How to Innovate Zirconia for Environmental Solutions?

Zirconia in Environmental Solutions: Background and Objectives

Zirconia, a versatile ceramic material, has gained significant attention in recent years for its potential applications in environmental solutions. The development of zirconia-based technologies has evolved from its traditional use in structural ceramics to innovative environmental applications. This technological progression is driven by the growing global demand for sustainable and efficient solutions to address pressing environmental challenges.

The primary objective of innovating zirconia for environmental solutions is to leverage its unique properties to develop advanced materials and technologies that can effectively tackle environmental issues. These properties include high thermal stability, excellent mechanical strength, and remarkable chemical resistance, making zirconia an ideal candidate for various environmental applications.

One of the key areas of focus is the development of zirconia-based catalysts and adsorbents for air and water purification. These materials have shown promising results in removing pollutants such as volatile organic compounds (VOCs), nitrogen oxides (NOx), and heavy metals from industrial emissions and wastewater. The goal is to enhance the efficiency and durability of these zirconia-based solutions to provide more effective and economical alternatives to existing environmental remediation technologies.

Another important objective is the exploration of zirconia's potential in renewable energy technologies. Researchers are investigating the use of zirconia in solid oxide fuel cells (SOFCs) as an electrolyte material, aiming to improve their performance and longevity. Additionally, zirconia-based materials are being studied for their potential in solar energy harvesting and storage applications, with the aim of developing more efficient and sustainable energy solutions.

The development of zirconia-based membranes for water treatment and desalination is another critical area of innovation. These membranes have the potential to significantly improve the efficiency of water purification processes, addressing the global challenge of water scarcity and contamination. The objective is to create robust, long-lasting membranes that can effectively remove a wide range of contaminants while maintaining high water flux rates.

Furthermore, researchers are exploring the use of zirconia in environmental sensing and monitoring applications. The goal is to develop highly sensitive and selective sensors that can detect and measure various environmental pollutants with greater accuracy and reliability. This innovation aims to enhance our ability to monitor and manage environmental quality in real-time, enabling more effective pollution control and environmental protection strategies.

As the field of environmental technology continues to evolve, the innovation of zirconia for environmental solutions is expected to play a crucial role in addressing global environmental challenges. The ongoing research and development efforts are focused on optimizing zirconia's properties, exploring new synthesis methods, and developing novel composite materials to unlock its full potential in environmental applications.

Market Analysis for Eco-friendly Zirconia Applications

The market for eco-friendly zirconia applications is experiencing significant growth, driven by increasing environmental concerns and stringent regulations across various industries. Zirconia, known for its exceptional properties such as high strength, thermal stability, and chemical resistance, is finding new applications in environmental solutions.

In the energy sector, zirconia-based materials are gaining traction for use in solid oxide fuel cells (SOFCs) and other clean energy technologies. The global SOFC market is projected to expand rapidly, with zirconia playing a crucial role in improving efficiency and durability. This growth is fueled by the increasing demand for clean and efficient power generation systems.

Water treatment is another key area where eco-friendly zirconia applications are seeing substantial market potential. Zirconia-based membranes and adsorbents are being developed for water purification and desalination processes, offering superior performance compared to traditional materials. The global water treatment market is expected to grow steadily, with zirconia-based solutions poised to capture a significant share.

In the automotive industry, zirconia is finding applications in catalytic converters and oxygen sensors, contributing to reduced emissions and improved fuel efficiency. As automotive manufacturers strive to meet stricter environmental standards, the demand for zirconia-based components is expected to rise.

The construction sector is also embracing eco-friendly zirconia applications. Zirconia-based coatings and additives are being used to enhance the durability and energy efficiency of buildings. This market segment is anticipated to grow as sustainable construction practices gain prominence globally.

Emerging applications in waste management and air purification systems are opening new avenues for zirconia-based materials. These include advanced filtration systems and catalysts for breaking down pollutants, addressing critical environmental challenges.

