Zirconia in Advanced Robotics: Enhancing Component Life

Zirconia in Robotics: Evolution and Objectives

Zirconia has emerged as a revolutionary material in the field of advanced robotics, marking a significant evolution in the development of high-performance components. The journey of zirconia in robotics can be traced back to the late 20th century when researchers began exploring its potential in industrial applications. Initially, zirconia was primarily used in static components due to its exceptional strength and wear resistance. However, as robotic systems became more sophisticated, the demand for materials that could withstand extreme conditions while maintaining precision increased dramatically.

The evolution of zirconia in robotics has been driven by the need for components that can operate in harsh environments, withstand high temperatures, and resist corrosion. Early applications focused on using zirconia in bearings and gears, where its superior hardness and low friction properties provided significant advantages over traditional materials. As manufacturing techniques improved, particularly in the realm of ceramic injection molding and precision machining, the use of zirconia expanded to more complex robotic parts.

A key milestone in the evolution of zirconia in robotics was the development of yttria-stabilized zirconia (YSZ), which enhanced the material's toughness and thermal shock resistance. This breakthrough allowed for the creation of robotic components that could maintain their structural integrity under rapid temperature changes and high stress conditions, opening up new possibilities in fields such as space exploration and deep-sea robotics.

The objectives of incorporating zirconia in advanced robotics are multifaceted. Primarily, the goal is to enhance the longevity and reliability of robotic components, particularly those subjected to extreme wear and tear. By utilizing zirconia, engineers aim to create robots that can operate for extended periods without the need for frequent maintenance or replacement of parts. This is especially crucial in applications where robot downtime can be costly or dangerous, such as in manufacturing plants or hazardous environment exploration.

Another key objective is to improve the precision and efficiency of robotic systems. Zirconia's dimensional stability and resistance to deformation under load make it an ideal material for components that require high accuracy, such as robotic arms and end effectors. The material's low thermal expansion coefficient also contributes to maintaining precision across varying temperature conditions, a critical factor in many industrial and scientific applications.

Looking forward, the objectives for zirconia in robotics include further miniaturization of components, enabling the development of more compact and agile robots. There is also a push towards creating biocompatible zirconia components for medical robots, leveraging the material's inert nature and compatibility with human tissue. As research continues, the goal is to unlock new properties of zirconia through advanced manufacturing techniques and novel composites, potentially revolutionizing the field of robotics even further.

Market Demand for Durable Robotic Components

The demand for durable robotic components has been steadily increasing across various industries, driven by the need for more reliable and long-lasting automation solutions. As robots become increasingly prevalent in manufacturing, healthcare, logistics, and other sectors, the market for high-performance components that can withstand harsh environments and prolonged use has expanded significantly.

In the manufacturing sector, which accounts for a substantial portion of the robotics market, there is a growing emphasis on reducing downtime and maintenance costs. This has led to a surge in demand for components that can operate continuously for extended periods without failure. Zirconia, with its exceptional wear resistance and thermal properties, has emerged as a promising material for enhancing the durability of critical robotic parts such as bearings, gears, and cutting tools.

The automotive industry, another major adopter of robotics, has shown particular interest in zirconia-based components for assembly line robots. These robots often operate in high-temperature environments and are subject to constant wear, making durable materials essential for maintaining production efficiency. The use of zirconia in robotic welding arms and precision handling tools has demonstrated significant improvements in component lifespan and performance.

In the healthcare sector, the adoption of surgical robots has created a niche market for ultra-durable, biocompatible components. Zirconia's chemical inertness and ability to withstand sterilization processes make it an ideal material for surgical robotic instruments that require frequent cleaning and sterilization. The demand for such components is expected to grow as minimally invasive robotic surgeries become more commonplace.

The logistics and warehousing industry has also contributed to the increasing demand for durable robotic components. With the rise of e-commerce and automated fulfillment centers, robots are being deployed in large numbers for picking, packing, and sorting operations. These robots often operate around the clock, necessitating components that can withstand continuous use and minimize maintenance intervals.

