How to Implement Zirconia in Precision Engineering?

Zirconia in Precision Engineering: Background and Objectives

Zirconia, a remarkable ceramic material, has emerged as a game-changer in precision engineering over the past few decades. Its unique combination of properties, including high strength, toughness, and wear resistance, has propelled it to the forefront of advanced materials science. The journey of zirconia in precision engineering began in the 1970s when researchers discovered its potential for structural applications.

The evolution of zirconia technology has been marked by significant milestones, from its initial use in cutting tools to its current applications in aerospace, medical devices, and microelectronics. The development of various zirconia compositions, such as yttria-stabilized zirconia (YSZ) and ceria-stabilized zirconia (CSZ), has expanded its versatility and performance in different engineering contexts.

As we delve into the implementation of zirconia in precision engineering, our primary objective is to explore the cutting-edge techniques and methodologies that enable the effective utilization of this material in high-precision applications. This involves understanding the intricate processes of zirconia synthesis, shaping, and finishing, as well as the challenges associated with its integration into complex engineering systems.

One of the key goals in this field is to optimize zirconia's mechanical properties for specific applications. This includes enhancing its fracture toughness, improving its thermal shock resistance, and fine-tuning its wear characteristics. Additionally, researchers are focused on developing novel zirconia-based composites that combine the best attributes of zirconia with those of other materials, opening up new possibilities in precision engineering.

Another critical objective is to refine the manufacturing processes for zirconia components. This encompasses advancements in powder metallurgy, sintering techniques, and precision machining methods. The aim is to achieve tighter tolerances, superior surface finishes, and more complex geometries in zirconia parts, thereby expanding its applicability in high-precision industries.

The implementation of zirconia in precision engineering also necessitates a deep understanding of its long-term performance under various operational conditions. This includes studying its behavior under extreme temperatures, corrosive environments, and high-stress scenarios. By comprehensively analyzing these factors, engineers can develop more reliable and durable zirconia-based solutions for critical applications.

As we look to the future, the trajectory of zirconia in precision engineering points towards even more sophisticated applications. From next-generation semiconductor manufacturing equipment to advanced biomedical implants, the potential of zirconia continues to expand. The ongoing research in this field aims to push the boundaries of what's possible with this extraordinary material, driving innovation across multiple industries and technological domains.

Market Demand Analysis for Zirconia-based Precision Components

The market demand for zirconia-based precision components has been experiencing significant growth in recent years, driven by the material's exceptional properties and its wide-ranging applications across various industries. Zirconia, known for its high strength, wear resistance, and biocompatibility, has become increasingly popular in precision engineering applications.

In the medical and dental sectors, zirconia-based components have seen a surge in demand, particularly for dental implants, crowns, and bridges. The material's aesthetic appeal, durability, and biocompatibility have made it a preferred choice over traditional metal-based alternatives. This trend is expected to continue as the global dental prosthetics market expands.

The aerospace and automotive industries have also shown increased interest in zirconia-based precision components. The material's high temperature resistance and low thermal conductivity make it ideal for use in engine components, sensors, and other high-stress applications. As these industries push for lighter, more efficient vehicles and aircraft, the demand for zirconia components is projected to grow steadily.

In the electronics sector, zirconia is gaining traction in the production of precision components for semiconductor manufacturing equipment. Its excellent electrical insulation properties and resistance to corrosive environments make it suitable for use in plasma chambers and other critical components. As the semiconductor industry continues to advance, the demand for high-purity zirconia components is expected to rise.

The growing focus on renewable energy sources has also created new opportunities for zirconia-based precision components. In the solar energy sector, zirconia is used in the production of crucibles for silicon ingot growth, a critical process in solar cell manufacturing. The material's high temperature stability and chemical inertness make it ideal for this application.

Market analysis indicates that the Asia-Pacific region, particularly China and Japan, is expected to be a major driver of growth in the zirconia-based precision components market. This is due to the rapid industrialization, increasing healthcare expenditure, and growing electronics manufacturing sector in these countries.

