Zirconia's Pursuit of Perfection in Material Science

Zirconia Evolution and Objectives

Zirconia, a remarkable ceramic material, has undergone significant evolution since its discovery in the late 18th century. Initially recognized for its unique properties, zirconia's journey in material science has been marked by continuous refinement and innovation. The primary objective in zirconia research has been to harness its exceptional characteristics while overcoming inherent limitations.

The evolution of zirconia began with its identification as a distinct mineral. However, it wasn't until the mid-20th century that its potential in advanced applications was fully realized. The discovery of transformation toughening in the 1970s marked a pivotal moment, dramatically enhancing zirconia's mechanical properties and expanding its use in various industries.

Subsequent decades saw intensive research focused on stabilizing zirconia's crystal structure. This led to the development of partially stabilized zirconia (PSZ) and tetragonal zirconia polycrystals (TZP), each offering unique advantages in terms of strength, toughness, and thermal stability. These advancements opened new avenues in fields ranging from dentistry to aerospace.

The pursuit of perfection in zirconia has been driven by several key objectives. Foremost among these is the enhancement of its mechanical properties, particularly fracture toughness and flexural strength. Researchers have aimed to optimize the balance between these properties to create materials suitable for high-stress applications.

Another critical objective has been to improve zirconia's thermal properties. This includes enhancing its resistance to thermal shock and expanding its operational temperature range, crucial for applications in extreme environments such as jet engines and thermal barrier coatings.

Biocompatibility has emerged as a significant focus in recent years, particularly for medical and dental applications. The goal has been to develop zirconia-based materials that are not only strong and durable but also safe for long-term use in the human body.

Manufacturability and cost-effectiveness have also been key objectives. Efforts have been made to develop more efficient production methods, reduce processing temperatures, and improve the consistency of zirconia products. This has been crucial for scaling up production and making zirconia more accessible for a wider range of applications.

Looking forward, the objectives in zirconia research continue to evolve. Current focus areas include developing nanostructured zirconia composites, exploring new stabilization techniques, and investigating the potential of zirconia in emerging fields such as solid oxide fuel cells and advanced sensors. The ultimate goal remains to push the boundaries of what's possible with this versatile material, striving for ever-greater perfection in its properties and applications.

Market Demand Analysis

The market demand for zirconia in material science has been experiencing significant growth, driven by its exceptional properties and versatility across various industries. The global zirconia market size was valued at approximately $4.8 billion in 2020 and is projected to reach $8.2 billion by 2028, growing at a CAGR of 6.9% during the forecast period.

One of the primary drivers of market demand is the increasing use of zirconia in dental applications. The dental industry has embraced zirconia as a preferred material for crowns, bridges, and implants due to its biocompatibility, durability, and aesthetic appeal. As the global population ages and dental care awareness improves, the demand for zirconia-based dental products is expected to surge.

The electronics industry is another significant contributor to the growing market demand for zirconia. With the rapid advancement of technology and the increasing miniaturization of electronic components, zirconia's excellent thermal and electrical insulation properties make it an ideal material for various applications, including solid oxide fuel cells, sensors, and ceramic capacitors.

In the automotive sector, zirconia is gaining traction as a crucial material for oxygen sensors and thermal barrier coatings. The push for more fuel-efficient and environmentally friendly vehicles has led to increased adoption of zirconia-based components, further driving market demand.

The aerospace industry is also fueling the demand for zirconia, particularly in the development of advanced thermal barrier coatings for jet engines. These coatings help improve engine efficiency and extend the lifespan of critical components, making zirconia an essential material in modern aircraft design.

Moreover, the growing focus on sustainable and eco-friendly materials has opened up new opportunities for zirconia in the construction and infrastructure sectors. Zirconia-based materials are being explored for their potential in enhancing the durability and performance of concrete structures, as well as in the development of advanced ceramics for architectural applications.

