How to Reduce Zirconia's Processing Costs?

Zirconia Processing Background and Objectives

Zirconia, a versatile ceramic material, has gained significant attention in various industries due to its exceptional properties. The development of zirconia processing techniques has evolved over several decades, driven by the increasing demand for high-performance materials in applications ranging from dental implants to thermal barrier coatings. The primary objective in zirconia processing is to achieve optimal mechanical, thermal, and chemical properties while minimizing production costs.

The evolution of zirconia processing can be traced back to the 1970s when researchers first recognized its potential as a structural ceramic. Initially, the focus was on developing methods to stabilize zirconia's crystal structure, as pure zirconia undergoes phase transformations that can lead to cracking and reduced mechanical strength. This led to the introduction of stabilizing agents such as yttria, magnesia, and ceria, which became crucial in enhancing zirconia's performance and expanding its applications.

As the demand for zirconia-based products grew, particularly in the medical and aerospace industries, the emphasis shifted towards improving processing techniques to enhance material properties and reduce manufacturing costs. Key developments included the refinement of powder synthesis methods, the optimization of sintering processes, and the introduction of advanced forming techniques such as injection molding and 3D printing.

The current technological landscape in zirconia processing is characterized by a drive towards more efficient and cost-effective production methods. This includes the exploration of novel sintering techniques, such as microwave sintering and spark plasma sintering, which offer the potential for reduced energy consumption and processing times. Additionally, there is a growing interest in developing nanostructured zirconia materials, which promise enhanced mechanical properties and improved sinterability.

Despite these advancements, the zirconia industry faces several challenges in reducing processing costs. These include the high energy requirements for sintering, the cost of high-purity raw materials, and the complexity of achieving consistent material properties across large production volumes. Addressing these challenges requires a multifaceted approach, combining innovations in material science, process engineering, and manufacturing technologies.

The objective of this technical research report is to explore and evaluate potential strategies for reducing zirconia's processing costs without compromising material quality or performance. This involves examining current processing methods, identifying bottlenecks and inefficiencies, and investigating emerging technologies that could revolutionize zirconia production. By analyzing these aspects, we aim to provide insights and recommendations that can guide future research and development efforts in the field of zirconia processing, ultimately leading to more cost-effective production methods and broader adoption of this remarkable material across various industries.

Market Analysis for Cost-Effective Zirconia Products

The market for cost-effective zirconia products has been experiencing significant growth in recent years, driven by increasing demand across various industries. Zirconia, known for its exceptional mechanical properties and biocompatibility, finds applications in sectors such as dental and medical implants, aerospace, electronics, and advanced ceramics. However, the high processing costs associated with zirconia production have been a limiting factor in its widespread adoption.

The global zirconia market size was valued at USD 4.8 billion in 2020 and is projected to reach USD 6.9 billion by 2026, growing at a CAGR of 6.2% during the forecast period. This growth is primarily attributed to the rising demand for zirconia in dental and medical applications, as well as in the automotive and aerospace industries. The dental sector, in particular, has been a major driver of zirconia demand, with the material being increasingly used for crowns, bridges, and implants due to its aesthetic appeal and durability.

Despite the positive market outlook, manufacturers face challenges in reducing production costs while maintaining product quality. The high energy consumption and complex processing steps involved in zirconia production contribute significantly to its overall cost. As a result, there is a growing focus on developing cost-effective manufacturing techniques and optimizing existing processes to make zirconia more accessible to a broader range of applications and end-users.

Several factors are influencing the market dynamics for cost-effective zirconia products. Technological advancements in manufacturing processes, such as improved sintering techniques and the development of nano-zirconia powders, are helping to reduce production costs and enhance material properties. Additionally, the increasing adoption of additive manufacturing technologies for zirconia production is opening up new possibilities for cost-effective and customized product development.

