How to Maximize Zirconia Performance in Cutting Tools?

Zirconia Cutting Tools: Background and Objectives

Zirconia has emerged as a significant material in the cutting tool industry, revolutionizing the way manufacturers approach precision machining. The evolution of zirconia in cutting tools can be traced back to the mid-20th century when ceramic materials began to gain traction in industrial applications. Initially, zirconia was primarily used as a coating material to enhance the durability of cutting tools. However, as research progressed, the potential of zirconia as a standalone material for cutting tools became increasingly apparent.

The development of zirconia cutting tools has been driven by the growing demand for high-performance machining solutions in industries such as aerospace, automotive, and medical device manufacturing. These sectors require tools capable of maintaining precision and efficiency when working with hard-to-machine materials like superalloys, hardened steels, and composites. Zirconia's unique properties, including high hardness, excellent wear resistance, and thermal stability, make it an ideal candidate for such challenging applications.

Over the years, researchers and engineers have focused on improving the microstructure and composition of zirconia to enhance its performance in cutting tools. Key advancements include the development of partially stabilized zirconia (PSZ) and tetragonal zirconia polycrystals (TZP), which exhibit superior mechanical properties compared to traditional ceramics. These innovations have significantly expanded the range of applications for zirconia cutting tools, enabling them to compete with and, in some cases, outperform conventional carbide and high-speed steel tools.

The primary objective in maximizing zirconia performance in cutting tools is to achieve an optimal balance between hardness, toughness, and thermal stability. This involves refining the material's grain structure, optimizing the stabilizing agents, and developing novel manufacturing processes to produce tools with consistent quality and performance. Additionally, researchers aim to enhance the tool's edge retention, reduce friction during cutting, and improve chip evacuation to increase overall machining efficiency.

Another critical goal is to expand the application range of zirconia cutting tools. While they have proven highly effective in certain niche applications, there is still significant potential for growth in broader machining operations. This includes developing zirconia tools suitable for high-speed machining, improving their performance in interrupted cutting conditions, and enhancing their compatibility with various coolant strategies.

As the industry continues to evolve, the focus is shifting towards developing hybrid and composite cutting tools that combine the benefits of zirconia with other advanced materials. This approach aims to create cutting tools that can adapt to a wider range of machining conditions while maintaining the superior wear resistance and thermal properties of zirconia. The ultimate goal is to establish zirconia-based cutting tools as a versatile and indispensable solution in modern manufacturing processes, capable of meeting the ever-increasing demands for precision, efficiency, and sustainability in industrial machining operations.

Market Analysis for High-Performance Cutting Tools

The market for high-performance cutting tools has experienced significant growth in recent years, driven by the increasing demand for precision machining across various industries. Zirconia-based cutting tools have emerged as a key player in this market, offering superior hardness, wear resistance, and thermal stability compared to traditional materials.

The global cutting tools market was valued at approximately $8.3 billion in 2020 and is projected to reach $10.5 billion by 2026, growing at a CAGR of 4.1% during the forecast period. Within this market, zirconia-based cutting tools are gaining traction due to their exceptional performance characteristics, particularly in high-speed and high-temperature applications.

Key industries driving the demand for high-performance cutting tools include automotive, aerospace, medical devices, and general manufacturing. The automotive sector, in particular, has been a major contributor to market growth, with the increasing adoption of lightweight materials and complex component designs requiring advanced cutting solutions.

The aerospace industry is another significant market for zirconia-based cutting tools, as manufacturers seek to improve efficiency and reduce costs in the production of aircraft components. The need for precision machining of difficult-to-cut materials like titanium alloys and composites has further boosted the demand for high-performance cutting tools.

Geographically, Asia-Pacific dominates the cutting tools market, accounting for over 40% of the global market share. This is primarily due to the rapid industrialization and growth of manufacturing sectors in countries like China, India, and Japan. North America and Europe follow closely, with strong demand from established manufacturing industries and ongoing technological advancements.

