Zirconia's Applications in Resistive Heating Devices

Zirconia in Heating: Background and Objectives

Zirconia, a remarkable ceramic material, has been at the forefront of technological advancements in resistive heating devices for several decades. Its unique properties, including high melting point, excellent thermal stability, and low thermal conductivity, have made it an ideal candidate for various heating applications. The evolution of zirconia in this field can be traced back to the mid-20th century when researchers first recognized its potential as a refractory material.

The primary objective of utilizing zirconia in resistive heating devices is to enhance efficiency, durability, and performance under extreme temperature conditions. As industries demand more robust and energy-efficient heating solutions, zirconia has emerged as a key material to meet these challenges. Its ability to withstand high temperatures while maintaining structural integrity has led to its widespread adoption in sectors such as aerospace, automotive, and industrial manufacturing.

Over the years, the development of zirconia-based heating elements has progressed significantly. Initial applications focused on simple resistive elements, but advancements in material science and engineering have led to more sophisticated designs. These include multi-layered structures, composite materials, and nano-engineered zirconia formulations, each aimed at optimizing specific aspects of heating performance.

The technological trajectory of zirconia in heating applications has been driven by several factors. Firstly, the push for energy efficiency has led to the development of zirconia-based elements that can operate at higher temperatures with lower power consumption. Secondly, the need for longer-lasting heating components has spurred research into improving the material's resistance to thermal shock and cycling.

Current research in this field is focused on several key areas. Scientists are exploring ways to enhance zirconia's electrical conductivity while maintaining its thermal properties, potentially leading to more efficient heating elements. Additionally, there is ongoing work to improve the material's compatibility with other components in heating systems, such as electrodes and insulation materials.

The future of zirconia in resistive heating devices looks promising, with potential breakthroughs on the horizon. Researchers are investigating the use of advanced manufacturing techniques, such as 3D printing, to create complex zirconia structures with optimized heating characteristics. Moreover, the integration of smart materials and sensors into zirconia-based heating elements could pave the way for more responsive and adaptive heating systems.

As we look ahead, the objectives for zirconia in heating applications continue to evolve. The focus is not only on improving performance but also on addressing environmental concerns. This includes developing more sustainable manufacturing processes for zirconia-based components and exploring ways to recycle or repurpose these materials at the end of their lifecycle.

Market Analysis for Zirconia-based Heating Solutions

The market for zirconia-based heating solutions has shown significant growth potential in recent years, driven by the increasing demand for high-performance, energy-efficient heating devices across various industries. Zirconia's unique properties, including its excellent thermal stability, low thermal conductivity, and high melting point, make it an ideal material for resistive heating applications.

In the industrial sector, zirconia-based heating elements are gaining traction in furnaces, kilns, and other high-temperature processing equipment. The aerospace industry has also shown interest in zirconia heating solutions for de-icing systems and thermal management in aircraft. Additionally, the automotive sector is exploring zirconia-based heating technologies for improving the efficiency of catalytic converters and exhaust gas treatment systems.

The consumer electronics market presents another promising avenue for zirconia-based heating solutions. With the growing popularity of electric vehicles, there is an increasing demand for efficient cabin heating systems that can operate without relying on waste heat from internal combustion engines. Zirconia-based heating elements offer rapid heating capabilities and uniform heat distribution, making them suitable for this application.

Market research indicates that the global zirconia market size was valued at over $5 billion in 2020, with a compound annual growth rate (CAGR) projected to exceed 5% from 2021 to 2028. While this figure encompasses all zirconia applications, the segment dedicated to heating solutions is expected to grow at an even faster rate due to increasing adoption in emerging technologies.

The Asia-Pacific region, particularly China and Japan, is anticipated to be the fastest-growing market for zirconia-based heating solutions. This growth is attributed to the rapid industrialization, technological advancements, and government initiatives promoting energy-efficient technologies in these countries. North America and Europe are also expected to witness substantial growth, driven by the automotive and aerospace industries' demand for advanced heating solutions.

