How to Innovate Zirconia Applications for Future Markets?

Zirconia Tech Evolution

Zirconia technology has undergone significant evolution since its discovery in the late 18th century. Initially recognized for its refractory properties, zirconia's potential remained largely untapped until the mid-20th century. The development of stabilized zirconia in the 1970s marked a pivotal moment, opening up new possibilities for its application across various industries.

The 1980s saw a surge in zirconia research, particularly in the field of ceramics. Scientists and engineers focused on improving its mechanical properties, leading to the development of partially stabilized zirconia (PSZ) and tetragonal zirconia polycrystals (TZP). These advancements significantly enhanced zirconia's strength, toughness, and wear resistance, making it suitable for a wider range of applications.

In the 1990s and early 2000s, zirconia found its way into the medical and dental industries. The material's biocompatibility and aesthetic properties made it an ideal choice for dental implants and prosthetics. Concurrently, the automotive and aerospace sectors began exploring zirconia's potential for high-temperature applications, such as thermal barrier coatings and fuel cell components.

The past two decades have witnessed a rapid expansion of zirconia applications. Nanotechnology has played a crucial role in this evolution, enabling the production of zirconia nanoparticles and nanocomposites with enhanced properties. These innovations have led to breakthroughs in areas such as catalysis, sensors, and energy storage devices.

Recent years have seen a growing interest in zirconia's potential for advanced manufacturing techniques, particularly additive manufacturing. 3D printing of zirconia components has opened up new possibilities for complex geometries and customized designs, especially in the medical and aerospace industries.

Looking ahead, the evolution of zirconia technology is expected to continue at an accelerated pace. Researchers are exploring novel synthesis methods and composite materials to further enhance zirconia's properties. The integration of zirconia with other advanced materials, such as graphene and carbon nanotubes, holds promise for next-generation applications in electronics and energy sectors.

As environmental concerns grow, there is an increasing focus on developing sustainable production methods for zirconia and exploring its potential in green technologies. This includes its use in more efficient fuel cells, advanced filtration systems, and environmentally friendly catalysts.

The future of zirconia technology lies in its ability to meet the demands of emerging markets and address global challenges. As research continues to unlock new properties and applications, zirconia is poised to play a crucial role in shaping the materials landscape of the future, driving innovation across multiple industries and contributing to technological advancements in ways we are only beginning to imagine.

Market Demand Analysis

The market demand for zirconia applications is experiencing significant growth across various industries, driven by its unique properties and versatility. In the dental sector, zirconia has become increasingly popular for crowns, bridges, and implants due to its biocompatibility, durability, and aesthetic appeal. The global dental zirconia market is projected to expand at a compound annual growth rate (CAGR) of over 7% in the coming years, fueled by rising dental procedures and growing awareness of oral health.

In the aerospace and automotive industries, zirconia's high strength, thermal resistance, and low thermal conductivity make it an attractive material for thermal barrier coatings and engine components. As these sectors focus on improving fuel efficiency and reducing emissions, the demand for zirconia-based materials is expected to surge. The global thermal barrier coatings market, where zirconia plays a crucial role, is anticipated to grow at a CAGR of around 6% over the next five years.

The electronics industry is another key driver of zirconia demand, particularly in the production of solid oxide fuel cells (SOFCs) and sensors. With the increasing focus on clean energy solutions and IoT applications, the market for zirconia-based electronic components is set to expand rapidly. The global SOFC market is forecasted to grow at a CAGR of over 25% in the coming years, presenting significant opportunities for zirconia applications.

In the field of advanced ceramics, zirconia is gaining traction for its use in cutting tools, wear-resistant components, and high-temperature applications. The global advanced ceramics market, including zirconia-based products, is expected to grow at a CAGR of around 8% over the next decade, driven by demand from industries such as manufacturing, energy, and defense.

The healthcare sector, beyond dentistry, is also showing increased interest in zirconia for orthopedic implants and surgical instruments. The biomedical zirconia market is projected to grow steadily, supported by an aging population and advancements in medical technology.

