How to Innovate Using Zirconia for Better Insulation?

Zirconia Insulation Background and Objectives

Zirconia, a ceramic material known for its exceptional thermal properties, has been a subject of interest in the field of insulation for several decades. The evolution of zirconia-based insulation technologies can be traced back to the mid-20th century when researchers first recognized its potential for high-temperature applications. Since then, the development of zirconia insulation has been driven by the increasing demand for more efficient and durable thermal management solutions across various industries.

The primary objective of innovating with zirconia for better insulation is to harness its unique characteristics, such as low thermal conductivity, high melting point, and excellent chemical stability, to create advanced insulation materials that outperform traditional options. This goal aligns with the broader trend of energy conservation and sustainability in industrial processes, aerospace applications, and building construction.

One of the key technological trends in zirconia insulation is the development of nanostructured zirconia materials. These materials exhibit enhanced thermal insulation properties due to their increased surface area and reduced thermal conductivity at the nanoscale. Researchers are exploring various synthesis methods and composite formulations to optimize the performance of nanostructured zirconia insulation.

Another significant trend is the integration of zirconia into multi-layered insulation systems. By combining zirconia with other complementary materials, engineers aim to create synergistic effects that enhance overall insulation performance across a wider range of temperatures and environmental conditions. This approach has shown promise in applications such as thermal barrier coatings for gas turbines and spacecraft heat shields.

The development of zirconia-based aerogels represents a frontier in insulation technology. These ultra-low-density materials leverage the inherent properties of zirconia while introducing a highly porous structure that further reduces thermal conductivity. Ongoing research in this area focuses on improving the mechanical strength and durability of zirconia aerogels to expand their practical applications.

As the field progresses, researchers are also investigating the potential of doped zirconia systems. By introducing specific impurities or additives into the zirconia crystal structure, it is possible to tailor its thermal and mechanical properties for specific insulation requirements. This approach opens up new possibilities for customized insulation solutions in demanding environments.

The technological objectives for zirconia insulation innovation include achieving higher temperature resistance, reducing thermal conductivity across a broader temperature range, enhancing mechanical strength and durability, and developing cost-effective manufacturing processes for large-scale production. Additionally, there is a growing emphasis on creating environmentally friendly and recyclable zirconia-based insulation materials to address sustainability concerns.

Market Analysis for Advanced Insulation Materials

The advanced insulation materials market is experiencing significant growth, driven by increasing demand for energy-efficient solutions across various industries. Zirconia, a ceramic material known for its exceptional thermal properties, is emerging as a promising candidate for innovative insulation applications. The global market for advanced insulation materials is projected to reach $20.5 billion by 2025, with a compound annual growth rate (CAGR) of 5.8% from 2020 to 2025.

The construction sector remains the largest consumer of advanced insulation materials, accounting for approximately 40% of the market share. This is primarily due to stringent building energy codes and a growing emphasis on sustainable construction practices. The industrial sector, including oil and gas, petrochemicals, and power generation, is also a significant contributor to market growth, representing about 30% of the demand.

Zirconia-based insulation materials are gaining traction in high-temperature applications, particularly in aerospace, automotive, and industrial furnaces. The aerospace industry, in particular, is showing keen interest in zirconia-based thermal barrier coatings for jet engines, which is expected to drive market growth in this segment by 7.2% annually over the next five years.

Geographically, North America and Europe are the leading markets for advanced insulation materials, collectively accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 7.5% during the forecast period, driven by rapid industrialization and urbanization in countries like China and India.

The market for zirconia-based insulation materials is relatively concentrated, with a few key players dominating the landscape. These include Saint-Gobain, Aspen Aerogels, and Unifrax. However, there is increasing competition from smaller, specialized manufacturers focusing on niche applications of zirconia in insulation.

One of the key trends shaping the market is the growing demand for eco-friendly and sustainable insulation materials. This has led to increased research and development efforts in bio-based and recycled insulation materials, which could potentially compete with zirconia-based solutions in certain applications.

