How to Prepare for Zirconia-Driven Industry Shifts?

Zirconia Technology Evolution and Objectives

Zirconia, a versatile ceramic material, has undergone significant technological evolution since its discovery in the late 18th century. Initially recognized for its refractory properties, zirconia's potential in various industries has expanded dramatically over the past few decades. The evolution of zirconia technology has been driven by the continuous pursuit of improved material properties and the exploration of novel applications.

In the early stages of its development, zirconia was primarily used in high-temperature applications due to its excellent thermal stability. However, the discovery of its phase transformation toughening mechanism in the 1970s marked a pivotal moment in zirconia technology. This breakthrough led to the development of partially stabilized zirconia (PSZ) and tetragonal zirconia polycrystals (TZP), which exhibited superior mechanical properties and opened up new possibilities for structural applications.

The objectives of zirconia technology have evolved in tandem with its material advancements. Initially focused on enhancing thermal resistance, the goals have expanded to include improving mechanical strength, wear resistance, and biocompatibility. In recent years, the emphasis has shifted towards developing nanostructured zirconia materials and exploring their potential in emerging fields such as energy storage, catalysis, and advanced electronics.

One of the primary objectives in zirconia technology is to optimize its properties for specific applications. This includes tailoring the grain size, porosity, and phase composition to achieve desired characteristics such as high strength, toughness, and chemical stability. Another crucial goal is to enhance the material's aging resistance, particularly in humid environments, to ensure long-term reliability in critical applications such as dental and orthopedic implants.

The development of advanced processing techniques has been instrumental in achieving these objectives. Methods such as sol-gel synthesis, hydrothermal processing, and spark plasma sintering have enabled greater control over zirconia's microstructure and properties. These techniques have facilitated the production of high-purity, fine-grained zirconia ceramics with improved performance characteristics.

Looking ahead, the future objectives of zirconia technology are likely to focus on addressing the challenges posed by emerging industrial trends. This includes developing zirconia-based materials for sustainable energy applications, such as solid oxide fuel cells and oxygen transport membranes. Additionally, there is growing interest in exploring the potential of zirconia in additive manufacturing processes, which could revolutionize the production of complex ceramic components.

As industries prepare for zirconia-driven shifts, understanding the technology's evolution and objectives is crucial. This knowledge will guide research and development efforts, inform strategic decisions, and help identify new opportunities for innovation and market growth in the rapidly evolving landscape of advanced materials.

Market Demand Analysis for Zirconia Applications

The global zirconia market is experiencing significant growth, driven by increasing demand across various industries. The versatility of zirconia, with its exceptional mechanical, thermal, and chemical properties, has led to its widespread adoption in sectors such as ceramics, electronics, healthcare, and energy.

In the dental industry, zirconia has become a preferred material for crowns, bridges, and implants due to its biocompatibility, durability, and aesthetic appeal. The growing emphasis on cosmetic dentistry and the rising prevalence of dental disorders are fueling the demand for zirconia-based dental products. This trend is expected to continue as the global population ages and dental care awareness increases.

The electronics sector is another key driver of zirconia demand. Zirconia's high dielectric constant and thermal stability make it an ideal material for manufacturing capacitors, sensors, and other electronic components. With the rapid expansion of the Internet of Things (IoT) and 5G technology, the demand for zirconia in electronic applications is projected to surge in the coming years.

In the automotive industry, zirconia is gaining traction as a material for oxygen sensors, fuel cells, and catalytic converters. The push towards cleaner and more efficient vehicles is driving the adoption of zirconia-based components, which contribute to improved fuel efficiency and reduced emissions. As environmental regulations become stricter worldwide, the demand for zirconia in automotive applications is expected to grow substantially.

The aerospace sector is also contributing to the increasing demand for zirconia. Its use in thermal barrier coatings for jet engine components helps improve engine efficiency and longevity. As the aerospace industry continues to innovate and seek materials that can withstand extreme conditions, zirconia's role is likely to expand further.

