Zirconia and Its Transformative Role in Product Design

Zirconia Evolution

Zirconia, a remarkable ceramic material, has undergone a significant evolution in its application to product design over the past few decades. Initially discovered in 1789 by German chemist Martin Heinrich Klaproth, zirconia's journey from a scientific curiosity to a versatile design material has been marked by continuous innovation and technological advancements.

In the early 20th century, zirconia's potential as a refractory material was first recognized, leading to its use in high-temperature applications such as furnace linings and crucibles. However, it wasn't until the 1970s that zirconia began to make its mark in product design, particularly with the development of partially stabilized zirconia (PSZ) and tetragonal zirconia polycrystals (TZP).

The 1980s saw a surge in zirconia's popularity in the dental industry, where its biocompatibility, strength, and aesthetic properties made it an ideal material for dental crowns and implants. This period marked a turning point in zirconia's evolution, as researchers and engineers began to explore its potential beyond traditional industrial applications.

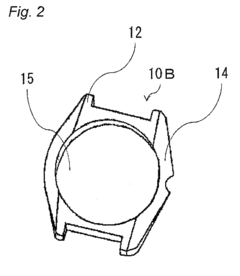

The 1990s and early 2000s witnessed a rapid expansion of zirconia's use in consumer products. The material's durability and scratch resistance made it an attractive option for luxury watches, with brands like Rado pioneering the use of high-tech ceramics in watchmaking. Simultaneously, zirconia's application in cutting tools and bearings grew, capitalizing on its wear resistance and thermal properties.

As manufacturing technologies advanced, particularly in the realm of 3D printing and computer-aided design, zirconia's potential in product design expanded further. The ability to create complex shapes and structures with precision opened up new possibilities in fields such as aerospace, automotive design, and consumer electronics.

In recent years, the focus has shifted towards enhancing zirconia's properties through nanostructuring and composite development. These advancements have led to improved mechanical properties, increased toughness, and better control over the material's aging behavior, making zirconia even more versatile in product design applications.

The evolution of zirconia in product design has been characterized by a continuous push towards maximizing its unique properties while overcoming its limitations. From its early days as a refractory material to its current status as a high-performance ceramic in various industries, zirconia's journey reflects the broader trends in materials science and engineering. As research continues, the future of zirconia in product design looks promising, with potential applications in emerging fields such as flexible electronics, advanced medical devices, and sustainable energy technologies.

Market Demand Analysis

The market demand for zirconia in product design has been experiencing significant growth, driven by its unique properties and versatile applications across various industries. The global zirconia market size was valued at USD 4.8 billion in 2020 and is projected to reach USD 8.2 billion by 2028, growing at a CAGR of 6.9% during the forecast period. This robust growth is primarily attributed to the increasing adoption of zirconia in dental and medical applications, as well as its expanding use in advanced ceramics and electronic components.

In the dental industry, zirconia has emerged as a preferred material for crowns, bridges, and implants due to its biocompatibility, durability, and aesthetic appeal. The rising prevalence of dental disorders and the growing emphasis on cosmetic dentistry are fueling the demand for zirconia-based dental products. Additionally, the aging population in developed countries is contributing to the increased need for dental restorations, further boosting market growth.

The electronics sector is another key driver of zirconia demand, particularly in the production of solid oxide fuel cells (SOFCs) and oxygen sensors. As the world shifts towards cleaner energy sources, the demand for SOFCs is expected to rise, consequently increasing the need for zirconia-based components. Moreover, the automotive industry's focus on reducing emissions and improving fuel efficiency has led to a higher adoption of oxygen sensors, which often utilize zirconia as a crucial material.

In the field of advanced ceramics, zirconia is gaining traction due to its exceptional mechanical properties, including high strength, toughness, and wear resistance. These characteristics make it an ideal material for applications in aerospace, automotive, and industrial machinery. The growing demand for lightweight and high-performance materials in these sectors is expected to drive the market for zirconia-based products.