The automotive industry is emerging as a promising market for zirconia-based insulation, particularly in electric vehicles (EVs). The need for efficient thermal management in EV batteries is driving innovation in this sector, with zirconia-based materials offering potential solutions for improved battery performance and safety.

In conclusion, the market analysis indicates a strong growth potential for advanced insulation materials, with zirconia-based solutions poised to play a significant role in high-performance applications. The increasing focus on energy efficiency and sustainability across industries is expected to drive continued innovation and market expansion in the coming years.

Current Zirconia Insulation Technologies and Challenges

Zirconia has emerged as a promising material for advanced insulation applications due to its exceptional thermal properties and stability at high temperatures. However, the current state of zirconia insulation technologies faces several challenges that need to be addressed to fully harness its potential.

One of the primary technologies in zirconia insulation is the use of yttria-stabilized zirconia (YSZ) coatings. These coatings are widely employed in thermal barrier applications, particularly in gas turbines and aerospace components. YSZ coatings offer excellent thermal insulation properties and can withstand extreme temperatures. However, they are limited by their relatively high thermal conductivity compared to other ceramic materials and susceptibility to sintering at very high temperatures, which can lead to reduced insulation performance over time.

Another significant technology is the development of zirconia-based aerogels. These ultra-low density materials exhibit exceptional insulation properties due to their highly porous structure. Zirconia aerogels have shown promise in applications requiring both thermal and acoustic insulation. However, the main challenges lie in their mechanical fragility and the complexity of the manufacturing process, which currently limits their widespread adoption in industrial applications.

Zirconia-based composite materials represent another important area of development. By combining zirconia with other ceramics or polymers, researchers aim to create materials with enhanced insulation properties while addressing some of the limitations of pure zirconia. For instance, zirconia-alumina composites have shown improved thermal shock resistance and mechanical strength. However, optimizing the composition and manufacturing processes to achieve the desired balance of properties remains a significant challenge.

The use of nanostructured zirconia for insulation is an emerging technology with great potential. Nanostructured zirconia coatings and bulk materials can offer improved insulation performance due to increased phonon scattering at grain boundaries. However, controlling the nanostructure during processing and ensuring its stability at high temperatures pose significant technical hurdles.

A major challenge across all zirconia insulation technologies is the trade-off between thermal insulation performance and mechanical properties. Enhancing porosity or reducing thermal conductivity often comes at the cost of decreased mechanical strength and durability. Finding innovative ways to overcome this trade-off is crucial for the advancement of zirconia-based insulation materials.

Another significant challenge is the high cost associated with zirconia production and processing. This economic factor limits the widespread adoption of zirconia insulation in many potential applications. Developing more cost-effective manufacturing methods and exploring alternative precursors are areas of ongoing research to address this challenge.

Lastly, the long-term stability and performance of zirconia insulation under various environmental conditions remain areas of concern. Issues such as phase transformations, grain growth, and chemical interactions with other materials at high temperatures can affect the insulation properties over time. Addressing these durability concerns is essential for the reliable use of zirconia insulation in critical applications.

Existing Zirconia Insulation Applications

01 Zirconia-based thermal insulation materials

Zirconia is used as a primary component in thermal insulation materials due to its excellent heat resistance and low thermal conductivity. These materials are often used in high-temperature applications such as furnaces, aerospace, and industrial processes. The zirconia-based insulation can be in various forms, including coatings, fibers, and porous structures.- Zirconia-based thermal insulation materials: Zirconia is used as a primary component in thermal insulation materials due to its excellent heat resistance and low thermal conductivity. These materials are often used in high-temperature applications such as furnaces, engines, and aerospace components. The zirconia-based insulation can be in various forms, including coatings, fibers, and porous structures.

- Zirconia composite insulation systems: Composite insulation systems incorporating zirconia are developed to enhance thermal performance and mechanical properties. These composites may combine zirconia with other materials such as alumina, silica, or yttria to create advanced insulation solutions. The resulting composites often exhibit improved durability, thermal shock resistance, and insulation efficiency.

- Zirconia insulation in electronic devices: Zirconia insulation is utilized in electronic components and devices to provide thermal management and electrical isolation. This application is particularly important in high-power electronics, semiconductor manufacturing, and microelectronics where heat dissipation and electrical insulation are critical factors.