As environmental concerns and sustainability become more prominent, there is a growing demand for zirconia in water treatment applications, particularly for membrane technologies and catalysts. This emerging market segment presents new opportunities for innovation and market expansion.

To capitalize on these market trends, companies must focus on developing novel zirconia-based products that address specific industry needs, improve manufacturing processes to reduce costs, and invest in research to explore new applications. Collaborations between material scientists, industry experts, and end-users will be crucial in driving innovation and expanding the market for zirconia applications across various sectors.

Current Challenges

Zirconia, a versatile ceramic material, faces several challenges in its current applications and future market expansion. One of the primary obstacles is the high cost of production, which limits its widespread adoption in various industries. The complex manufacturing process, involving high-temperature sintering and precision machining, contributes significantly to the overall expense. This cost factor often makes zirconia less competitive compared to alternative materials in price-sensitive markets.

Another significant challenge lies in the material's inherent brittleness. While zirconia exhibits excellent strength and hardness, its susceptibility to sudden fracture under certain conditions poses concerns for long-term reliability in critical applications. This characteristic limits its use in scenarios where impact resistance or flexibility is crucial, necessitating careful design considerations and potential trade-offs in performance.

The limited thermal shock resistance of zirconia presents additional hurdles in expanding its application range. Rapid temperature changes can induce stress within the material, leading to cracking or failure. This constraint restricts zirconia's use in environments with frequent thermal cycling or extreme temperature fluctuations, narrowing its potential market segments.

Furthermore, the complexity of processing and shaping zirconia components poses challenges in manufacturing efficiency and scalability. The material's hardness, while beneficial for wear resistance, makes it difficult to machine and form into intricate shapes. This limitation can hinder innovation in product design and restrict the development of complex geometries that might be required for advanced applications.

The environmental impact of zirconia production and disposal is an emerging concern that needs addressing for future market growth. The energy-intensive manufacturing process and the limited recyclability of zirconia products raise questions about sustainability. As global industries increasingly prioritize eco-friendly materials and processes, finding ways to reduce the environmental footprint of zirconia becomes crucial for its long-term viability.

Lastly, the lack of standardization in zirconia grades and properties across different manufacturers creates challenges in quality control and consistency. This variability can lead to uncertainties in performance and reliability, potentially limiting customer confidence and adoption rates in new markets. Establishing industry-wide standards and improving quality assurance processes are essential steps in overcoming this hurdle and expanding zirconia's market presence.

Existing Applications

01 Zirconia synthesis and processing methods

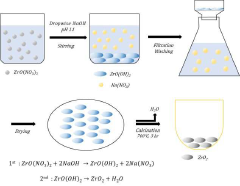

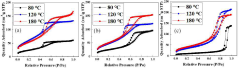

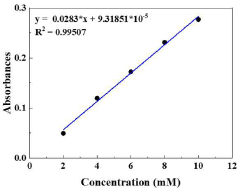

Various techniques for synthesizing and processing zirconia materials, including sol-gel methods, hydrothermal synthesis, and sintering processes. These methods aim to control the crystalline structure, particle size, and properties of zirconia for different applications.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods aim to produce zirconia with specific properties suitable for different applications in industries such as ceramics, electronics, and catalysis.

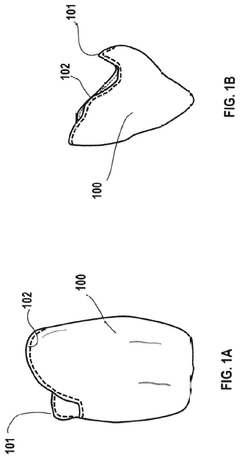

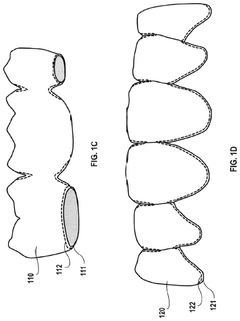

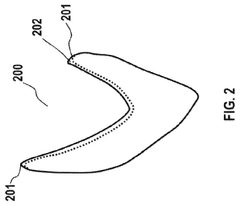

- Zirconia-based dental materials: Zirconia is widely used in dental applications due to its biocompatibility, strength, and aesthetic properties. Innovations in this field include improved formulations for dental prosthetics, crowns, and implants, as well as novel manufacturing techniques to enhance the material's performance and durability in oral environments.