Despite the positive outlook, challenges remain in the widespread adoption of zirconia in precision engineering. The high cost of production and processing compared to traditional materials is a significant barrier. However, ongoing research and development efforts are focused on improving manufacturing processes and reducing costs, which could lead to broader market penetration in the coming years.

In conclusion, the market demand for zirconia-based precision components shows strong growth potential across multiple industries. As technology advances and manufacturing processes improve, the material's unique properties are likely to drive increased adoption in precision engineering applications, opening up new opportunities for innovation and market expansion.

Current State and Challenges in Zirconia Implementation

The implementation of zirconia in precision engineering has made significant strides in recent years, yet it still faces several challenges. Currently, zirconia is widely recognized for its exceptional mechanical properties, including high strength, toughness, and wear resistance. These characteristics make it an ideal material for various precision engineering applications, such as cutting tools, bearings, and medical implants.

One of the primary advantages of zirconia in precision engineering is its ability to maintain dimensional stability under extreme conditions. This property is particularly valuable in applications requiring high precision and reliability. Moreover, zirconia's biocompatibility has led to its increased use in medical and dental implants, where it offers superior aesthetics and durability compared to traditional materials.

However, despite these advancements, several challenges persist in the widespread implementation of zirconia in precision engineering. The most significant hurdle is the material's susceptibility to low-temperature degradation, also known as aging. This phenomenon can lead to a gradual reduction in the material's mechanical properties over time, potentially compromising the long-term performance of zirconia-based components.

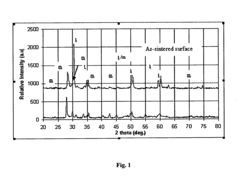

Another challenge lies in the complex manufacturing processes required to produce high-quality zirconia components. Precision engineering demands tight tolerances and consistent material properties, which can be difficult to achieve with zirconia due to its high hardness and brittleness. The sintering process, crucial for achieving the desired mechanical properties, requires careful control of temperature and atmosphere to prevent defects and ensure uniform density.

The cost of zirconia raw materials and processing equipment also presents a barrier to wider adoption in some precision engineering applications. While the material offers superior performance in many cases, the higher initial investment can be a deterrent for some manufacturers, particularly in cost-sensitive industries.

Furthermore, the limited availability of specialized knowledge and expertise in working with zirconia poses a challenge. Many engineers and technicians are more familiar with traditional materials, and the unique properties of zirconia require specific handling and processing techniques that are not widely understood.

Addressing these challenges requires ongoing research and development efforts. Current focus areas include improving the aging resistance of zirconia through compositional modifications and surface treatments, developing more efficient and cost-effective manufacturing processes, and enhancing the material's machinability without compromising its mechanical properties.

In conclusion, while zirconia has established itself as a valuable material in precision engineering, overcoming the existing challenges will be crucial for its broader implementation. Continued advancements in material science, manufacturing technologies, and engineering practices are necessary to fully harness the potential of zirconia in precision engineering applications.

Existing Zirconia Implementation Techniques and Methodologies

01 Zirconia synthesis and processing methods

Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods can involve different precursors, reaction conditions, and post-processing steps to achieve desired properties for specific applications.- Zirconia synthesis and processing: Various methods for synthesizing and processing zirconia materials, including techniques for controlling particle size, crystalline structure, and purity. This encompasses sol-gel processes, hydrothermal synthesis, and other advanced manufacturing techniques to produce zirconia with specific properties for different applications.

- Zirconia-based composites and coatings: Development of composite materials and coatings incorporating zirconia to enhance mechanical, thermal, and chemical properties. This includes zirconia-reinforced ceramics, zirconia-containing protective coatings, and hybrid materials combining zirconia with other substances for improved performance in various industrial and technological applications.

