How to Enhance Zirconia‑Conductivity for Sensors?

Zirconia Conductivity Enhancement: Background and Objectives

Zirconia, a versatile ceramic material, has gained significant attention in the field of sensor technology due to its unique properties. The enhancement of zirconia conductivity for sensors represents a critical area of research and development, with far-reaching implications for various industries. This technological pursuit aims to improve the performance, reliability, and efficiency of sensors across multiple applications.

The evolution of zirconia-based sensors can be traced back to the 1960s when the material's potential for oxygen sensing was first recognized. Since then, the field has witnessed remarkable progress, driven by the increasing demand for high-performance sensors in automotive, aerospace, and industrial sectors. The primary objective of enhancing zirconia conductivity is to overcome the limitations of current sensor technologies and unlock new possibilities in sensing capabilities.

One of the key drivers behind this technological advancement is the growing need for more accurate and responsive sensors in critical applications. For instance, in automotive emissions control systems, zirconia-based oxygen sensors play a crucial role in optimizing engine performance and reducing harmful emissions. By enhancing the conductivity of zirconia, researchers aim to develop sensors with faster response times, improved sensitivity, and extended operational lifetimes.

The pursuit of enhanced zirconia conductivity also aligns with broader trends in materials science and nanotechnology. As our understanding of material properties at the nanoscale continues to expand, new avenues for manipulating and optimizing zirconia's conductive properties are emerging. This includes exploring novel doping strategies, investigating composite materials, and leveraging advanced manufacturing techniques to create tailored microstructures.

Furthermore, the enhancement of zirconia conductivity has implications beyond traditional sensing applications. As the Internet of Things (IoT) and smart technologies continue to proliferate, there is an increasing demand for sensors that can operate in diverse environments and integrate seamlessly with other systems. Improved zirconia conductivity could enable the development of more versatile and robust sensors capable of meeting these evolving requirements.

The technological objectives in this field are multifaceted. They include not only increasing the overall conductivity of zirconia but also enhancing its stability across a wide range of temperatures and environmental conditions. Additionally, researchers are focusing on improving the material's selectivity to specific target molecules or ions, thereby expanding its potential applications in chemical and biological sensing.

As we delve deeper into the challenge of enhancing zirconia conductivity for sensors, it is essential to consider the interdisciplinary nature of this endeavor. Success in this field requires collaboration between materials scientists, chemists, physicists, and engineers. By combining insights from these diverse disciplines, researchers aim to develop innovative solutions that push the boundaries of sensor technology and pave the way for next-generation sensing devices.

Market Analysis for High-Performance Zirconia-Based Sensors

The global market for high-performance zirconia-based sensors is experiencing significant growth, driven by increasing demand across various industries. These sensors, known for their exceptional stability, durability, and performance in harsh environments, are finding widespread applications in automotive, aerospace, healthcare, and industrial sectors.

In the automotive industry, zirconia-based sensors play a crucial role in emission control systems, helping manufacturers meet stringent environmental regulations. The growing emphasis on reducing vehicle emissions and improving fuel efficiency is expected to further boost the demand for these sensors. Additionally, the rise of electric vehicles presents new opportunities for zirconia-based sensors in battery management systems.

The aerospace sector is another key market for high-performance zirconia-based sensors. These sensors are essential for monitoring engine performance, fuel efficiency, and emissions in aircraft. As the aerospace industry continues to focus on developing more efficient and environmentally friendly aircraft, the demand for advanced sensing technologies is projected to increase.

In the healthcare sector, zirconia-based sensors are gaining traction in medical devices and diagnostic equipment. Their biocompatibility and stability make them ideal for applications such as glucose monitoring, oxygen sensing, and gas analysis in medical environments. The aging population and increasing prevalence of chronic diseases are driving factors for the growth of medical sensing technologies.

Industrial applications of zirconia-based sensors are expanding rapidly, particularly in process control, environmental monitoring, and energy management. These sensors are valued for their ability to operate reliably in high-temperature and corrosive environments, making them indispensable in industries such as oil and gas, chemical processing, and power generation.

The market for high-performance zirconia-based sensors is characterized by intense competition and continuous innovation. Key players are investing heavily in research and development to enhance sensor performance, reduce costs, and expand application areas. Emerging trends include the integration of zirconia sensors with IoT and AI technologies, enabling real-time data analysis and predictive maintenance capabilities.