The medical industry is another area where zirconia is witnessing increased demand. Its biocompatibility and wear resistance make it an excellent choice for orthopedic implants and surgical instruments. As the global healthcare sector continues to expand and innovate, the demand for zirconia in medical applications is expected to grow substantially.

In conclusion, the market demand for zirconia in material science is robust and diverse, spanning multiple industries and applications. The ongoing pursuit of perfection in material properties, coupled with the material's versatility, positions zirconia as a critical component in various high-performance and advanced technology applications, ensuring sustained market growth in the foreseeable future.

Zirconia Challenges

Zirconia, a remarkable ceramic material, faces several challenges in its pursuit of perfection in material science. One of the primary obstacles is its inherent brittleness, which limits its application in high-stress environments. This characteristic makes zirconia susceptible to sudden failure under certain conditions, particularly when subjected to tensile stresses or impact forces.

Another significant challenge lies in the control of zirconia's phase transformations. The material exists in different crystalline structures depending on temperature and pressure, with the tetragonal-to-monoclinic transformation being particularly crucial. While this transformation can enhance fracture toughness through a mechanism known as transformation toughening, it can also lead to volume changes that induce internal stresses and potential microcracking.

The sintering process of zirconia presents its own set of challenges. Achieving full densification while maintaining a fine-grained microstructure is critical for optimal mechanical properties. However, the high temperatures required for sintering can lead to grain growth, which can negatively impact the material's strength and toughness. Balancing these factors to produce consistently high-quality zirconia components remains a complex task.

Zirconia's sensitivity to moisture, particularly at elevated temperatures, poses another challenge. This phenomenon, known as low-temperature degradation or aging, can result in a gradual loss of strength and toughness over time. Addressing this issue is crucial for applications where long-term stability under humid conditions is required, such as in biomedical implants or certain industrial settings.

The development of zirconia composites and nanostructured zirconia materials presents both opportunities and challenges. While these approaches offer potential improvements in mechanical properties and functionality, they also introduce complexities in processing and quality control. Achieving uniform dispersion of secondary phases or maintaining nano-scale features during processing and sintering requires advanced techniques and careful optimization.

Lastly, the cost-effective production of high-purity zirconia powders with controlled particle size and morphology remains a challenge. The quality of the starting powder significantly influences the final properties of zirconia components. Developing economical methods to produce powders that meet stringent specifications is essential for expanding zirconia's commercial applications and competitiveness against other advanced materials.

Current Zirconia Solutions

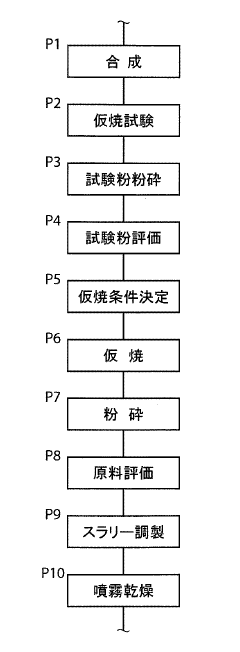

01 Zirconia synthesis and processing methods

Various methods for synthesizing and processing zirconia to achieve high-quality materials. This includes techniques for controlling particle size, crystalline structure, and purity during production. Advanced processing methods aim to enhance the mechanical and optical properties of zirconia for different applications.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia to achieve high-quality materials. This includes techniques for controlling particle size, crystalline structure, and purity during production. Advanced processing methods aim to enhance the mechanical and optical properties of zirconia for different applications.

- Zirconia-based dental materials: Development of zirconia-based materials specifically for dental applications. These materials are designed to provide excellent aesthetics, durability, and biocompatibility for dental restorations such as crowns, bridges, and implants. Techniques for improving the translucency and color matching of zirconia dental materials are emphasized.

- Surface treatment and coating of zirconia: Methods for modifying the surface properties of zirconia through various treatments and coatings. These techniques aim to enhance the material's performance in specific applications, such as improving wear resistance, increasing adhesion to other materials, or modifying optical properties.