The competitive landscape of the zirconia market is characterized by the presence of several key players, including Saint-Gobain, Tosoh Corporation, and Daiichi Kigenso Kagaku Kogyo Co., Ltd. These companies are investing in research and development to improve production efficiency and develop innovative products that meet the growing demand for cost-effective zirconia solutions. Furthermore, strategic partnerships and collaborations between material suppliers, manufacturers, and end-users are becoming increasingly common as the industry seeks to address cost challenges collectively.

In conclusion, the market analysis for cost-effective zirconia products reveals a promising outlook, with significant growth potential across various industries. However, addressing the challenge of reducing processing costs remains crucial for unlocking the full market potential of zirconia. As the industry continues to evolve, innovations in manufacturing processes and material science will play a pivotal role in shaping the future of cost-effective zirconia products.

Current Challenges in Zirconia Processing

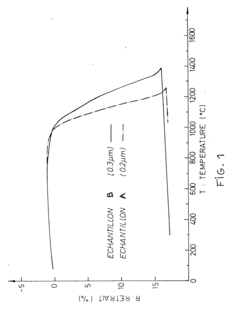

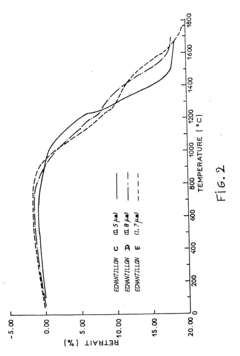

Zirconia processing faces several significant challenges that impact its production costs and overall efficiency. One of the primary issues is the high energy consumption required during the sintering process. Zirconia typically requires temperatures exceeding 1500°C for full densification, which translates to substantial energy expenditure and increased production costs.

Another major challenge lies in the raw material costs. High-purity zirconia powders, essential for producing high-quality ceramics, are relatively expensive. The need for additives and stabilizers, such as yttria, further adds to the material costs. Additionally, the processing of these raw materials often involves multiple steps, including milling and granulation, which contribute to the overall expenses.

The complexity of shape forming techniques presents another hurdle. Advanced shaping methods like injection molding or 3D printing, while offering design flexibility, often require specialized equipment and expertise, driving up production costs. Traditional forming methods like pressing may be more cost-effective but can limit the complexity of the final product.

Machining and finishing of zirconia components pose significant challenges due to the material's hardness and brittleness. Post-sintering machining is often necessary to achieve precise dimensions and surface finishes, but it is time-consuming and requires specialized tools, contributing to higher processing costs.

Quality control and consistency in production represent ongoing challenges. Zirconia's properties can be sensitive to processing conditions, and maintaining uniform characteristics across batches requires stringent control measures. This necessity for precise control over various processing parameters adds complexity and cost to the manufacturing process.

The environmental impact of zirconia processing is also a growing concern. The high-temperature sintering process not only consumes significant energy but also produces greenhouse gas emissions. As environmental regulations become stricter, manufacturers face the challenge of implementing more sustainable practices without compromising product quality or dramatically increasing costs.

Lastly, the scalability of production processes presents a challenge, particularly for companies looking to increase output while maintaining cost-effectiveness. Scaling up production often requires significant capital investment in equipment and facilities, which can be a barrier for smaller manufacturers or those entering the market.

Existing Cost Reduction Strategies for Zirconia Processing

01 Raw material selection and preparation

The choice and preparation of raw materials significantly impact zirconia processing costs. High-quality zirconia powders and additives can improve efficiency but may increase initial costs. Proper selection and preparation techniques can optimize the balance between quality and cost-effectiveness in zirconia production.- Raw material selection and preparation: The choice and preparation of raw materials significantly impact zirconia processing costs. High-quality zirconia powders and additives can reduce processing steps and improve final product quality, potentially lowering overall costs. Proper particle size distribution and purity of starting materials are crucial factors.

- Sintering techniques and optimization: Advanced sintering techniques, such as microwave sintering or spark plasma sintering, can reduce processing time and energy consumption, thereby lowering costs. Optimizing sintering parameters like temperature, pressure, and atmosphere can improve densification and reduce the need for post-processing steps.