Geographically, North America and Europe are currently the largest markets for high-performance zirconia-based sensors, owing to their advanced industrial infrastructure and stringent regulatory standards. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and growing investments in healthcare and aerospace sectors.

Current Challenges in Zirconia Conductivity for Sensing Applications

Zirconia-based sensors face several critical challenges in achieving optimal conductivity for sensing applications. One of the primary issues is the inherently low ionic conductivity of zirconia at room temperature. This limitation restricts the sensor's performance and responsiveness, particularly in applications requiring rapid and accurate measurements at ambient conditions.

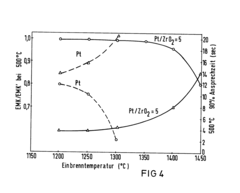

The conductivity of zirconia is highly temperature-dependent, with significant improvements observed at elevated temperatures. However, this temperature sensitivity poses challenges for sensor design and operation, as maintaining high temperatures can be energy-intensive and impractical for many sensing applications. Additionally, the need for high-temperature operation can lead to increased sensor complexity and reduced longevity due to thermal stress on components.

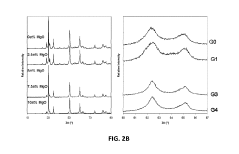

Another significant challenge is the stability of zirconia's crystal structure and its impact on conductivity. The phase transitions of zirconia, particularly between its monoclinic, tetragonal, and cubic forms, can affect its conductivity properties. Stabilizing the desired crystal structure, typically the cubic phase, which exhibits higher ionic conductivity, remains a persistent challenge in zirconia-based sensor development.

Dopant incorporation, while effective in enhancing conductivity, introduces its own set of challenges. Finding the optimal dopant type, concentration, and distribution within the zirconia matrix is crucial for maximizing conductivity without compromising other essential properties such as mechanical strength and chemical stability. The interaction between dopants and the zirconia lattice can lead to complex defect structures, which may either enhance or hinder ionic conductivity depending on their nature and concentration.

The microstructure of zirconia also plays a critical role in its conductivity. Grain boundaries and interfaces can act as barriers to ion transport, reducing overall conductivity. Controlling grain size, porosity, and interface properties during material synthesis and processing is challenging but essential for optimizing conductivity.

Environmental factors pose additional challenges for zirconia-based sensors. Exposure to varying atmospheric conditions, particularly in the presence of reactive gases or moisture, can affect the surface properties and conductivity of zirconia. Developing sensors that maintain stable and reliable performance across a range of environmental conditions remains a significant hurdle.

Lastly, the integration of zirconia-based sensing elements into practical devices presents its own set of challenges. Issues such as electrode design, sensor packaging, and signal processing must be addressed to fully leverage the enhanced conductivity of zirconia in real-world sensing applications. Balancing the trade-offs between conductivity, sensitivity, selectivity, and long-term stability in a single sensor design continues to be a complex engineering challenge.

Existing Methods for Improving Zirconia Ionic Conductivity

01 Doping zirconia to enhance conductivity

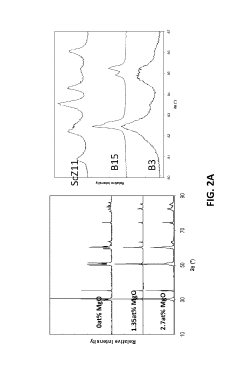

Doping zirconia with various elements or compounds can significantly improve its electrical conductivity. This method involves introducing specific impurities into the zirconia crystal structure, which creates charge carriers and enhances ionic or electronic conductivity. Common dopants include yttria, scandia, and other rare earth oxides.- Doped zirconia for improved conductivity: Zirconia can be doped with various elements to enhance its electrical conductivity. Common dopants include yttria, scandia, and other rare earth oxides. The introduction of these dopants creates oxygen vacancies in the crystal structure, facilitating ion movement and increasing overall conductivity. This approach is particularly useful in applications such as solid oxide fuel cells and oxygen sensors.

- Nanostructured zirconia for conductivity enhancement: Nanostructuring zirconia materials can significantly improve their conductivity properties. This can be achieved through various methods such as creating nanoparticles, nanowires, or nanocomposites. The increased surface area and unique properties at the nanoscale contribute to enhanced ion mobility and electron transport, leading to improved conductivity in zirconia-based materials.