Key market players in the zirconia-based heating solutions sector include established materials science companies and specialized manufacturers. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of zirconia-based heating elements. Collaborations between material suppliers, device manufacturers, and end-users are becoming increasingly common to accelerate innovation and market adoption.

Despite the promising outlook, challenges such as high initial costs and competition from alternative materials like silicon carbide and aluminum nitride persist. However, ongoing technological advancements and economies of scale are expected to gradually address these issues, further expanding the market potential for zirconia-based heating solutions across various industries.

Zirconia's Current Status in Resistive Heating

Zirconia has emerged as a significant material in the field of resistive heating devices, with its current status reflecting both promising advancements and ongoing challenges. The material's high melting point, excellent thermal stability, and low thermal conductivity make it particularly suitable for high-temperature applications in resistive heating elements.

In recent years, zirconia-based heating elements have gained traction in various industrial sectors, including aerospace, automotive, and semiconductor manufacturing. These elements demonstrate superior performance in extreme temperature environments, often outperforming traditional metallic heating elements. The current market for zirconia in resistive heating is experiencing steady growth, driven by the increasing demand for more efficient and durable heating solutions in advanced manufacturing processes.

One of the key developments in zirconia's application for resistive heating is the refinement of its electrical properties through doping and compositional modifications. Yttria-stabilized zirconia (YSZ) has become a standard in the industry, offering improved ionic conductivity and mechanical stability. This has led to the development of more efficient heating elements capable of operating at temperatures exceeding 2000°C with minimal degradation.

However, challenges persist in the widespread adoption of zirconia-based heating devices. The material's inherent brittleness and susceptibility to thermal shock remain significant hurdles. Researchers and manufacturers are actively working on composite formulations and novel fabrication techniques to address these issues. Efforts are underway to develop zirconia-based heating elements with enhanced toughness and thermal shock resistance without compromising their electrical properties.

The current manufacturing landscape for zirconia resistive heating elements is characterized by a mix of established players and innovative startups. Traditional ceramic manufacturers have expanded their product lines to include zirconia-based heating solutions, while new entrants are focusing on niche applications and advanced manufacturing techniques such as additive manufacturing for complex geometries.

In terms of technological readiness, zirconia-based resistive heating elements have reached a level of maturity that allows for their implementation in various industrial applications. However, there is still significant room for improvement in terms of cost-effectiveness and large-scale production. The current focus is on optimizing manufacturing processes to reduce production costs and improve the consistency of material properties across batches.

Research institutions and industry collaborations are driving further innovations in this field. Current research trends include the exploration of nanostructured zirconia composites for enhanced performance, the development of self-healing zirconia materials to extend operational lifetimes, and the integration of smart sensing capabilities within zirconia heating elements for real-time monitoring and control.

Existing Zirconia Heating Device Designs

01 Zirconia synthesis and processing methods

Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods can involve different precursors, reaction conditions, and post-processing steps to achieve desired properties for specific applications.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods can involve different precursors, reaction conditions, and post-processing steps to achieve desired properties for specific applications.

- Zirconia-based composites and coatings: Zirconia is used in composite materials and coatings to enhance mechanical, thermal, and chemical properties. These composites can include other ceramics, metals, or polymers, and are applied in various industries such as aerospace, automotive, and electronics.

- Dental and biomedical applications of zirconia: Zirconia is widely used in dental and biomedical applications due to its biocompatibility, strength, and aesthetic properties. It is used for dental implants, crowns, bridges, and other prosthetic devices, as well as in orthopedic implants and surgical instruments.

- Zirconia in fuel cells and energy applications: Zirconia, particularly yttria-stabilized zirconia, is used as an electrolyte material in solid oxide fuel cells. It also finds applications in other energy-related technologies such as oxygen sensors and thermal barrier coatings for gas turbines.

- Zirconia in optical and electronic applications: Zirconia is utilized in various optical and electronic applications due to its high refractive index, transparency, and dielectric properties. It is used in optical coatings, fiber optics, and as a high-k dielectric material in semiconductor devices.