- Additive manufacturing and near-net-shape processing: Utilizing additive manufacturing techniques for zirconia processing can reduce material waste and machining costs. Near-net-shape processing methods minimize the need for expensive post-sintering machining, potentially leading to significant cost savings in complex geometries.

- Process automation and quality control: Implementing automated processing systems and advanced quality control measures can reduce labor costs and minimize material waste. In-line monitoring and real-time process adjustments can improve yield and consistency, leading to overall cost reductions in zirconia processing.

- Recycling and waste management: Developing efficient methods for recycling zirconia waste and off-spec products can significantly reduce raw material costs. Implementing closed-loop processing systems and optimizing waste management strategies can lead to more cost-effective and environmentally friendly zirconia production.

02 Sintering process optimization

Optimizing the sintering process is crucial for reducing zirconia processing costs. Advanced sintering techniques, temperature control, and atmosphere management can improve energy efficiency and product quality. Innovations in sintering technology can lead to significant cost savings in zirconia manufacturing.Expand Specific Solutions03 Machining and shaping techniques

Efficient machining and shaping techniques are essential for reducing zirconia processing costs. Advanced cutting tools, CNC machining, and near-net-shape forming can minimize material waste and processing time. Innovative approaches to zirconia shaping can significantly impact overall production costs.Expand Specific Solutions04 Recycling and waste management

Implementing effective recycling and waste management strategies can substantially reduce zirconia processing costs. Reclaiming and reprocessing zirconia waste, as well as utilizing byproducts, can improve resource efficiency. Proper waste management techniques contribute to both cost reduction and environmental sustainability in zirconia production.Expand Specific Solutions05 Quality control and process automation

Integrating advanced quality control measures and process automation can optimize zirconia processing costs. Automated inspection systems, real-time monitoring, and data-driven process control can reduce defects and improve yield. Implementing these technologies may require initial investment but can lead to long-term cost savings in zirconia manufacturing.Expand Specific Solutions

Key Players in Zirconia Manufacturing Industry

The market for reducing zirconia processing costs is in a growth phase, driven by increasing demand across various industries. The global zirconia market size is projected to expand significantly, with a compound annual growth rate of around 5% expected in the coming years. Technological maturity varies among key players, with companies like Tosoh Corp., Kuraray Noritake Dental, Inc., and BASF Corp. leading in innovation. These firms are investing heavily in research and development to optimize production processes and reduce costs. Emerging players such as Zibo Jiahua Advanced Material Resources Co., Ltd. and Emeishan Zhongshan Xincailiao Science & Technology Co. Ltd. are also making strides in cost-effective zirconia processing, intensifying competition in the market.

Tosoh Corp.

Kuraray Noritake Dental, Inc.

Innovative Technologies in Zirconia Production

- A process involving the heat treatment of an aerosol containing a mixture of inorganic zirconium and stabilizing compounds, such as yttrium, calcium, or cerium, without the need for organic precursors or solvents, using a temperature range of 400° to 500°C for short durations and calcination between 650° and 1250°C, produces highly reactive and homogeneous fine zirconia powders.

- A process involving the agglomeration of zirconia powder through build-up granulation to create a granulate that is flowable and can be processed without binders, allowing for direct sintering and reduced material loss, using a suspension with minimal organic components and agglomerating without the addition or removal of liquids.

Environmental Impact of Zirconia Manufacturing

The environmental impact of zirconia manufacturing is a critical consideration in the quest to reduce processing costs. The production of zirconia involves several energy-intensive processes, including mining, refining, and sintering, which contribute significantly to its carbon footprint. The extraction of zircon sand, the primary raw material for zirconia production, often requires extensive mining operations that can lead to habitat destruction and soil erosion. Furthermore, the refining process typically involves high-temperature treatments and chemical reactions, consuming substantial amounts of energy and potentially releasing harmful emissions.