- Zirconia composites and reinforced materials: Development of composite materials incorporating zirconia to enhance overall material properties. This includes the creation of zirconia-reinforced ceramics, polymers, or metal matrix composites. These materials often exhibit improved strength, toughness, and thermal properties compared to their non-reinforced counterparts.

- Stabilization and phase control of zirconia: Techniques for stabilizing specific crystalline phases of zirconia and controlling phase transformations. This is crucial for maintaining desired properties in various applications, particularly in high-temperature or high-stress environments. Methods may include doping with other elements or precise control of processing conditions.

02 Zirconia-based dental materials

Development of zirconia-based materials specifically for dental applications. These materials are designed to provide excellent aesthetics, durability, and biocompatibility for dental restorations such as crowns, bridges, and implants. Techniques for improving the translucency and color matching of zirconia dental materials are emphasized.Expand Specific Solutions03 Surface treatment and coating of zirconia

Methods for modifying the surface properties of zirconia through various treatments and coatings. These techniques aim to enhance the material's performance in specific applications, such as improving adhesion, wear resistance, or aesthetic properties. Surface treatments may include chemical etching, plasma treatment, or application of specialized coatings.Expand Specific Solutions04 Zirconia composites and reinforced materials

Development of composite materials incorporating zirconia to enhance overall material properties. This includes the creation of zirconia-reinforced ceramics, polymers, or metal matrix composites. These materials aim to combine the beneficial properties of zirconia with those of other materials for improved performance in various applications.Expand Specific Solutions05 Zirconia in advanced applications

Exploration of novel applications for zirconia in advanced fields such as electronics, energy storage, and biomedical devices. This includes the use of zirconia in solid oxide fuel cells, sensors, catalysts, and advanced medical implants. Research focuses on tailoring zirconia properties for these specialized applications.Expand Specific Solutions

Key Industry Players

The pursuit of perfection in zirconia material science is currently in a mature growth phase, with a global market size expected to reach $2.1 billion by 2026. The technology's maturity is evident in its widespread adoption across various industries, particularly in dental and medical applications. Key players like Tosoh Corp., Kuraray Noritake Dental, Inc., and 3M Innovative Properties Co. are driving innovation in this field. These companies, along with others such as Saint-Gobain and Sumitomo Chemical Co., Ltd., are focusing on enhancing zirconia's properties, including strength, durability, and biocompatibility. The competitive landscape is characterized by ongoing research and development efforts, with academic institutions like Harbin Institute of Technology and California Institute of Technology contributing to advancements in zirconia technology.

Tosoh Corp.

Kuraray Noritake Dental, Inc.

Zirconia Innovations

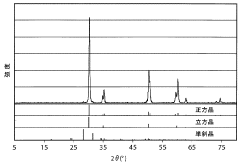

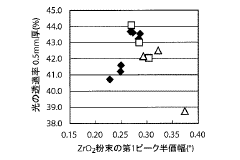

- A zirconia raw material powder with a crystal phase exclusively composed of tetragonal crystals, a half-width of the first XRD peak between 0.26 to 0.31 degrees, and a BET specific surface area of 17 m²/g is used, followed by pressure molding and controlled firing, eliminating the need for HIP treatment and ensuring high translucency and mechanical strength.

- A zirconia mill blank containing zirconium oxide, a stabilizing oxide material, and a water-soluble compound salt with calcium, magnesium, or rare earth elements like yttrium and lanthanum, where the stabilizing material is within 2-7 mol% and the water-soluble compound salt is within 0.1-3.5 mol%, supported on the surface of the ceramic particles, is used to create a semi-fired body that maintains high strength and improves translucency.

Environmental Impact

Zirconia, a remarkable ceramic material, has gained significant attention in material science due to its exceptional properties. However, its environmental impact throughout its lifecycle is a crucial aspect that requires careful consideration. The production of zirconia involves energy-intensive processes, primarily in the mining and refining stages. The extraction of zirconium from its ore, typically zircon sand, requires substantial energy inputs and may lead to habitat disruption in mining areas.