- Dental and biomedical applications of zirconia: Utilization of zirconia in dental and biomedical fields, focusing on its biocompatibility, aesthetic properties, and mechanical strength. This covers zirconia-based dental implants, prosthetics, and other medical devices that leverage zirconia's unique characteristics for improved patient outcomes and longevity of medical implants.

- Zirconia in fuel cells and energy applications: Integration of zirconia materials in fuel cells, particularly solid oxide fuel cells (SOFCs), and other energy-related applications. This includes the use of zirconia as an electrolyte material, catalyst support, and in other components to enhance energy conversion efficiency and durability of fuel cell systems.

- Stabilization and phase transformation of zirconia: Techniques for stabilizing zirconia in specific crystalline phases and controlling phase transformations. This involves the addition of dopants, heat treatments, and other methods to manipulate the crystal structure of zirconia for tailored properties in applications ranging from structural ceramics to electronic components.

02 Zirconia-based dental materials

Zirconia is widely used in dental applications due to its biocompatibility, strength, and aesthetic properties. Innovations in this field include improved formulations for dental prosthetics, coatings, and composite materials that enhance durability and mimic natural tooth appearance.Expand Specific Solutions03 Zirconia in advanced ceramics and composites

Zirconia is incorporated into advanced ceramic and composite materials to enhance mechanical properties, thermal resistance, and chemical stability. These materials find applications in aerospace, automotive, and industrial sectors where high performance under extreme conditions is required.Expand Specific Solutions04 Stabilized zirconia for fuel cells and sensors

Stabilized zirconia, particularly yttria-stabilized zirconia (YSZ), is crucial in solid oxide fuel cells and oxygen sensors. Research focuses on improving ionic conductivity, thermal stability, and long-term performance of these materials under operating conditions.Expand Specific Solutions05 Zirconia nanoparticles and their applications

Zirconia nanoparticles are developed for various applications including catalysis, coatings, and biomedical uses. Research in this area focuses on controlling nanoparticle size, shape, and surface properties to tailor their performance for specific applications.Expand Specific Solutions

Key Players in Zirconia Manufacturing and Precision Engineering

The implementation of zirconia in precision engineering is in a mature growth phase, with a steadily expanding market driven by increasing demand in various industries. The global zirconia market size is projected to reach significant figures, reflecting its widespread adoption. Technologically, zirconia applications are well-established, with ongoing refinements and innovations. Companies like 3M Innovative Properties Co., Tosoh Corp., and Saint-Gobain Centre de Recherches et d'Études Européen SAS are at the forefront, continuously advancing zirconia's capabilities in precision engineering. Academic institutions such as the University of Connecticut and Rutgers State University of New Jersey contribute to research and development, while industrial players like BYD Co., Ltd. and Sumitomo Chemical Co., Ltd. focus on practical applications and large-scale production.

3M Innovative Properties Co.

Kuraray Noritake Dental, Inc.

Core Innovations in Zirconia Material Science and Engineering

- Simultaneously adding yttria, ceria, and chromia to partially stabilized zirconia in specific proportions to create a microstructure with high tetragonal phase content, resulting in a ceramic with bending strength over 1150 MPa and fracture toughness over 15 MPa.m1/2, achieved through a process involving mixing, compacting, and sintering with controlled temperature and time.

- A production method involving milling a semi-sintered zirconia body to achieve the approximate outer shape before complete sintering, followed by precise milling of the completely sintered implant bridge for fitting parts and screw holes using a CAD/CAM system, ensuring high accuracy and strength.

Environmental Impact and Sustainability of Zirconia Usage

The implementation of zirconia in precision engineering has significant environmental implications and sustainability considerations. Zirconia, as a ceramic material, offers several advantages in terms of durability and performance, but its production and use also present challenges from an environmental perspective.

The mining and processing of zirconium, the primary raw material for zirconia production, can have substantial environmental impacts. Open-pit mining operations often lead to habitat destruction, soil erosion, and potential water pollution. The extraction process also requires considerable energy input, contributing to greenhouse gas emissions. However, compared to some other materials used in precision engineering, such as rare earth elements, zirconium mining generally has a lower environmental footprint.