In the energy sector, zirconia is finding applications in solid oxide fuel cells and nuclear power plants. Its ability to withstand high temperatures and corrosive environments makes it an attractive material for these demanding applications. As the world transitions towards cleaner energy sources, the demand for zirconia in this sector is expected to rise.

The healthcare industry, beyond dentistry, is also exploring new applications for zirconia. Its use in orthopedic implants and surgical tools is growing due to its biocompatibility and wear resistance. With an aging global population and advancements in medical technology, the healthcare sector is poised to become a significant driver of zirconia demand in the future.

Current Zirconia Technology Landscape and Challenges

The current zirconia technology landscape is characterized by rapid advancements and growing applications across various industries. Zirconia, a versatile ceramic material, has gained significant traction due to its exceptional properties, including high strength, toughness, and chemical resistance. The global zirconia market has been experiencing steady growth, driven by increasing demand in sectors such as healthcare, electronics, and energy.

In the healthcare industry, zirconia has revolutionized dental implants and prosthetics, offering superior aesthetics and biocompatibility compared to traditional materials. The adoption of CAD/CAM technology has further enhanced the precision and efficiency of zirconia-based dental restorations. However, challenges remain in improving the long-term stability and reducing the cost of zirconia dental products.

The electronics sector has embraced zirconia for its excellent dielectric properties and thermal stability. Zirconia-based components are increasingly used in sensors, solid oxide fuel cells, and high-temperature applications. The miniaturization trend in electronics presents both opportunities and challenges for zirconia technology, as manufacturers strive to develop thinner and more complex zirconia structures.

In the energy sector, zirconia plays a crucial role in solid oxide fuel cells and oxygen sensors. The push for cleaner energy solutions has accelerated research into zirconia-based materials for more efficient and durable fuel cells. However, cost reduction and scalability remain significant hurdles for widespread adoption.

One of the primary challenges facing the zirconia industry is the limited supply of high-quality zirconium minerals. The concentration of zirconium deposits in a few countries creates potential supply chain vulnerabilities. Additionally, the energy-intensive production process of zirconia contributes to environmental concerns and increased costs.

The development of advanced manufacturing techniques, such as additive manufacturing and nanoscale engineering, presents both opportunities and challenges for zirconia technology. These methods offer the potential for creating complex geometries and tailored microstructures but require significant research and development to optimize material properties and production efficiency.

Standardization and quality control pose another challenge in the zirconia industry. As applications expand, there is a growing need for consistent standards and testing protocols to ensure product reliability and performance across different sectors.

In conclusion, while zirconia technology has made significant strides, addressing these challenges will be crucial for preparing for industry shifts. Innovations in material science, manufacturing processes, and supply chain management will be key to unlocking the full potential of zirconia-driven industrial transformations.

Existing Zirconia Production and Application Methods

01 Zirconia synthesis and processing methods

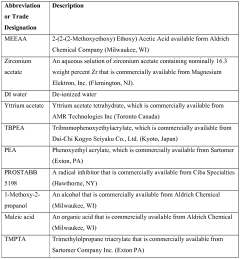

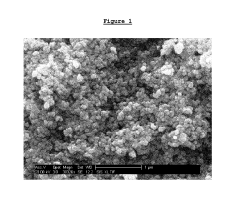

Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods may involve specific temperature treatments, chemical reactions, or mechanical processes to produce zirconia with desired properties for different applications.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are explored, including novel techniques for producing zirconia powders, ceramics, and composites. These methods aim to improve the material's properties, such as strength, durability, and thermal stability, for diverse applications in industries like electronics, aerospace, and medical devices.

- Zirconia-based dental materials: Zirconia is widely used in dental applications due to its biocompatibility, aesthetics, and mechanical properties. Research focuses on developing improved zirconia-based materials for dental implants, crowns, and bridges, with emphasis on enhancing translucency, strength, and long-term stability in the oral environment.