As industries push towards Industry 4.0 and smart manufacturing, the integration of sensors and IoT devices into robotic systems has further emphasized the need for durable components. Zirconia's electrical insulating properties make it suitable for housing sensitive electronic components in harsh industrial environments, protecting them from electromagnetic interference and physical damage.

The market demand for durable robotic components is not limited to traditional industrial settings. Emerging applications in extreme environments, such as deep-sea exploration, space missions, and nuclear power plants, are driving the development of ultra-durable robotic systems. In these scenarios, the use of advanced materials like zirconia becomes critical for ensuring the longevity and reliability of robotic components under extreme conditions.

Current Zirconia Applications and Challenges

Zirconia has found significant applications in advanced robotics, particularly in enhancing component life. Currently, this material is utilized in various robotic parts, including gears, bearings, and cutting tools, due to its exceptional mechanical properties and wear resistance. In industrial robotics, zirconia components are employed in high-stress environments where traditional materials fail to meet performance requirements.

One of the primary applications of zirconia in robotics is in precision gears and transmission systems. These components benefit from zirconia's high strength, hardness, and low friction coefficient, resulting in improved efficiency and longevity. Zirconia gears exhibit minimal wear and maintain dimensional stability over extended periods, crucial for maintaining accuracy in robotic movements.

Another notable application is in robotic end effectors and grippers. Zirconia's chemical inertness and biocompatibility make it ideal for use in medical and food processing robots, where contamination risks must be minimized. The material's resistance to corrosion and high temperatures also makes it suitable for robots operating in harsh industrial environments.

Despite these advantages, several challenges persist in the widespread adoption of zirconia in robotics. One significant hurdle is the high cost of zirconia components compared to traditional materials like steel or aluminum. This cost factor often limits its use to high-end or specialized robotic applications where performance justifies the expense.

Manufacturing complexity presents another challenge. Zirconia's hardness, while beneficial for wear resistance, makes it difficult to machine and shape into complex geometries often required in robotic components. This limitation necessitates advanced manufacturing techniques, further increasing production costs and time.

The brittleness of zirconia, particularly under certain conditions, remains a concern. While its overall toughness is high, zirconia can be susceptible to sudden failure under impact or extreme stress. This characteristic requires careful design considerations and may limit its use in certain high-impact robotic applications.

Thermal management is another challenge when using zirconia in robotics. Although the material has low thermal conductivity, which can be advantageous in some scenarios, it can also lead to heat buildup in certain applications. This necessitates innovative cooling solutions, especially in high-speed or high-load robotic systems.

Addressing these challenges is crucial for expanding the use of zirconia in advanced robotics. Ongoing research focuses on developing cost-effective manufacturing processes, improving the material's toughness without compromising other properties, and optimizing design methodologies to leverage zirconia's strengths while mitigating its limitations.

Existing Zirconia Integration Solutions

01 Zirconia component manufacturing and processing

Various methods and techniques are employed in the manufacturing and processing of zirconia components to enhance their lifespan. These include specialized sintering processes, surface treatments, and the use of specific additives or dopants to improve the material's properties. Advanced manufacturing techniques can result in zirconia components with improved density, strength, and overall durability.- Zirconia component manufacturing and processing: Various methods and techniques for manufacturing and processing zirconia components to enhance their lifespan. This includes specific sintering processes, surface treatments, and the use of additives to improve the material's properties and durability.

- Zirconia component design optimization: Strategies for optimizing the design of zirconia components to extend their operational life. This involves considerations such as shape, thickness, and structural reinforcement to distribute stress and minimize wear.

- Monitoring and predicting zirconia component lifespan: Methods and systems for monitoring the condition of zirconia components and predicting their remaining lifespan. This includes the use of sensors, data analysis, and predictive modeling to assess wear and schedule maintenance or replacement.