In the manufacturing phase, the production of zirconia ceramics involves high-temperature processes, which are energy-intensive. This energy consumption is a key factor in the material's overall environmental impact. Nevertheless, advancements in production technologies have led to more efficient processes, reducing energy requirements and associated emissions over time.

One of the most significant environmental benefits of using zirconia in precision engineering is its exceptional durability and longevity. Zirconia components often outlast their metal counterparts, reducing the need for frequent replacements. This extended lifespan translates to reduced material consumption and waste generation over the long term, aligning with sustainability goals.

Zirconia's chemical inertness is another positive attribute from an environmental standpoint. Unlike some metals used in precision engineering, zirconia does not corrode or leach harmful substances into the environment during its use phase. This characteristic makes it particularly suitable for applications in sensitive environments or where material contamination is a concern.

End-of-life considerations for zirconia components present both challenges and opportunities. While zirconia is not biodegradable, it is recyclable. Advanced recycling techniques can recover zirconia from used components, reducing the demand for virgin materials. However, the recycling process is complex and energy-intensive, requiring specialized facilities.

The sustainability of zirconia usage in precision engineering can be further enhanced through various strategies. These include optimizing manufacturing processes to reduce energy consumption, developing more efficient recycling technologies, and exploring bio-based alternatives for certain applications where feasible. Additionally, implementing life cycle assessment (LCA) methodologies can help identify areas for improvement in the environmental performance of zirconia-based products.

As industries increasingly prioritize sustainability, the role of zirconia in precision engineering is likely to evolve. Research into more environmentally friendly production methods and the development of circular economy models for zirconia products will be crucial in maximizing the material's sustainability potential while maintaining its superior performance characteristics.

Quality Control and Standards for Zirconia-based Components

Quality control and standards play a crucial role in the implementation of zirconia in precision engineering. The unique properties of zirconia, including its high strength, wear resistance, and chemical inertness, make it an ideal material for various precision components. However, these same properties also present challenges in manufacturing and quality assurance processes.

To ensure the reliability and performance of zirconia-based components, stringent quality control measures must be implemented throughout the production process. This begins with the selection of raw materials, where the purity and composition of zirconia powders are carefully controlled. Particle size distribution and morphology are critical factors that influence the final properties of the sintered components.

During the manufacturing process, key parameters such as sintering temperature, pressure, and atmosphere must be precisely controlled to achieve the desired microstructure and mechanical properties. Advanced process monitoring techniques, including in-situ sensors and real-time data analysis, are often employed to maintain consistency and detect any deviations from the optimal processing conditions.

Post-production quality control involves a battery of tests and inspections to verify the components' dimensional accuracy, surface finish, and mechanical properties. Non-destructive testing methods, such as ultrasonic inspection and X-ray computed tomography, are commonly used to detect internal defects or inhomogeneities that could compromise the performance of the components.

International standards organizations, such as ISO and ASTM, have developed specific guidelines for the testing and characterization of zirconia-based materials. These standards cover a wide range of properties, including density, hardness, fracture toughness, and wear resistance. Adherence to these standards ensures consistency and comparability across different manufacturers and applications.

In precision engineering applications, where tolerances are often measured in microns, the dimensional stability of zirconia components is of paramount importance. Specialized metrology equipment and techniques are employed to verify the geometric accuracy of complex shapes and features. This may include the use of coordinate measuring machines (CMMs) with sub-micron resolution and optical profilometry for surface texture analysis.

The development of industry-specific standards for zirconia-based components in precision engineering is an ongoing process. As new applications emerge and manufacturing technologies advance, these standards must evolve to address the unique requirements of each sector. Collaboration between manufacturers, end-users, and regulatory bodies is essential to establish relevant and effective quality control protocols.