The jewelry and luxury goods industry has also recognized the potential of zirconia as a diamond simulant and decorative material. Its brilliance, hardness, and affordability compared to natural diamonds have made it popular among consumers seeking high-quality yet cost-effective jewelry options. This trend is particularly evident in emerging markets where the middle-class population is expanding rapidly.

Despite the positive market outlook, challenges such as the high production costs of high-purity zirconia and the availability of alternative materials in certain applications may hinder market growth to some extent. However, ongoing research and development efforts aimed at improving production processes and expanding applications are expected to mitigate these challenges and create new opportunities for market expansion.

Zirconia Tech Challenges

Despite the numerous advantages of zirconia in product design, several technical challenges persist in its widespread adoption and optimal utilization. One of the primary hurdles is the complexity of controlling the phase transformation of zirconia. The material's unique property of transforming from tetragonal to monoclinic phase under stress can enhance its toughness, but managing this transformation precisely in various applications remains difficult.

The manufacturing process of zirconia components presents another significant challenge. Achieving consistent quality and dimensional accuracy in zirconia parts, especially for complex geometries, requires advanced sintering techniques and precise control over the entire production process. The high sintering temperatures needed for zirconia can lead to issues such as warping, shrinkage, and porosity, which can compromise the final product's performance and aesthetics.

Surface finishing of zirconia components is another area that demands attention. While zirconia can be polished to a high luster, achieving uniform surface finishes across complex shapes or large surface areas can be time-consuming and resource-intensive. This challenge is particularly evident in applications where both functional performance and aesthetic appeal are crucial.

The integration of zirconia with other materials in composite structures or multi-material products poses additional technical difficulties. Ensuring strong and durable bonds between zirconia and other materials, such as metals or polymers, requires innovative joining techniques and careful consideration of thermal expansion coefficients and chemical compatibility.

Customization and coloration of zirconia for specific applications represent another set of challenges. While zirconia can be colored through the addition of metal oxides, achieving consistent and stable colors across different production batches and under various environmental conditions remains a complex task. This is particularly important in industries like dentistry and luxury goods, where aesthetic consistency is paramount.

Lastly, the long-term stability and aging behavior of zirconia in various environments continue to be areas of concern. The phenomenon of low-temperature degradation, where zirconia can slowly transform and lose strength over time when exposed to moisture, needs to be addressed for applications requiring long-term reliability. Developing strategies to mitigate this effect without compromising other desirable properties of zirconia is an ongoing challenge for researchers and engineers in the field.

Current Zirconia Solutions

01 Zirconia synthesis and processing methods

Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods aim to produce zirconia with specific properties for different applications, such as improved mechanical strength or thermal stability.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods can involve different precursors, reaction conditions, and post-processing steps to achieve desired properties for specific applications.

- Zirconia-based composites and coatings: Development of zirconia-based composites and coatings for enhanced mechanical, thermal, and chemical properties. These materials often combine zirconia with other ceramics, metals, or polymers to create advanced materials with improved performance in various industrial and technological applications.

- Dental and biomedical applications of zirconia: Utilization of zirconia in dental and biomedical fields, including dental implants, crowns, and orthopedic implants. The material's biocompatibility, strength, and aesthetic properties make it suitable for these applications, with ongoing research focusing on improving its performance and integration with biological tissues.

- Zirconia in fuel cells and energy applications: Application of zirconia in solid oxide fuel cells and other energy-related technologies. The material's unique properties, such as oxygen ion conductivity and high-temperature stability, make it valuable for these applications, with research focusing on optimizing its performance and durability.

- Stabilization and phase transformation of zirconia: Methods for stabilizing zirconia in its various crystalline phases and controlling phase transformations. This includes the use of dopants and specific processing techniques to achieve desired crystal structures and properties for different applications, such as improving toughness and thermal stability.