- Zirconia composites and hybrid materials: Development of zirconia-based composites and hybrid materials to improve component durability. This involves combining zirconia with other materials or reinforcing elements to enhance its mechanical properties and resistance to wear and degradation.

- Environmental and operational factors affecting zirconia component life: Analysis of environmental and operational factors that impact the lifespan of zirconia components. This includes studies on temperature fluctuations, chemical exposure, and mechanical stresses, as well as strategies to mitigate their effects and prolong component life.

02 Zirconia component design optimization

The design of zirconia components plays a crucial role in their longevity. Optimizing the shape, size, and structural features of zirconia components can significantly impact their performance and lifespan. This includes considerations for stress distribution, thermal management, and wear resistance. Advanced modeling and simulation techniques are often used to refine designs for specific applications.Expand Specific Solutions03 Zirconia composite materials

Incorporating zirconia into composite materials or combining it with other ceramics or metals can enhance its properties and extend component life. These composites often exhibit improved mechanical strength, thermal resistance, and wear characteristics compared to pure zirconia. The selection of complementary materials and the method of integration are critical factors in developing high-performance zirconia-based composites.Expand Specific Solutions04 Monitoring and predictive maintenance of zirconia components

Implementing advanced monitoring systems and predictive maintenance strategies can significantly extend the life of zirconia components. This includes the use of sensors, data analytics, and machine learning algorithms to detect early signs of wear or potential failure. Regular inspection and timely maintenance based on these predictive models can prevent premature component failure and optimize replacement schedules.Expand Specific Solutions05 Environmental and operational considerations for zirconia components

The operational environment and conditions significantly impact the lifespan of zirconia components. Factors such as temperature fluctuations, chemical exposure, and mechanical stresses need to be carefully managed. Implementing appropriate protective measures, such as coatings or controlled atmospheres, and optimizing operational parameters can help extend the life of zirconia components in various industrial applications.Expand Specific Solutions

Key Players in Zirconia-Enhanced Robotics

The application of zirconia in advanced robotics for enhancing component life is in a growth phase, with increasing market size and technological maturity. The global market for zirconia in robotics is expanding as manufacturers seek more durable and efficient materials. Companies like Kyocera Corp., NSK Ltd., and Saint-Gobain are at the forefront of developing zirconia-based solutions for robotic applications. The technology's maturity is advancing, with firms such as Oerlikon Metco and Kobe Steel contributing to improved manufacturing processes. Research institutions like Harbin Institute of Technology and the Nuclear Power Institute of China are pushing the boundaries of zirconia's capabilities in extreme environments, further driving innovation in the field.

Kyocera Corp.

Oerlikon Metco (US), Inc.

Breakthrough Zirconia Formulations for Robotics

- A method for forming high precision ceramic elements using yttria-doped tetragonal zirconia polycrystal (Y-TZP) and zirconia-based composite materials for drive system components, such as center links, rollers, and sprockets, through processes like dry pressing, cold isostatic pressing, and sintering, which provide improved wear and abrasion resistance without the need for lubrication.

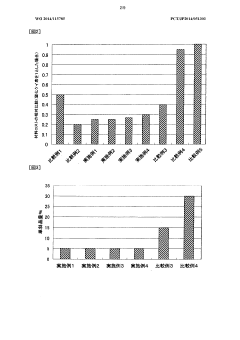

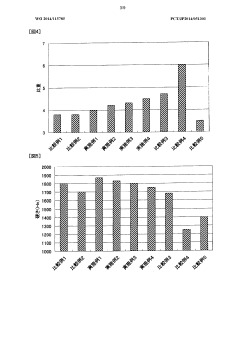

- The use of alumina-zirconia ceramics with an alumina component of 70 to 95% by mass, high-purity alumina raw material powder (>99.9% purity), and ceria-based zirconia stabilization, along with additives like magnesia and calcia, enhances sinterability and mechanical strength while reducing low-temperature deterioration.