- Zirconia-based composite materials for tailored conductivity: Combining zirconia with other materials to form composites can result in tailored conductivity properties. This approach allows for the integration of zirconia's beneficial properties with those of other conductive materials. Examples include zirconia-ceria composites, zirconia-alumina composites, and zirconia-based cermet materials. These composites can offer improved conductivity while maintaining other desirable characteristics of zirconia.

- Surface modification techniques for zirconia conductivity: Various surface modification techniques can be employed to enhance the conductivity of zirconia. These may include surface coating, ion implantation, or chemical treatments. By altering the surface properties, it's possible to create conductive pathways or modify the electronic structure of zirconia, leading to improved overall conductivity. This approach is particularly useful in thin film applications and electronic devices.

- Temperature-dependent conductivity of zirconia: The conductivity of zirconia is highly temperature-dependent, with significant increases observed at elevated temperatures. This property is crucial in high-temperature applications such as solid oxide fuel cells and oxygen sensors. Understanding and optimizing the temperature-conductivity relationship is essential for designing efficient zirconia-based devices and materials for specific operating conditions.

02 Controlling grain size and microstructure

The conductivity of zirconia can be influenced by manipulating its grain size and microstructure. Smaller grain sizes and specific microstructural arrangements can lead to increased grain boundary conductivity. This approach often involves careful control of sintering conditions and the addition of grain growth inhibitors.Expand Specific Solutions03 Surface modification techniques

Modifying the surface of zirconia through various treatments can enhance its conductivity. These techniques may include coating with conductive materials, creating surface defects, or altering the surface chemistry. Such modifications can improve charge transfer at interfaces and enhance overall conductivity.Expand Specific Solutions04 Composite materials with zirconia

Developing composite materials that incorporate zirconia can lead to improved conductivity. This approach involves combining zirconia with other conductive materials or creating unique structures that facilitate charge transport. These composites can exhibit enhanced electrical properties while maintaining the desirable characteristics of zirconia.Expand Specific Solutions05 Temperature and atmosphere control

The conductivity of zirconia can be significantly affected by temperature and atmospheric conditions. Controlling these parameters during processing and application can optimize the material's conductive properties. This may involve high-temperature treatments, specific gas environments, or rapid thermal cycling to induce favorable changes in the zirconia structure.Expand Specific Solutions

Key Players in Zirconia-Based Sensor Industry

The enhancement of zirconia conductivity for sensors is a critical area of research in the mature sensor technology market. The industry is in a growth phase, with increasing demand for high-performance sensors across various sectors. The global market for zirconia-based sensors is expanding, driven by applications in automotive, industrial, and environmental monitoring. Companies like Fuji Electric, DENSO, Robert Bosch, and NGK Insulators are at the forefront of this technology, investing heavily in R&D to improve zirconia conductivity. The technological maturity varies, with established players like Hitachi and Bosch leading in innovation, while newer entrants like Bloom Energy and CeramTec are bringing fresh approaches to the field. Universities and research institutions are also contributing significantly to advancing the technology's conductivity and overall performance.

Robert Bosch GmbH

NGK Insulators, Ltd.

Innovative Approaches to Enhance Zirconia Conductivity

- Development of a solid oxide fuel cell electrolyte composition using zirconia stabilized with scandia, and at least one of magnesia, zinc oxide, indium oxide, and gallium oxide, with specific dopant combinations to enhance ionic conductivity and stability, including scandia and indium oxide or scandia, indium oxide, and ceria, to achieve higher conductivity at lower temperatures.

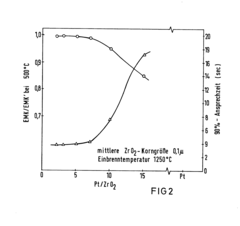

- Incorporating stabilized ZrO2 into the electrode material to maintain porosity and adhesion, and optimizing the Pt/ZrO2 ratio and baking temperature to enhance mechanical and electrical stability, while reducing sintering and improving sensitivity and response speed.

Environmental Impact of Zirconia-Based Sensor Production

The production of zirconia-based sensors has significant environmental implications that warrant careful consideration. The manufacturing process involves several stages, each with its own environmental impact. Initially, the extraction of zirconium from its primary ore, zircon, requires energy-intensive mining operations. This process often leads to habitat disruption and potential soil and water contamination if not properly managed.