02 Zirconia-based composites and coatings

Development of zirconia-based composites and coatings for enhanced performance in various applications. These materials combine zirconia with other substances to improve properties such as wear resistance, thermal insulation, or chemical stability. Applications include protective coatings for industrial equipment and components for extreme environments.Expand Specific Solutions03 Zirconia in dental and medical applications

Use of zirconia in dental and medical fields, particularly for prosthetics and implants. Zirconia's biocompatibility, strength, and aesthetic properties make it suitable for dental crowns, bridges, and orthopedic implants. Research focuses on improving the material's longevity and integration with biological tissues.Expand Specific Solutions04 Zirconia in fuel cells and energy applications

Application of zirconia in fuel cells and other energy-related technologies. Zirconia's unique properties, such as its oxygen ion conductivity at high temperatures, make it valuable for solid oxide fuel cells and oxygen sensors. Research aims to optimize zirconia's performance in these energy conversion and storage devices.Expand Specific Solutions05 Zirconia in advanced ceramics and refractory materials

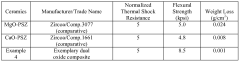

Utilization of zirconia in advanced ceramics and refractory materials for high-temperature applications. Zirconia's excellent thermal properties and chemical resistance make it suitable for use in furnace linings, thermal barrier coatings, and other high-temperature industrial applications. Research focuses on improving the material's thermal shock resistance and long-term stability.Expand Specific Solutions

Key Industry Players

The zirconia market is in a growth phase, driven by increasing demand across various industries, particularly in dental and medical applications. The global market size is expanding rapidly, with projections indicating substantial growth in the coming years. Technologically, zirconia is reaching maturity in some applications while still evolving in others. Companies like Kuraray Noritake Dental, Saint-Gobain, and Tosoh Corp. are leading in dental and industrial applications, while research institutions such as Harbin Institute of Technology and Loughborough University are pushing boundaries in advanced materials. Emerging players like BYD Co., Ltd. are exploring zirconia's potential in new sectors, indicating a dynamic and competitive landscape with opportunities for innovation and market expansion.

Tosoh Corp.

VITA Zahnfabrik H. Rauter GmbH & Co. KG

Zirconia Innovations

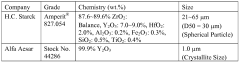

- The development of dark bluish ceramics comprising zirconia with a stabilizing agent, aluminum oxide (1-30% by mass), cobalt oxide (0.5-5% by mass), and either chromium oxide, nickel oxide, or iron oxide (up to 1% by mass), which suppresses grain growth and enhances mechanical properties while achieving a dark bluish color tone.

- A stabilized zirconia ceramic composition with a multimodal grain distribution and a preservative component is developed, featuring at least 20% of a coarse grain mode with a D50 size of 5-800 μm, 1% of a fine grain mode with a D50 size up to one-fourth of the coarse grain, and 1% of a preservative component, providing enhanced thermal shock resistance and chemical stability.

Zirconia Sustainability

Zirconia, a versatile and sustainable material, is increasingly gaining attention in product design due to its exceptional properties and environmental benefits. As industries strive for more sustainable practices, zirconia emerges as a promising alternative to traditional materials, offering a unique combination of durability, aesthetics, and eco-friendliness.

One of the key sustainability advantages of zirconia lies in its longevity. The material's exceptional hardness and wear resistance contribute to extended product lifespans, reducing the need for frequent replacements and minimizing waste generation. This durability factor aligns with the principles of circular economy, promoting resource efficiency and reducing the overall environmental impact of consumer goods.

Furthermore, zirconia's production process can be optimized for sustainability. Advanced manufacturing techniques, such as precision sintering and near-net-shape forming, minimize material waste during fabrication. These processes not only conserve raw materials but also reduce energy consumption, contributing to a lower carbon footprint compared to conventional manufacturing methods.

The recyclability of zirconia products presents another significant sustainability benefit. While not as easily recyclable as some metals, zirconia can be ground and repurposed for various applications, including abrasives and refractory materials. This potential for material recovery and reuse further enhances its circular economy credentials, reducing the demand for virgin raw materials.