Despite the promising outlook, challenges remain in scaling up production and reducing costs for widespread adoption of eco-friendly zirconia applications. However, ongoing research and development efforts are focused on overcoming these barriers, potentially leading to breakthroughs in material synthesis and processing techniques.

The market for eco-friendly zirconia applications is characterized by a mix of established players and innovative startups. Collaborations between research institutions and industry are driving innovation, accelerating the development of novel zirconia-based solutions for environmental challenges.

As sustainability becomes a key focus across industries, the demand for eco-friendly materials is expected to surge. Zirconia, with its unique properties and versatility, is well-positioned to meet this demand, offering environmentally responsible solutions across multiple sectors.

Current Challenges in Zirconia-based Environmental Technologies

Zirconia-based environmental technologies face several significant challenges that hinder their widespread adoption and effectiveness. One of the primary issues is the high cost associated with zirconia production and processing. The complex manufacturing processes and energy-intensive methods required to produce high-quality zirconia materials contribute to elevated expenses, limiting their application in large-scale environmental solutions.

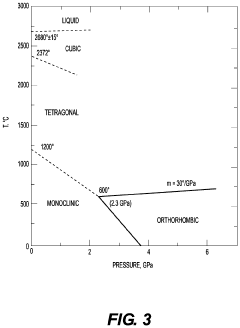

Another critical challenge is the limited thermal stability of zirconia at elevated temperatures. While zirconia exhibits excellent mechanical properties and chemical resistance, its performance can degrade under extreme heat conditions. This limitation restricts its use in high-temperature applications, such as advanced catalytic converters or thermal barrier coatings for industrial equipment operating in harsh environments.

The durability and long-term performance of zirconia-based materials in diverse environmental conditions also present ongoing concerns. Exposure to various pollutants, pH levels, and mechanical stresses can lead to degradation over time, potentially reducing the effectiveness of zirconia-based solutions in water treatment, air purification, and other environmental applications.

Furthermore, the optimization of zirconia's surface properties for specific environmental applications remains a challenge. Tailoring the surface area, porosity, and functionality of zirconia materials to enhance their adsorption capacity, catalytic activity, or ion exchange properties is crucial for improving their performance in environmental remediation processes.

The scalability of zirconia-based technologies for large-scale environmental solutions is another significant hurdle. Translating laboratory-scale successes to industrial-scale applications while maintaining efficiency and cost-effectiveness poses considerable engineering and economic challenges.

Additionally, the environmental impact of zirconia production itself requires attention. The mining and processing of zirconium ores can have negative ecological consequences, necessitating the development of more sustainable production methods and life cycle assessments to ensure that zirconia-based solutions truly offer net environmental benefits.

Lastly, the integration of zirconia-based materials with other advanced technologies, such as nanotechnology or smart materials, presents both opportunities and challenges. While such integrations could potentially enhance the performance and versatility of zirconia in environmental applications, they also introduce complexities in terms of material design, manufacturing, and long-term stability that need to be addressed.

Existing Zirconia-based Environmental Remediation Techniques

01 Zirconia synthesis and processing methods

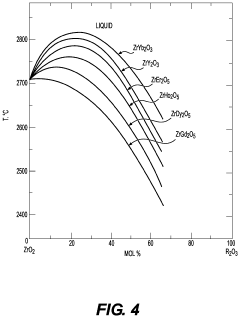

Various methods for synthesizing and processing zirconia are explored, including novel techniques for producing zirconia powders, ceramics, and composites. These methods aim to improve the properties and performance of zirconia-based materials for different applications.- Zirconia synthesis and processing methods: Various techniques for synthesizing and processing zirconia materials, including sol-gel methods, hydrothermal synthesis, and sintering processes. These methods aim to control the crystalline structure, particle size, and properties of zirconia for different applications.