The market for zirconia-based cutting tools is characterized by intense competition among key players, including Sandvik, Kennametal, Mitsubishi Materials, and Kyocera. These companies are investing heavily in research and development to enhance the performance of zirconia-based tools and expand their product portfolios.

As manufacturers across industries continue to prioritize efficiency, productivity, and cost-effectiveness, the demand for high-performance cutting tools is expected to grow steadily. Zirconia-based tools are well-positioned to capture a significant share of this market, driven by their superior properties and ability to meet the evolving needs of modern manufacturing processes.

Current Challenges in Zirconia Cutting Tool Technology

Zirconia cutting tools have gained significant attention in the manufacturing industry due to their exceptional hardness, wear resistance, and thermal stability. However, several challenges persist in maximizing their performance and widespread adoption. One of the primary issues is the inherent brittleness of zirconia, which can lead to chipping and premature tool failure under high-stress cutting conditions. This brittleness limits the application of zirconia tools in heavy-duty machining operations where toughness is crucial.

Another significant challenge is the difficulty in achieving and maintaining a sharp cutting edge. While zirconia's hardness contributes to its wear resistance, it also makes the material challenging to grind and shape into precise cutting geometries. This limitation can affect the tool's cutting efficiency and surface finish quality, particularly in high-precision applications.

The thermal management of zirconia cutting tools presents another hurdle. Although zirconia has good thermal stability compared to some other ceramics, it still experiences thermal shock under rapid temperature changes during cutting operations. This can lead to micro-cracks and accelerated wear, reducing tool life and reliability.

Adhesion between the zirconia cutting edge and the workpiece material is also a concern, especially when machining ductile materials like certain metals. This adhesion can cause built-up edge formation, which negatively impacts surface finish and dimensional accuracy of the machined parts.

The cost-effectiveness of zirconia cutting tools remains a challenge for widespread industrial adoption. While their performance can be superior in certain applications, the higher initial cost compared to traditional carbide tools and the specialized knowledge required for their optimal use can deter some manufacturers from integrating them into their processes.

Furthermore, the limited toughness of zirconia tools restricts their use in interrupted cutting operations or when machining materials with inconsistent hardness. This limitation narrows the range of applications where zirconia tools can be effectively employed, potentially requiring manufacturers to maintain multiple tooling systems for different operations.

Addressing these challenges requires a multifaceted approach, combining materials science innovations, advanced manufacturing techniques, and optimized cutting strategies. Researchers and manufacturers are exploring various avenues, including the development of composite zirconia materials, novel coating technologies, and improved tool geometries to enhance performance and broaden the application scope of zirconia cutting tools.

Existing Strategies for Enhancing Zirconia Performance

01 Mechanical properties of zirconia

Zirconia exhibits excellent mechanical properties, including high strength, toughness, and wear resistance. These characteristics make it suitable for various applications in industries such as aerospace, automotive, and medical devices. The performance of zirconia can be further enhanced through specific processing techniques and composition adjustments.- Mechanical properties of zirconia: Zirconia exhibits exceptional mechanical properties, including high strength, toughness, and wear resistance. These characteristics make it suitable for various applications in industries such as aerospace, automotive, and medical devices. The performance of zirconia can be further enhanced through specific processing techniques and composition adjustments.

- Thermal stability and insulation: Zirconia demonstrates excellent thermal stability and insulation properties, making it valuable in high-temperature applications. It maintains its structural integrity and performance under extreme heat conditions, which is crucial in industries such as ceramics, refractories, and thermal barrier coatings.

- Optical and electrical properties: Zirconia possesses unique optical and electrical properties, including high refractive index and ionic conductivity. These characteristics make it suitable for applications in optical coatings, solid oxide fuel cells, and sensors. The performance of zirconia in these areas can be tailored through doping and microstructure control.

