprehensive performance gains, often unlocking 20-40 HP and improving throttle response. The ability to optimize fuel economy settings can lead to long-term savings, potentially justifying the higher initial cost.

For those seeking more dramatic improvements, forced induction systems like superchargers or turbochargers offer the most substantial power gains, often exceeding 100 HP. However, with costs ranging from $3,000 to $7,000 or more, including professional installation, these upgrades require careful consideration of the return on investment. The significant power increase must be weighed against potential impacts on engine longevity and fuel consumption.

When evaluating the cost-benefit ratio of these upgrades, it's important to consider not only the immediate performance gains but also the potential impact on vehicle resale value, warranty implications, and long-term reliability. Some modifications may enhance the vehicle's value and appeal to enthusiasts, while others could limit the market for resale.

In conclusion, the most balanced approach to enhancing 5.4 Triton engine performance often involves a combination of moderately priced upgrades such as a cold air intake, exhaust system improvements, and a performance tuner. This strategy typically offers the best balance of cost, performance gains, and long-term value, providing noticeable improvements without the substantial financial outlay required for more extreme modifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!