- Zirconia-based dental materials: Development of zirconia-based materials for dental applications, such as crowns, bridges, and implants. These materials offer high strength, biocompatibility, and aesthetic properties suitable for dental restorations.

- Zirconia in catalysis and fuel cells: Utilization of zirconia as a catalyst support or component in various catalytic processes and as an electrolyte material in solid oxide fuel cells. Zirconia's stability and ionic conductivity make it valuable for these applications.

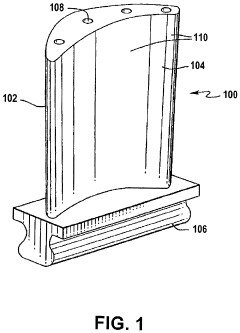

- Zirconia-based coatings and thin films: Development of zirconia-based coatings and thin films for various applications, including thermal barrier coatings, wear-resistant surfaces, and optical coatings. These coatings offer improved durability and performance in harsh environments.

- Zirconia composites and nanostructures: Creation of zirconia-based composite materials and nanostructures with enhanced properties, such as improved mechanical strength, toughness, and thermal stability. These materials find applications in aerospace, automotive, and biomedical industries.

02 Zirconia in dental applications

Zirconia is widely used in dental applications due to its biocompatibility, strength, and aesthetic properties. Research focuses on developing zirconia-based dental materials, including crowns, bridges, and implants, with improved durability and appearance.Expand Specific Solutions03 Zirconia-based catalysts and catalyst supports

Zirconia is utilized as a catalyst or catalyst support in various chemical processes. Research in this area focuses on developing zirconia-based catalysts with enhanced activity, selectivity, and stability for applications in petrochemical, environmental, and energy industries.Expand Specific Solutions04 Zirconia coatings and thin films

Zirconia coatings and thin films are developed for various applications, including thermal barrier coatings, wear-resistant surfaces, and optical coatings. Research focuses on improving deposition techniques, adhesion, and performance of zirconia-based coatings.Expand Specific Solutions05 Zirconia in advanced ceramics and composites

Zirconia is incorporated into advanced ceramics and composites to enhance their mechanical, thermal, and electrical properties. Research in this area focuses on developing novel zirconia-based materials with improved strength, toughness, and functionality for various industrial applications.Expand Specific Solutions

Key Players in Zirconia Environmental Solutions Industry

The innovation of zirconia for environmental solutions is in a growth phase, with increasing market size and technological advancements. The global zirconia market is expanding, driven by its versatile applications in environmental remediation, catalysis, and sustainable materials. Companies like Daiichi Kigenso Kagaku Kogyo, UBE Corp., and Saint-Gobain are at the forefront of research and development, focusing on enhancing zirconia's properties for environmental applications. The technology's maturity varies across different applications, with some areas like water treatment and air purification showing higher readiness levels. Academic institutions such as the University of Connecticut and Donghua University are contributing to fundamental research, while industrial players like Toyota Motor Corp. and China Petroleum & Chemical Corp. are exploring practical implementations, indicating a collaborative ecosystem driving innovation in this field.

Daiichi Kigenso Kagaku Kogyo Co., Ltd.

UBE Corp.

Breakthrough Innovations in Zirconia for Eco-solutions

- A method involving mixing a dicarboxylic acid compound with a zirconium compound in an aqueous medium, followed by the addition of a water-soluble organic base, and subsequent hydrothermal treatment at controlled temperatures, eliminating the need for washing processes and enhancing stability across a broader pH range.

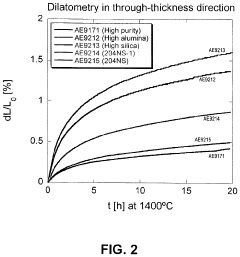

- Development of ultra-pure stabilized zirconia and hafnia alloys with low impurity concentrations and rare earth oxide stabilizers, such as yttria or ytterbia, to reduce sintering rates and stabilize the microstructure, resulting in a ceramic material with enhanced thermal resistance and durability.