- Biocompatibility and dental applications: Zirconia exhibits excellent biocompatibility, making it ideal for medical and dental applications. Its performance in dental implants, crowns, and bridges is particularly noteworthy due to its strength, aesthetics, and resistance to corrosion. The material's properties can be optimized for specific dental requirements through various processing methods.

- Chemical resistance and catalytic properties: Zirconia demonstrates high chemical resistance and catalytic properties, making it valuable in chemical processing and environmental applications. Its performance as a catalyst support or as a catalyst itself can be enhanced through surface modifications and nanostructuring techniques. The material's stability in harsh chemical environments contributes to its versatility in various industrial processes.

02 Thermal properties and stability of zirconia

Zirconia demonstrates remarkable thermal properties, including high melting point and low thermal conductivity. These attributes make it an ideal material for high-temperature applications such as thermal barrier coatings and refractory materials. The thermal stability of zirconia can be improved through the addition of stabilizing agents or by controlling its crystal structure.Expand Specific Solutions03 Optical properties of zirconia

Zirconia possesses unique optical properties, including high refractive index and transparency in certain wavelength ranges. These characteristics make it suitable for applications in optical components, such as lenses and optical fibers. The optical performance of zirconia can be tailored by controlling its composition and microstructure.Expand Specific Solutions04 Biocompatibility and dental applications of zirconia

Zirconia exhibits excellent biocompatibility, making it an ideal material for dental and medical implants. Its performance in dental applications includes high strength, wear resistance, and aesthetic properties. The biocompatibility of zirconia can be further enhanced through surface modifications and specific processing techniques.Expand Specific Solutions05 Chemical resistance and catalytic properties of zirconia

Zirconia demonstrates exceptional chemical resistance and catalytic properties, making it suitable for applications in harsh chemical environments and as a catalyst support. Its performance in these areas can be improved through the control of surface area, porosity, and the addition of specific dopants or modifiers.Expand Specific Solutions

Key Players in Zirconia Cutting Tool Industry

The zirconia cutting tools market is in a growth phase, driven by increasing demand for high-performance machining solutions across industries. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, zirconia cutting tools are reaching maturity, with companies like Kennametal, Kyocera, and Sandvik leading innovation. These firms are focusing on enhancing zirconia's toughness, wear resistance, and thermal stability. Emerging players such as Sumitomo Electric Industries and Saint-Gobain are also contributing to advancements in zirconia composites and coatings. The competitive landscape is characterized by a mix of established manufacturers and specialized materials science companies, all striving to maximize zirconia's performance in cutting applications.

Sumitomo Electric Hardmetal Ltd.

Kennametal, Inc.

Innovative Approaches in Zirconia Cutting Tool Design

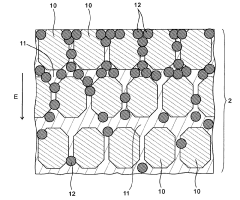

- A zirconia raw material composition containing specific proportions of yttria, silica, sodium oxide, and alumina, along with controlled particle sizes and surface silica compounds, forms a compressive stress layer on the surface of the sintered body, preventing internal stress and phase transformation.

- Incorporating 5-35 weight-% disc-shaped whiskers with specific dimensions and monoclinic or tetragonal zirconia particles into alumina or silicon nitride matrices, optionally with chromium and refractory nitrides or carbides, to enhance toughness and thermal conductivity.

Environmental Impact of Zirconia Cutting Tools

The environmental impact of zirconia cutting tools is a crucial consideration in the broader context of sustainable manufacturing practices. Zirconia, as a ceramic material, offers several environmental advantages over traditional cutting tool materials such as tungsten carbide or high-speed steel. The production of zirconia cutting tools generally requires less energy compared to metal-based alternatives, resulting in a lower carbon footprint during the manufacturing process.