During the manufacturing process, the high temperatures required for sintering zirconia contribute to increased energy consumption and associated greenhouse gas emissions. However, advancements in production techniques, such as microwave sintering and spark plasma sintering, have shown promise in reducing energy requirements and minimizing environmental footprint.

The durability and longevity of zirconia products offer a positive environmental aspect. Its resistance to wear, corrosion, and thermal shock translates to extended product lifespans, potentially reducing the need for frequent replacements and the associated resource consumption. This characteristic is particularly beneficial in applications such as dental implants, where the material's biocompatibility and longevity contribute to reduced medical waste.

Recycling and end-of-life management of zirconia products present both challenges and opportunities. While the material itself is not biodegradable, its chemical stability ensures it does not leach harmful substances into the environment. However, the recycling of zirconia-based products is currently limited due to the complexity of separating it from other materials in composite structures.

Research into more sustainable production methods and recycling techniques for zirconia is ongoing. Innovations in green chemistry approaches, such as using bio-based precursors and low-temperature synthesis routes, show potential for reducing the environmental impact of zirconia production. Additionally, the development of efficient recycling processes, including methods for recovering zirconia from industrial waste streams, could significantly improve the material's overall environmental profile.

As the demand for high-performance materials continues to grow, balancing the exceptional properties of zirconia with environmental considerations becomes increasingly important. The pursuit of perfection in zirconia science must therefore extend beyond material properties to encompass sustainable production practices, efficient use of resources, and responsible end-of-life management. This holistic approach will be crucial in ensuring that zirconia's contributions to various industries remain aligned with global sustainability goals.

Zirconia Applications

Zirconia, a remarkable ceramic material, has found widespread applications across various industries due to its exceptional properties. In the field of dentistry, zirconia has revolutionized the production of dental implants and crowns. Its biocompatibility, high strength, and aesthetic appeal make it an ideal choice for dental restorations. Zirconia-based dental prosthetics offer superior durability and natural appearance, closely mimicking the look of natural teeth.

In the aerospace industry, zirconia plays a crucial role in thermal barrier coatings for jet engine components. Its low thermal conductivity and high melting point enable it to protect underlying metal structures from extreme temperatures, significantly enhancing the efficiency and lifespan of aircraft engines. Additionally, zirconia's resistance to corrosion and wear makes it valuable in the manufacturing of precision components for aerospace applications.

The automotive sector has also embraced zirconia technology, particularly in the development of oxygen sensors for engine management systems. These sensors, which utilize zirconia's unique ionic conductivity properties, help optimize fuel efficiency and reduce emissions in modern vehicles. Furthermore, zirconia-based ceramic bearings are increasingly being used in high-performance automotive applications due to their superior wear resistance and reduced friction.

In the field of electronics, zirconia finds applications in the production of solid oxide fuel cells (SOFCs). Its excellent ionic conductivity at high temperatures makes it an ideal electrolyte material for these efficient energy conversion devices. SOFCs powered by zirconia-based electrolytes offer promising solutions for clean and sustainable energy generation.

The medical industry benefits from zirconia's biocompatibility and mechanical strength in the production of orthopedic implants. Zirconia-based hip and knee replacements demonstrate excellent wear resistance and longevity, improving patient outcomes and reducing the need for revision surgeries. Additionally, zirconia's radiopacity makes it valuable in medical imaging applications, allowing for clear visualization of implants in X-rays and CT scans.

In the realm of advanced ceramics, zirconia serves as a key component in the development of cutting tools and wear-resistant components. Its exceptional hardness and toughness make it suitable for machining difficult-to-cut materials, such as hardened steels and superalloys. Zirconia-based cutting tools offer extended tool life and improved surface finish in demanding manufacturing processes.