- Zirconia in advanced ceramics and composites: Zirconia plays a crucial role in the development of advanced ceramics and composites. Research focuses on enhancing the mechanical, thermal, and electrical properties of zirconia-based materials for applications in aerospace, automotive, and energy sectors. This includes the creation of novel composite structures and the optimization of material properties.

- Zirconia in catalysis and environmental applications: Zirconia-based materials are explored for their catalytic properties and potential in environmental applications. This includes the development of zirconia-supported catalysts for various chemical processes, as well as the use of zirconia in pollution control technologies and water treatment systems.

- Surface modification and functionalization of zirconia: Techniques for modifying and functionalizing zirconia surfaces are investigated to tailor the material's properties for specific applications. This includes the development of coatings, surface treatments, and the incorporation of additives to enhance characteristics such as wear resistance, chemical stability, and biocompatibility.

02 Zirconia-based dental materials

Development of zirconia-based materials for dental applications, such as crowns, bridges, and implants. These materials offer high strength, biocompatibility, and aesthetic properties suitable for dental restorations.Expand Specific Solutions03 Zirconia in catalysis and fuel cells

Utilization of zirconia as a catalyst support or component in catalytic systems and solid oxide fuel cells. Zirconia's thermal stability and oxygen ion conductivity make it valuable for these applications.Expand Specific Solutions04 Zirconia coatings and thin films

Methods for depositing zirconia coatings and thin films on various substrates. These coatings can provide wear resistance, thermal insulation, and corrosion protection in industrial applications.Expand Specific Solutions05 Zirconia composites and nanostructures

Development of zirconia-based composites and nanostructured materials, combining zirconia with other materials to enhance mechanical, thermal, and electrical properties for advanced applications in aerospace, electronics, and energy sectors.Expand Specific Solutions

Key Industry Players

The zirconia applications market is in a growth phase, driven by increasing demand across various industries. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, zirconia applications are evolving rapidly, with companies like Tosoh Corp., Kyocera Corp., and Saint-Gobain Ceramics & Plastics leading innovation efforts. These firms, along with research institutions such as Harbin Institute of Technology and Central South University, are pushing the boundaries of zirconia's capabilities. The competitive landscape is diverse, featuring both established players and emerging companies, each striving to develop novel applications and improve existing ones. As the technology matures, we're seeing a shift towards more specialized and high-performance zirconia products, opening up new market opportunities across sectors like electronics, healthcare, and advanced materials.

Kyocera Corp.

Tosoh Corp.

Innovative Research

- Zirconia powder with a specific surface area of 200 to 250 m2/g, average pore size of 3 to 4.5 nm, and average particle diameter of 1 to 5 µm, produced through a method involving dissolving a zirconium precursor, adding a basic solution, heating, separating and drying solids, and calcining, to achieve uniform drug release.

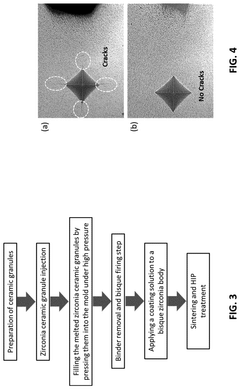

- A method involving ceramic injection molding of yttria-stabilized zirconia powder with a thermoplastic organic binder, followed by heat treatment, application of a tantalum or niobium-containing solution to form a functional gradient coating layer, and hot isostatic pressing to enhance flexural strength and fracture toughness.

Sustainability Aspects

Sustainability has become a critical aspect in the development and application of zirconia materials for future markets. As industries worldwide strive to reduce their environmental footprint, zirconia's unique properties offer significant potential for sustainable innovations. The material's exceptional durability and resistance to wear and corrosion contribute to longer product lifespans, reducing the need for frequent replacements and minimizing waste generation.