One of the key environmental benefits of zirconia cutting tools is their extended lifespan. Due to their high wear resistance and thermal stability, these tools can maintain their cutting edge for longer periods, reducing the frequency of tool replacement. This longevity translates to fewer resources consumed in tool production and less waste generated over time. Additionally, the reduced need for tool changes leads to decreased machine downtime, further enhancing overall energy efficiency in manufacturing operations.

Zirconia cutting tools also contribute to improved machining efficiency, which indirectly benefits the environment. Their ability to operate at higher cutting speeds and feed rates allows for faster material removal, potentially reducing the overall energy consumption of machining processes. This increased efficiency can lead to shorter production times and lower power requirements, contributing to a reduction in the carbon footprint of manufacturing activities.

The use of zirconia in cutting tools also presents opportunities for dry machining or minimal lubrication techniques. This approach significantly reduces or eliminates the need for cutting fluids, which are often associated with environmental concerns due to their disposal and potential contamination of water sources. By enabling dry machining, zirconia cutting tools help minimize the environmental impact related to coolant usage and disposal.

However, it is important to consider the end-of-life aspects of zirconia cutting tools. While they offer extended service life, the disposal or recycling of worn-out zirconia tools presents challenges. Unlike metal-based tools, which can be more easily recycled, the recycling process for ceramic materials like zirconia is more complex and less developed. This aspect highlights the need for further research and development in recycling technologies for advanced ceramic materials to fully realize their environmental potential.

In conclusion, zirconia cutting tools offer significant environmental advantages through their energy-efficient production, extended lifespan, improved machining efficiency, and potential for dry machining. However, to maximize their positive environmental impact, continued efforts are needed to address end-of-life management and recycling challenges. As industries increasingly focus on sustainable manufacturing practices, the role of zirconia cutting tools in reducing environmental footprint becomes increasingly significant.

Cost-Benefit Analysis of Zirconia vs. Alternative Materials

When considering the implementation of zirconia in cutting tools, a comprehensive cost-benefit analysis is crucial to determine its viability compared to alternative materials. Zirconia offers several advantages that can potentially justify its higher initial cost. The material's exceptional hardness and wear resistance contribute to extended tool life, reducing the frequency of replacements and associated downtime. This longevity can lead to significant cost savings over time, particularly in high-volume production environments.

The thermal properties of zirconia also play a role in its cost-effectiveness. Its low thermal conductivity helps maintain the cutting edge's integrity during high-speed operations, potentially allowing for increased cutting speeds and productivity. This improved performance can translate into higher output and reduced machining times, offsetting the initial investment in zirconia-based tools.

However, the cost analysis must also consider the challenges associated with zirconia. The material's brittleness can lead to chipping or fracturing under certain conditions, potentially resulting in unexpected tool failures and production interruptions. The cost of mitigating these risks through careful tool design and application-specific engineering should be factored into the overall analysis.

When compared to traditional carbide cutting tools, zirconia generally comes at a premium. The manufacturing process for zirconia tools is more complex and energy-intensive, contributing to higher production costs. However, the extended tool life and potential for improved cutting performance may justify this higher upfront expense in many applications.

Alternatives such as ceramic-based cutting tools or diamond-coated inserts should also be considered in the cost-benefit analysis. While these materials may offer similar or even superior performance in certain applications, they often come with their own set of trade-offs in terms of cost, brittleness, or limitations in machining certain materials.

The economic viability of zirconia in cutting tools is highly dependent on the specific application and production environment. In high-precision machining or when working with difficult-to-cut materials, the benefits of zirconia may more readily outweigh its costs. Conversely, in less demanding applications or where tool life is not a critical factor, traditional materials may prove more cost-effective.

To maximize the cost-benefit ratio of zirconia cutting tools, manufacturers should focus on optimizing tool design and application parameters. This includes developing specialized geometries that leverage zirconia's unique properties while minimizing its weaknesses. Additionally, investing in advanced coating technologies can further enhance the performance and longevity of zirconia tools, potentially improving their cost-effectiveness across a broader range of applications.