Environmental Impact of Zirconia in Robotics

The environmental impact of zirconia in robotics is a crucial consideration as advanced robotics continue to integrate this material into their components. Zirconia, known for its exceptional durability and resistance to wear, offers significant advantages in extending the lifespan of robotic parts. However, its environmental footprint must be carefully evaluated throughout its lifecycle.

The production of zirconia involves mining and processing zirconium-bearing minerals, which can lead to habitat disruption and energy-intensive refining processes. These activities contribute to carbon emissions and potential soil and water contamination if not properly managed. However, the long-term benefits of using zirconia in robotics may offset some of these initial environmental costs.

In the operational phase, zirconia-enhanced robotic components demonstrate superior performance and longevity. This increased durability translates to fewer replacements and repairs, effectively reducing the overall material consumption and waste generation associated with robotic maintenance. The extended lifespan of zirconia components also means less frequent manufacturing of replacement parts, further minimizing the environmental impact of production processes.

The use of zirconia in robotics can lead to improved energy efficiency in robotic systems. Its low thermal conductivity and high strength-to-weight ratio allow for the design of lighter, more efficient robots that consume less energy during operation. This reduction in energy consumption contributes to lower greenhouse gas emissions over the robot's operational lifetime.

At the end of a robot's life cycle, the recyclability of zirconia components becomes a critical factor. While zirconia itself is not biodegradable, it can be recycled and repurposed, potentially reducing the need for new raw material extraction. However, the recycling process for zirconia-containing components may require specialized techniques and facilities, which are not yet widely available.

The integration of zirconia in robotics also has indirect environmental benefits. Robots equipped with zirconia components can perform tasks in harsh environments more effectively and for longer periods. This capability enables their use in environmental monitoring, cleanup operations, and sustainable manufacturing processes, contributing to broader environmental protection efforts.

As the robotics industry continues to evolve, there is a growing emphasis on sustainable design and circular economy principles. Manufacturers are increasingly considering the entire lifecycle of robotic components, including those made with zirconia. This holistic approach aims to minimize environmental impact from production to disposal, with a focus on recyclability and responsible sourcing of materials.

Cost-Benefit Analysis of Zirconia Components

The implementation of zirconia components in advanced robotics presents a complex cost-benefit scenario that requires careful analysis. Initially, the higher cost of zirconia materials compared to traditional alternatives may seem prohibitive. However, when considering the long-term benefits, the economic advantages become apparent.

Zirconia components offer superior wear resistance and durability, significantly extending the operational lifespan of robotic parts. This longevity translates to reduced frequency of replacements, minimizing downtime and maintenance costs. In high-precision applications, the dimensional stability of zirconia ensures consistent performance over extended periods, reducing the need for recalibration and adjustments.

The thermal properties of zirconia also contribute to cost savings. Its low thermal conductivity helps maintain stable operating temperatures in robotic systems, potentially reducing cooling requirements and associated energy costs. Additionally, zirconia's resistance to corrosion and chemical attack extends its applicability in harsh environments, eliminating the need for frequent replacements due to material degradation.

From a manufacturing perspective, while initial tooling costs for zirconia components may be higher, the ability to produce complex geometries through advanced ceramic processing techniques can lead to part consolidation. This reduction in the number of components not only simplifies assembly but also decreases potential failure points, further reducing maintenance costs.

The enhanced performance characteristics of zirconia-based robotic components can also lead to improved productivity and output quality. This indirect benefit, while harder to quantify, can significantly impact the overall return on investment. For instance, in precision manufacturing or medical robotics, the superior properties of zirconia can enable more accurate and reliable operations, potentially opening new market opportunities or improving product quality.

However, it's crucial to consider the specific application when evaluating the cost-benefit ratio. In some cases, the performance improvements may not justify the increased material costs. A thorough lifecycle cost analysis, considering factors such as initial investment, operational costs, maintenance requirements, and expected service life, is essential for making informed decisions on implementing zirconia components in advanced robotics.