Water usage is another environmental concern in zirconia manufacturing. The production process requires large volumes of water for cooling, cleaning, and chemical reactions. In water-scarce regions, this can strain local water resources and potentially lead to conflicts with other water users. Additionally, the wastewater generated during production may contain trace amounts of heavy metals and other contaminants, necessitating proper treatment before discharge to prevent water pollution.

The use of chemical additives in zirconia processing also poses environmental risks. Stabilizers, binders, and other additives used to enhance the properties of zirconia can be toxic or persistent in the environment if not properly managed. Proper handling, storage, and disposal of these chemicals are essential to minimize their environmental impact and comply with increasingly stringent regulations.

Waste management is a significant challenge in zirconia manufacturing. The production process generates various types of waste, including slag, dust, and off-spec materials. Improper disposal of these wastes can lead to soil and groundwater contamination. However, there are opportunities for improvement in this area, such as developing recycling techniques for zirconia waste or finding alternative uses for byproducts in other industries.

Energy efficiency improvements offer a dual benefit of reducing both environmental impact and processing costs. Implementing more efficient furnaces, optimizing heating cycles, and recovering waste heat can significantly decrease energy consumption and associated greenhouse gas emissions. Additionally, transitioning to renewable energy sources for powering manufacturing facilities can further reduce the carbon footprint of zirconia production.

Adopting cleaner production technologies and practices is crucial for mitigating the environmental impact of zirconia manufacturing. This may include implementing closed-loop systems to minimize water consumption and waste generation, using more environmentally friendly chemical additives, and improving air filtration systems to reduce emissions. Such measures not only benefit the environment but can also lead to cost savings through improved resource efficiency and reduced regulatory compliance costs.

Supply Chain Optimization for Zirconia Production

Supply chain optimization plays a crucial role in reducing the processing costs of zirconia production. By streamlining the entire supply chain, from raw material sourcing to final product delivery, manufacturers can significantly improve efficiency and reduce overall expenses.

One key aspect of supply chain optimization is the strategic sourcing of raw materials. Zircon sand, the primary raw material for zirconia production, can be sourced from various locations worldwide. Establishing long-term relationships with reliable suppliers and negotiating favorable contracts can help secure a stable supply at competitive prices. Additionally, diversifying the supplier base can mitigate risks associated with supply disruptions and price fluctuations.

Efficient inventory management is another critical factor in optimizing the supply chain. Implementing just-in-time (JIT) inventory systems can help reduce storage costs and minimize the risk of obsolescence. Advanced forecasting techniques and real-time inventory tracking systems can ensure that production facilities maintain optimal stock levels without overstocking or experiencing shortages.

Transportation and logistics optimization can lead to substantial cost savings in zirconia production. Careful route planning, consolidation of shipments, and selection of cost-effective transportation modes can reduce freight expenses. Utilizing intermodal transportation, where appropriate, can offer a balance between cost and speed. Furthermore, implementing advanced logistics management software can improve visibility across the supply chain and enable better decision-making.

Process integration and automation throughout the supply chain can enhance overall efficiency. Implementing Enterprise Resource Planning (ERP) systems can facilitate seamless communication between different departments and streamline operations. Automated warehousing systems and robotic process automation in production facilities can reduce labor costs and minimize errors.

Collaboration with suppliers and customers is essential for effective supply chain optimization. Sharing demand forecasts and production schedules with suppliers can help them plan their operations more efficiently, potentially leading to cost reductions that can be passed on to the manufacturer. Similarly, working closely with customers to understand their needs and preferences can help optimize production schedules and reduce waste.

Continuous improvement initiatives, such as Six Sigma and Lean Manufacturing, can be applied to the entire supply chain to identify and eliminate inefficiencies. Regular audits and performance assessments can help identify areas for improvement and drive ongoing optimization efforts.

By implementing these supply chain optimization strategies, zirconia manufacturers can achieve significant reductions in processing costs, improve operational efficiency, and enhance their competitive position in the market.