02 Zirconia-based composites and materials

Development of zirconia-based composites and materials by combining zirconia with other substances to enhance properties such as strength, toughness, and thermal stability. These materials find applications in various fields including dentistry, aerospace, and electronics.Expand Specific Solutions03 Zirconia in dental applications

Use of zirconia in dental applications, including dental implants, crowns, and bridges. The material's biocompatibility, aesthetics, and mechanical properties make it suitable for various dental prosthetics and restorations.Expand Specific Solutions04 Zirconia coatings and thin films

Methods for depositing zirconia coatings and thin films on various substrates. These coatings can provide enhanced wear resistance, thermal insulation, and corrosion protection in diverse applications such as cutting tools, optical devices, and fuel cells.Expand Specific Solutions05 Stabilized zirconia and phase transformation

Techniques for stabilizing zirconia in its various crystalline phases and controlling phase transformations. This includes the use of dopants and specific processing conditions to achieve desired mechanical and thermal properties for applications in sensors, fuel cells, and high-temperature materials.Expand Specific Solutions

Key Players in Zirconia Heating Industry

The market for zirconia in resistive heating devices is in a growth phase, driven by increasing demand for high-performance materials in various industries. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, zirconia applications in this field are advancing rapidly, with companies like Kyocera Corp., Saint-Gobain Ceramics & Plastics, Inc., and CeramTec GmbH leading innovation. These firms, along with others such as Oerlikon Metco and Shinagawa Refractories Co., Ltd., are developing advanced zirconia-based solutions for improved thermal efficiency and durability in resistive heating devices. Research institutions like the University of Connecticut and Rutgers State University are contributing to technological advancements, pushing the boundaries of zirconia's capabilities in this application.

Saint-Gobain Ceramics & Plastics, Inc.

CeramTec GmbH

Core Innovations in Zirconia Heating Elements

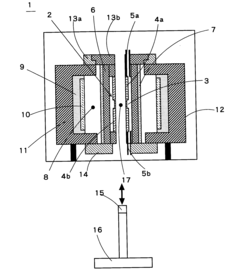

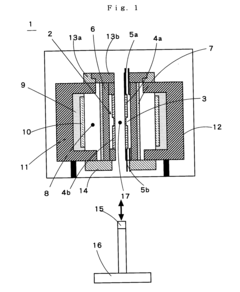

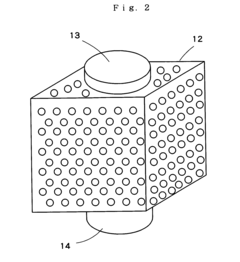

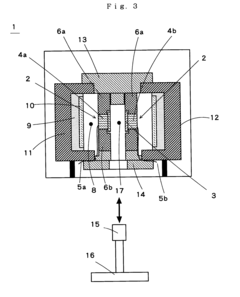

- The design incorporates a hollow zirconia-based heating element with a gap between the center furnace body and preheating means, utilizing a zirconia-based heat-insulating member and a preheating element on the inner surface of a cylindrical insulating member, along with an outer heat-insulating member to dissipate heat effectively, eliminating the need for water cooling and enhancing durability.