- Zirconia in fuel cell technology: Zirconia plays a crucial role in solid oxide fuel cell (SOFC) technology as an electrolyte material. Research in this area focuses on improving the ionic conductivity of zirconia-based electrolytes, enhancing their performance at lower operating temperatures, and increasing the overall efficiency of fuel cell systems.

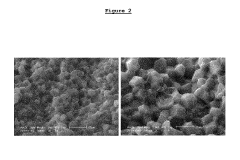

- Zirconia coatings and thin films: The development of zirconia coatings and thin films is explored for various applications, including thermal barrier coatings, wear-resistant surfaces, and optical coatings. Research focuses on improving deposition techniques, enhancing adhesion to substrates, and optimizing the microstructure of zirconia films for specific performance requirements.

- Zirconia nanoparticles and composites: The synthesis and application of zirconia nanoparticles and nanocomposites are investigated for various fields, including catalysis, biomedicine, and advanced materials. Research focuses on controlling particle size and morphology, improving dispersion in composite matrices, and enhancing the functional properties of zirconia-based nanomaterials.

02 Zirconia-based composites and materials

Development of composite materials incorporating zirconia, such as ceramic composites, dental materials, and advanced structural materials. These composites often combine zirconia with other substances to enhance properties like strength, durability, and biocompatibility.Expand Specific Solutions03 Applications of zirconia in catalysis

Utilization of zirconia as a catalyst or catalyst support in various chemical processes. This includes its use in environmental applications, fuel cell technology, and industrial chemical production, leveraging zirconia's unique surface properties and stability.Expand Specific Solutions04 Zirconia in dental and medical applications

Use of zirconia in dental prosthetics, implants, and other medical devices. The material's biocompatibility, aesthetic properties, and mechanical strength make it suitable for various dental and medical applications, including crowns, bridges, and orthopedic implants.Expand Specific Solutions05 Zirconia coatings and thin films

Development of zirconia-based coatings and thin films for various applications, including thermal barrier coatings, wear-resistant surfaces, and optical coatings. These coatings can enhance the performance and durability of underlying materials in high-temperature or corrosive environments.Expand Specific Solutions

Key Players in Zirconia Industry and Market Dynamics

The zirconia industry is experiencing significant growth and technological advancements, driven by its versatile applications across various sectors. The market is in a mature growth phase, with a projected global market size reaching billions of dollars in the coming years. Technological maturity varies across applications, with dental and industrial sectors leading in innovation. Companies like 3M Innovative Properties Co., Tosoh Corp., and Ivoclar Vivadent AG are at the forefront of zirconia technology development, focusing on improving material properties and manufacturing processes. Emerging players such as Aidite Technology Co., Ltd. and Kuraray Noritake Dental, Inc. are also making significant contributions, particularly in the dental sector. The industry is characterized by intense competition and continuous research and development efforts to enhance zirconia's performance and expand its applications.

Kuraray Noritake Dental, Inc.

Tosoh Corp.

Core Innovations in Zirconia Material Science

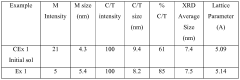

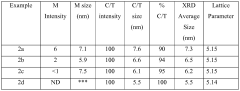

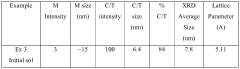

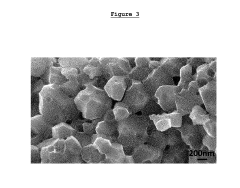

- Zirconia-based particles with 0.02 to 20 mole percent lanthanide element oxide and 0 to 15 mole percent yttrium oxide are synthesized using a hydrothermal treatment method, resulting in crystalline particles with an average primary size of no greater than 100 nanometers, which are then used in sols, composites, and sintered bodies to enhance mechanical properties and refractive index.

- A porous, pre-densified CeO2-stabilized ZrO2 ceramic is created through spark plasma sintering followed by re-oxidation, resulting in a dense, tetragonal phase-rich material with improved microstructure and mechanical properties, suitable for dental restorations.