In the energy sector, zirconia-based solid oxide fuel cells (SOFCs) are emerging as a promising clean energy technology. These fuel cells offer high efficiency and low emissions, making them an attractive option for sustainable power generation. Ongoing research focuses on improving the performance and cost-effectiveness of zirconia-based SOFCs, potentially revolutionizing distributed energy systems and contributing to the transition towards renewable energy sources.

The automotive industry is another area where zirconia's sustainability aspects shine. Its use in advanced ceramic coatings for engine components can significantly enhance fuel efficiency and reduce emissions. As the industry shifts towards electric vehicles, zirconia's role in improving battery technology and thermal management systems becomes increasingly important, supporting the development of more sustainable transportation solutions.

In the field of water treatment, zirconia-based membranes and adsorbents show promise for efficient and environmentally friendly purification processes. These materials can effectively remove contaminants from water while requiring less energy and fewer chemicals compared to conventional methods. This application aligns with global efforts to ensure access to clean water and promote sustainable water management practices.

The construction sector is exploring zirconia-based materials for sustainable building solutions. Zirconia's thermal insulation properties can contribute to energy-efficient buildings, reducing heating and cooling costs. Additionally, its durability and resistance to weathering can lead to longer-lasting structures, minimizing the need for repairs and replacements over time.

As sustainability becomes increasingly important in product design and manufacturing, zirconia's potential for recycling and reuse is being investigated. While challenges exist due to its high melting point and chemical stability, innovative recycling techniques are being developed to recover and repurpose zirconia from end-of-life products, further enhancing its sustainability profile.

To fully leverage zirconia's sustainability aspects, future research should focus on optimizing production processes to reduce energy consumption and minimize waste. Additionally, exploring bio-based precursors for zirconia synthesis could further enhance its environmental credentials. By addressing these challenges and capitalizing on zirconia's inherent sustainable properties, industries can innovate and develop more environmentally friendly products and processes for future markets.

Regulatory Landscape

The regulatory landscape for zirconia applications is complex and evolving, with various standards and guidelines in place across different regions and industries. In the medical field, zirconia-based dental implants and prosthetics are subject to stringent regulations by health authorities such as the FDA in the United States and the EMA in Europe. These agencies require extensive clinical trials and safety assessments before approving new zirconia-based medical devices.

In the aerospace and automotive sectors, zirconia components must comply with strict safety and performance standards set by organizations like the FAA and NHTSA. These regulations often focus on material properties, durability, and resistance to extreme conditions. As zirconia finds new applications in these industries, manufacturers must navigate an intricate web of certifications and compliance requirements.

Environmental regulations also play a significant role in shaping the future of zirconia applications. With increasing emphasis on sustainability, regulators are scrutinizing the environmental impact of zirconia production and disposal. This has led to the development of more eco-friendly manufacturing processes and recycling initiatives for zirconia-based products.

In the electronics industry, zirconia's use in advanced ceramics for semiconductors and other components is subject to regulations governing electronic waste and hazardous materials. The RoHS directive in the European Union, for instance, restricts the use of certain substances in electrical and electronic equipment, influencing the design and composition of zirconia-based electronic components.

As zirconia applications expand into new markets, regulatory bodies are adapting their frameworks to address emerging technologies. For example, the use of zirconia in energy storage systems and fuel cells is prompting regulators to develop new standards for safety and performance in these applications. This dynamic regulatory environment presents both challenges and opportunities for innovators in the zirconia field.

To successfully innovate zirconia applications for future markets, companies must adopt a proactive approach to regulatory compliance. This involves staying abreast of regulatory changes, engaging with regulatory bodies during the development process, and investing in research to demonstrate the safety and efficacy of new zirconia-based products. Collaboration between industry stakeholders, research institutions, and regulatory agencies will be crucial in shaping a regulatory landscape that fosters innovation while ensuring public safety and environmental protection.