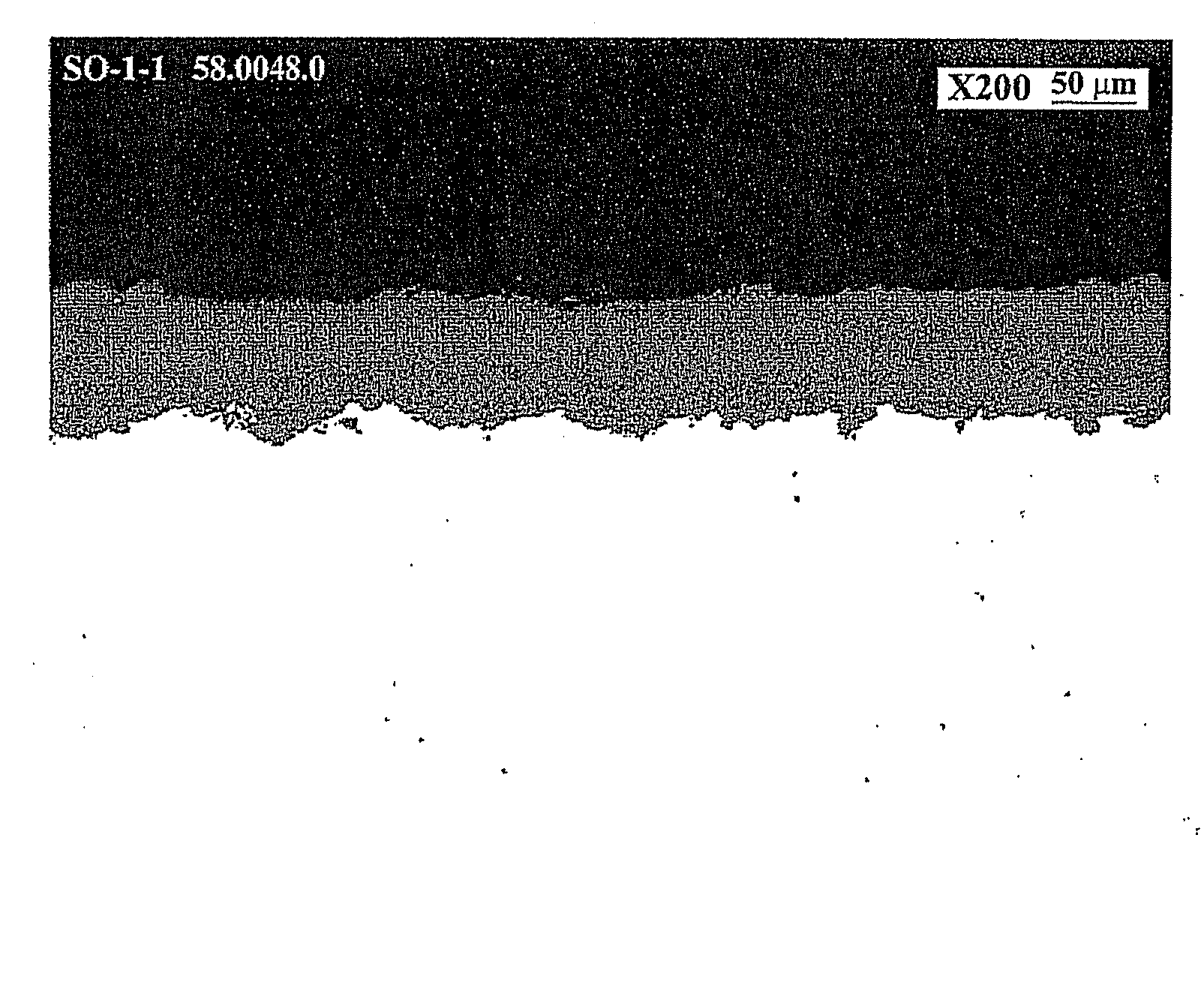

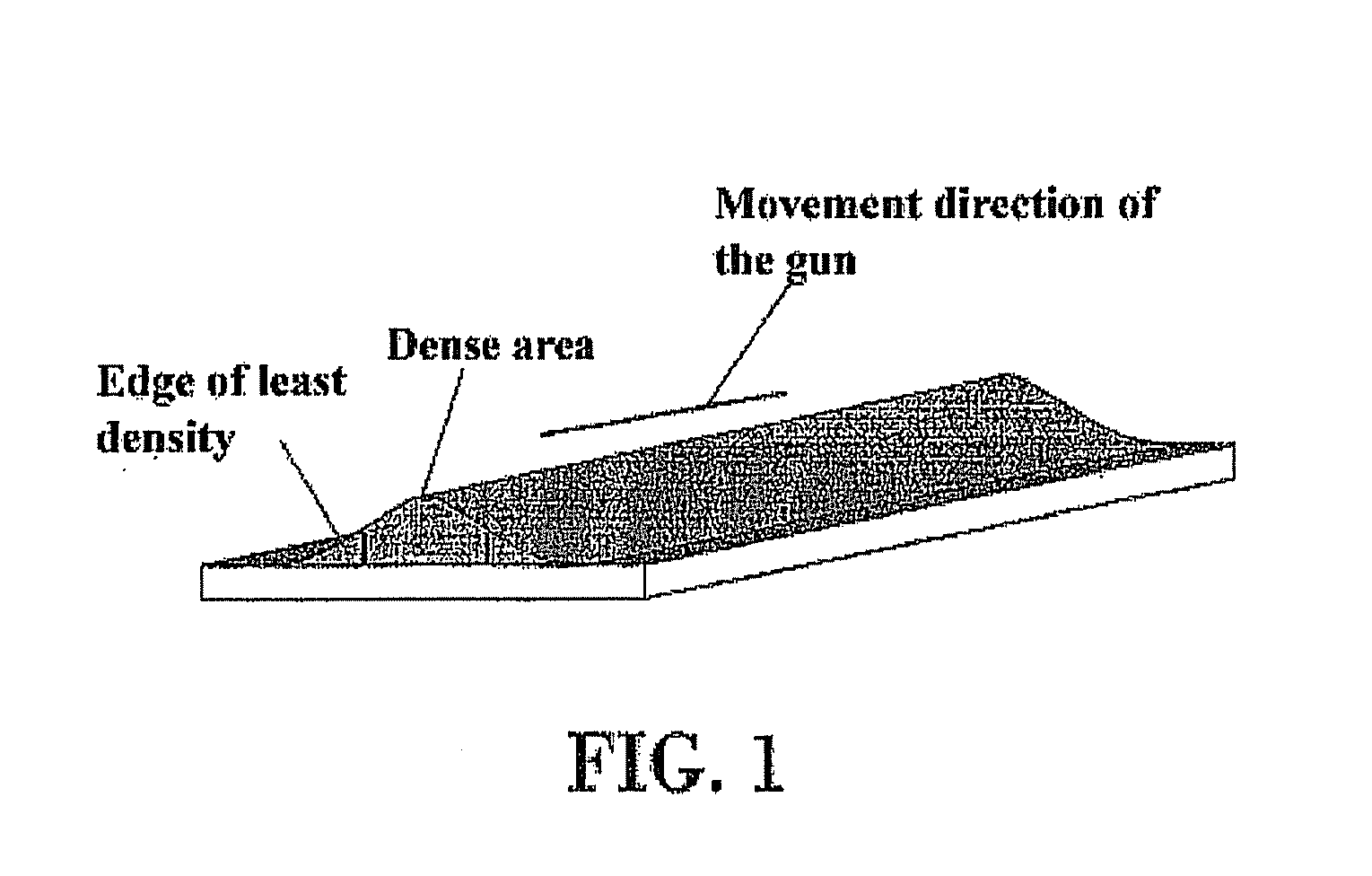

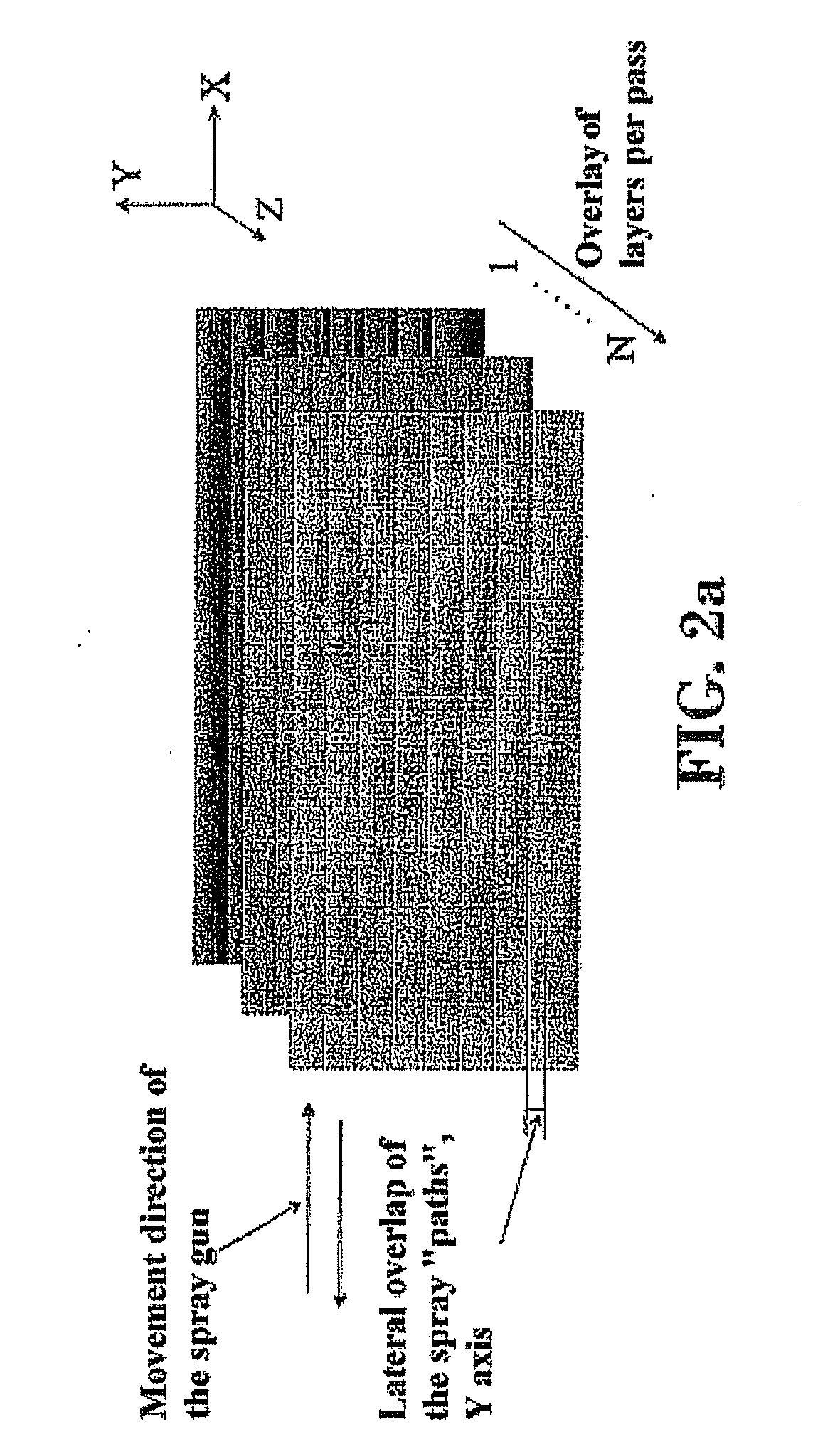

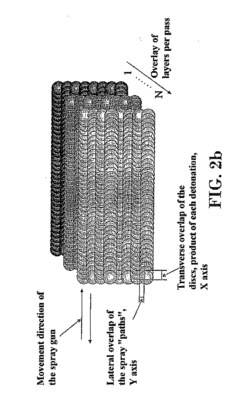

- The high frequency pulse detonation thermal spray process generates cyclic explosions exceeding 10 Hz, using energetic gas mixtures to melt and accelerate ceramic particles, achieving high-density coatings with minimal substrate heating and reduced gas consumption, allowing for thicker coatings in fewer passes and eliminating defects through controlled overlap and grit blasting effects.

Environmental Impact of Zirconia Heating Devices

The environmental impact of zirconia heating devices is a crucial consideration in their widespread adoption and long-term sustainability. These devices offer several environmental advantages over traditional heating methods, primarily due to their high efficiency and durability.

Zirconia-based heating elements demonstrate superior energy efficiency compared to conventional resistive heating materials. This increased efficiency translates to reduced energy consumption, which in turn leads to lower greenhouse gas emissions associated with power generation. The ability of zirconia heating devices to reach high temperatures quickly and maintain them consistently further contributes to energy savings, as less power is wasted during heating cycles.