- Zirconia-based insulation coatings: Specialized coatings containing zirconia are developed for insulation purposes. These coatings can be applied to various substrates to provide thermal protection and corrosion resistance. The coatings may be engineered with specific porosity, thickness, and composition to optimize their insulating properties for different applications.

- Manufacturing processes for zirconia insulation: Various manufacturing techniques are employed to produce zirconia-based insulation materials. These may include sol-gel processes, plasma spraying, chemical vapor deposition, and sintering methods. The manufacturing processes are optimized to control the microstructure, porosity, and phase composition of the zirconia insulation, which directly influence its thermal and mechanical properties.

02 Zirconia composite insulation systems

Composite insulation systems incorporating zirconia are developed to enhance thermal performance and mechanical properties. These systems often combine zirconia with other materials such as alumina, silica, or yttria to create advanced insulation solutions. The composites can be tailored for specific applications, offering improved durability and insulation efficiency.Expand Specific Solutions03 Zirconia insulation in electronic devices

Zirconia insulation is utilized in electronic components and devices to provide thermal management and electrical isolation. This application is particularly important in high-power electronics, semiconductor manufacturing, and miniaturized devices where heat dissipation and electrical insulation are critical.Expand Specific Solutions04 Manufacturing processes for zirconia insulation

Various manufacturing techniques are employed to produce zirconia insulation materials, including sol-gel processes, plasma spraying, and sintering. These methods allow for the creation of different forms of zirconia insulation, such as coatings, powders, and bulk materials, each tailored for specific applications and performance requirements.Expand Specific Solutions05 Zirconia insulation in extreme environments

Zirconia-based insulation materials are developed for use in extreme environments, such as high-temperature, corrosive, or oxidizing conditions. These specialized insulation solutions are designed to maintain their properties and performance under severe operating conditions, making them suitable for applications in aerospace, energy production, and chemical processing industries.Expand Specific Solutions

Key Players in Zirconia Insulation Industry

The innovation landscape for zirconia-based insulation is in a growth phase, with increasing market size driven by demand for high-performance thermal barriers. The technology's maturity varies across applications, ranging from established use in aerospace to emerging opportunities in energy and electronics. Key players like Saint-Gobain Ceramics & Plastics, Praxair Technology, and 3M Innovative Properties are advancing material formulations and manufacturing processes. Semiconductor Energy Laboratory and QUALCOMM are exploring zirconia's potential in microelectronics, while companies such as Safran Aircraft Engines and Siemens are focusing on industrial and aerospace applications. This competitive field is characterized by ongoing R&D efforts to enhance zirconia's insulating properties, durability, and cost-effectiveness across diverse sectors.

Saint-Gobain Ceramics & Plastics, Inc.