Environmental Impact of Zirconia Production and Use

The production and use of zirconia have significant environmental implications that must be carefully considered as industries prepare for zirconia-driven shifts. The mining and processing of zircon, the primary source of zirconia, can lead to substantial land disturbance and habitat destruction. Open-pit mining operations often result in deforestation and soil erosion, impacting local ecosystems and biodiversity. Additionally, the extraction process typically involves water-intensive methods, potentially straining local water resources and affecting aquatic environments.

The refining of zircon into zirconia is an energy-intensive process that contributes to greenhouse gas emissions. The high temperatures required for zircon decomposition and zirconia stabilization consume considerable amounts of fossil fuels, primarily natural gas or coal. This energy consumption translates into a significant carbon footprint for zirconia production, raising concerns about its role in climate change mitigation efforts.

Waste management is another critical environmental aspect of zirconia production. The process generates various by-products and residues, some of which may contain radioactive elements naturally present in zircon ore. Proper disposal and long-term storage of these materials are essential to prevent soil and groundwater contamination. Furthermore, the fine particulate matter produced during processing can pose air quality risks if not adequately controlled.

On the positive side, the durability and longevity of zirconia-based products can contribute to resource conservation. Products made with zirconia often have extended lifespans, reducing the need for frequent replacements and potentially lowering overall material consumption. This characteristic aligns with circular economy principles and can help mitigate some of the environmental impacts associated with production.

As industries increasingly adopt zirconia-based technologies, there is a growing emphasis on developing more sustainable production methods. Research into alternative energy sources for processing, such as renewable electricity or hydrogen, could significantly reduce the carbon intensity of zirconia manufacturing. Additionally, efforts to improve recycling technologies for zirconia-containing products are underway, aiming to create closed-loop systems that minimize waste and reduce the demand for virgin materials.

The environmental impact of zirconia use varies depending on the specific application. In some cases, such as in advanced ceramics for energy-efficient technologies, zirconia can contribute to overall environmental benefits by improving energy efficiency or enabling cleaner industrial processes. However, the end-of-life management of zirconia-containing products remains a challenge, particularly in complex applications where material separation is difficult.

Supply Chain Resilience for Zirconia-Based Industries

In the face of zirconia-driven industry shifts, supply chain resilience becomes paramount for businesses reliant on this versatile material. The increasing demand for zirconia across various sectors, including ceramics, electronics, and healthcare, necessitates a robust and adaptable supply chain strategy.

To enhance supply chain resilience, companies must first diversify their sourcing strategies. Relying on a single supplier or geographical region for zirconia procurement exposes businesses to significant risks. By establishing relationships with multiple suppliers across different regions, companies can mitigate the impact of localized disruptions, such as natural disasters or geopolitical tensions.

Implementing advanced inventory management systems is crucial for maintaining optimal stock levels. Real-time tracking and predictive analytics can help businesses anticipate demand fluctuations and adjust their inventory accordingly. This approach minimizes the risk of stockouts while avoiding excessive carrying costs associated with overstocking.

Vertical integration presents another avenue for strengthening supply chain resilience. By acquiring or partnering with upstream suppliers, companies can gain greater control over the production and distribution of zirconia-based materials. This strategy not only secures a more stable supply but also provides opportunities for cost optimization and quality control.

Investing in alternative materials research and development can provide a safety net against zirconia supply chain disruptions. While zirconia offers unique properties, exploring potential substitutes or complementary materials can offer flexibility in product design and manufacturing processes.

Collaboration and information sharing across the supply chain network are essential for building resilience. Establishing transparent communication channels with suppliers, distributors, and customers enables faster response times to potential disruptions and facilitates coordinated problem-solving efforts.

Lastly, embracing digital transformation and Industry 4.0 technologies can significantly enhance supply chain visibility and agility. Internet of Things (IoT) devices, blockchain for traceability, and artificial intelligence for demand forecasting are just a few examples of technologies that can revolutionize zirconia-based supply chains, making them more responsive and resilient to industry shifts.