The refining of zirconium into zirconia involves high-temperature processes that consume substantial amounts of energy, contributing to greenhouse gas emissions. The use of chemical treatments in this stage may also generate hazardous waste that requires specialized disposal methods to prevent environmental contamination.

In the sensor fabrication phase, the production of thin zirconia films often employs techniques such as chemical vapor deposition or sputtering. These processes may utilize environmentally sensitive gases and chemicals, necessitating stringent control measures to prevent atmospheric pollution and worker exposure.

The incorporation of dopants to enhance zirconia conductivity introduces additional environmental concerns. Some dopants may be rare earth elements, the mining of which can have severe ecological consequences, including soil erosion and water pollution. The handling and disposal of these materials require careful protocols to avoid environmental contamination.

Electronic component integration in sensor production involves the use of various metals and alloys, some of which may be toxic or difficult to recycle. This stage also generates electronic waste, which poses a growing environmental challenge globally due to its complex composition and potential for leaching harmful substances into ecosystems.

However, it's important to note that zirconia-based sensors often contribute to environmental monitoring and efficiency improvements in various industries. Their long lifespan and stability can reduce the frequency of replacement, potentially offsetting some of the environmental costs associated with their production.

Efforts to mitigate the environmental impact of zirconia sensor production include developing more efficient manufacturing processes, exploring eco-friendly dopants, and implementing comprehensive recycling programs for end-of-life sensors. Additionally, research into alternative materials and production methods that maintain or enhance sensor performance while reducing environmental footprint is ongoing.

As the demand for high-performance sensors grows, balancing technological advancement with environmental stewardship becomes increasingly crucial. The industry is gradually moving towards more sustainable practices, but significant challenges remain in minimizing the overall ecological impact of zirconia-based sensor production.

Standardization and Quality Control in Zirconia Sensor Manufacturing

Standardization and quality control are crucial aspects of zirconia sensor manufacturing, particularly when aiming to enhance zirconia conductivity for improved sensor performance. The implementation of rigorous standards and quality control measures ensures consistency, reliability, and optimal functionality of zirconia-based sensors across various applications.

One key area of focus in standardization is the raw material selection process. Establishing strict criteria for zirconia powder purity, particle size distribution, and chemical composition is essential. These parameters directly influence the final sensor's conductivity and overall performance. Implementing standardized testing protocols for raw materials helps maintain consistency across different batches and suppliers.

The manufacturing process itself requires standardized procedures to ensure uniformity in sensor production. This includes precise control of sintering temperatures, dwell times, and atmospheric conditions during the fabrication of zirconia sensors. Standardized process parameters help achieve consistent microstructure and grain boundary characteristics, which are critical factors in enhancing zirconia conductivity.

Quality control measures throughout the production line are vital for maintaining high standards. This involves regular in-process inspections, utilizing advanced analytical techniques such as X-ray diffraction (XRD) and scanning electron microscopy (SEM) to assess the crystalline structure and morphology of the zirconia sensors. Implementing statistical process control (SPC) methods helps identify and address variations in the manufacturing process that could affect sensor conductivity.

Electrical characterization is another crucial aspect of quality control in zirconia sensor manufacturing. Standardized testing procedures for measuring ionic conductivity, impedance, and response time ensure that each sensor meets the required performance specifications. Establishing acceptance criteria based on these measurements helps maintain consistent quality across production batches.

Traceability is an essential component of quality control in zirconia sensor manufacturing. Implementing a robust system for tracking raw materials, process parameters, and finished products allows for quick identification and resolution of any issues that may arise. This system also facilitates continuous improvement efforts by providing valuable data for analysis and optimization of the manufacturing process.

Calibration and validation procedures play a significant role in ensuring the accuracy and reliability of zirconia sensors. Standardized calibration methods, using certified reference materials and precise instrumentation, help maintain consistency across different production runs and between different manufacturing facilities.

To further enhance zirconia conductivity for sensors, ongoing research and development efforts should be integrated into the standardization and quality control framework. This includes exploring new dopants, optimizing grain boundary engineering techniques, and investigating novel manufacturing processes. Standardizing the evaluation and implementation of these advancements ensures that improvements in zirconia conductivity are consistently applied across the production line.