Saint-Gobain Isover

Innovative Zirconia Insulation Research

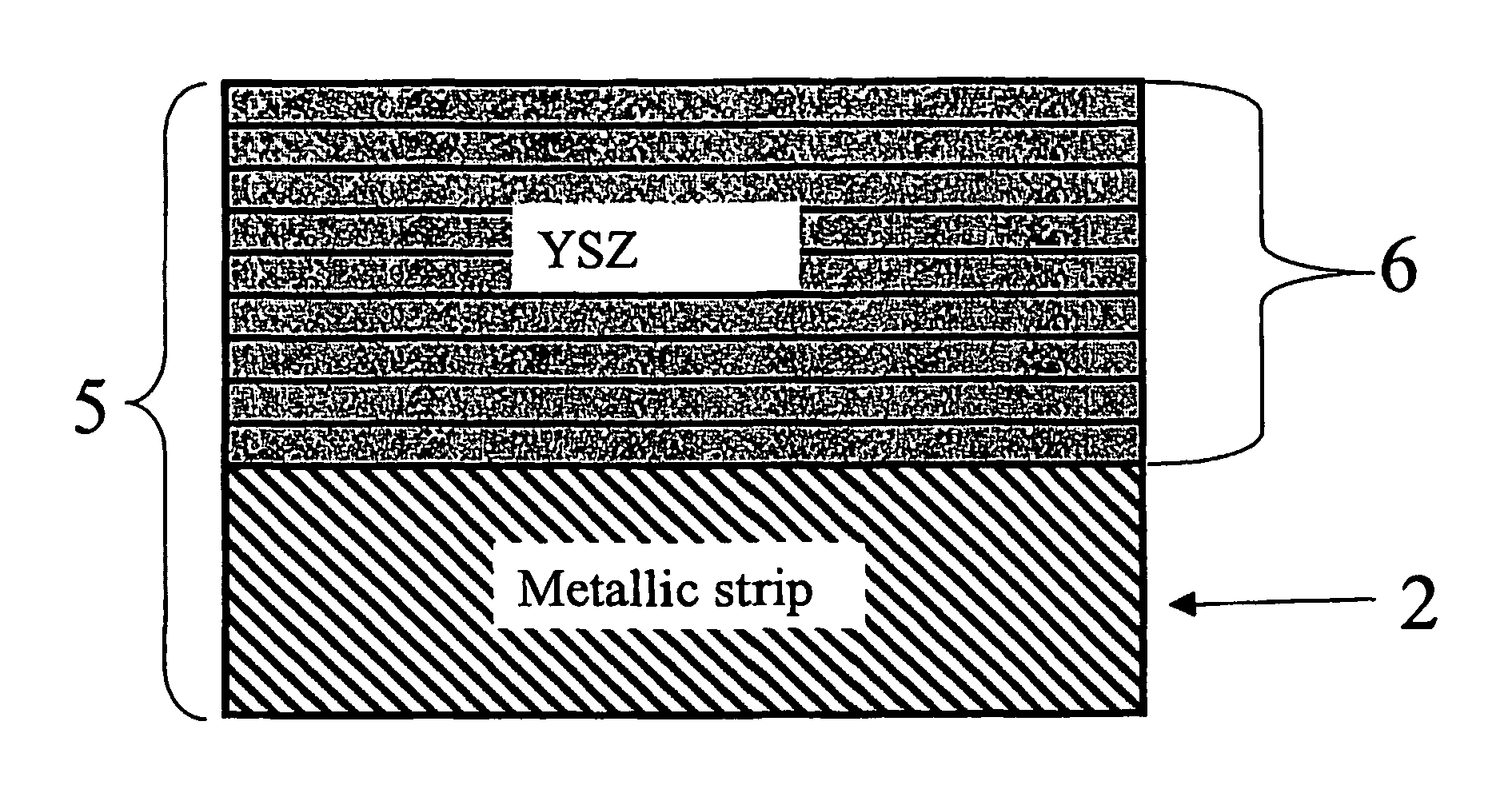

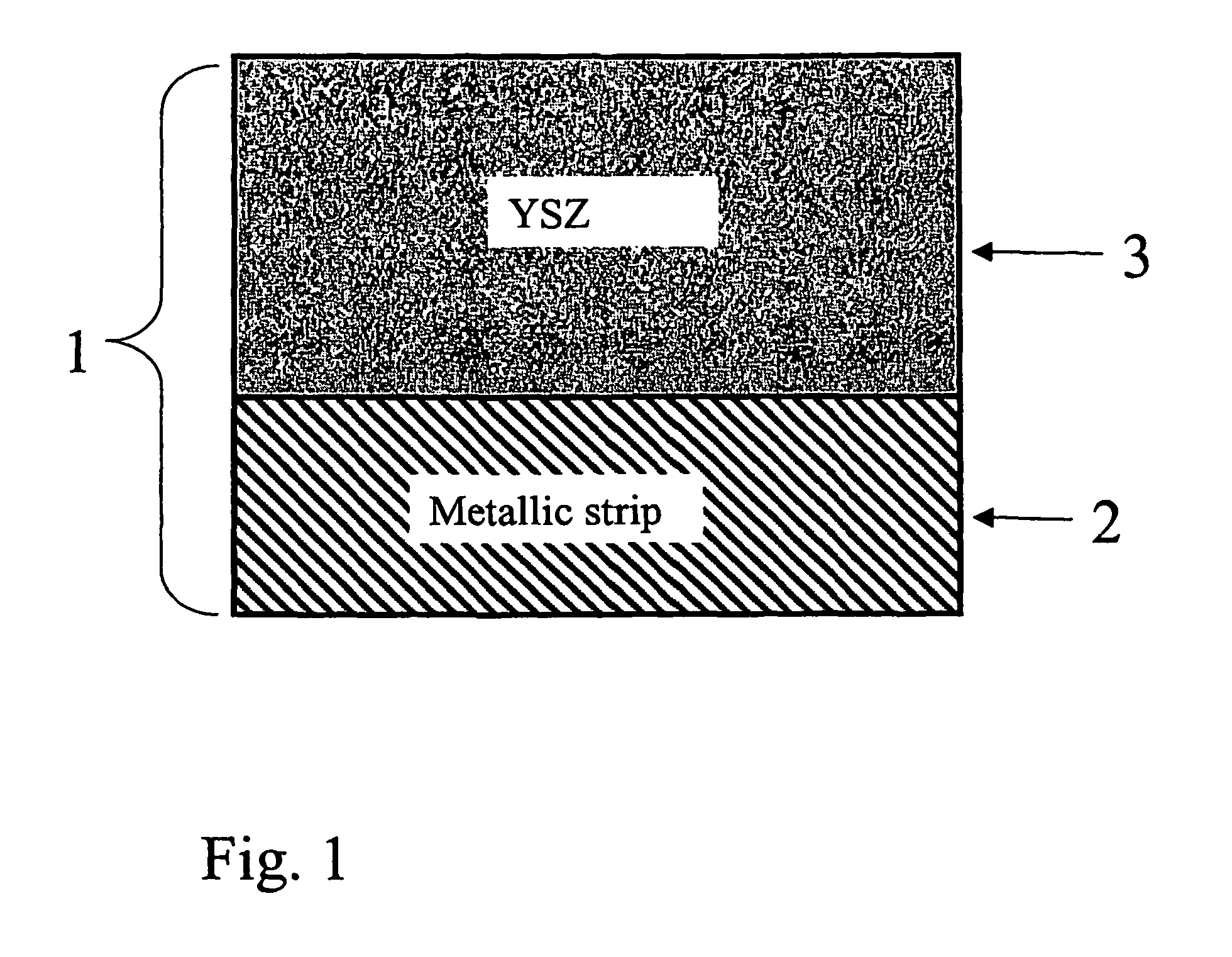

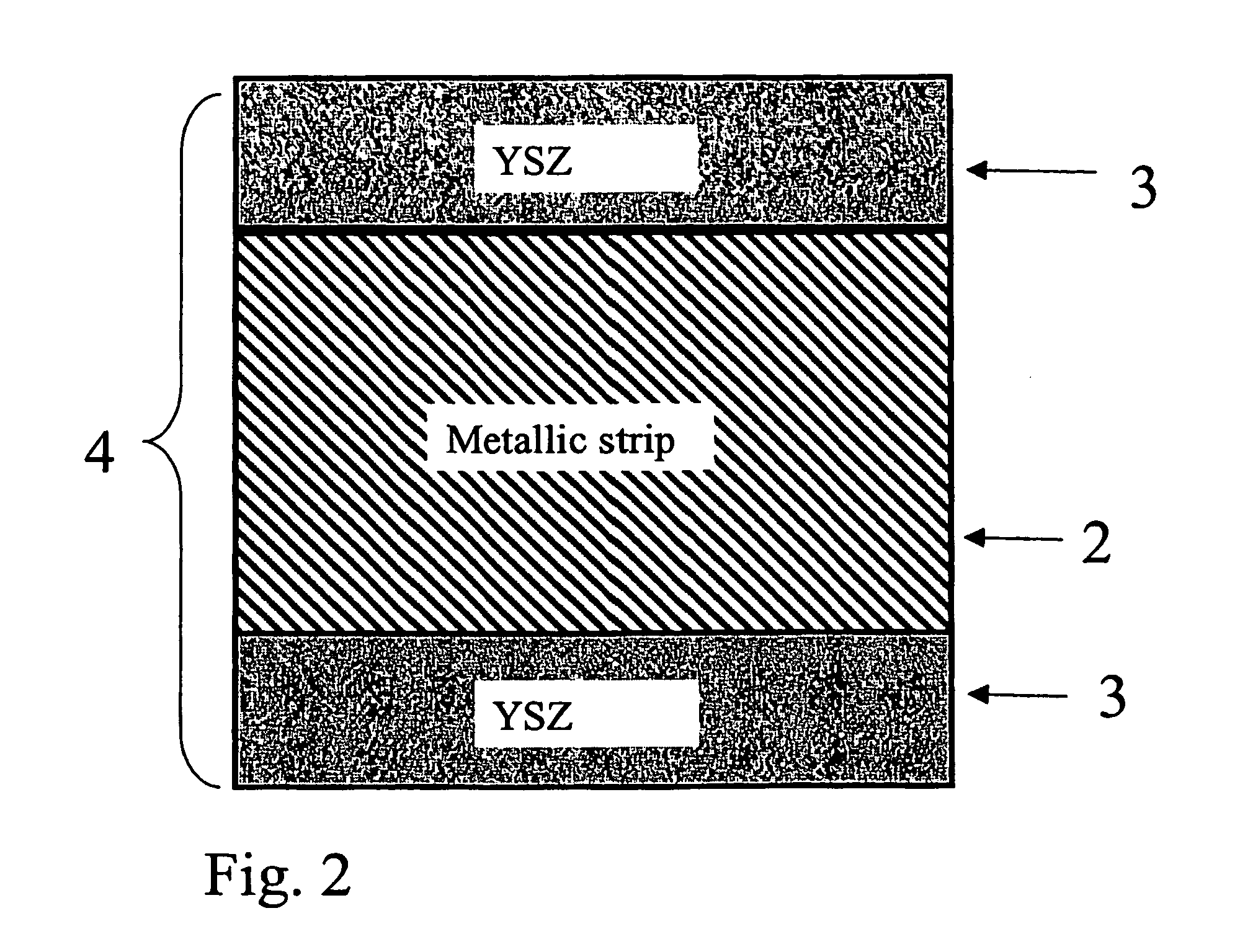

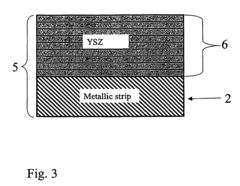

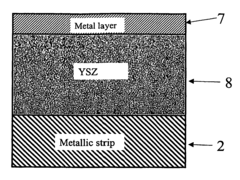

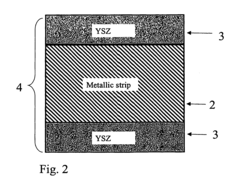

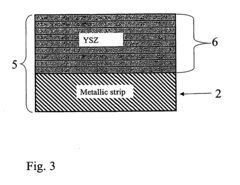

- A zirconia-coated metallic strip product with a low thermal expansion mismatch is developed, where a thin, uniform, and dense yttrium-stabilized zirconia layer is applied to the metallic strip, optionally with a multi-layer structure, to ensure excellent adhesion and electrical insulation, and a metal back contact is added as needed for specific thin film products.

- A zirconia-coated metallic strip product with a low thermal expansion mismatch is developed, where a thin, uniform, and dense yttrium-stabilized zirconia layer is applied to match the thermal expansion of the metallic strip substrate, ensuring good adhesion and electrical insulation, and optionally coated on both sides to prevent curling during heat treatments, with a metal back contact layer added for electrical connectivity.

Environmental Impact of Zirconia Insulation

The environmental impact of zirconia insulation is a crucial consideration in its application and innovation. Zirconia, as an advanced ceramic material, offers superior insulation properties that can significantly reduce energy consumption in various industries. This reduction in energy usage translates to lower greenhouse gas emissions, contributing to global efforts in combating climate change.