In terms of environmental impact, zirconia offers advantages over certain alternative materials. For instance, when compared to some plastics or metals, zirconia products often have a lower overall lifecycle impact due to their longevity and potential for recycling. Additionally, zirconia's inert nature means it does not leach harmful substances into the environment, making it a safer choice for both consumers and ecosystems.

The energy efficiency of zirconia-based products also contributes to their sustainability profile. In applications such as thermal barrier coatings or high-temperature components, zirconia's excellent thermal insulation properties can lead to significant energy savings in various industries, from aerospace to energy production.

As sustainability becomes an increasingly critical factor in product design and material selection, zirconia's role is likely to expand. Its unique combination of performance characteristics and environmental benefits positions it as a material of choice for designers and engineers seeking to create more sustainable products across diverse sectors.

Zirconia Design Impact

Zirconia has emerged as a transformative material in product design, revolutionizing various industries with its unique properties and versatile applications. This ceramic material's impact on design has been profound, offering designers and engineers new possibilities for creating innovative and high-performance products.

One of the most significant impacts of zirconia in product design is its ability to combine strength and aesthetics. Its exceptional mechanical properties, including high flexural strength and fracture toughness, allow for the creation of durable and long-lasting products. Simultaneously, zirconia's natural white color and ability to be tinted or colored provide designers with a wide range of aesthetic options, making it an ideal material for both functional and visually appealing products.

In the field of dentistry, zirconia has transformed the design of dental prosthetics. Its biocompatibility, coupled with its strength and aesthetic qualities, has led to the development of more natural-looking and longer-lasting dental crowns, bridges, and implants. This has not only improved patient satisfaction but also revolutionized the way dental professionals approach restorative treatments.

The jewelry industry has also been significantly impacted by zirconia's design potential. Cubic zirconia, a synthetic gemstone made from zirconium dioxide, has become a popular alternative to diamonds. Its brilliance and durability have allowed designers to create affordable yet visually stunning jewelry pieces, democratizing access to high-end designs.

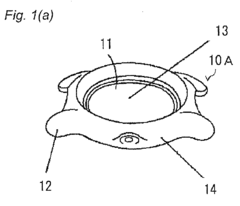

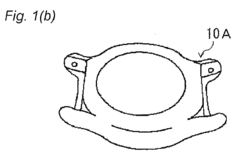

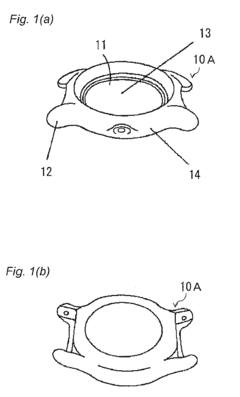

In the realm of consumer electronics, zirconia has found applications in the design of smartphone and smartwatch components. Its scratch resistance and durability make it an excellent choice for device screens and casings, enhancing product longevity and user experience. The material's ability to be polished to a high shine also contributes to the premium look and feel of these devices.

Zirconia's impact extends to industrial design as well. Its high temperature resistance and low thermal conductivity have led to its use in the design of cutting tools, bearings, and other components subjected to extreme conditions. This has enabled the creation of more efficient and longer-lasting industrial equipment, contributing to improved productivity and reduced maintenance costs.

The automotive industry has also benefited from zirconia's design capabilities. Its use in oxygen sensors, which are critical components in modern engine management systems, has improved fuel efficiency and reduced emissions. Additionally, zirconia's application in ceramic brake rotors has led to the design of high-performance braking systems that offer superior heat resistance and reduced weight compared to traditional metal rotors.

As designers and engineers continue to explore the potential of zirconia, its impact on product design is likely to grow even further. The material's unique combination of properties opens up new avenues for innovation across various sectors, promising to shape the future of product design in exciting and unexpected ways.