Regulatory Framework for Zirconia in Environmental Applications

The regulatory framework for zirconia in environmental applications is a complex and evolving landscape that plays a crucial role in shaping the development and implementation of zirconia-based solutions for environmental challenges. As zirconia continues to gain prominence in various environmental applications, regulatory bodies worldwide are adapting their policies to ensure the safe and effective use of this material.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the use of zirconia in water treatment processes, particularly in the removal of heavy metals and other contaminants. These regulations outline specific performance standards, safety requirements, and monitoring protocols that must be adhered to when utilizing zirconia-based materials in water purification systems.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to zirconia and its compounds used in environmental applications. This comprehensive framework requires manufacturers and importers to register their substances and provide detailed information on their properties, potential risks, and safe handling procedures.

In Asia, countries like Japan and South Korea have developed their own regulatory frameworks for zirconia in environmental applications. The Japanese Ministry of the Environment has established guidelines for the use of zirconia in air pollution control technologies, focusing on its application in catalytic converters and emissions reduction systems.

International standards organizations, such as the International Organization for Standardization (ISO), have also contributed to the regulatory landscape by developing specific standards for zirconia materials used in environmental applications. These standards address issues such as material purity, performance criteria, and testing methodologies.

As the potential environmental applications of zirconia continue to expand, regulatory bodies are increasingly focusing on lifecycle assessments and sustainability considerations. This includes regulations pertaining to the sourcing of raw materials, energy consumption during production, and end-of-life disposal or recycling of zirconia-based products.

The regulatory framework also extends to occupational health and safety aspects related to the production and handling of zirconia materials. Agencies such as the Occupational Safety and Health Administration (OSHA) in the United States have established exposure limits and safety protocols for workers involved in zirconia-related industries.

As research and innovation in zirconia-based environmental solutions progress, regulatory frameworks are expected to evolve accordingly. This dynamic relationship between technological advancements and regulatory adaptation will continue to shape the landscape for zirconia's application in addressing environmental challenges.

Life Cycle Assessment of Zirconia-based Environmental Solutions

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of zirconia-based solutions throughout their entire lifecycle. This comprehensive analysis encompasses raw material extraction, manufacturing processes, use phase, and end-of-life disposal or recycling. For zirconia-based environmental solutions, the LCA begins with the mining and processing of zirconium minerals, primarily zircon sand.

The production phase of zirconia involves energy-intensive processes such as calcination and sintering, which contribute significantly to the overall environmental footprint. However, the durability and long lifespan of zirconia products often offset these initial impacts over time. During the use phase, zirconia-based solutions demonstrate superior performance in various environmental applications, including water purification, air pollution control, and catalytic converters.

One of the key advantages of zirconia in environmental solutions is its chemical stability and resistance to corrosion. This property extends the operational life of zirconia-based products, reducing the frequency of replacement and associated environmental impacts. In water treatment applications, zirconia membranes exhibit excellent filtration efficiency and longevity, potentially lowering the overall energy consumption and chemical usage compared to conventional treatment methods.

The end-of-life stage of zirconia products presents both challenges and opportunities. While zirconia is not biodegradable, its inert nature minimizes the risk of environmental contamination during disposal. Furthermore, the recyclability of zirconia is an area of growing interest, with potential for recovering and reprocessing the material for subsequent use in various applications.

When comparing zirconia-based solutions to alternatives, LCA studies often reveal favorable outcomes in terms of long-term environmental impact. The extended lifespan and high performance of zirconia products frequently result in reduced resource consumption and lower cumulative emissions over time. However, it is essential to consider the specific application and local environmental conditions when drawing conclusions from LCA results.

To further improve the environmental profile of zirconia-based solutions, ongoing research focuses on optimizing production processes, exploring alternative raw material sources, and developing more efficient recycling techniques. These efforts aim to minimize the initial environmental burden associated with zirconia production while maximizing its benefits in environmental applications.