The longevity of zirconia heating elements is another significant factor in their environmental profile. With a lifespan often exceeding that of traditional heating elements, zirconia-based devices require less frequent replacement. This durability reduces the environmental burden associated with manufacturing, transportation, and disposal of heating components over time.

In terms of material sustainability, zirconia is relatively abundant and can be sourced from various locations worldwide. While the extraction and processing of zirconia do have environmental impacts, these are generally considered less severe than those associated with some rare earth elements used in other advanced technologies.

The operational characteristics of zirconia heating devices also contribute to their environmental benefits. They produce minimal emissions during use, unlike combustion-based heating systems that release pollutants directly into the atmosphere. This aspect is particularly important for indoor air quality and overall environmental health.

However, it is essential to consider the full lifecycle environmental impact of zirconia heating devices. The production process of high-purity zirconia and the fabrication of heating elements do require significant energy input and may involve the use of chemicals. Proper recycling and disposal methods for used zirconia heating elements are also crucial to minimize their end-of-life environmental impact.

As the technology continues to evolve, ongoing research is focused on further improving the environmental performance of zirconia heating devices. This includes efforts to optimize production processes, enhance energy efficiency, and develop more effective recycling methods for used components. The integration of zirconia heating devices into broader energy-efficient systems and smart technologies also holds promise for additional environmental benefits through optimized energy management.

Thermal Efficiency Comparison with Alternatives

Zirconia-based resistive heating devices have gained significant attention in recent years due to their superior thermal efficiency compared to traditional alternatives. This comparative analysis aims to evaluate the thermal efficiency of zirconia-based heating elements against other commonly used materials in resistive heating applications.

When compared to conventional metallic heating elements, such as those made from nichrome or kanthal alloys, zirconia-based heaters demonstrate markedly improved thermal efficiency. The high melting point of zirconia, approximately 2700°C, allows for operation at much higher temperatures than metallic alternatives, which typically have maximum operating temperatures around 1400°C. This higher temperature capability translates directly into improved thermal efficiency, as the heat transfer rate increases with temperature difference.

Zirconia's low thermal conductivity also contributes to its superior efficiency. While metals conduct heat rapidly, leading to significant energy losses, zirconia's insulating properties help concentrate heat where it is needed most. This characteristic results in faster heating times and reduced energy consumption, particularly in applications requiring localized or targeted heating.

In comparison to other ceramic heating elements, such as silicon carbide or molybdenum disilicide, zirconia still holds several advantages. Its chemical stability at high temperatures surpasses that of many other ceramics, reducing degradation and extending the operational lifespan of heating devices. This longevity factor indirectly contributes to overall system efficiency by minimizing replacement and maintenance requirements.

Zirconia's unique electrical properties also play a crucial role in its thermal efficiency. Unlike metallic heaters, which maintain relatively constant resistivity with temperature, zirconia exhibits a negative temperature coefficient of resistance. This means its electrical resistance decreases as temperature increases, allowing for self-regulating heating behavior. This characteristic can lead to more uniform heating and improved energy utilization compared to alternatives that require complex control systems to achieve similar results.

From an environmental perspective, zirconia-based heating elements often demonstrate superior efficiency in terms of energy-to-heat conversion. This translates to lower power consumption and reduced carbon footprint when compared to less efficient alternatives. In industrial processes where heating constitutes a significant portion of energy usage, the adoption of zirconia-based systems can lead to substantial energy savings and decreased environmental impact.

However, it is important to note that the thermal efficiency advantages of zirconia are most pronounced in high-temperature applications. For low to medium temperature ranges, traditional heating elements may still offer competitive efficiency, especially when factoring in the higher initial costs associated with zirconia-based systems. Therefore, the choice between zirconia and alternative materials should be carefully evaluated based on the specific requirements of each application, considering factors such as operating temperature, heating uniformity, and long-term energy savings.