One of the primary environmental benefits of zirconia insulation is its longevity. Unlike traditional insulation materials that may degrade over time, zirconia maintains its performance characteristics for extended periods. This durability reduces the need for frequent replacements, minimizing waste generation and the associated environmental impacts of manufacturing and disposal.

In the production phase, zirconia insulation requires high-temperature processing, which can be energy-intensive. However, advancements in manufacturing technologies are continuously improving the energy efficiency of production processes. The use of renewable energy sources in zirconia production facilities can further mitigate the environmental footprint of its manufacture.

Zirconia's resistance to chemical corrosion and high temperatures makes it an excellent choice for harsh industrial environments. This resistance not only extends the lifespan of insulation but also reduces the risk of harmful chemical leaching into the environment. In applications such as nuclear power plants, zirconia's stability contributes to enhanced safety and reduced environmental risks associated with potential accidents.

The use of zirconia in thermal barrier coatings for gas turbines and jet engines leads to improved fuel efficiency and reduced emissions in the aerospace and power generation sectors. This indirect environmental benefit is significant, considering the large-scale energy consumption in these industries.

Recycling and end-of-life management of zirconia insulation present both challenges and opportunities. While the material itself is not biodegradable, its inert nature prevents harmful decomposition products. Research into effective recycling methods for zirconia-based materials is ongoing, with potential for recovering and reusing the material in new applications, further reducing its environmental impact.

In the context of building insulation, zirconia-based materials can contribute to the development of more energy-efficient structures. This aligns with global green building initiatives, potentially leading to substantial reductions in the carbon footprint of the built environment over time.

As innovations in zirconia insulation continue, there is a growing focus on incorporating sustainability principles throughout the material's lifecycle. This includes exploring bio-based precursors for zirconia production, optimizing manufacturing processes for reduced environmental impact, and developing more efficient application methods to maximize the material's insulative properties while minimizing resource use.

Cost-Benefit Analysis of Zirconia Insulation

The cost-benefit analysis of zirconia insulation reveals a compelling case for its adoption in various industrial and commercial applications. Initially, the implementation of zirconia-based insulation systems may require a higher upfront investment compared to traditional insulation materials. This is primarily due to the advanced manufacturing processes and the intrinsic value of zirconia as a raw material. However, the long-term benefits often outweigh these initial costs, making it an economically viable solution for many industries.

One of the most significant advantages of zirconia insulation is its exceptional thermal efficiency. The material's low thermal conductivity translates into reduced heat loss, which can lead to substantial energy savings over time. In high-temperature industrial processes, such as in furnaces or kilns, the use of zirconia insulation can result in decreased fuel consumption and lower operational costs. These energy savings not only contribute to cost reduction but also align with sustainability goals by reducing carbon emissions.

The durability and longevity of zirconia insulation systems present another key benefit. Unlike many conventional insulation materials that degrade over time, zirconia maintains its structural integrity and insulating properties even under extreme conditions. This resilience translates into reduced maintenance and replacement costs, extending the lifespan of the insulation system and minimizing production downtime in industrial settings.

In terms of space efficiency, zirconia insulation often allows for thinner insulation layers without compromising thermal performance. This characteristic can be particularly valuable in applications where space is at a premium, such as in aerospace or automotive industries. The ability to achieve high insulation with less material can lead to weight reduction in final products, potentially improving fuel efficiency in transportation applications.

However, it's important to consider potential drawbacks. The specialized nature of zirconia insulation may require specific expertise for installation and maintenance, which could incur additional costs. Additionally, in applications where extreme temperature fluctuations are common, the thermal shock resistance of zirconia must be carefully evaluated to prevent potential cracking or failure.

From an environmental perspective, the production of zirconia insulation may have a higher initial carbon footprint compared to some traditional materials. However, the long-term energy savings and reduced need for replacement can offset this impact over the lifecycle of the insulation system. This aspect is particularly relevant in industries striving to meet stringent environmental regulations and sustainability targets.

In conclusion, while the initial investment in zirconia insulation may be higher, the long-term benefits in energy efficiency, durability, and space optimization often justify the cost. The decision to implement zirconia insulation should be based on a comprehensive analysis of specific application requirements, long-term operational costs, and environmental considerations.